Cutting insert

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

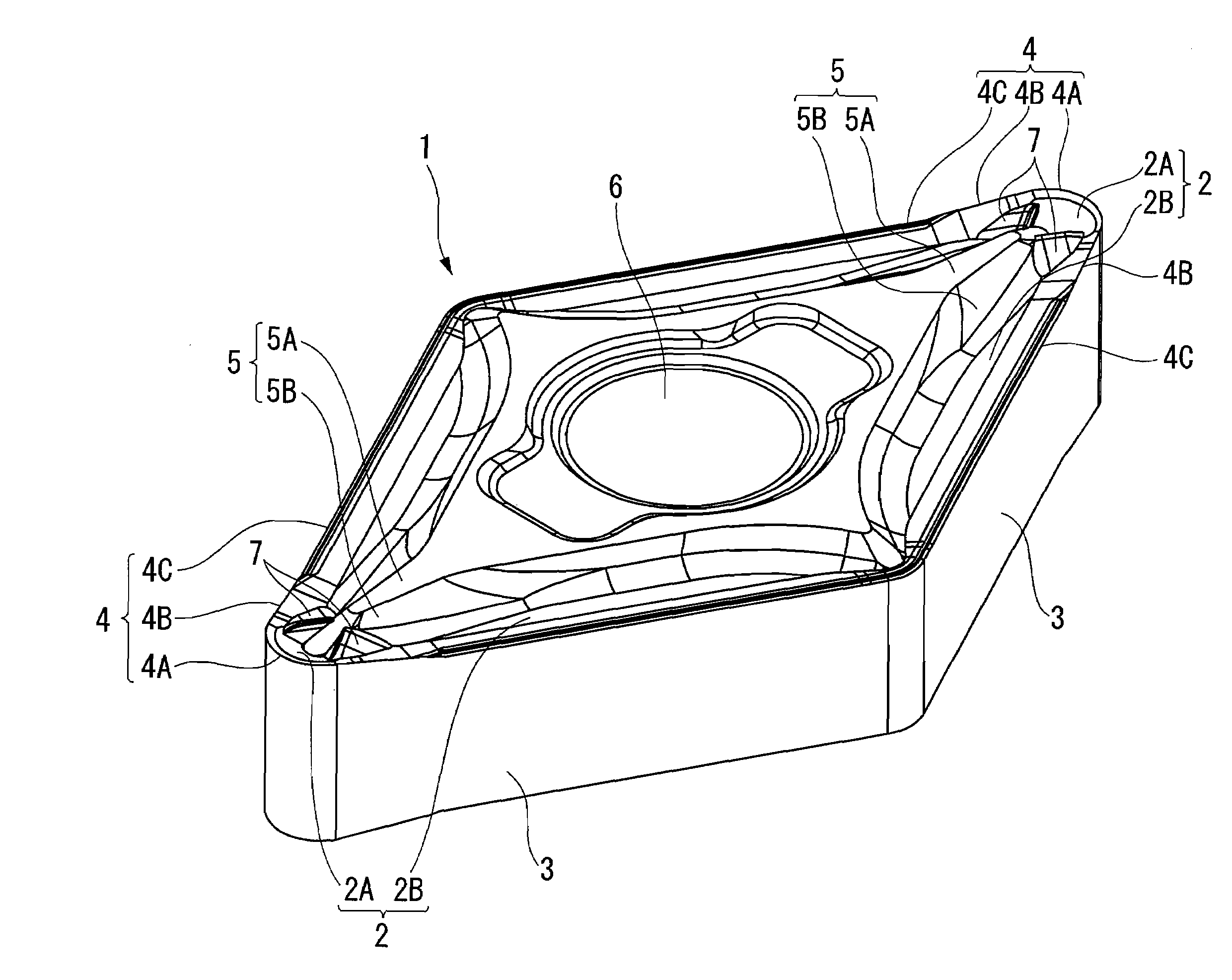

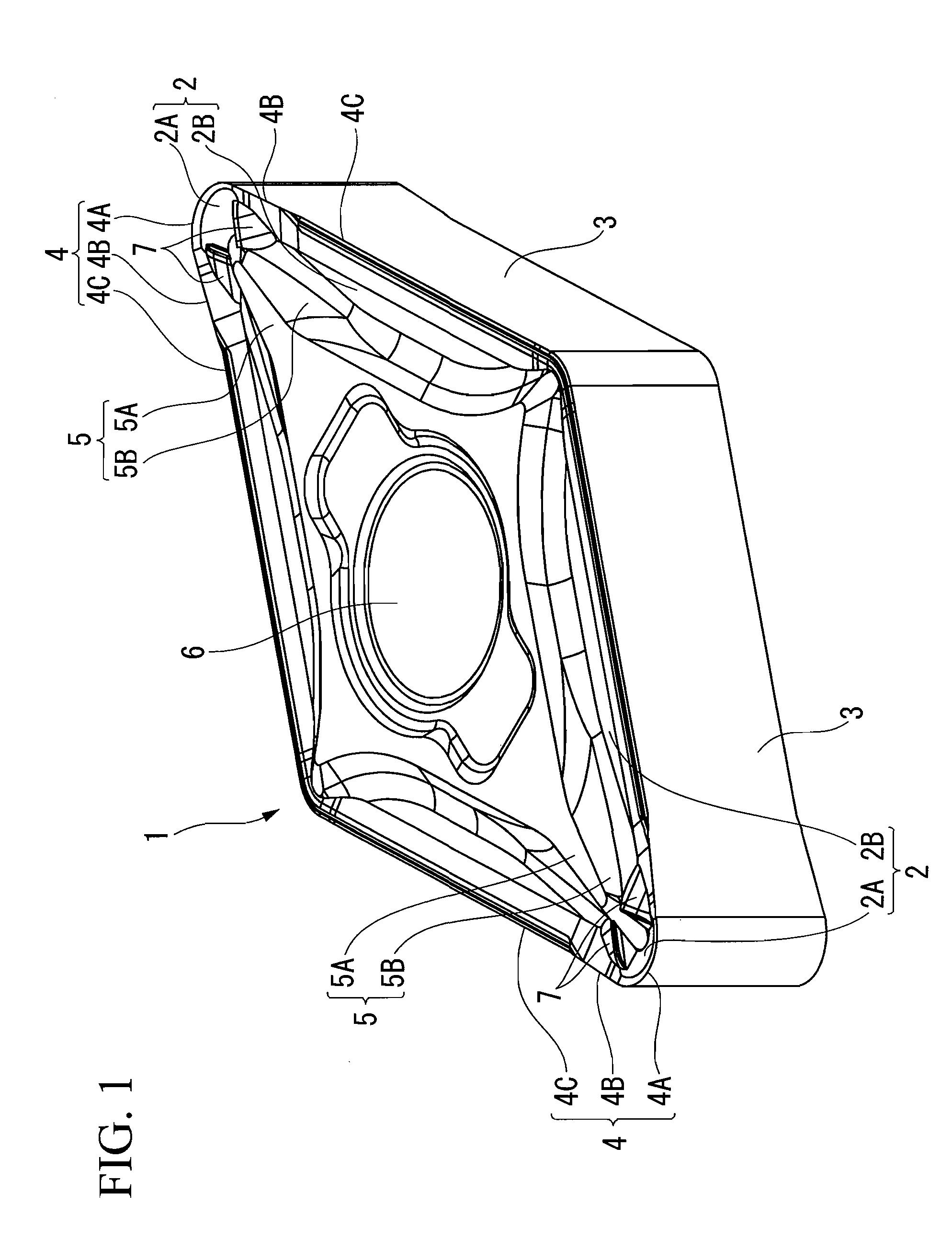

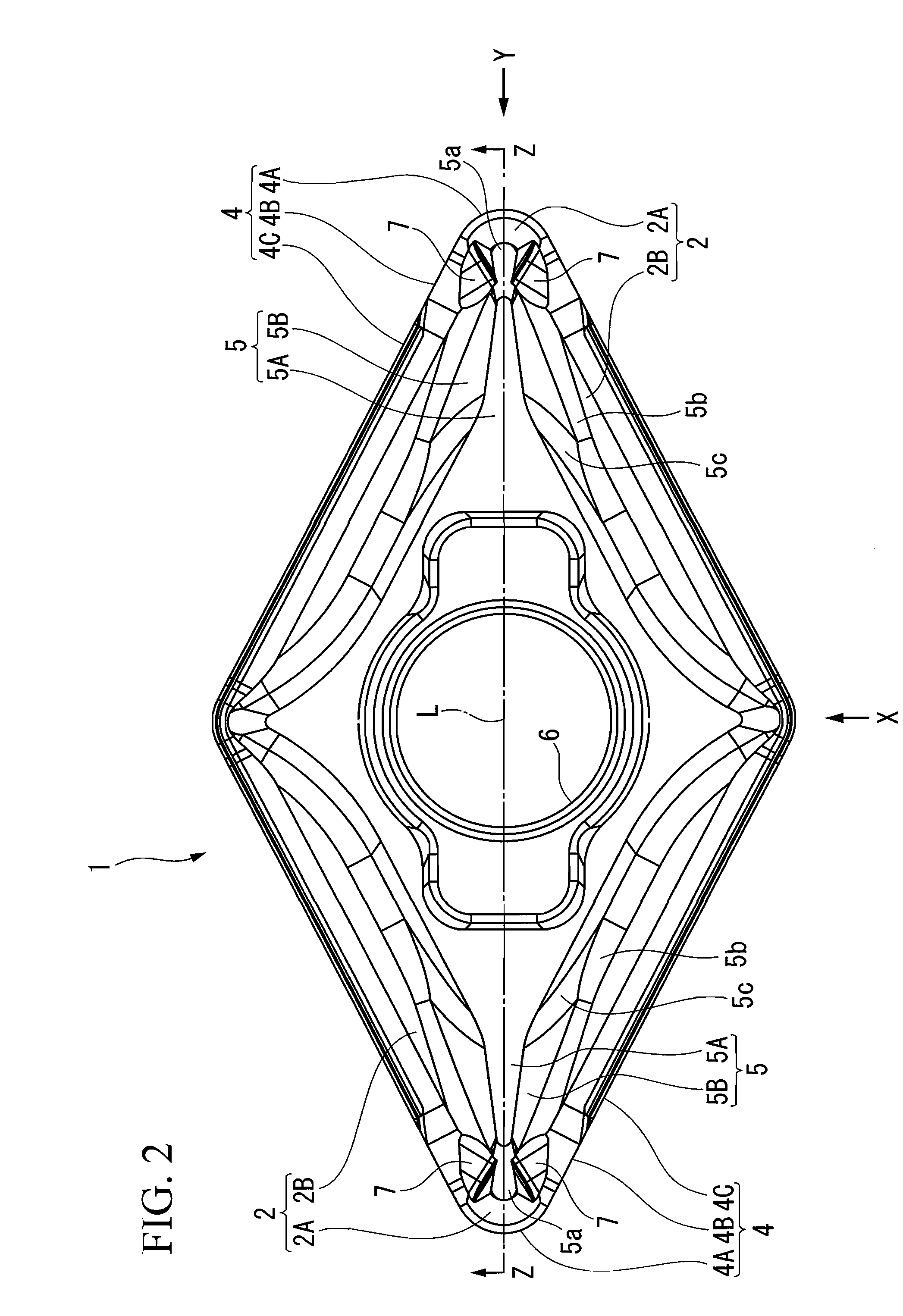

[0051]FIGS. 1 to 9 show a first embodiment of the present invention. According to the embodiment, the insert body 1 is formed in a polygonal plate shape (particularly a rhombic plate shape) by hard material such as sintered hard alloy. The insert body 1 is configured as a negative type insert in which rake faces 2 are formed on the pair of rhombus-shaped surfaces and flank faces 3 disposed in the vicinity of the rake faces 2 extend parallel to the thickness direction (up and down directions in FIGS. 3 to 5) of the insert body 1. In the insert body 1, the pair of rhombus-shaped surfaces is symmetrically formed to be reversible, is symmetrically formed to be rotated by 180 degrees about the central line of the rhombic plate surfaces, and is symmetrically formed with respect to planes extended in parallel to the thickness direction between rhombus-shaped acute corner portions and obtuse corner portions, respectively.

[0052]A cutting edge 4 is formed on peripheral border of the rake face...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com