Spur gear drive for an internal combustion engine

a gear drive and internal combustion engine technology, applied in the direction of valve drives, valve details, valve arrangements, etc., can solve the problems of large installation space and relatively complex production of double gears, and achieve the effect of being smaller and lighter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

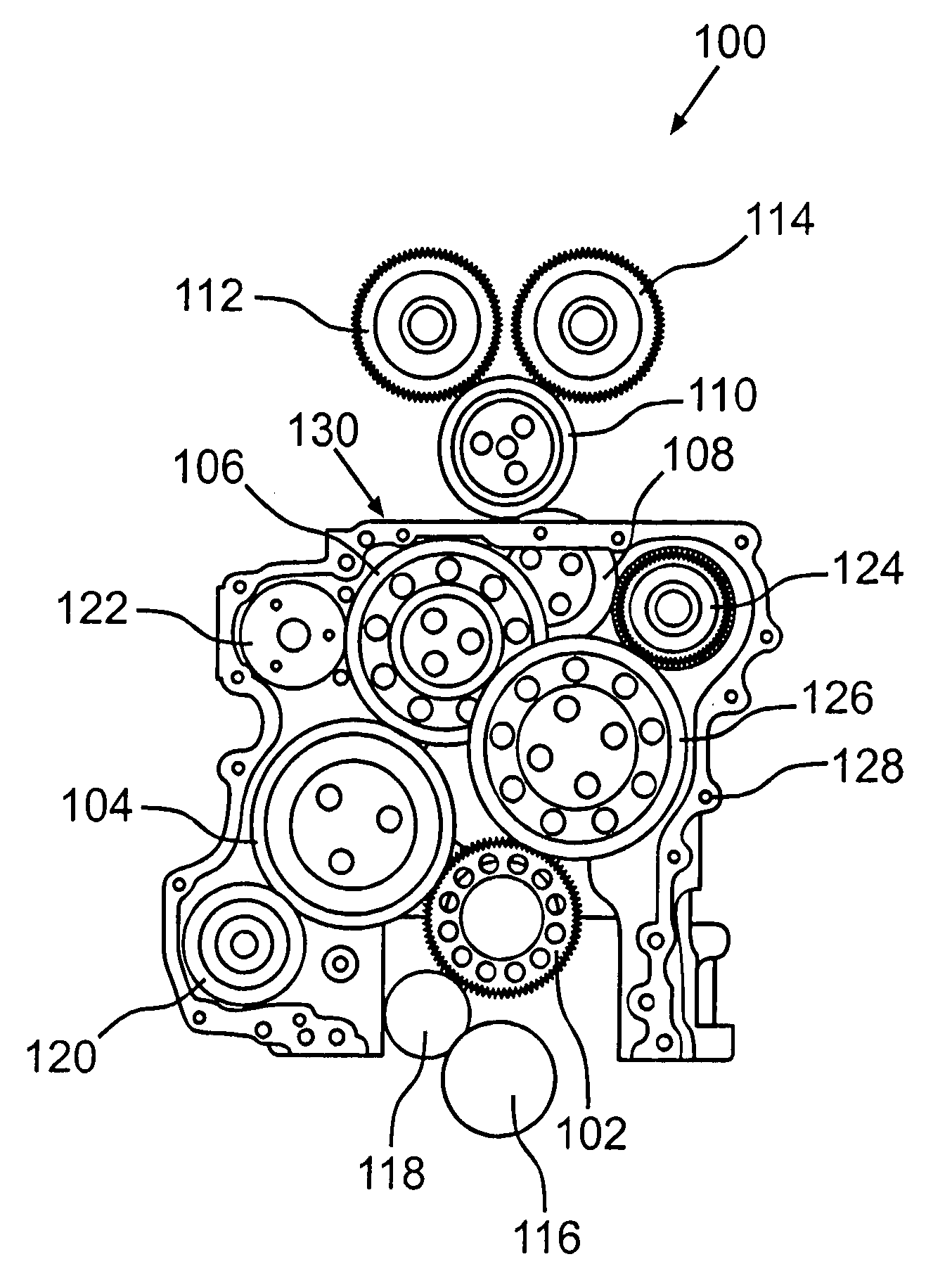

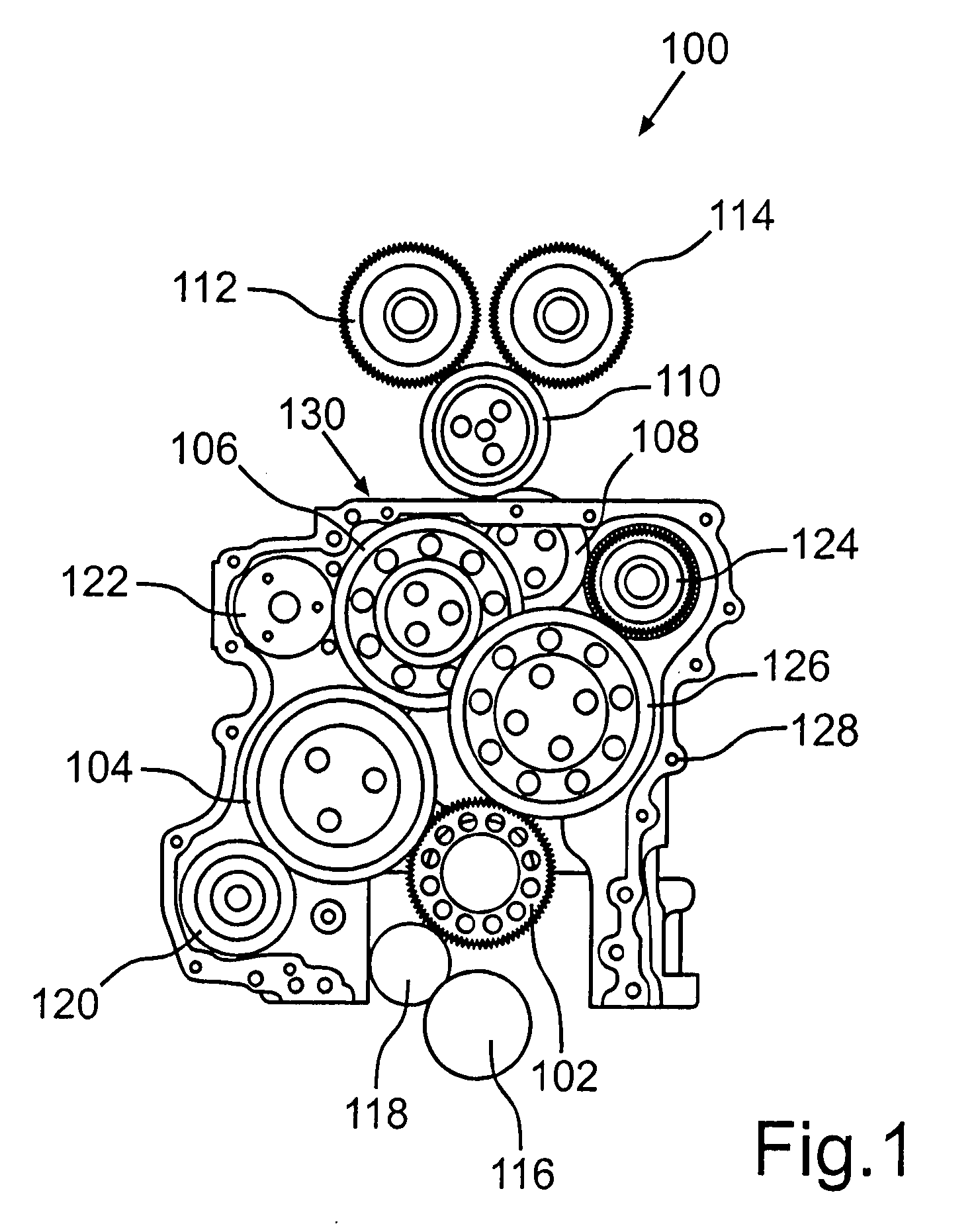

[0025]The preferred first embodiment of a spur gear drive 100 according to the invention as shown in FIG. 1 is provided for an internal combustion engine that is, specifically, a diesel engine with a 10.6 liter displacement volume. The spur gear drive 100 comprises a crankshaft gear 102 which drives a first camshaft gear 112 and a second camshaft gear 114 via a first intermediate gear 104, a second intermediate gear 106, a third intermediate gear 108 and a fourth intermediate gear 110. The first camshaft gear 112 serves for controlling the inlet valves, and the second camshaft gear 114 serves for controlling the outlet valves, so that, as it can be seen from FIG. 1, the internal combustion engine is a so-called DOHC machine.

