Adjustable stiffness shaft structure

a shaft structure and adjustable technology, applied in the field of golf clubs and fishing rod shafts, can solve the problems of golf ball to slice, complex process, high cost, etc., and achieve the effect of easy chang

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

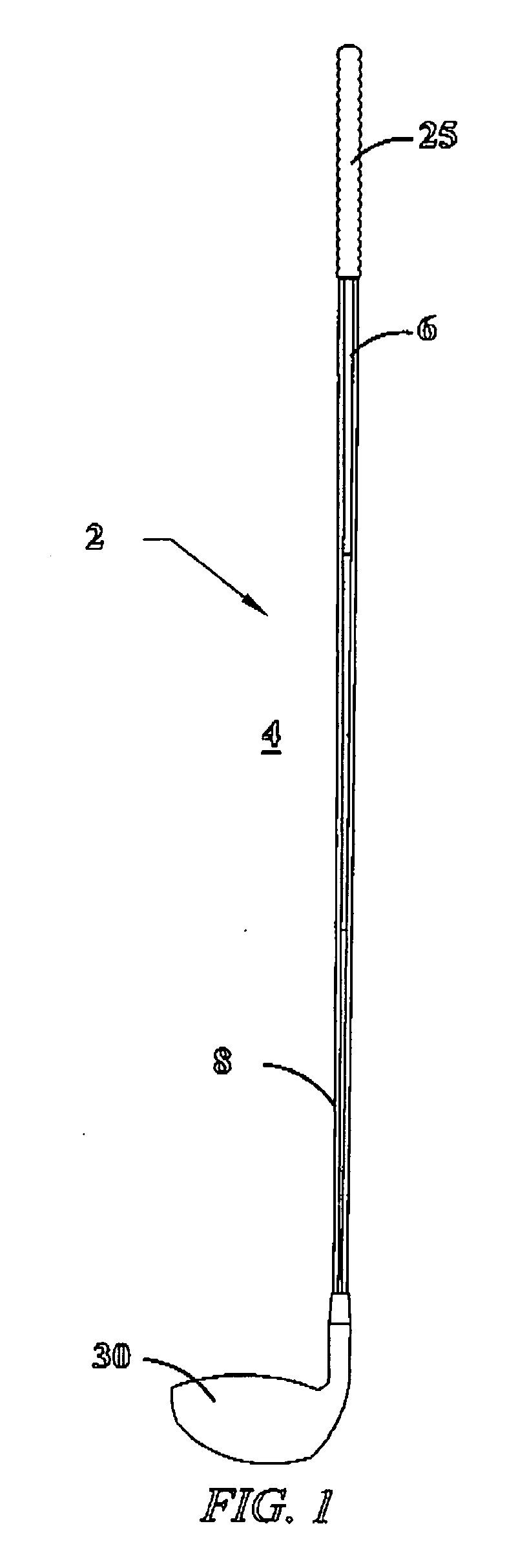

[0025]FIG. 1 reveals an illustrative golf club 2 that incorporates an embodiment of a shaft structure 4 of the present invention. In the preferred embodiment, shaft structure 4 includes an inner shaft structure 6 and outer shaft structure 8. Outer shaft structure 8 is fashioned as a conventional golf shaft with an associated stiffness. Those skilled in the art will recognize that a multitude of materials may be used for both the inner and outer shaft structure and that using alternative materials does not deviate from the scope or spirit of the present invention. Stiffness is indicated by stiffness indicator 5 which is affixed firmly to the butt and of the grip. Indication of stiffness is demonstrated by the dial markings of stiffness indicator 5 and by the relative position of the capstan 20.

