Image reading apparatus and control method thereof

a reading apparatus and image technology, applied in the direction of electrical equipment, pictoral communication, etc., can solve the problems of front end of original catches on elastic members, streaks will occur on read images read by image sensors, and continue to occur, so as to reduce the number of streaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

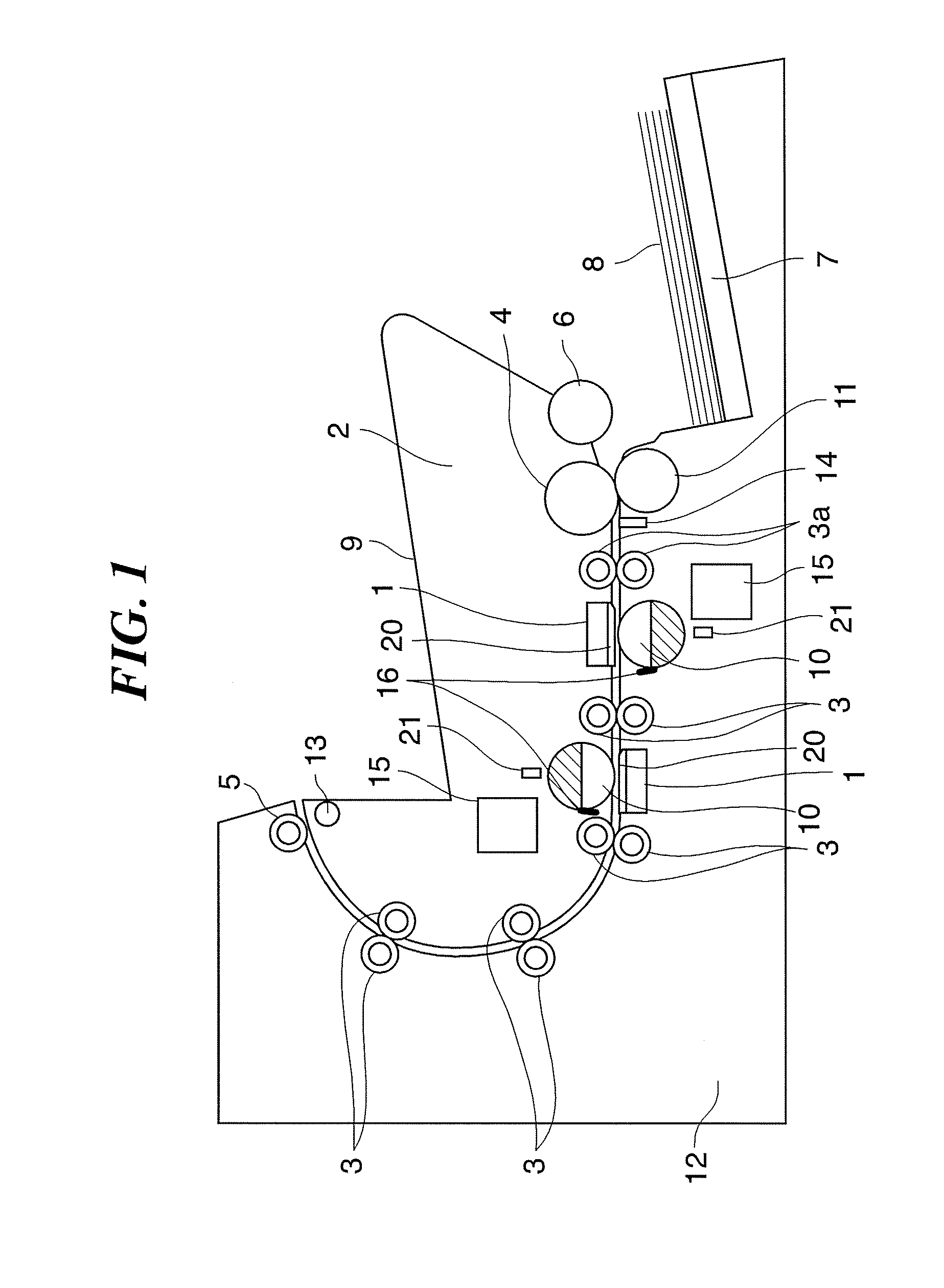

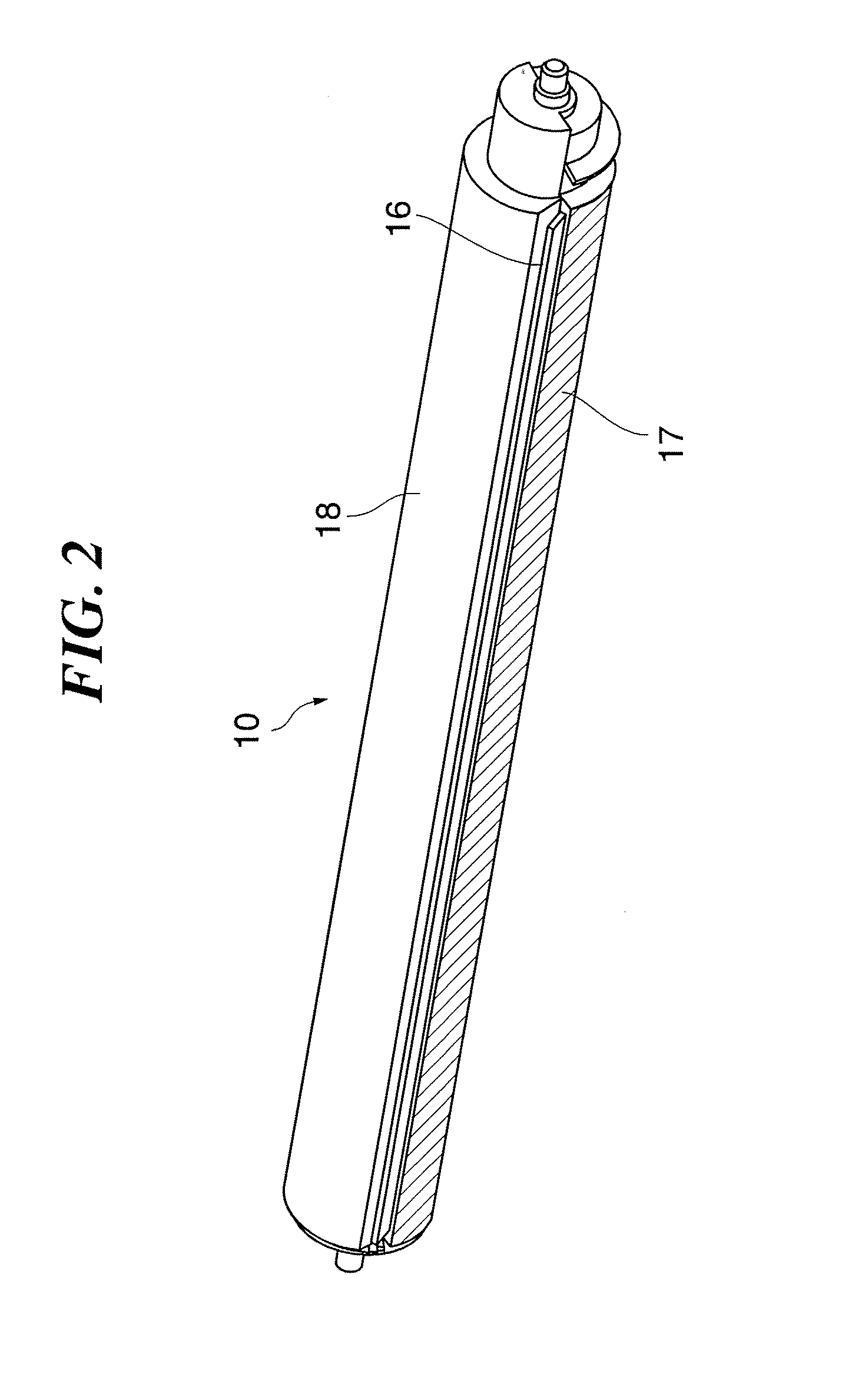

[0072]FIG. 1 is a cross-sectional diagram schematically showing a configuration of an image reading apparatus according to the present invention, and FIG. 2 is a perspective view for explaining a platen roller shown in FIG. 1.

[0073]With this image reading apparatus, as shown in FIG. 1, when an original mounting table 7 on which originals 8 are placed is elevated and an original 8 contacts a pickup roller 6, the original 8 picked up by the pickup roller 6 is fed by a feeding roller 4.

[0074]When two or more originals 8 are picked up at the same time by the pickup roller 6, the originals 8 are separated into individual sheets by a retard roller 11 and then fed. An image on the fed original 8 is read by an image sensor 1 and the read image data is transferred to an image processing section, not shown. The front end and the rear end of the fed original 8 are detected by a registration sensor 14. Conveying timing and the like are controlled by controlling the rotation and stopping of a re...

third embodiment

[0140]FIG. 10 is a cross-sectional diagram schematically showing a configuration of an image reading apparatus according to the present invention. Since the basic configuration of the image reading apparatus according to the present embodiment is approximately the same as the