Counter-rotating axial-flow fan

a technology of axial flow fan and axial bore, which is applied in the direction of machines/engines, stators, liquid fuel engines, etc., can solve the problems of insufficient coupling between and the fitting portions of the first and second divided housing units are applied with excessive force, so as to prevent the breakage of the engagement portion between the engaging member and the engaged member

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

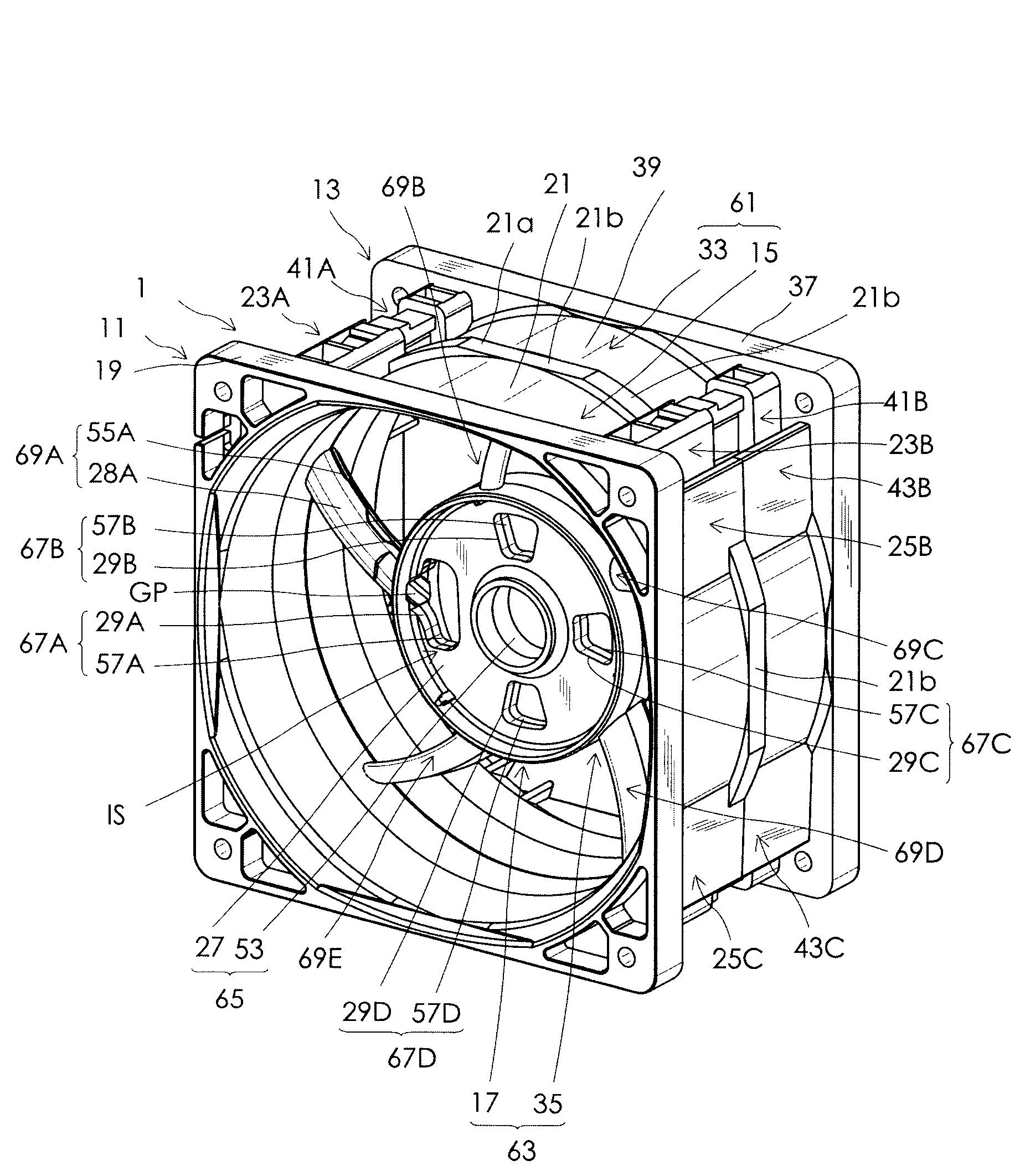

