Structural Insulated Header

a structural insulation and header technology, applied in the direction of girders, heat-insulating coatings, building repairs, etc., can solve the problems of affecting the stability of the structure, and affecting the integrity of the larger structure, so as to strengthen the load-bearing capacity of the beam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

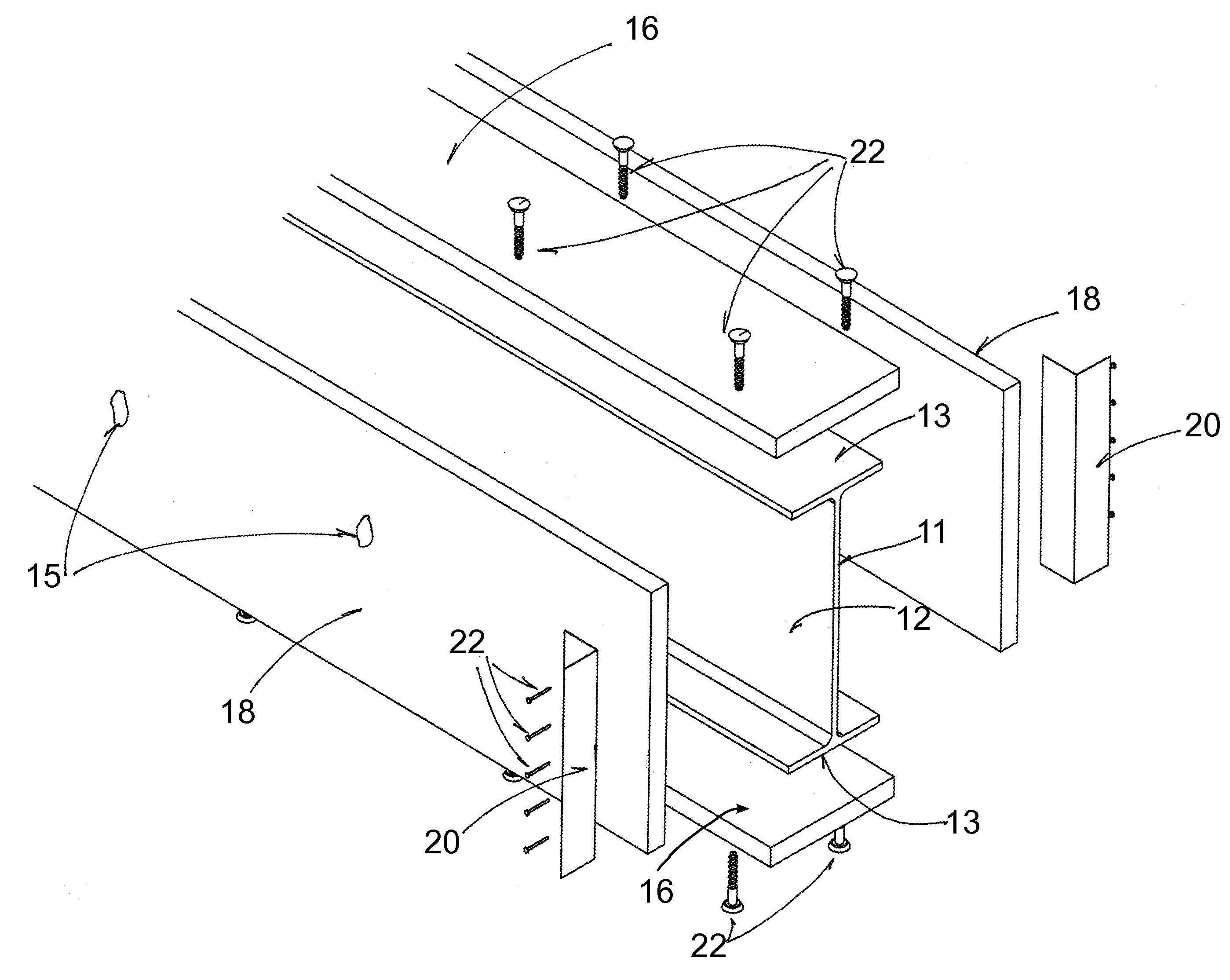

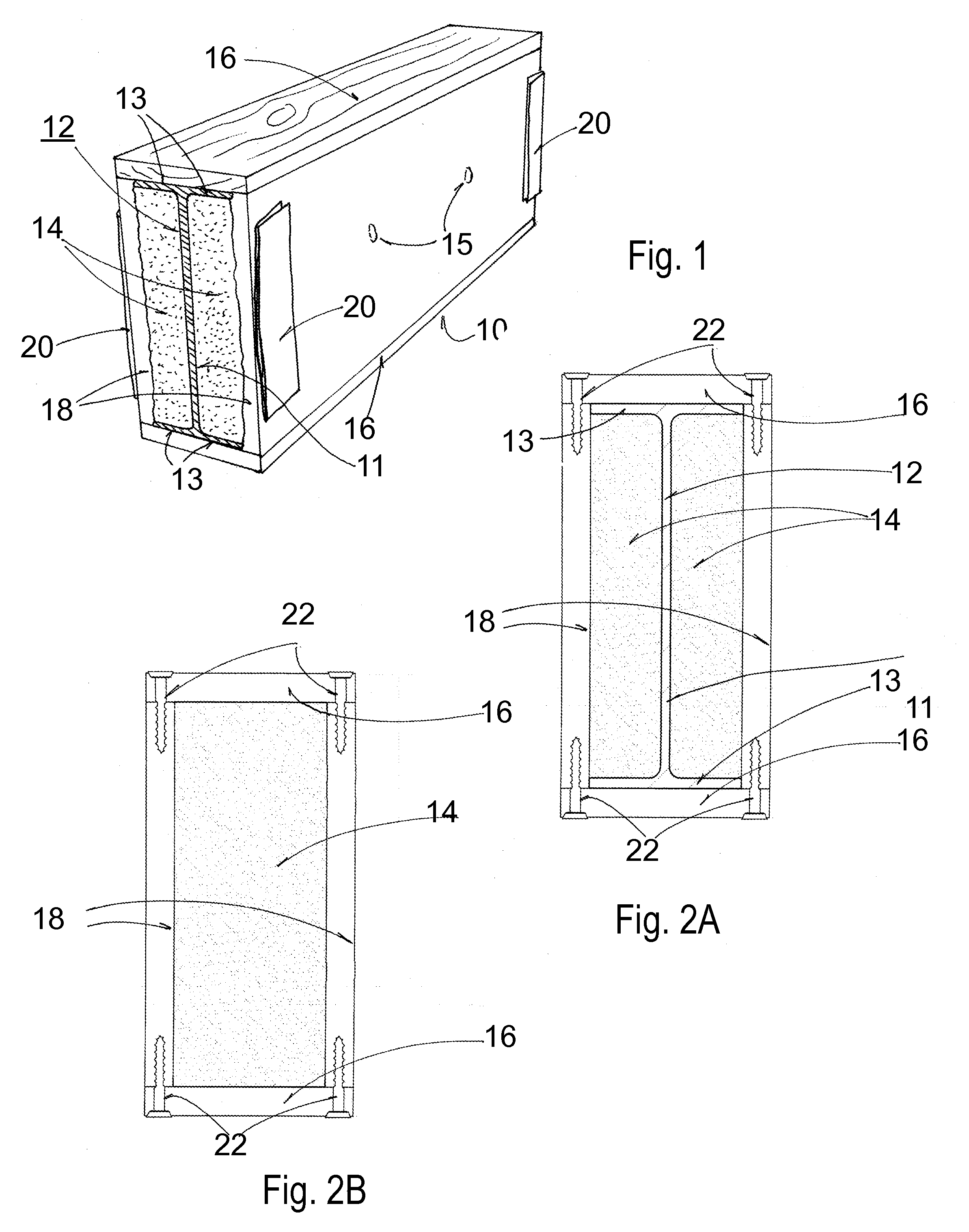

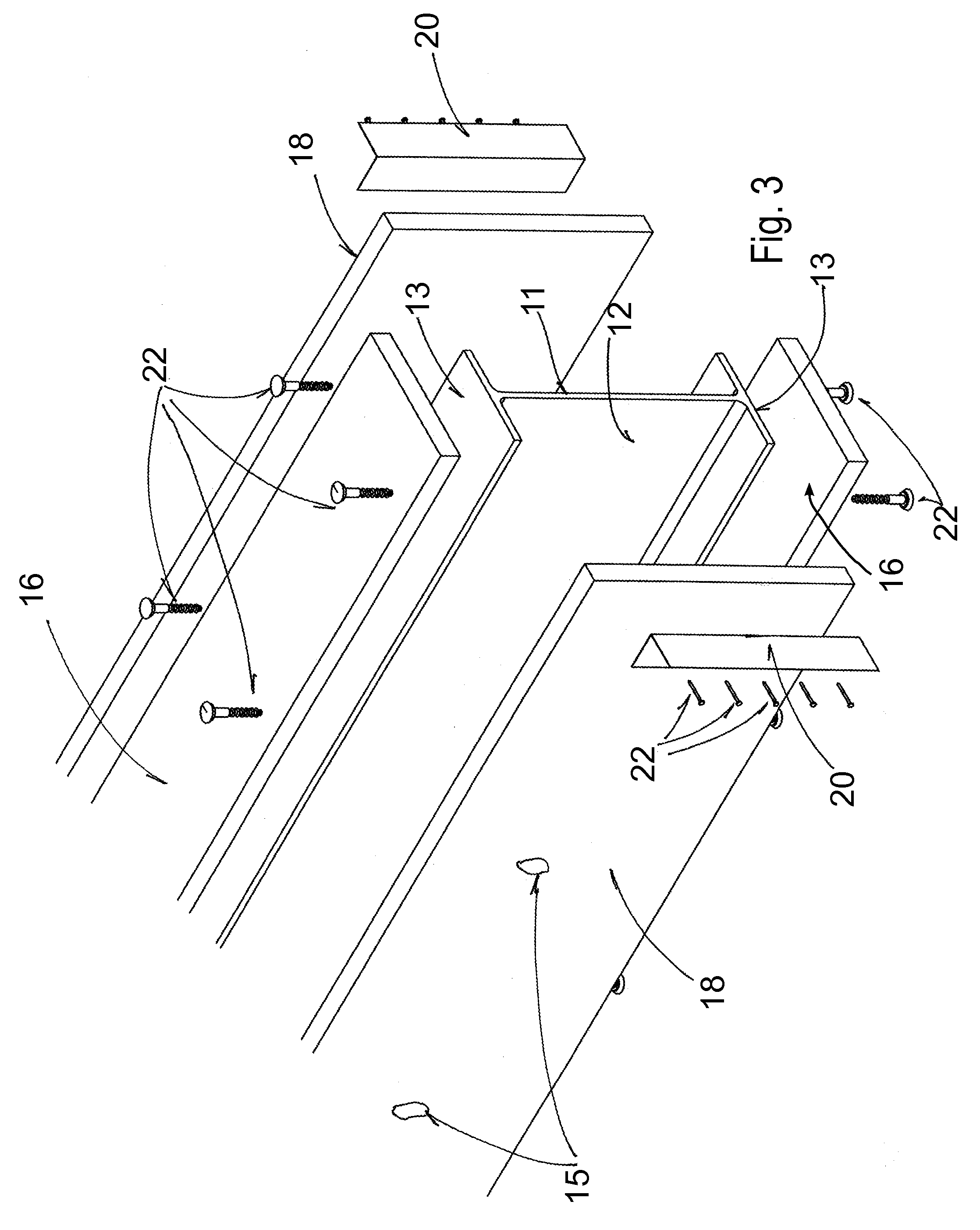

[0047]The structural header as shown in FIGS. 1, 2A, 2B, and 3; consisting primarily of a beam 10, one embodiment of which FIG. 2A is an example, comprising a pre-manufactured box beam 10a comprising a pair of horizontal members 16 connected with a pair of vertical members 18 with an insulation space 14 generally comprised of structural foam.

[0048]In another embodiment shown in FIG. 2B an element known in the trade as an “I” beam is added to the system. The beam 12, which is typically made of a metal such as steel, and is comprised of a web portion 11 which is a vertical member for load bearing, being nominally 8 to 12 inched in height, and two flange portions 13 located on the top and bottom of the web portion 11, being nominally 4 inches in width, for lateral stability. While the beam 12 is typically quite strong compared with wooden framing for construction purposes, it does not provide good nailing or attaching surfaces typically required in conjunction with wooden framing. Addi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com