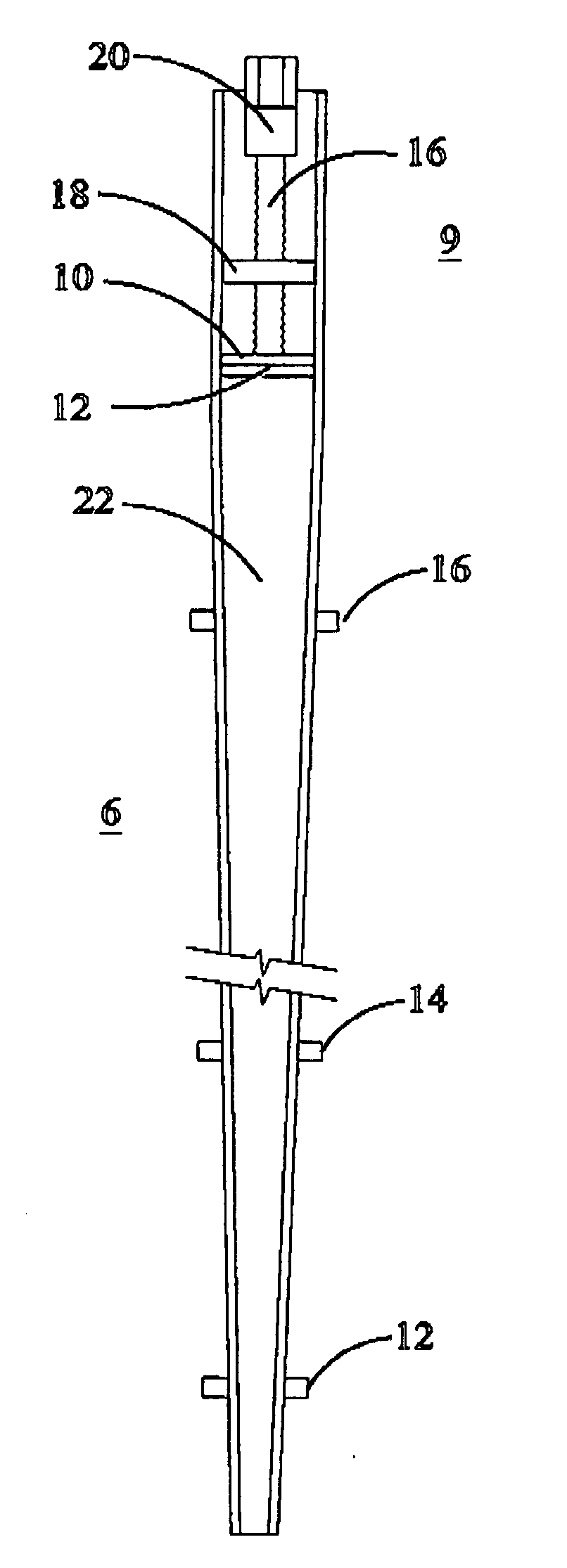

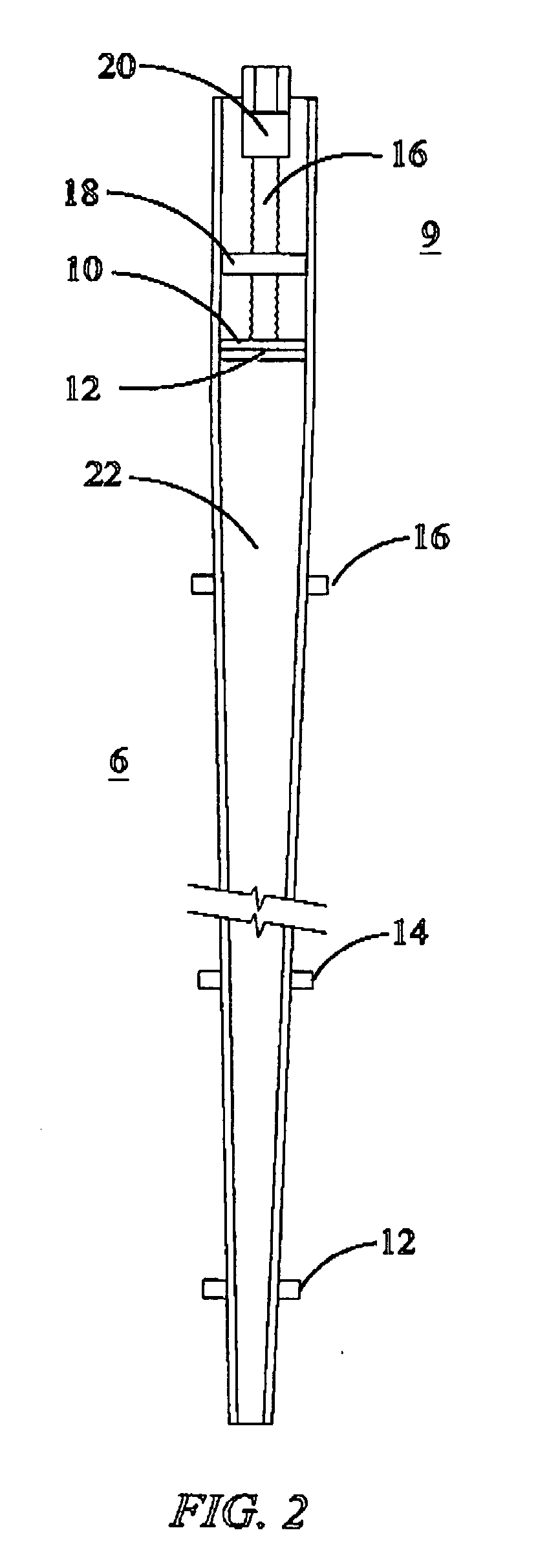

[0026]With reference to FIG. 2 inner shaft structure 6 is comprised of a proximal end and a distal end. Proximal end of inner shaft structure 6 is further comprised of pressurization unit 9. Di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com