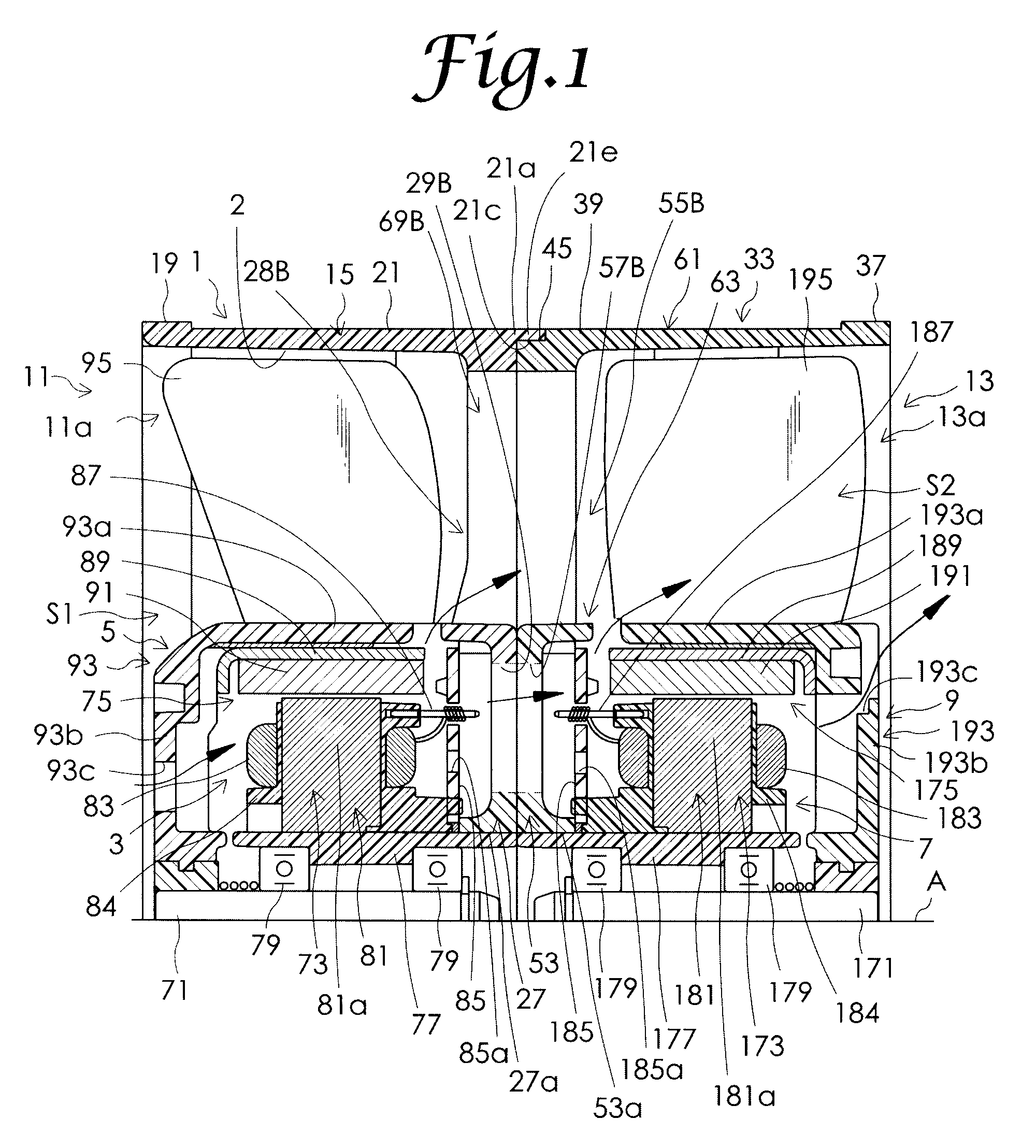

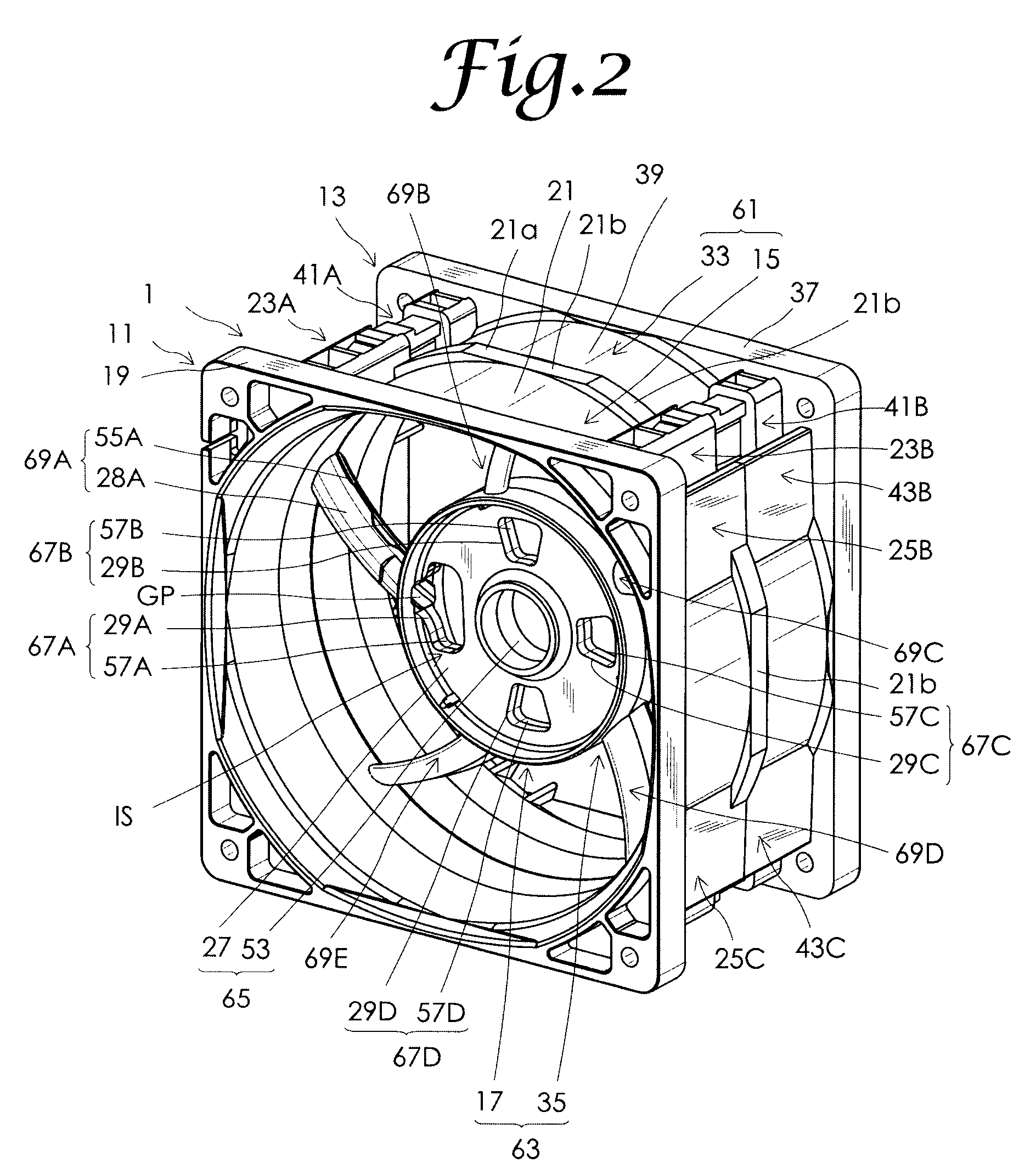

[0031]Now, an embodiment of the present invention will be described in detail with reference to the accompanying drawings. FIG. 1 is a cross-sectional view showing a half portion of a counter-rotating axial-flow fan in the embodiment of the present invention. As shown in FIG. 1, the counter-rotating axial-flow fan in this embodiment includes a housing 1, a first motor 3, a first impeller 5, a second motor 7, and a second impeller 9. The housing 1 comprises a housing body 61 including an air channel 2, a motor support frame 6 disposed in a central portion of the air channel 2. Further, as shown in FIGS. 2 to 6, the housing 1 is constituted from a first divided housing unit 11 and a second divided housing unit 13 that are coupled through a coupling structure. FIGS. 2 to 4 are a perspective view of the housing 1, a plan view of the housing 1, and a left side view of the housing 1, respectively. FIG. 5 is a partial cross-sectional view as taken along line V-V in FIG. 3. FIG. 6 is a cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com