Tape binding device

a technology of tape binding and tape, which is applied in the direction of binding material applications, paper/cardboard containers, bundling machine details, etc., can solve the problem of partially excessive belt tension, and achieve the effect of significantly reducing the number of times of bending the belt, significantly reducing the belt tension, and partially excessive belt tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]Preferred embodiments of the present invention will be described while referring to the attached drawings.

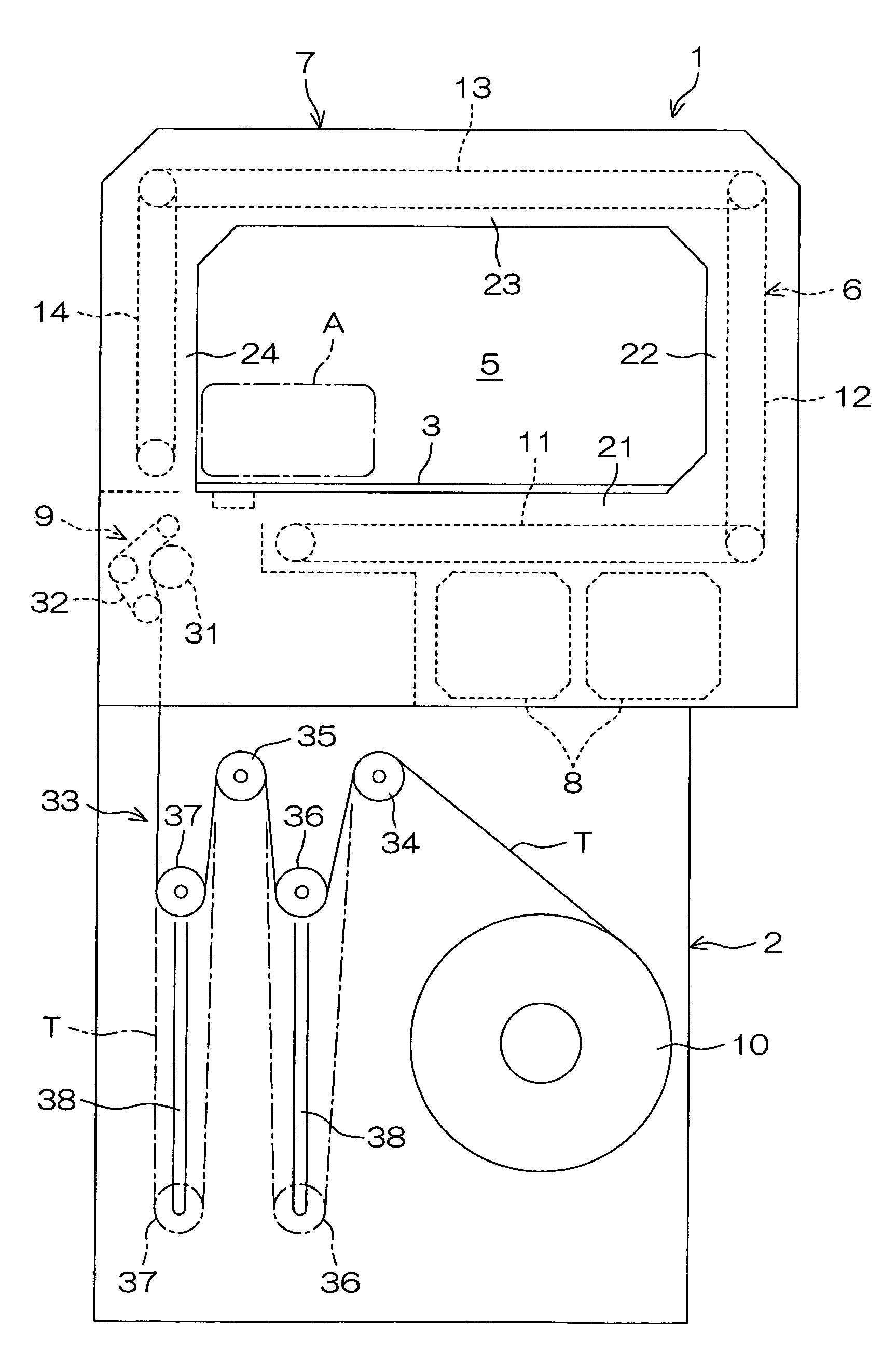

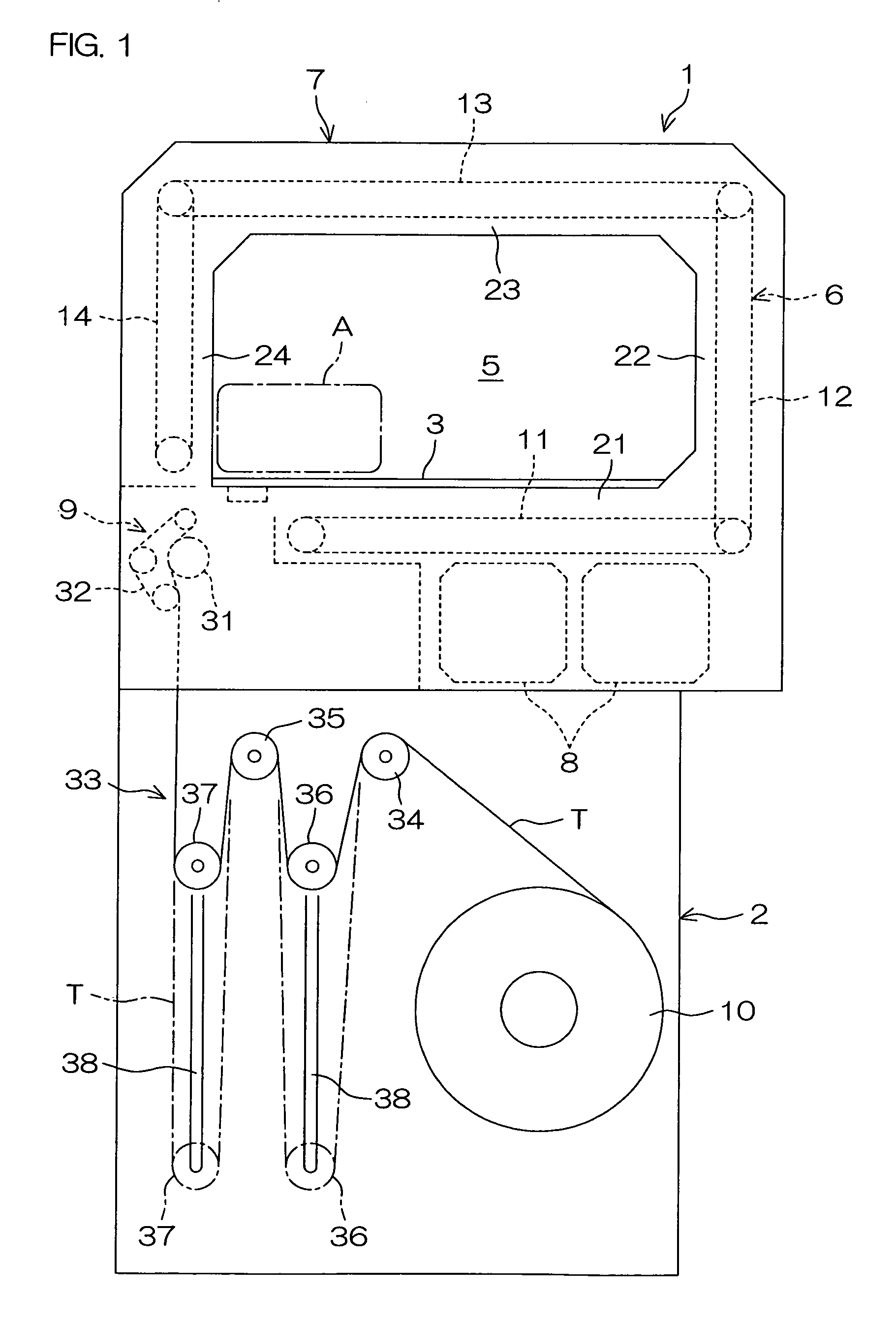

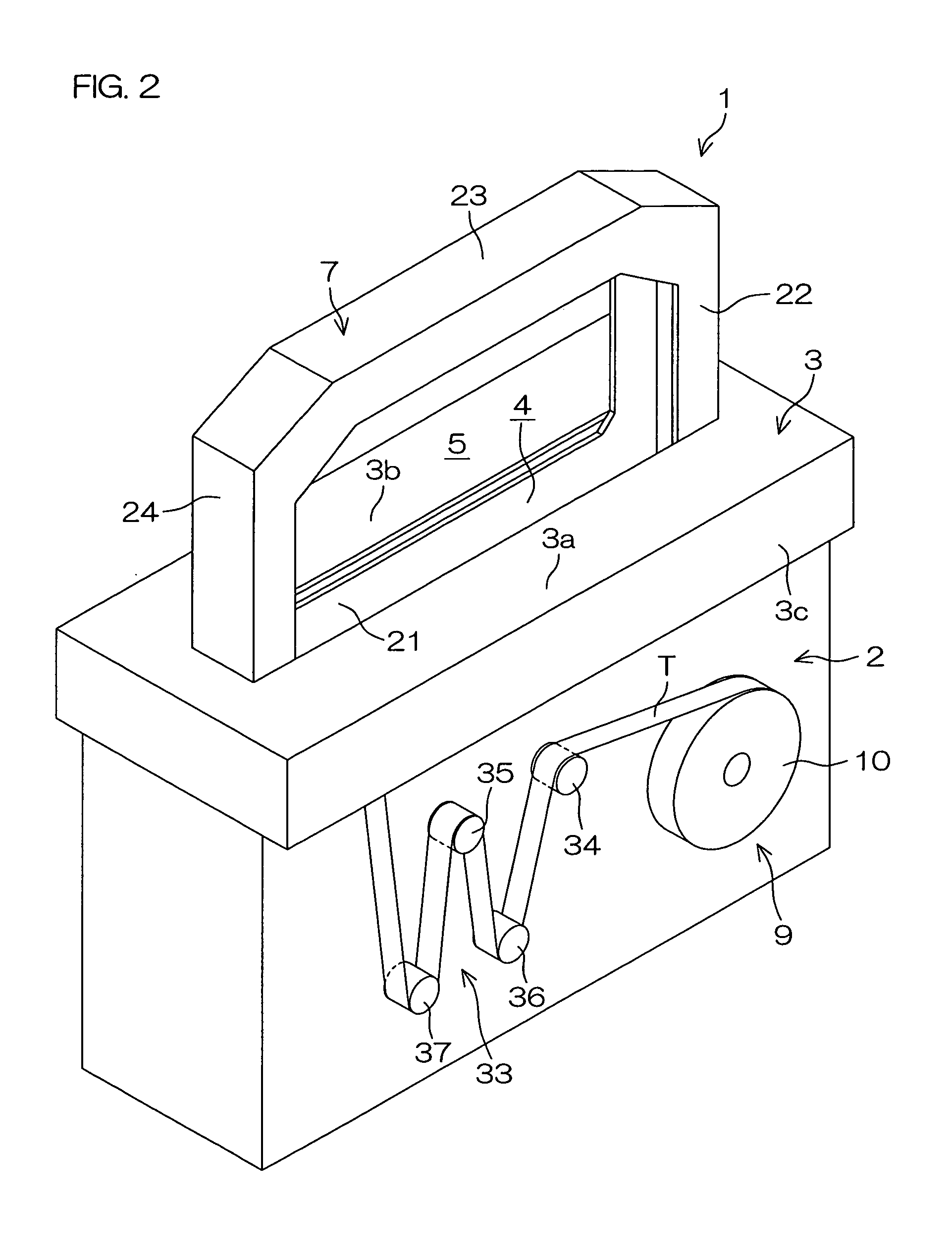

[0041]FIG. 1 is a schematic front view of a tape binding device 1 according to an embodiment of the present invention, and FIG. 2 is a schematic perspective view of the tape binding device 1. Referring to FIG. 1, the tape binding device 1 includes a device main body 2, and a table 3, on which a material to be bound A is to be placed, provided at the center in the height direction of the device main body 2. As shown in FIG. 2, a tape passage groove 4 through which a tape T for binding the material to be bound A vertically passes is formed in the table 3. The table 3 has a front part 3a and a rear part 3b sandwiching the tape passage groove 4 therebetween in the front and rear direction. Furthermore, there is provided a peripheral wall 3c extending downward from the table 3.

[0042]As shown in FIG. 1, a loop formation space 5 for forming a loop at an end of the tape T is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com