System and method for manufacturing optical display

a technology of optical display and manufacturing method, which is applied in the field of systems and methods for manufacturing optical displays, can solve problems such as quality degradation, and achieve the effects of reducing the number of working processes, simplifying the packing operation, and reducing the work load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

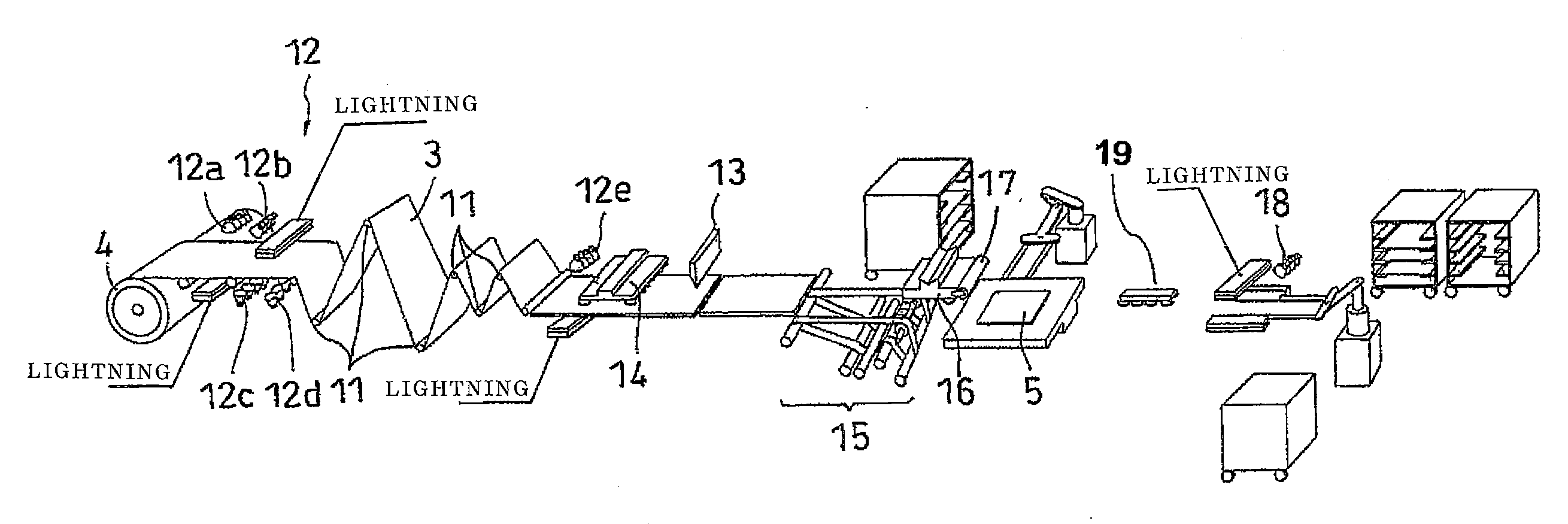

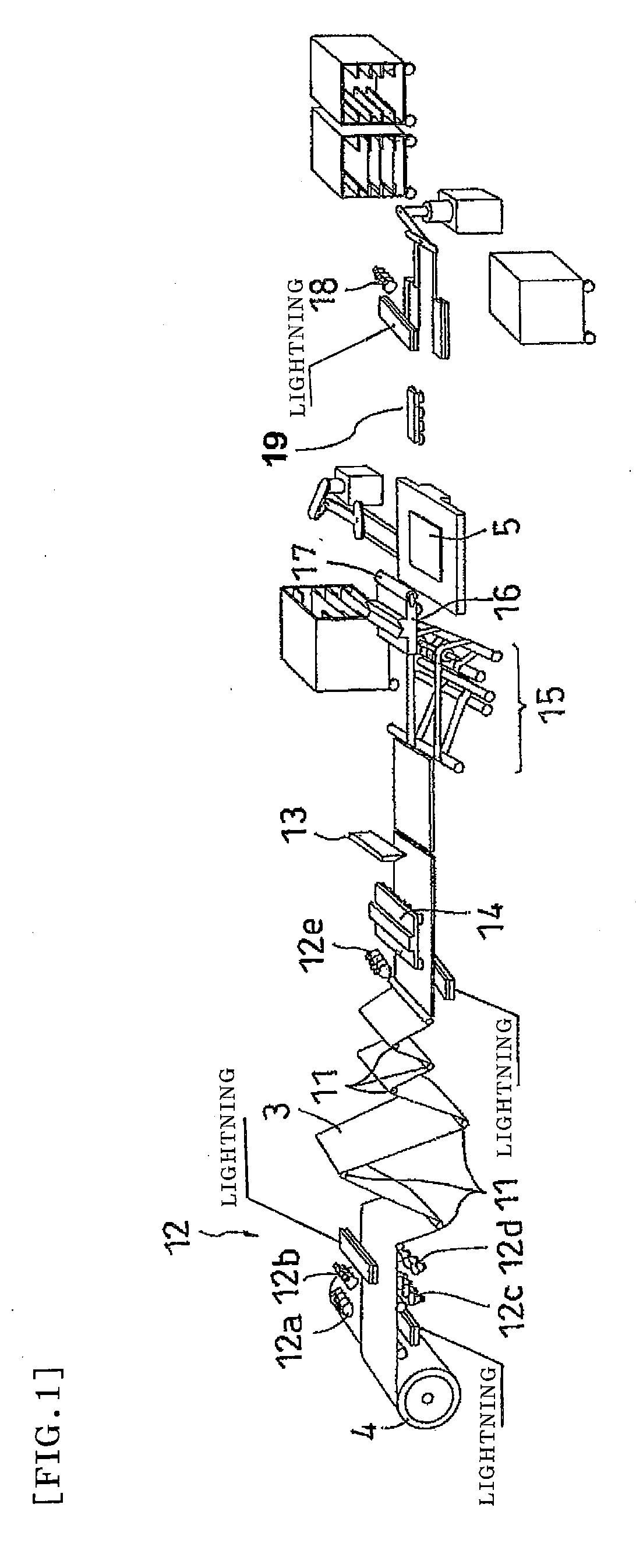

Image

Examples

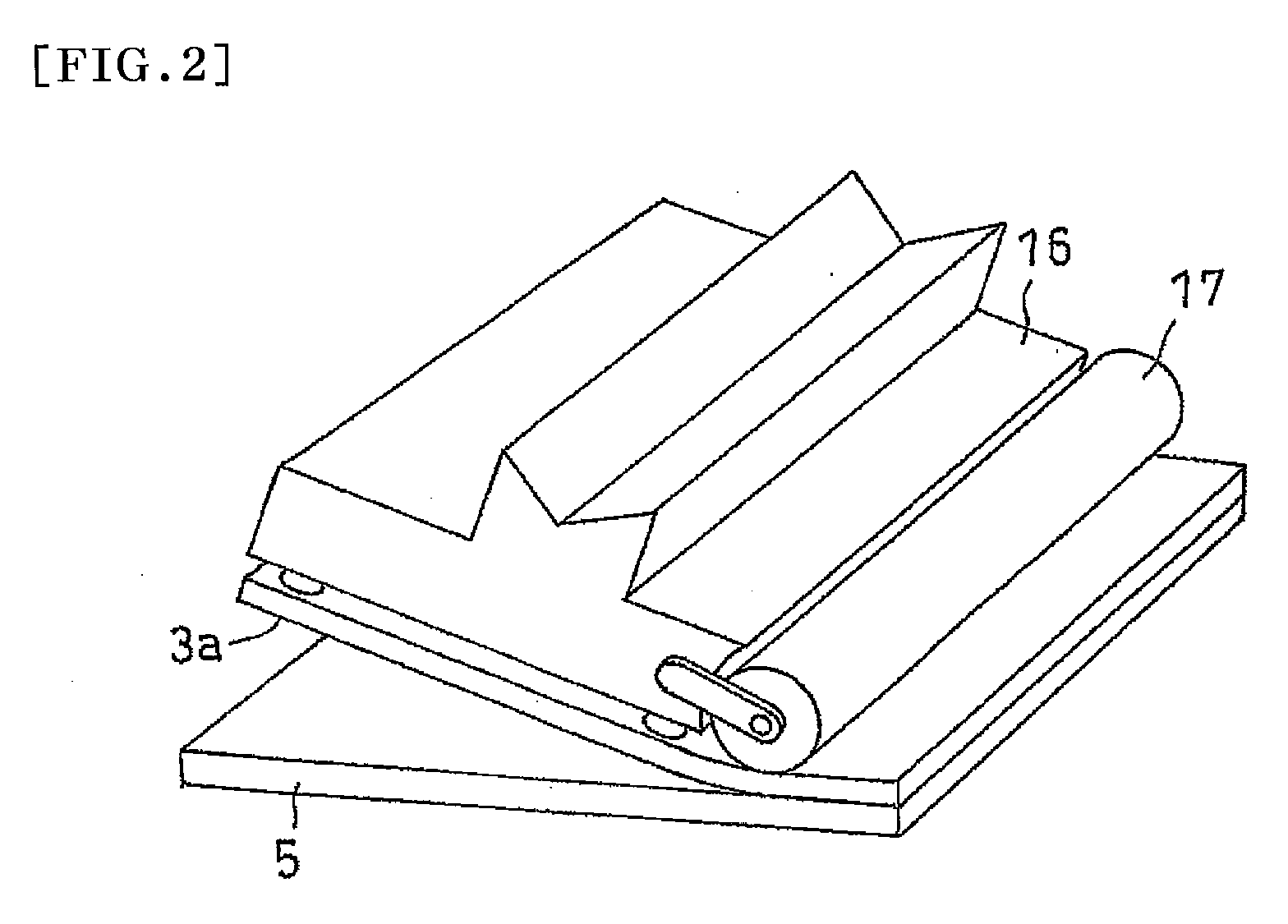

Embodiment Construction

[0026]Preferred embodiments of the invention are described below. Sheet-Shaped Product, Optical Display Unit and Optical Display

[0027]A description is given of some embodiments using a raw polarizing plate as an example of the sheet-shaped product to be handled according to the invention. The raw polarizing plate is in the form of a long film, and polarizing plates each with a specific size are punched (or cut) from the film-shaped raw polarizing plate. For example, the raw polarizing plate may be produced by sticking a triacetylcellulose film (transparent protective film) to both the front and back sides of a previously prepared polyvinyl alcohol film (polarizer). It is necessary to detect whether or not defects (such as scratches and foreign matter) are present on the surface of or in the interior of the raw polarizing plate with such a multilayer structure. The defects are detected by the detection means described later.

[0028]The raw polarizing plate may be produced by a manufact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com