Solenoid pump

a solenoid pump and solenoid technology, applied in the direction of pump control, positive displacement liquid engine, motor parameter, etc., can solve the problems of premature fatigue, wear and failure of the pump,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

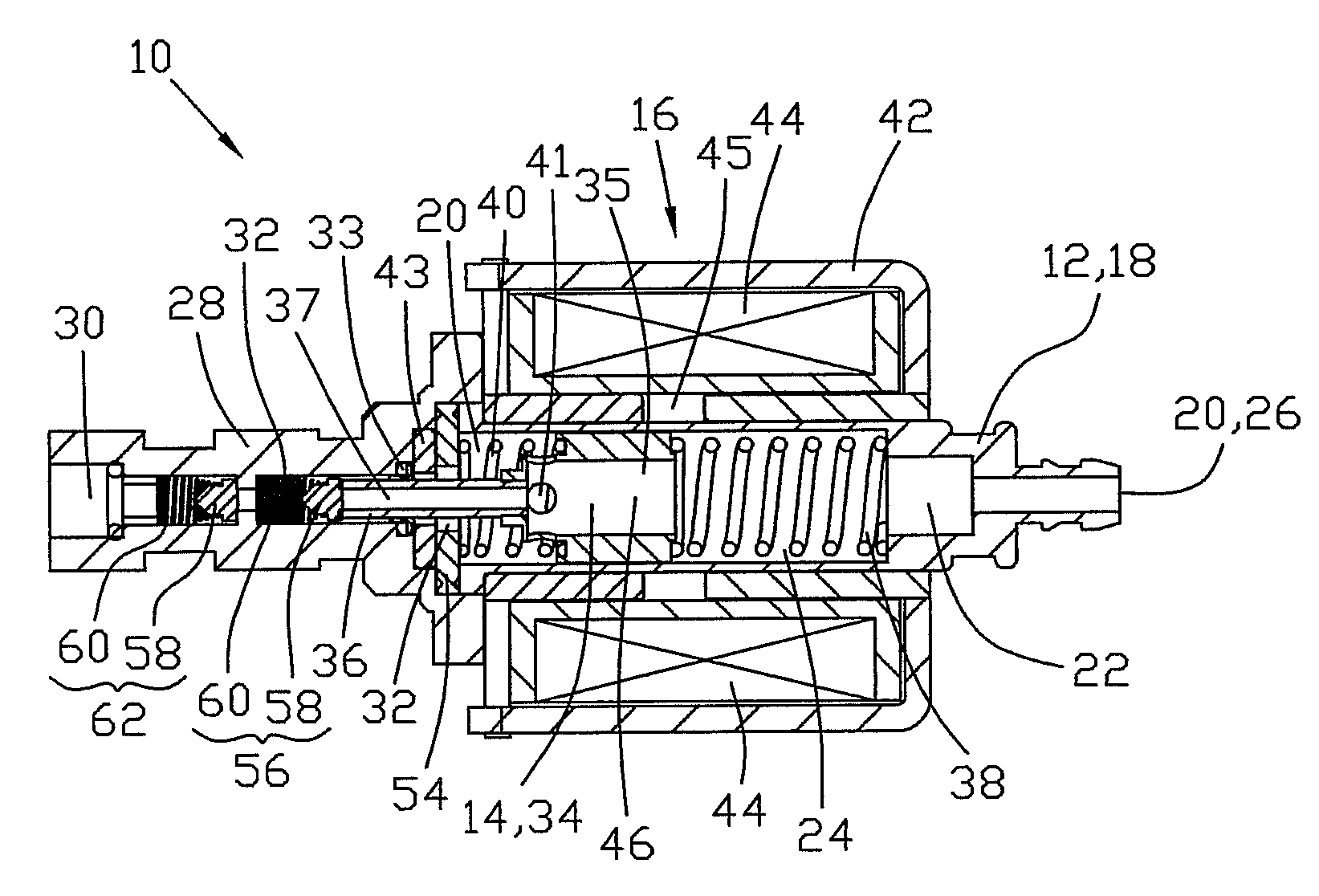

[0025]Referring firstly to FIG. 1 of the drawings, there is shown a solenoid pump 10 which comprises a pump housing 12, a linear reciprocatable plunger 14, and electro-motion means 16 for moving the plunger 14 in a reciprocating manner. The electro-motion means is preferably, in the form of a solenoid.

[0026]The pump housing 12 includes a hollow housing body 18 having two open ends 20 and a stepped-bore 22 therethrough. A plunger chamber 24 is provided within the housing body 18 and is defined primarily by the stepped-bore 22. A first one of the open ends 20 of the housing body 18 forms a liquid inlet port 26 for liquid flow into the plunger chamber 24, and an end cap 28 is fastened, typically by bolts, to the housing body 18 to close a second one of the open ends 20.

[0027]The end cap 28 includes a central rectilinear liquid-outlet passage 30 therethrough. The liquid-outlet passage defines a pump chamber 32 leading from the plunger chamber 24. The plunger chamber 24 is cylindrical an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com