Isothermal power

a technology of isothermal power and expansion device, which is applied in the direction of steam engine plants, machines/engines, mechanical equipment, etc., can solve the problems that cannot be done with an adiabatic expansion device, and achieve the effect of reducing mechanical losses in the compression and expansion device and effectively producing an approximate isothermal compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Single-Phase Gas Isothermal Heat Engine

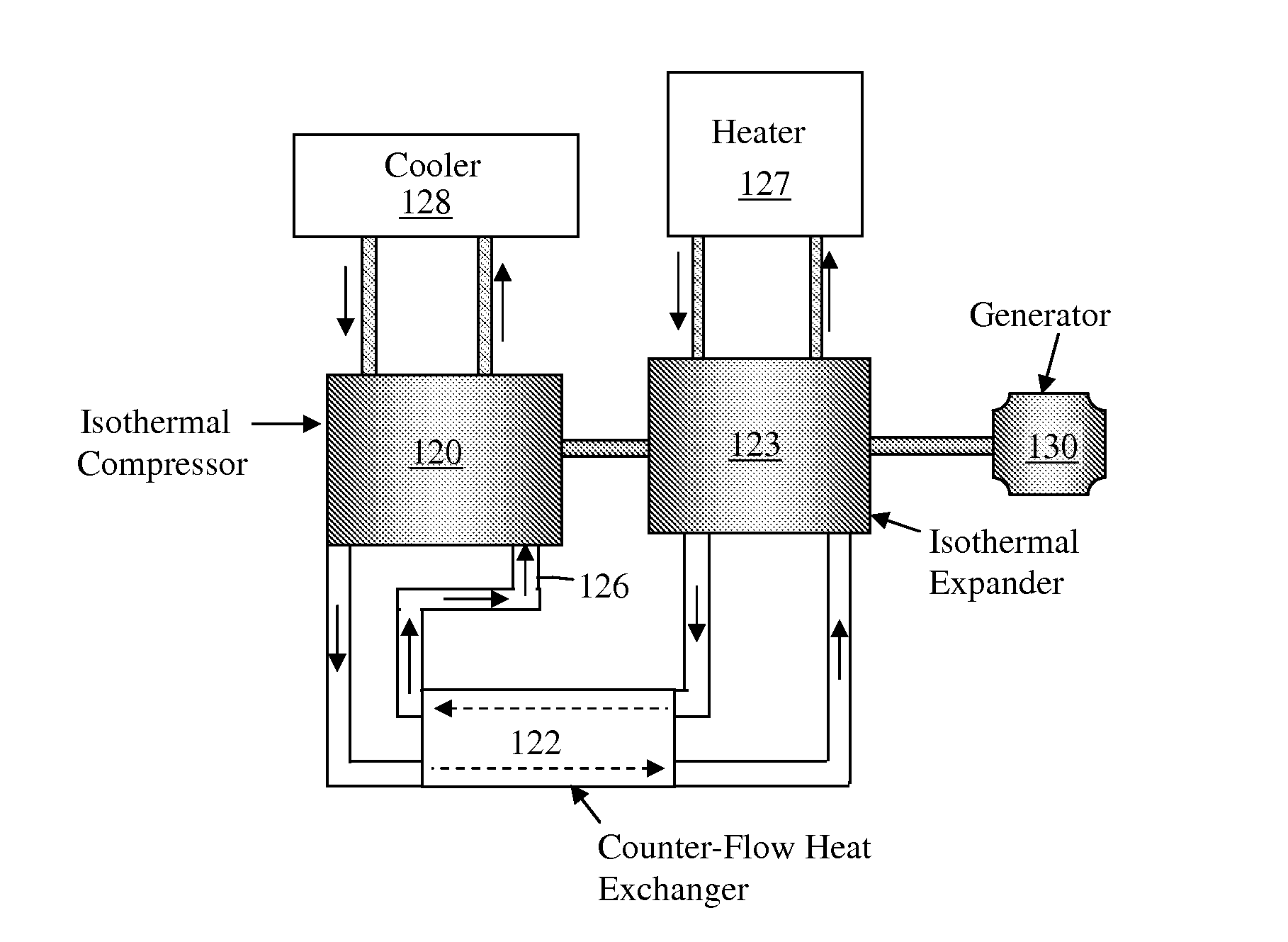

[0037]FIG. 1 shows a layout for the single-phase gas isothermal engine system. The gas is compressed in the isothermal compressor. In order to keep the gas at constant temperature, a cooler is necessary, since compression of a gas tends to heat it.

[0038]For efficient heat transfer, the cooler can supply a liquid to channels beneath the surfaces in the compressor. The liquid evaporates as it removes heat from the surfaces. The vapor flows to the cooler, where it is condensed and returned to the compressor.

[0039]For adequate heat flow, the heater should supply heat at slightly higher temperature than the isothermal temperature of the expander, and the cooler should supply a fluid that is at slightly lower temperature than the compressor isothermal temperature.

[0040]In FIG. 1, the isothermal compressor 120 draws air (or other gas) in through pipe 126 and compresses it. The compressed gas from the isothermal compressor then flows through the counte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com