conventional image reading apparatus already described with reference to FIG. 30, portions overlapping with or corresponding to the image reading apparatus shown in FIG. 30 will be assigned like reference characters and a description thereof will either be omitted or simplified.

[0141]As shown in FIG. 10, in the image reading apparatus according to the present embodiment, skew detection sensors 140 and 141 are disposed upstream of the registration sensor 314, and a platen roller 125 is used instead of the conventional platen roller 310.

[0142]Describing now the platen roller 125 with reference to FIG. 12, the platen roller 125 includes a half-cylindrical black member 126, a half-cylindrical white member 127 and a...

fifth embodiment

[0189]With the present fifth embodiment, a cleaning mode setting screen such as that shown in FIG. 19 is displayed on an operation display portion of the image reading apparatus or a display portion of an external control apparatus (a PC or the like) connected to the image reading apparatus.

[0190]In the setting screen shown in FIG. 19, when “cleaning is performed if skew is detected” (hereinafter referred to as the “cleaning priority mode”) is selected, the control circuit 900 performs the control of the third embodiment described above to alter timings according to the skew amount and performs cleaning, and when “cleaning is not performed if skew amount is large” (hereinafter referred to as the “speed priority mode”) is selected, the control circuit 900 performs the control of the fourth embodiment described above. The speed priority mode may alternatively be arranged so that “cleaning is not performed when a skew is detected”. As shown, with the present embodiment, since a cleanin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com