Frameless construction using single and double panels

a frameless, single-panel technology, applied in the direction of walls, building roofs, building repairs, etc., can solve the problems of affecting the stability of the structure, the inability to meet the needs of modular housing, so as to eliminate eliminate the need for thermal breaks, and the effect of reducing the need for ductwork

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

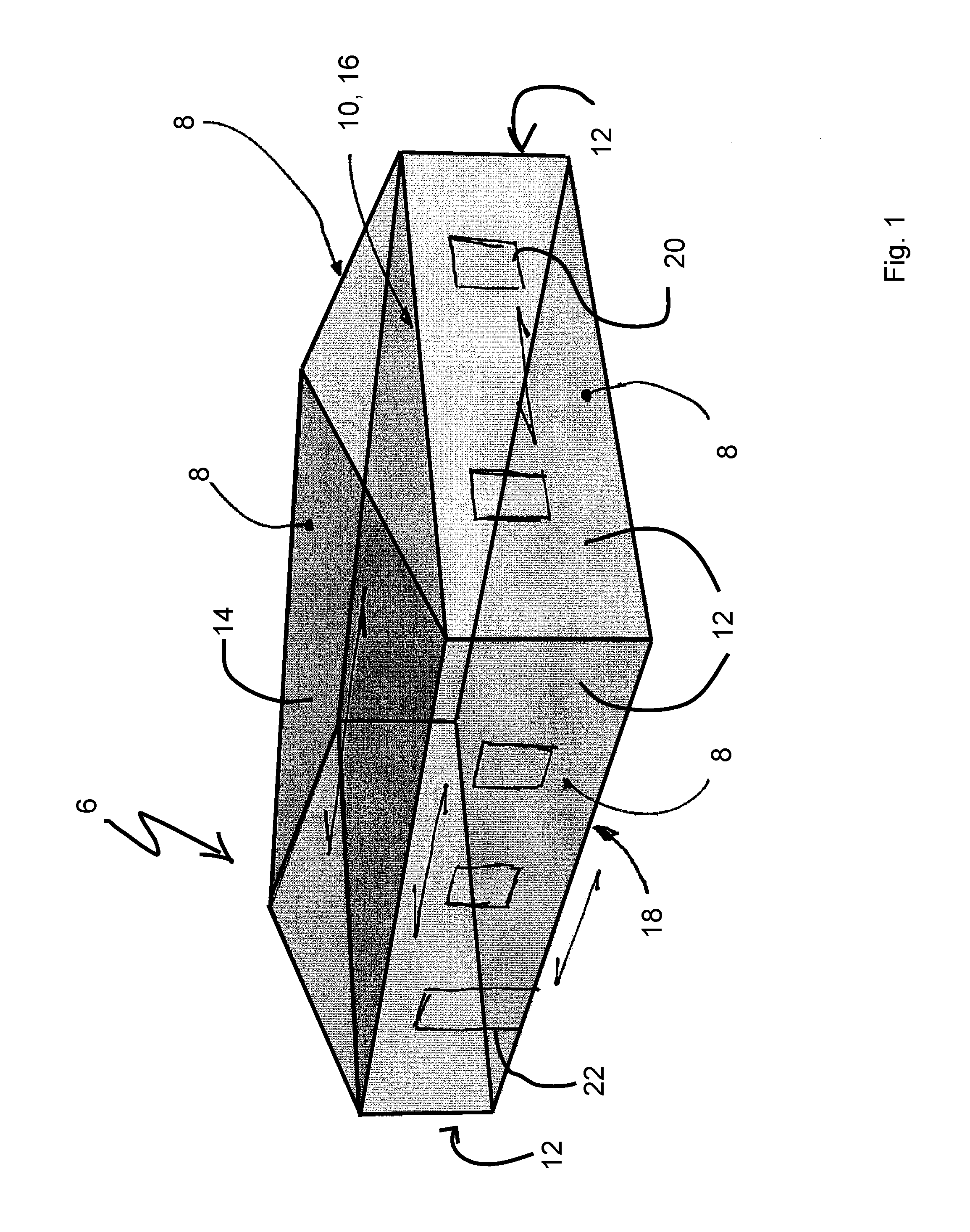

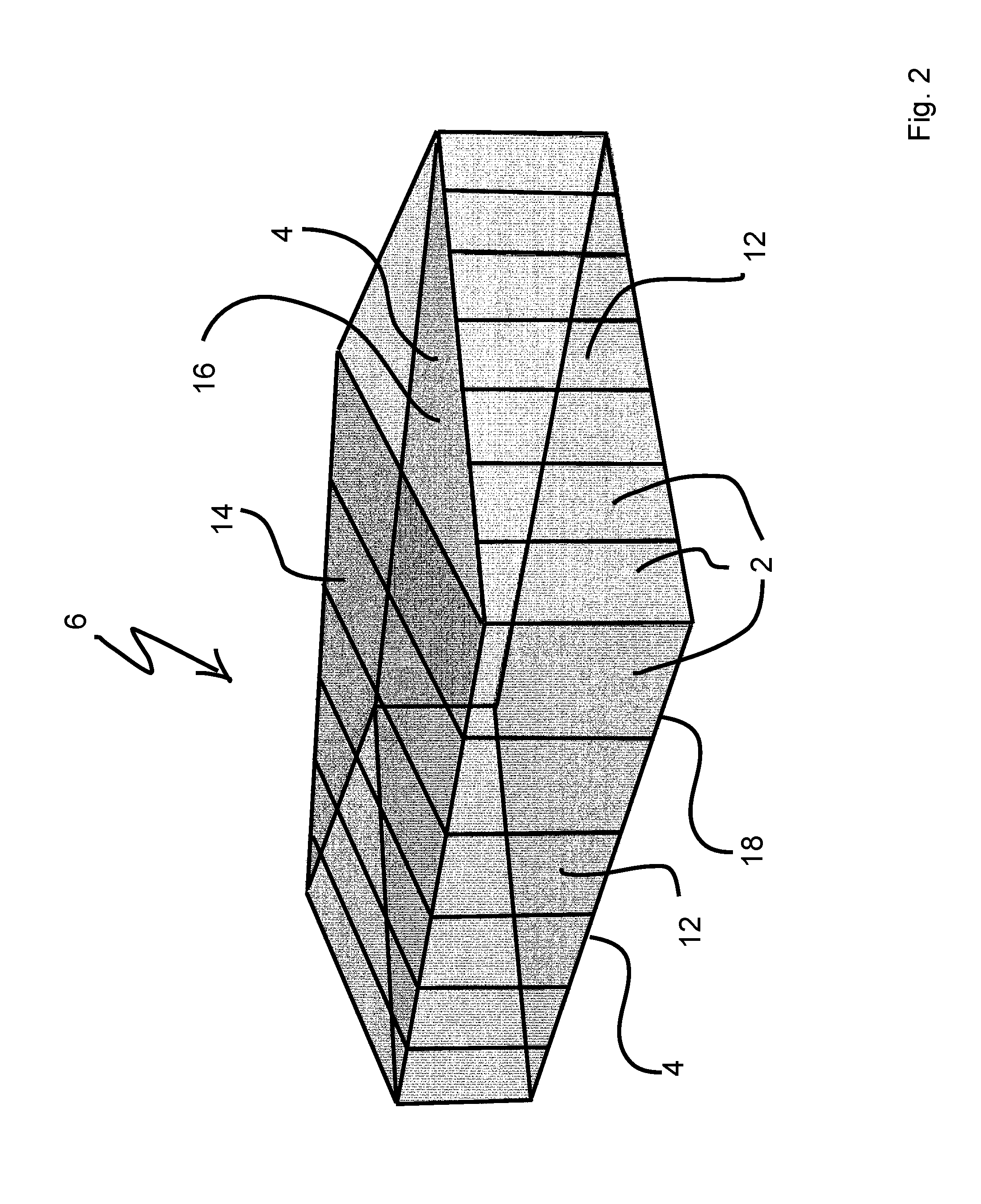

second embodiment

[0092]Turning next to FIG. 2, a second embodiment is shown. In this embodiment, the house 6 is also built without a frame, but instead of continuous panels 8, 10, its walls 12, floor 18, ceiling 16, and roof 14 are built of smaller single and multi-plenum panels 2, 4—typically sized 8 feet by 4 feet, and herein referred to as unit panels 2, 4. These unit panels 2,4 are each easier to handle and individually are faster to erect. But, because of the many number of unit panels necessary, the total installation time can be longer than the house in FIG. 1 utilizing continuous panels.

[0093]It should also be noted that an embodiment (not shown) utilizing a combination of both unit 2, 4 and continuous 8, 10 panels in a single building 6 construction falls within the scope of this invention. As just one example, the building may have walls 12 with unit panels 2, 4 as shown in FIG. 2, and floors 18, ceiling 16, and roof 14 with continuous panels 8, 10 as shown in FIG. 1.

[0094]Turning next to ...

first embodiment

[0103]Turning now to FIG. 4, the roof connector 34 is shown. The roof connector 34 is anticipated to be continuous hollow triangular prism, most likely formed of the same material along each side. The roof connectors are designed to resist downward and upward forces as well as lateral or horizontal sheer forces and bending forces or moments. The roof connectors 34, via mechanical and / or adhesive connections to adjacent single and / or multi plenum panels, are designed to be an integral part of the structural system increasing the structural strength of the building.

[0104]This is a typical roof connector 34 made of wood. It is anticipated that it would be constructed of long strips of plywood or OSB with staggered joints, and / or finger-jointed material. The roof connector 34 could also be constructed from typical “2×” lumber of 1½″ thickness.

