Flexible circuit structure with stretchability and method of manufacturing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

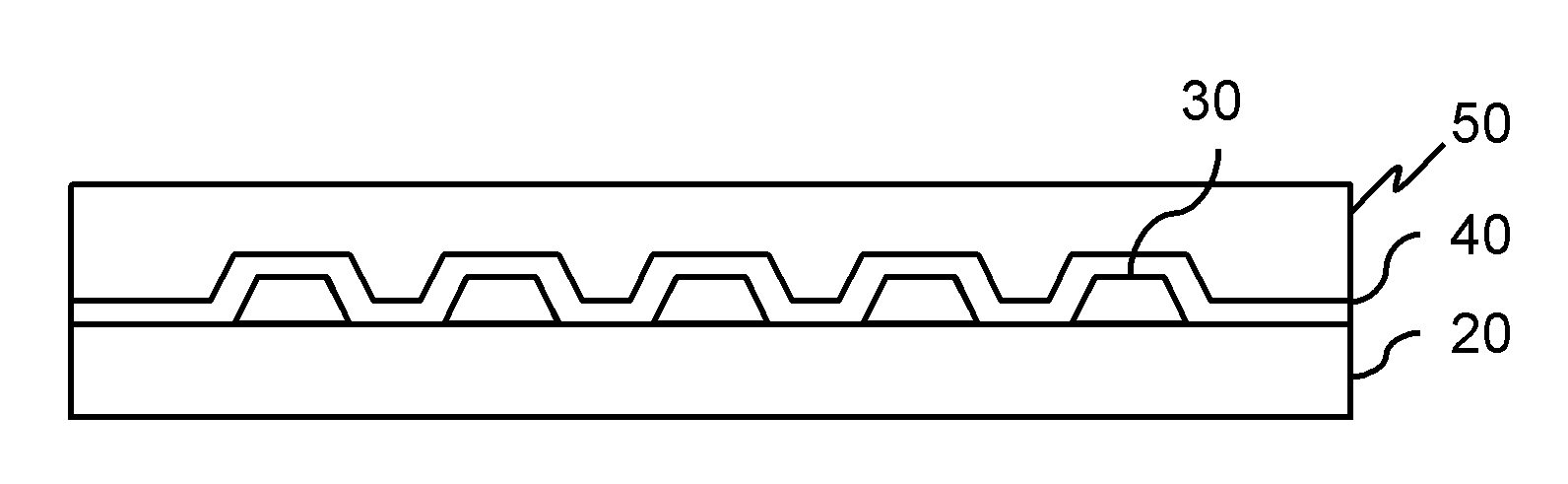

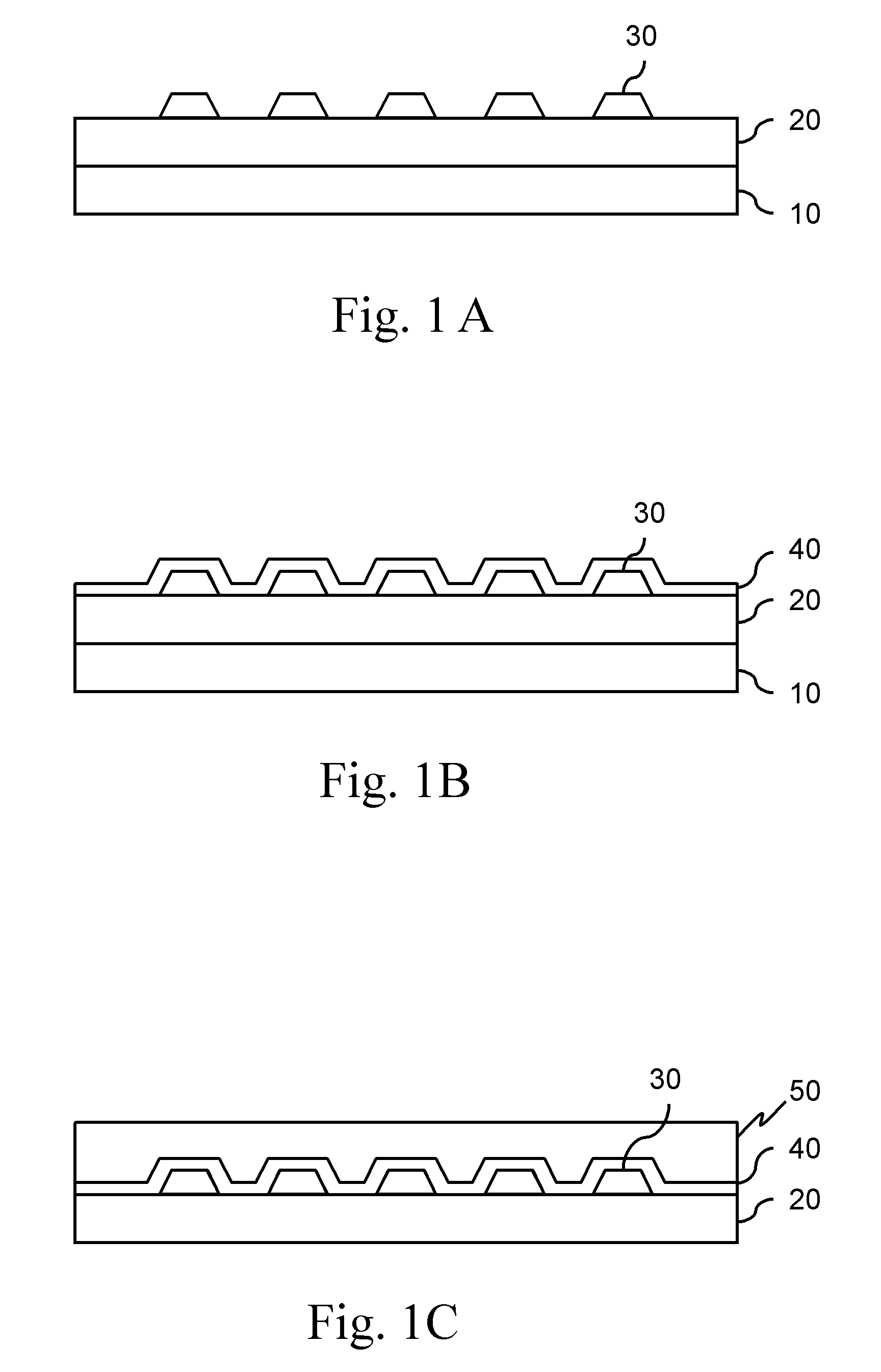

[0039]FIGS. 1A, 1B, and 1C are respectively schematic sectional views of a flexible circuit structure according to the present invention. As shown in FIG. 1C, the flexible circuit structure with stretchability of the present invention includes a flexible substrate 20, a plurality of flexible bumps 30, a metal layer 40, and a flexible material layer 50.

[0040]Firstly, as shown in FIG. 1A, in the flexible circuit structure with stretchability of the present invention, the flexible substrate 20 is attached on a supporting substrate 10 through a thermal release manner or a UV release manner. The material of the flexible substrate 20 includes polyimide (PI) or polydimethylsiloxane (PDMS). Then, a plurality of compressible flexible bumps 30 is deposited on the flexible substrate 20 at predetermined positions for implanting the metal circuit, and the compressibility of the flexible bumps 30 is higher than that of the flexible substrate 20. The material of the flexible bumps 30 includes poly...