[0026]The camshaft gears 112, 114 are arranged for driving a first and a second camshaft. The spur gear drive 100 extends below the crankshaft gear 102, and at the end opposite the camshaft gears 112, 114, is provided with an oil pump gear 116 which is driven by ...

second embodiment

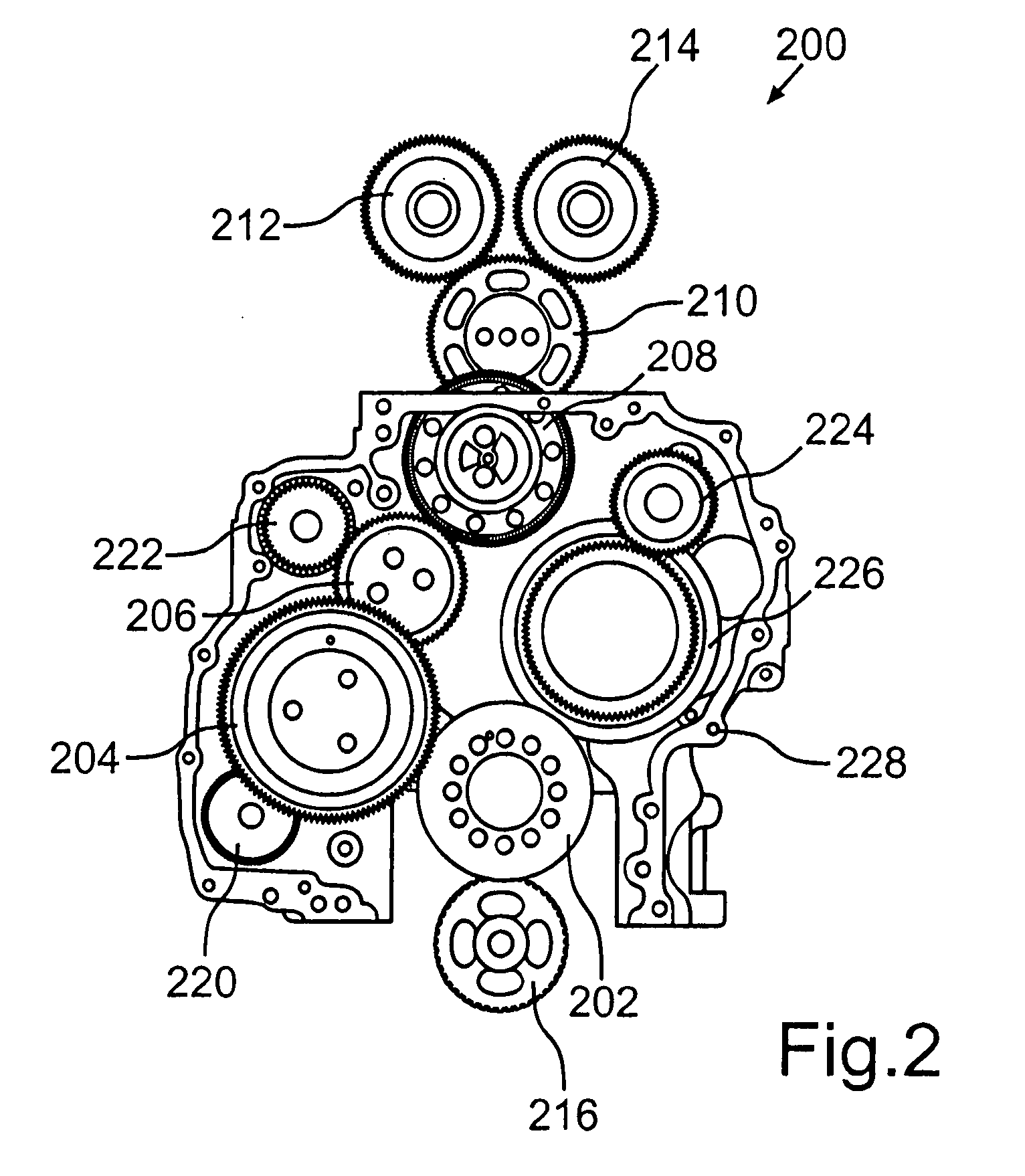

[0038]In connection with FIG. 3 it is explained how a third intermediate gear 208 can be arranged so as to be moveable with respect to an upper edge 230 of an engine block or, respectively, a gear supported on the cylinder head of the engine, which is shown in particular for the spur gear drive 200 of the second embodiment shown in FIG. 2.

[0039]The third intermediate gear 208 is rotatably supported by a bearing journal 232 which is mounted to the cylinder block (not shown—FIG. 3 shows the gear arrangement from the rear, that is the cylinder block side) by mounting bolts 236. The bearing journal is held by a pin 234, which extends into a bore in the cylinder block front wall and is pivotally supported thereby. The bolts 236 extend through elongated holes 238 in the bearing journal 232 so that the bearing journal can be firmly mounted to the cylinder block front wall by tightening of the bolts 236. With the bolts 236 loosened the bearing journal 232 can be pivoted about the pin 234 du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com