Slotwall mounting assembly

a technology for mounting brackets and slotwalls, which is applied to show shelves, domestic applications, and hangers, etc., can solve the problems of multiple parts and assembly, difficult to handle, and easy to be dislodged from the slotwall after installation, so as to improve the flexibility of the locking flange, reduce the effort, and adapt to existing slotwall accessories.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]For purposes of the following description, the terms “upper,”“lower,”“left,”“rear,”“front,”“vertical,”“horizontal” and derivatives of such terms shall relate to the invention as oriented in FIG. 12. However, it is to be understood that the invention may assume various alternative orientations and configuration, except where expressly specified to the contrary. It is also to be understood that the devices and processes illustrated in the attached drawings, and described in the following specification are simply exemplary embodiments of the inventive concepts defined in the inventive concepts of this invention. Specific dimensions and other physical characteristics relating to the embodiments disclosed herein are not to be considered as limiting unless expressly stated otherwise.

[0033]I. Overview

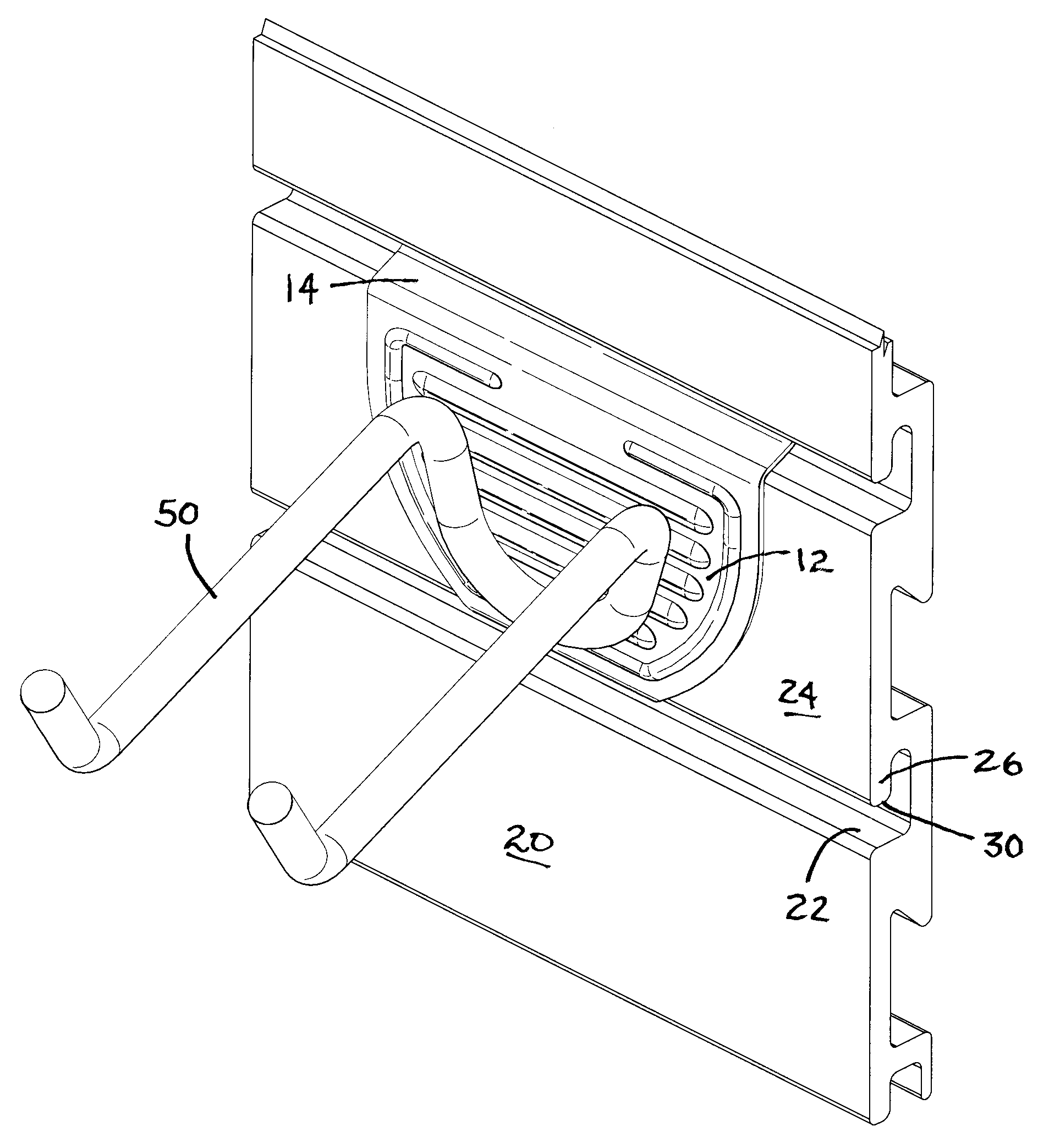

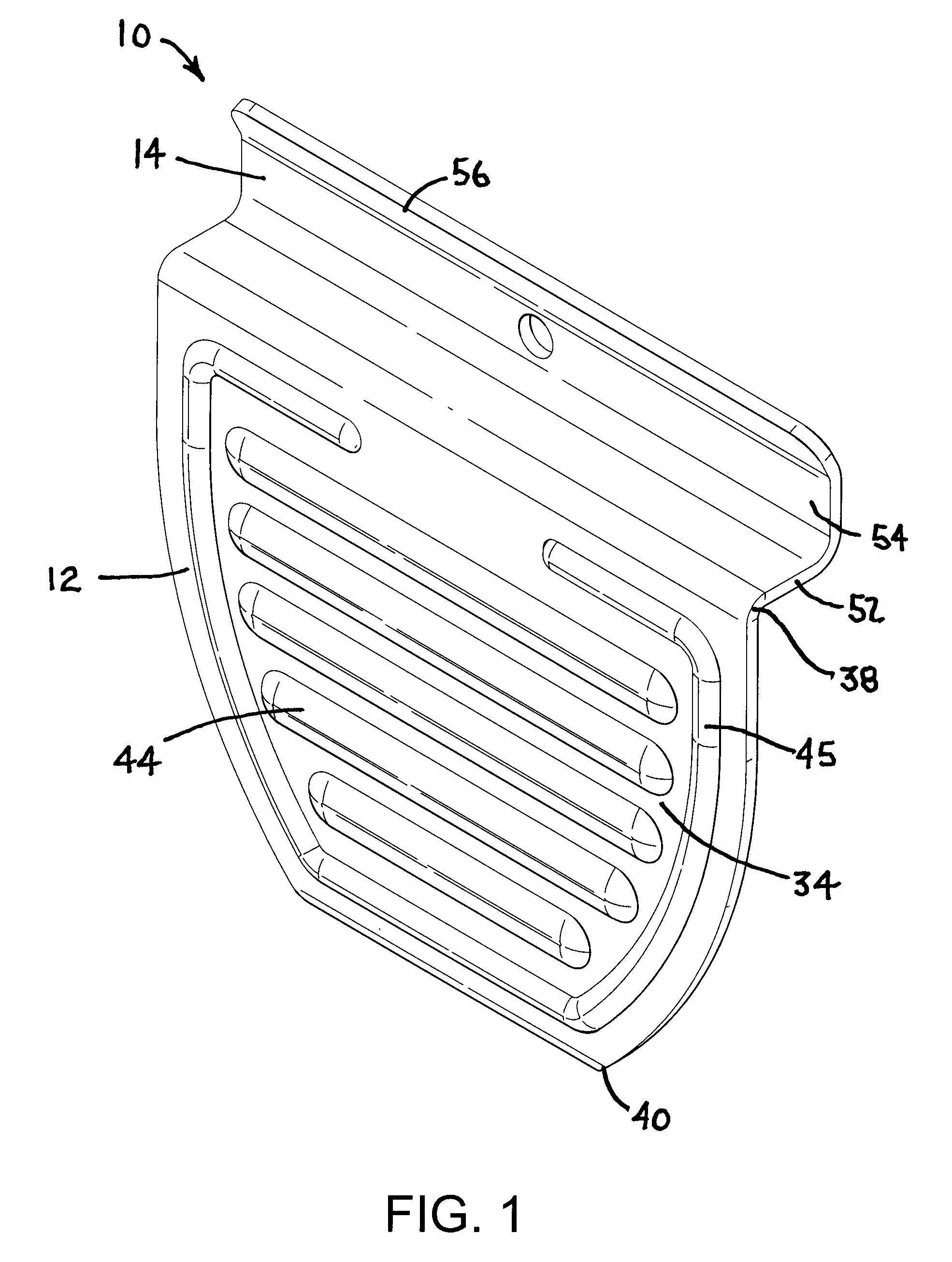

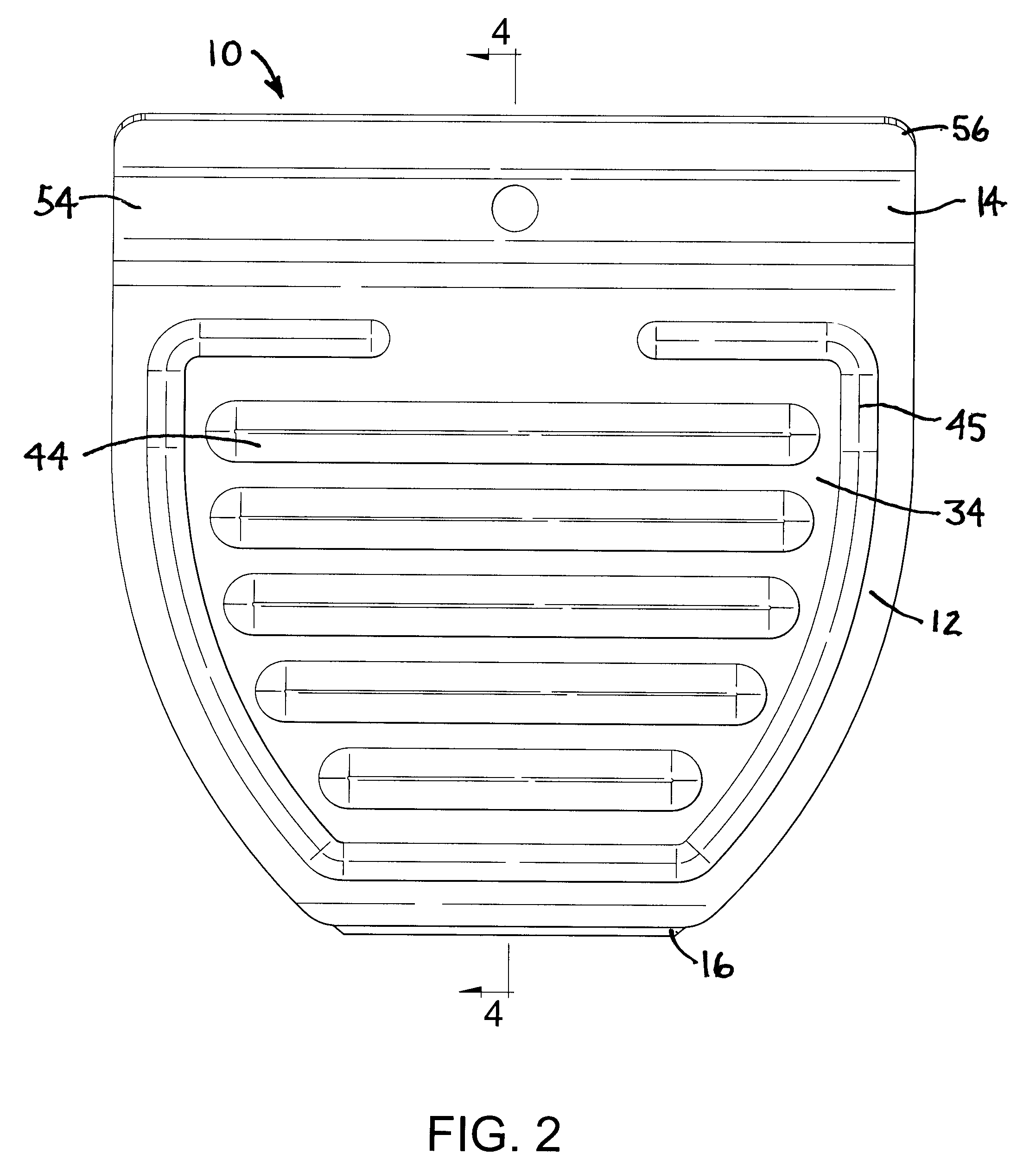

[0034]A slotwall mounting bracket in accordance with a preferred embodiment of the present invention is shown in FIGS. 1 and 3 generally designated 10. The mounting bracket includes a ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com