Palletlike arrangement for packaging goods

a kind of packaging and pallet technology, applied in the direction of packaging, containers to prevent mechanical damage, applications, etc., can solve the problems of time required, logistical effort and expens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

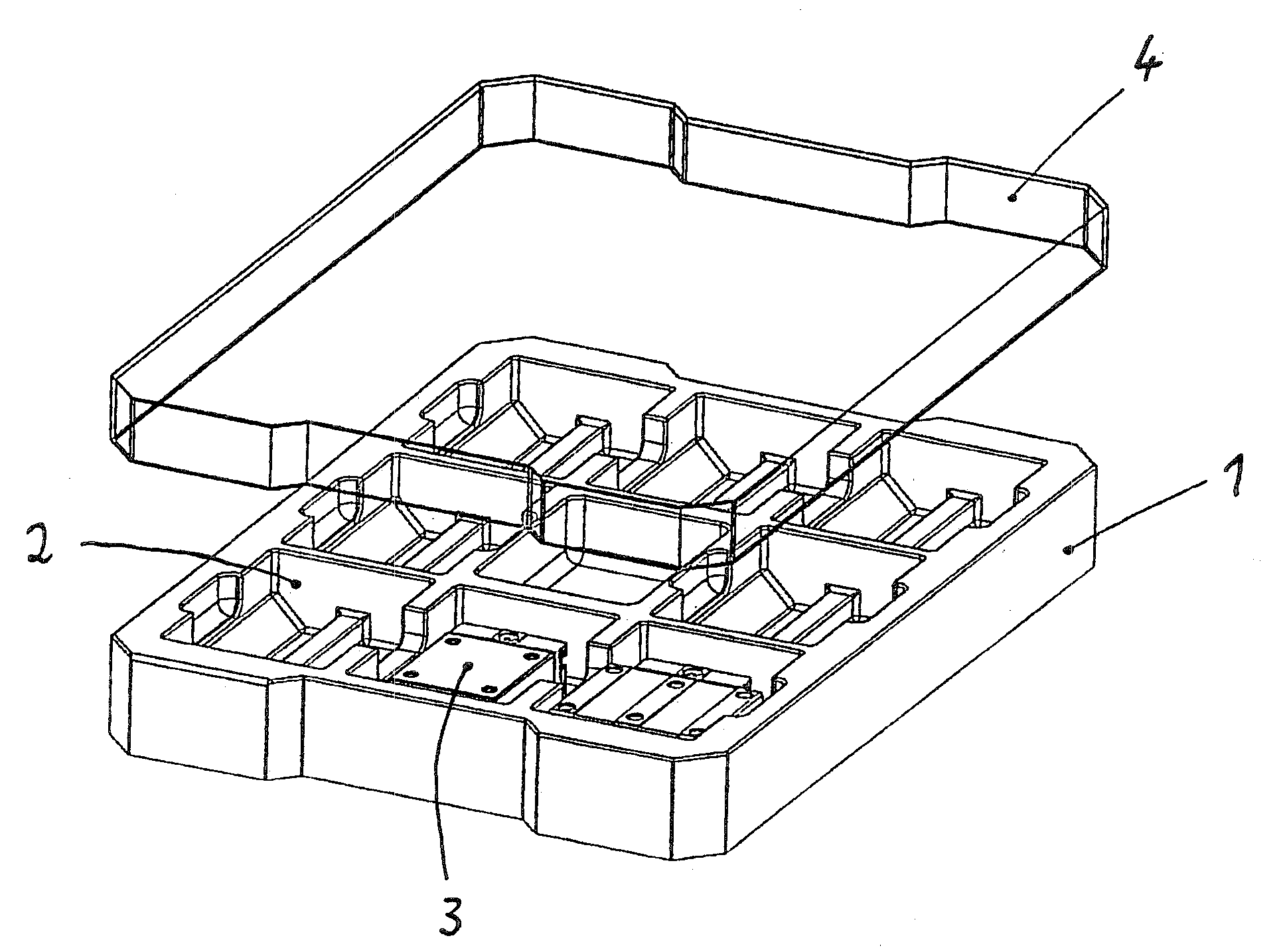

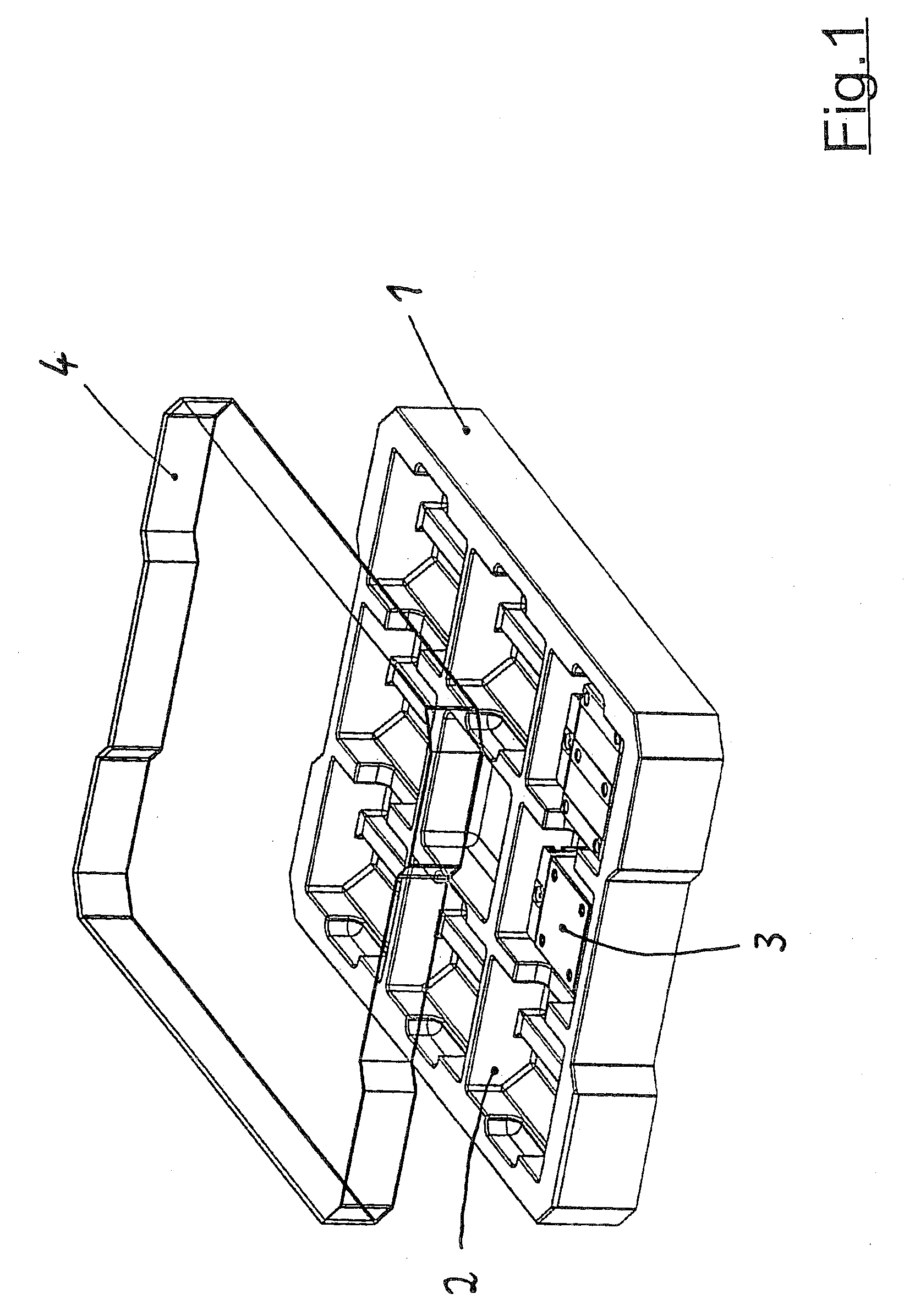

[0027]In FIG. 1, the packaging container 1 has a total of nine recesses 2, each for receiving one guide carriage 3 of a linear unit—the latter not further shown.

[0028]The packaging container 1 comprises a thin-walled plastic and is made by forming, especially by deep drawing. The packaging container 1 can be closed with a cap 4, which can be fitted in internesting fashion over the packaging container 1. The edge of the cap 4, in the closed state, covers approximately two-thirds of the height of the packaging container 1. The cap 4 is thus connected in form-locking fashion but detachably to the packaging container 1 and is thus reusable. To allow the contents of the packaging container 1 to be seen from the outside, the cap 4 comprises a transparent plastic.