second embodiment

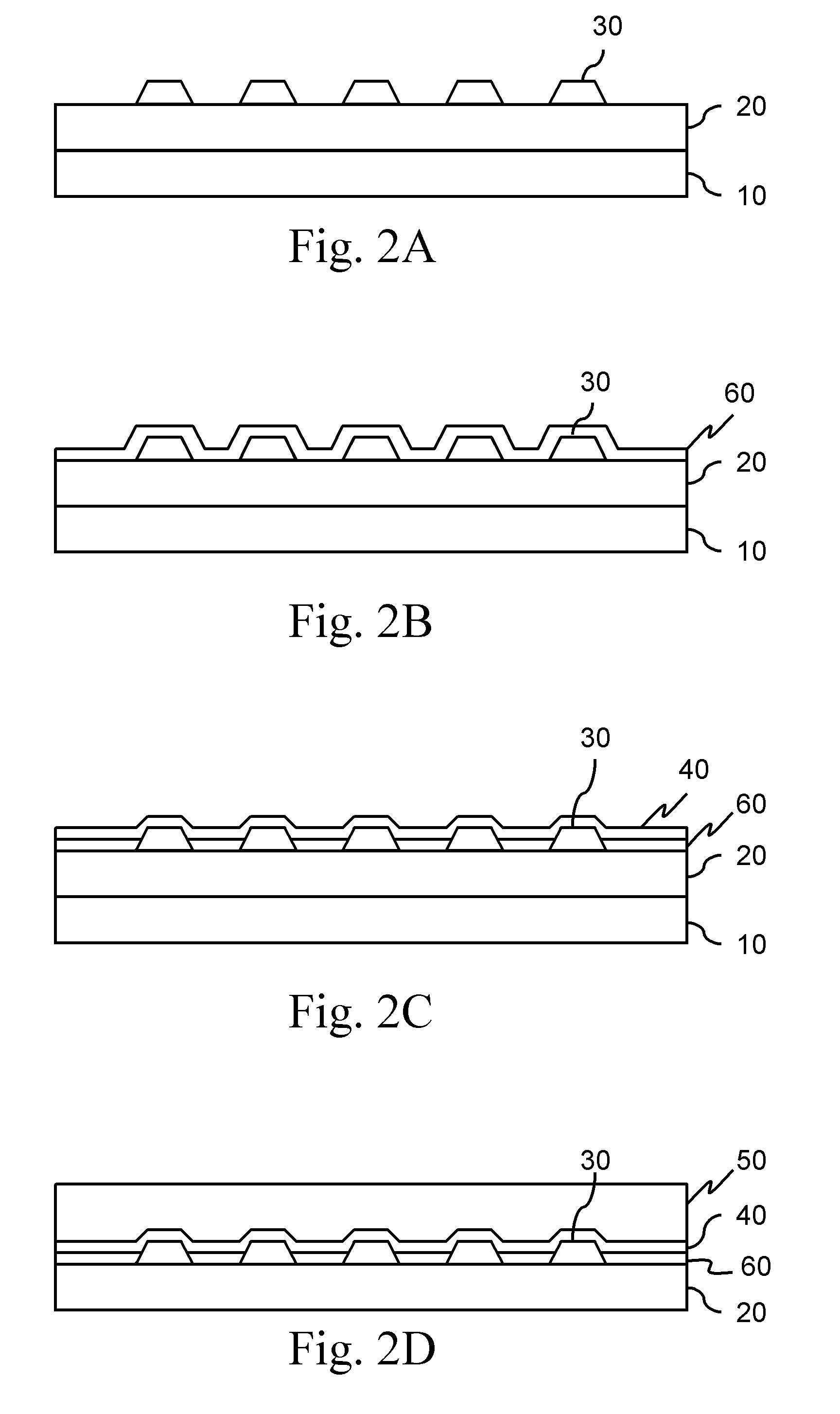

[0042]FIGS. 2A, 2B, 2C, and 2D are respectively schematic sectional views of a flexible circuit structure according to the present invention. As shown in FIG. 2D, the flexible circuit structure with stretchability of the present invention includes a flexible substrate 20, a plurality of flexible bumps 30, a metal layer 40, a flexible material layer 50, and a buffer layer 60.

[0043]Firstly, as shown in FIG. 2A, in the flexible circuit structure with stretchability of the present invention, the flexible substrate 20 is attached on a supporting substrate 10 through the thermal release manner or the UV release manner. The material of the flexible substrate 20 includes polyimide (PI) or polydimethylsiloxane (PDMS). Then, a plurality of compressible flexible bumps 30 is deposited on the flexible substrate 20 at predetermined positions for implanting the metal circuit, and the compressibility of the flexible bumps 30 is higher than that of the flexible substrate 20. The material of the flex...

fourth embodiment

[0046]FIGS. 4A, 4B, and 4C are respectively schematic sectional views of a flexible circuit structure according to the present invention. As shown in FIG. 4C, the flexible circuit structure with stretchability of the present invention includes a flexible substrate 20, a plurality of flexible bumps 30, a metal layer 40, a first flexible material layer 51, a second flexible material layer 52, an active element 70, and via holes 80.

[0047]Firstly, as shown in FIG. 4A, in the flexible circuit structure with stretchability of the present invention, the flexible substrate 20 is attached on a supporting substrate 10 through the thermal release manner or the UV release manner. The material of the flexible substrate 20 includes polyimide (PI) or polydimethylsiloxane (PDMS). Then, the active element 70 (e.g., a chip) is disposed on the surface of the flexible substrate 20 in a direction facing the flexible substrate 20. Next, the first flexible material layer 51 is implanted on the active elem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

| Compressibility | aaaaa | aaaaa |

| Stretchability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com