Method and apparatus for positioning reinforcing members within hardened material structures

a technology for reinforcing members and hardening materials, applied in the direction of building reinforcements, paving reinforcements, construction, etc., can solve the problems of increasing shipping and supervision costs, erode reinforcing members, and single elevation positioning devices suffer, so as to eliminate or minimize the voids in the hardening material. , the effect of accurate and efficient positioning of reinforcing members

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

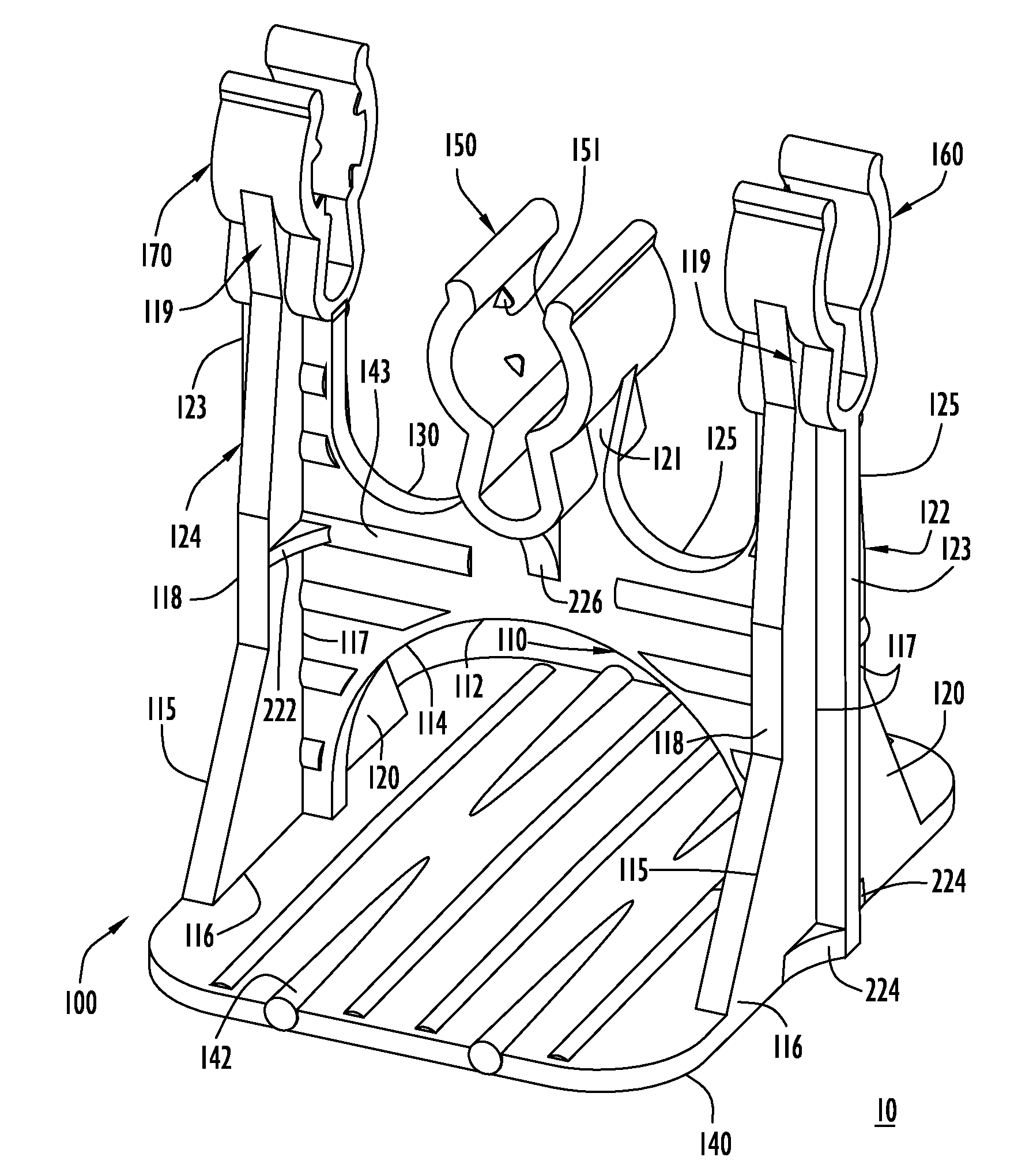

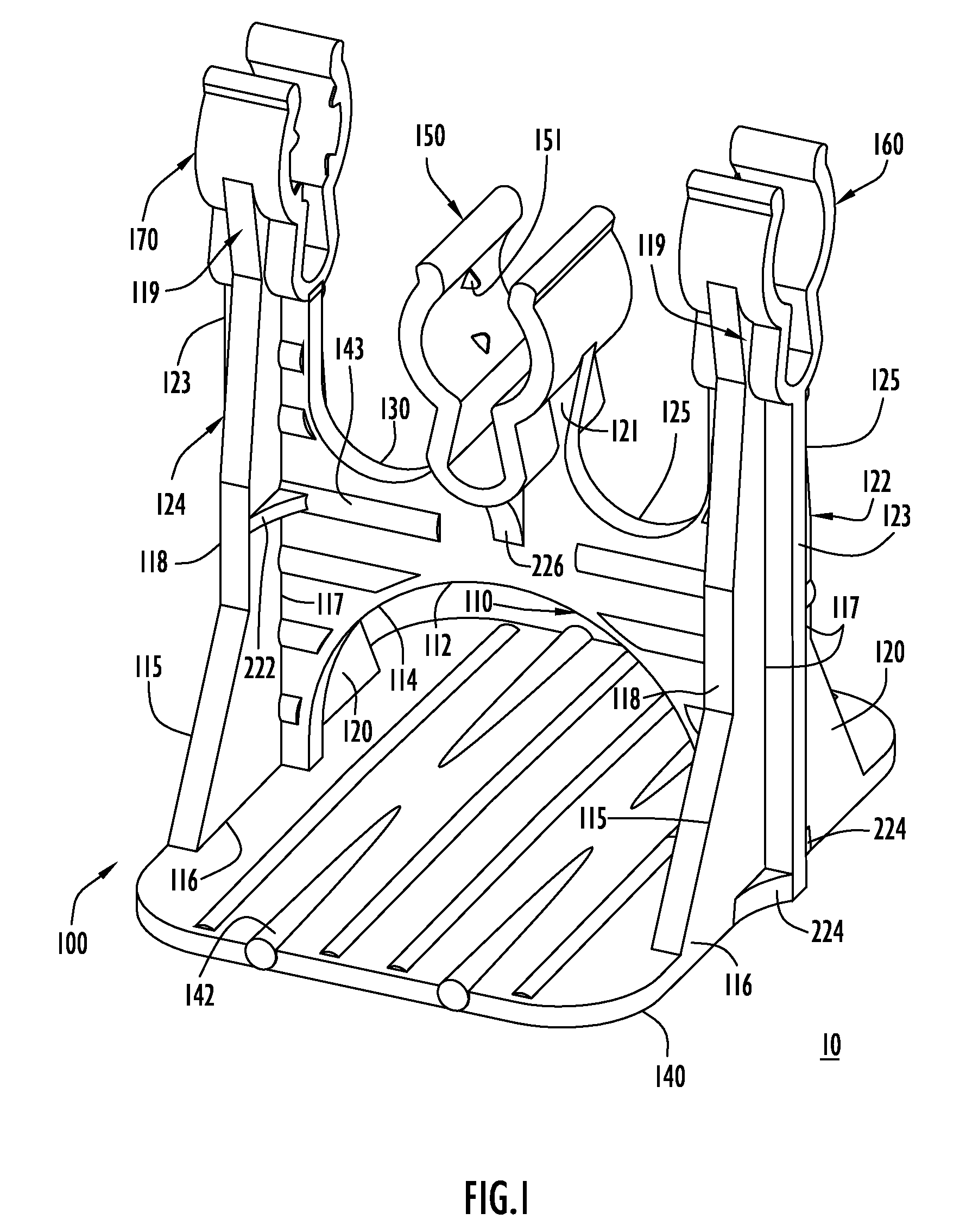

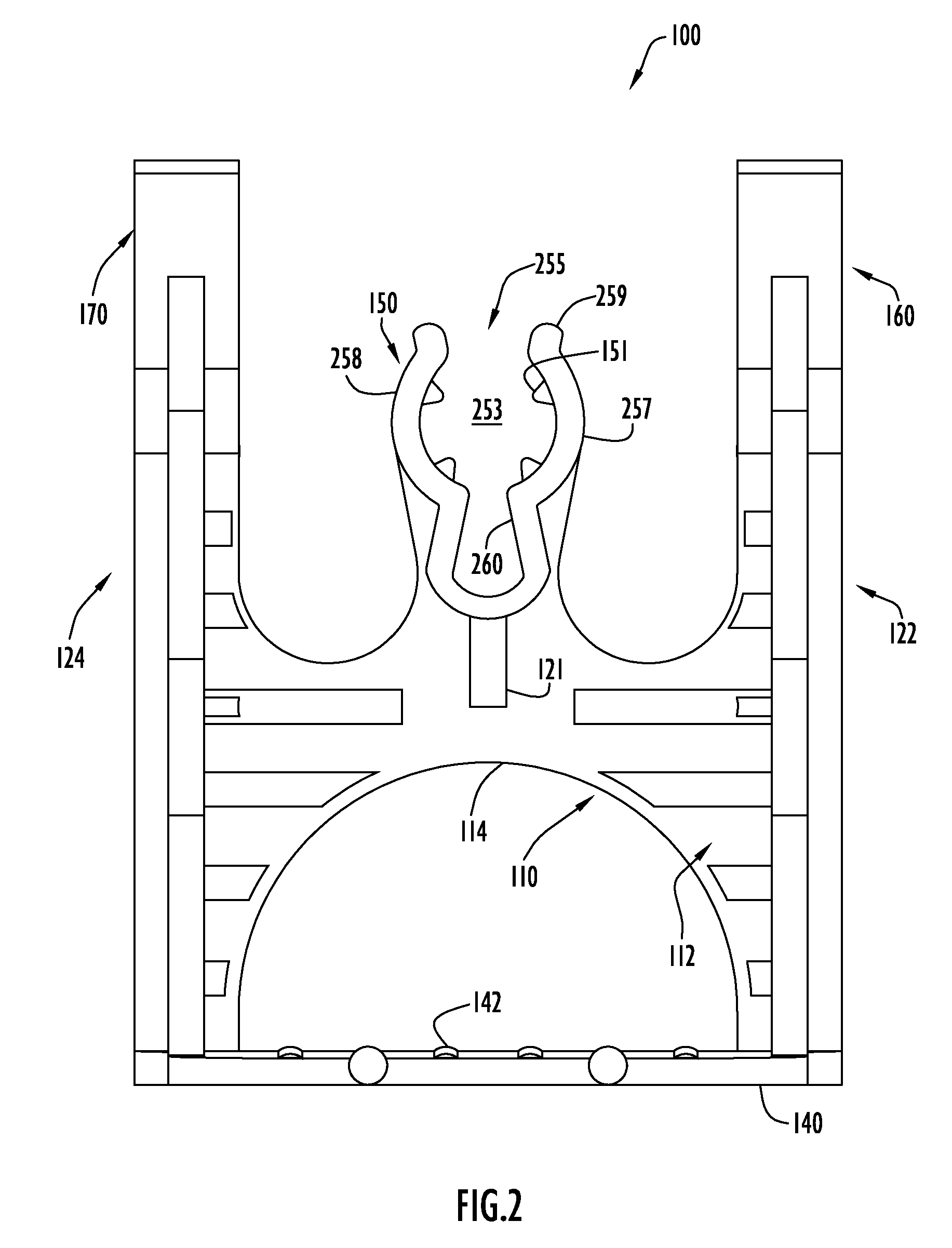

[0024]The present invention embodiments pertain to an effective, low cost and lightweight support device (or chair) configured to precisely position reinforcing members (e.g., rebar) in a hardened material (e.g., concrete, etc.) structure. A support device according to an embodiment of the present invention is illustrated in FIGS. 1-3. Specifically, support device 100 includes a base 140, a support member 110 supported by base 140, and a plurality of receptacles or clips 150, 160, 170 extending from support member 110 to receive reinforcing members as described below.

[0025]Base 140 contacts a support surface 10 and supports support member 110 in a steady manner during use. Typically, support surface 10 is an interior surface of a containment structure (e.g., the temporary support decking of a building floor slab, etc.) within which the hardening material is placed. In addition, base 140 may engage support surface 10 in any orientation (e.g., horizontally for supporting reinforcing m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com