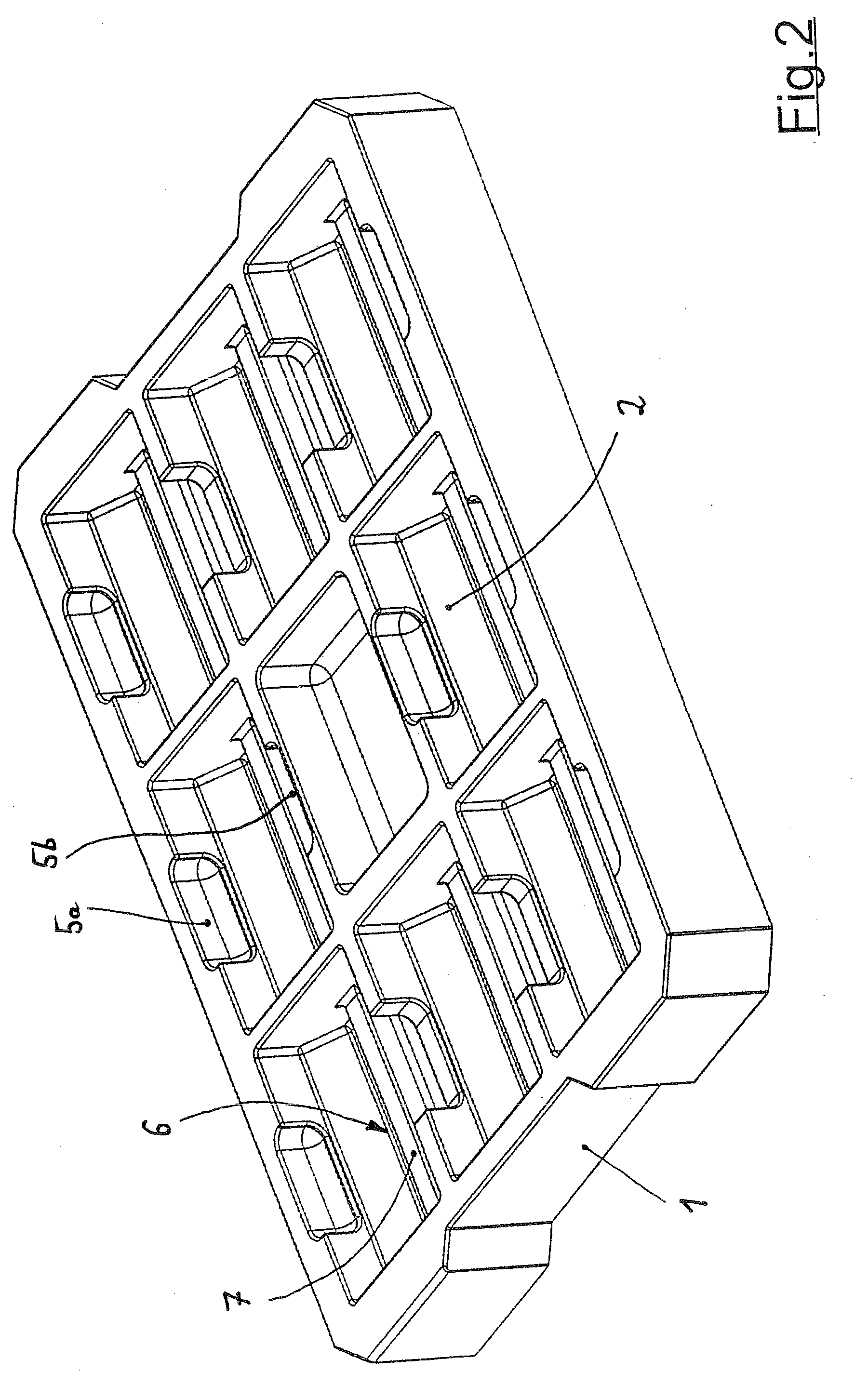

[0029]As seen more clearly in FIG. 2, each recess 2 for receiving guide carriages—not shown here—is equipped with graspable indentations 5a and 5b, which are diametrically opposite one another with respect to the receptacle 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com