[0105]The roof connector 34 will typically have at least one roof adjacent surface 38 that attaches to the roof panel 14. For roof connectors 34 u...

third embodiment

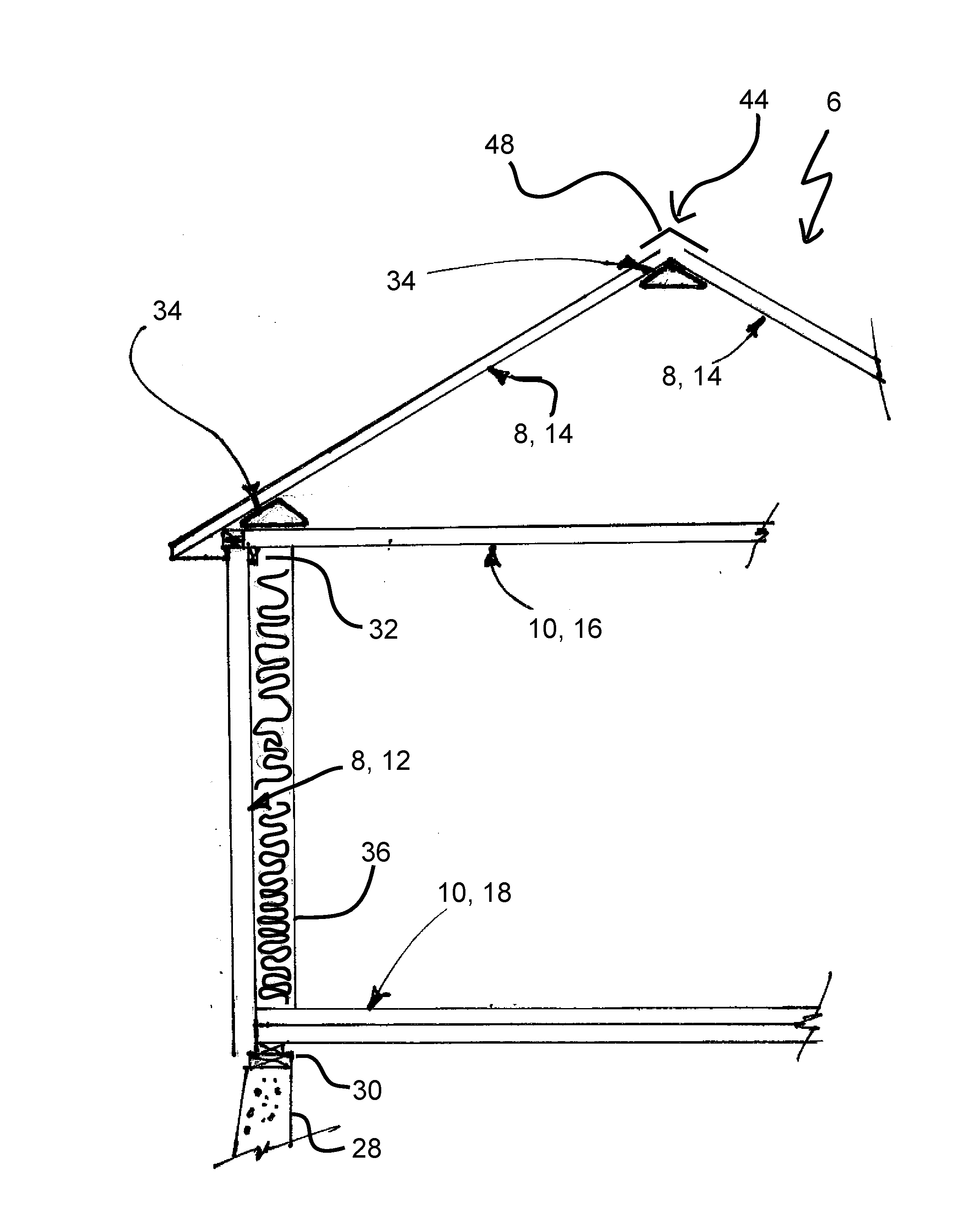

[0155]In this third embodiment, a lower single plenum panel 2, 8 wall panel 12 is assembled using methods previously described as a load bearing wall 12. Lower wall blocking 32 is preferably mechanically and adhesively attached to top of the interior sheet 54 sheet of the lower single plenum panel 2, 8 wall 12 to support a horizontal multi plenum panel 4, 10, which is used for both the lower level ceiling 16 and the upper level floor 18. This horizontal multi-plenum panel 4, 10 has edge blocking 70 to facilitate mechanical and adhesive attachment to the lower wall blocking 32.

[0156]After installation of the horizontal multi-plenum panel 4, 10, an upper (vertically oriented) load bearing single plenum panel 2, 8 wall panel 12 is placed on and vertically aligned with the lower wall panel 12, as shown in FIG. 17. The upper wall panel 12 is preferably mechanically and adhesively attached to the edge blocking 70 and an additional upper wall blocking 32 added to the second floor level. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com