Surfboard Stringer Reinforcing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

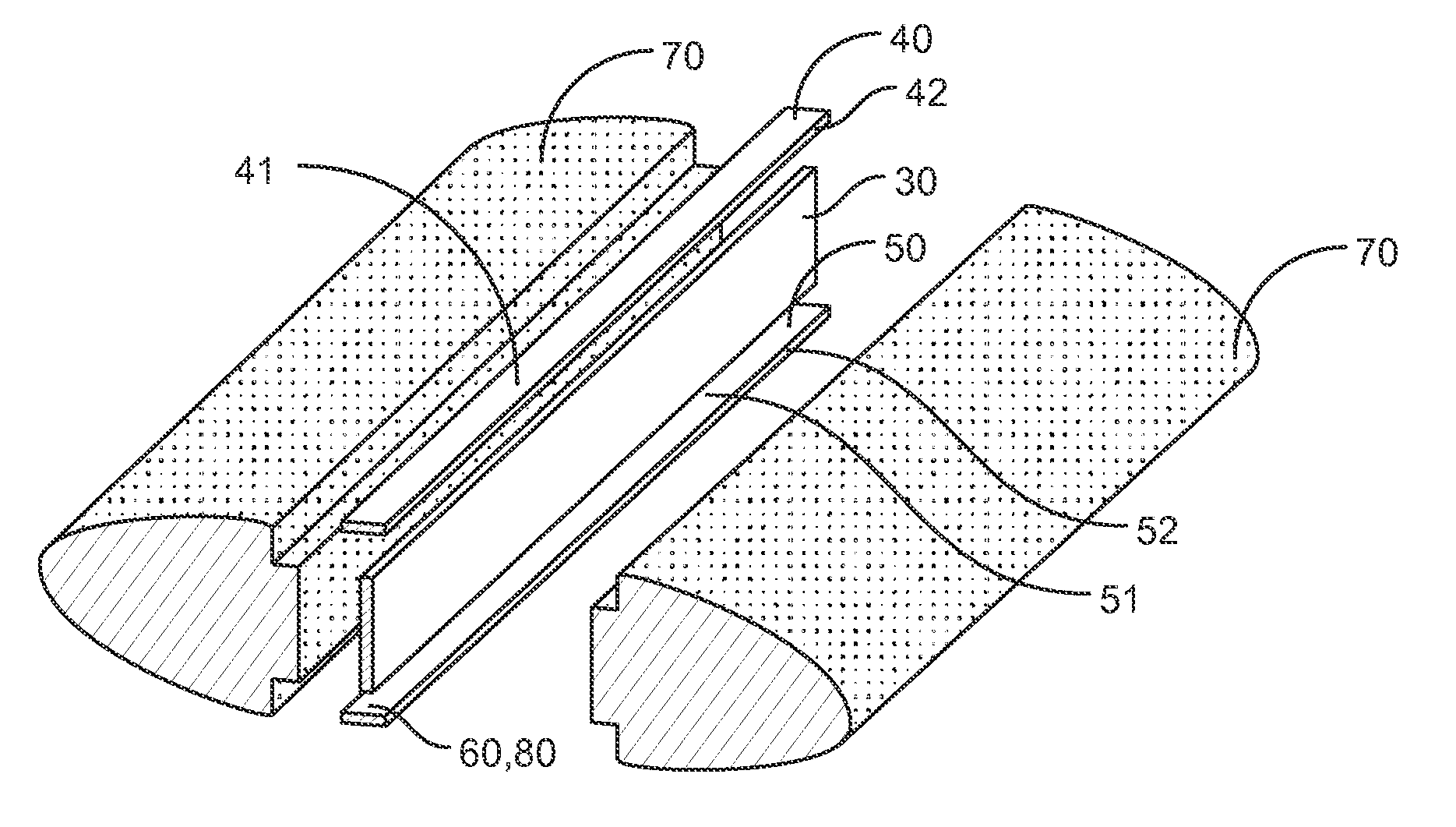

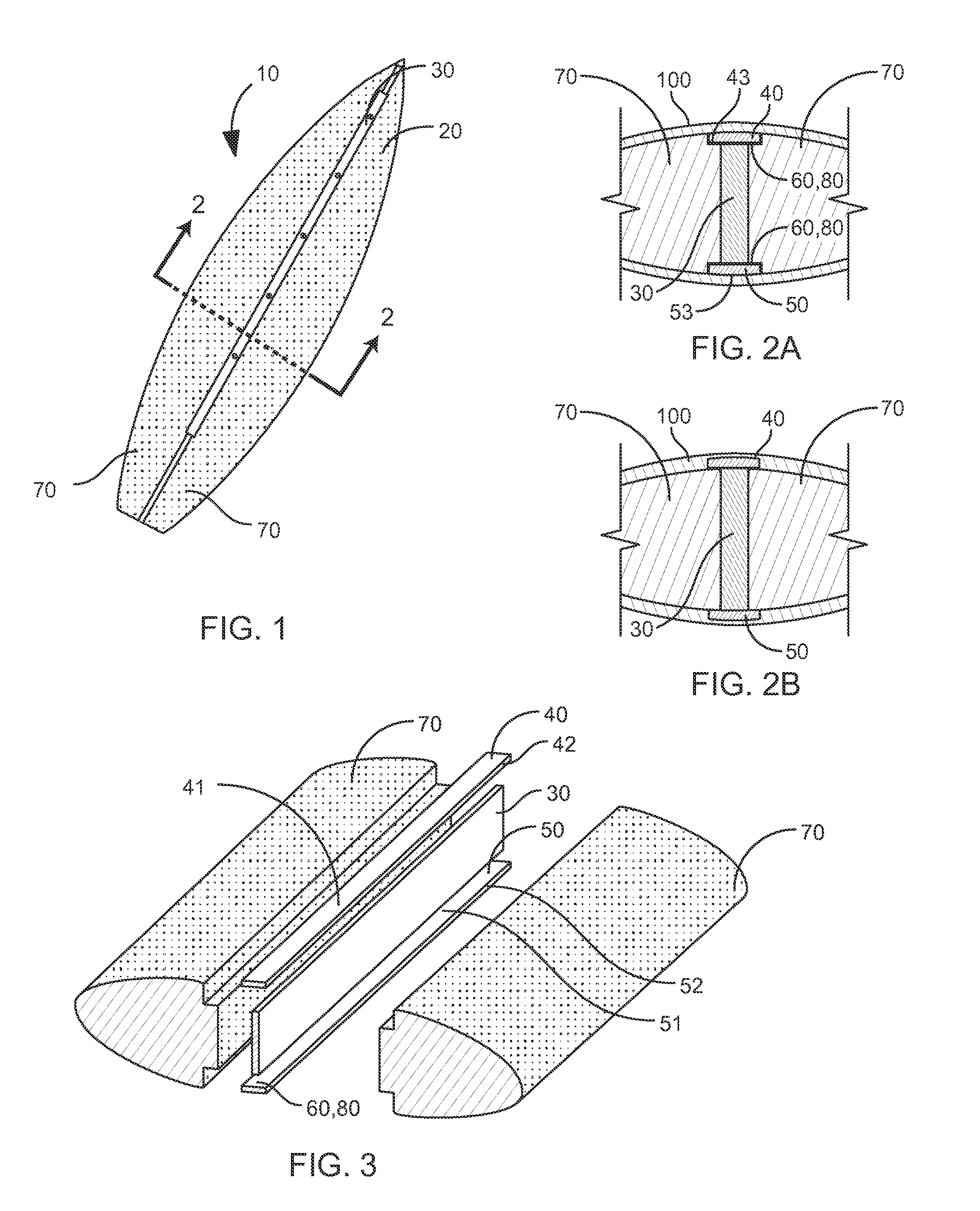

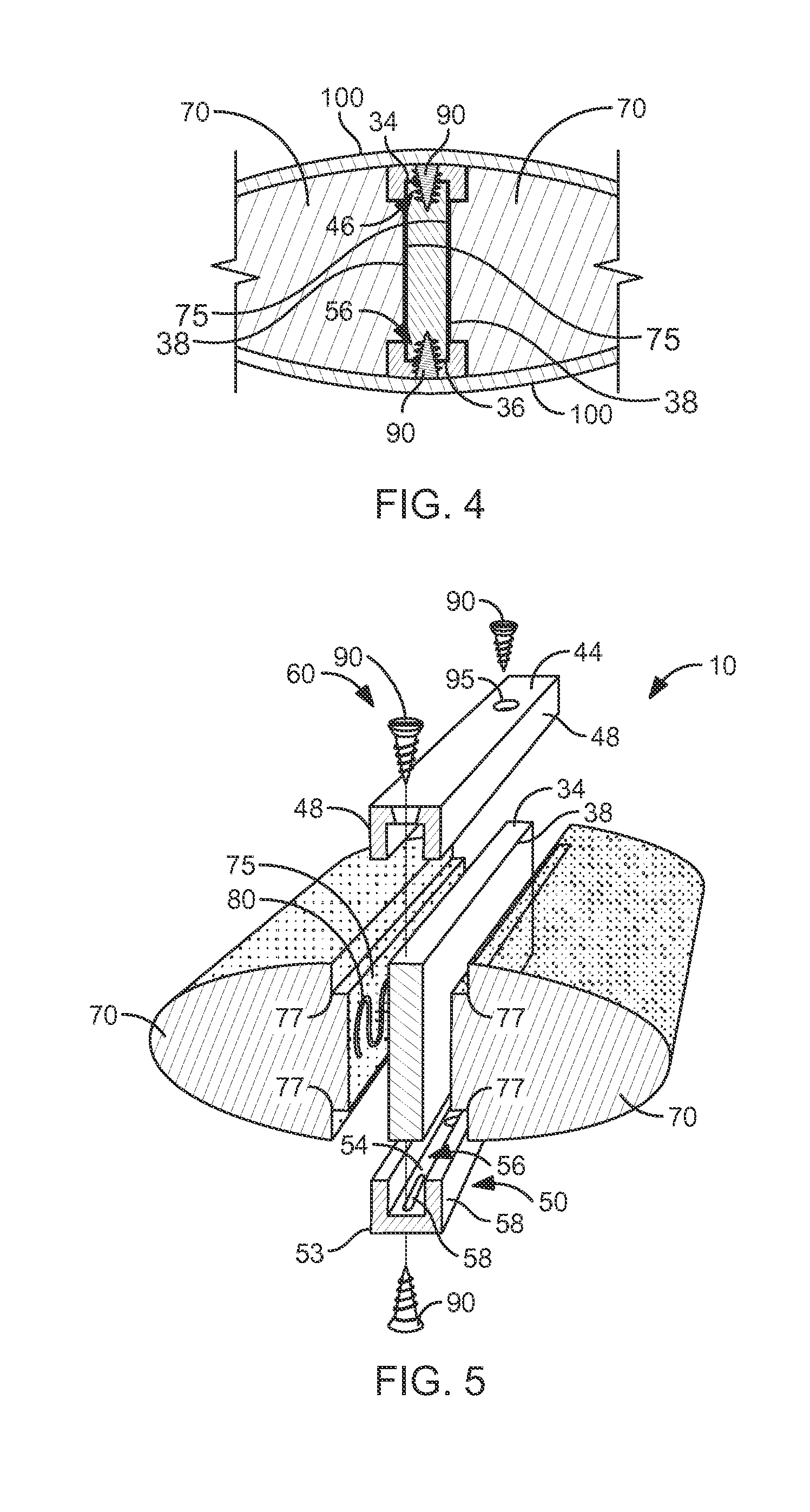

[0024]FIG. 1 illustrates a reinforcing system 10 for a floatation device 20, such as a surfboard. Such a floatation device 20 has an elongated stringer 30 that has at least a top edge 34 and a bottom edge 36. Such stringers 30 are typically made from balsa wood, carbon fiber-based material, epoxy resin, plastic, or the like.

[0025]The reinforcing system 10 of the present invention includes an elongated top bracket 40 comprising a top side 41, a bottom side 42, and a peripheral side edge 43. The top and bottom sides, 41, 42 are each wider than the top and bottom edges 34, 36 of the stringer 30. The cross-sectional shape of the top bracket 40 is preferably rectangular, as illustrated best in FIG. 2A. Such a top bracket 40 may be made from a carbon fiber-based material, a plastic material, a resin material, or the like, provided that the bracket 40 has suitable strength against breaking yet is somewhat resilient.

[0026]Similarly, an elongated bottom bracket 50 is also included that compr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shape | aaaaa | aaaaa |

| Adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com