Condenser

a technology of condensers and condensers, which is applied in the field of condensers, can solve the problems of reducing the refrigeration efficiency of the refrigeration cycle and affecting the condensation performance, and achieve the effect of effectively suppressing reducing the impairment of condensation performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

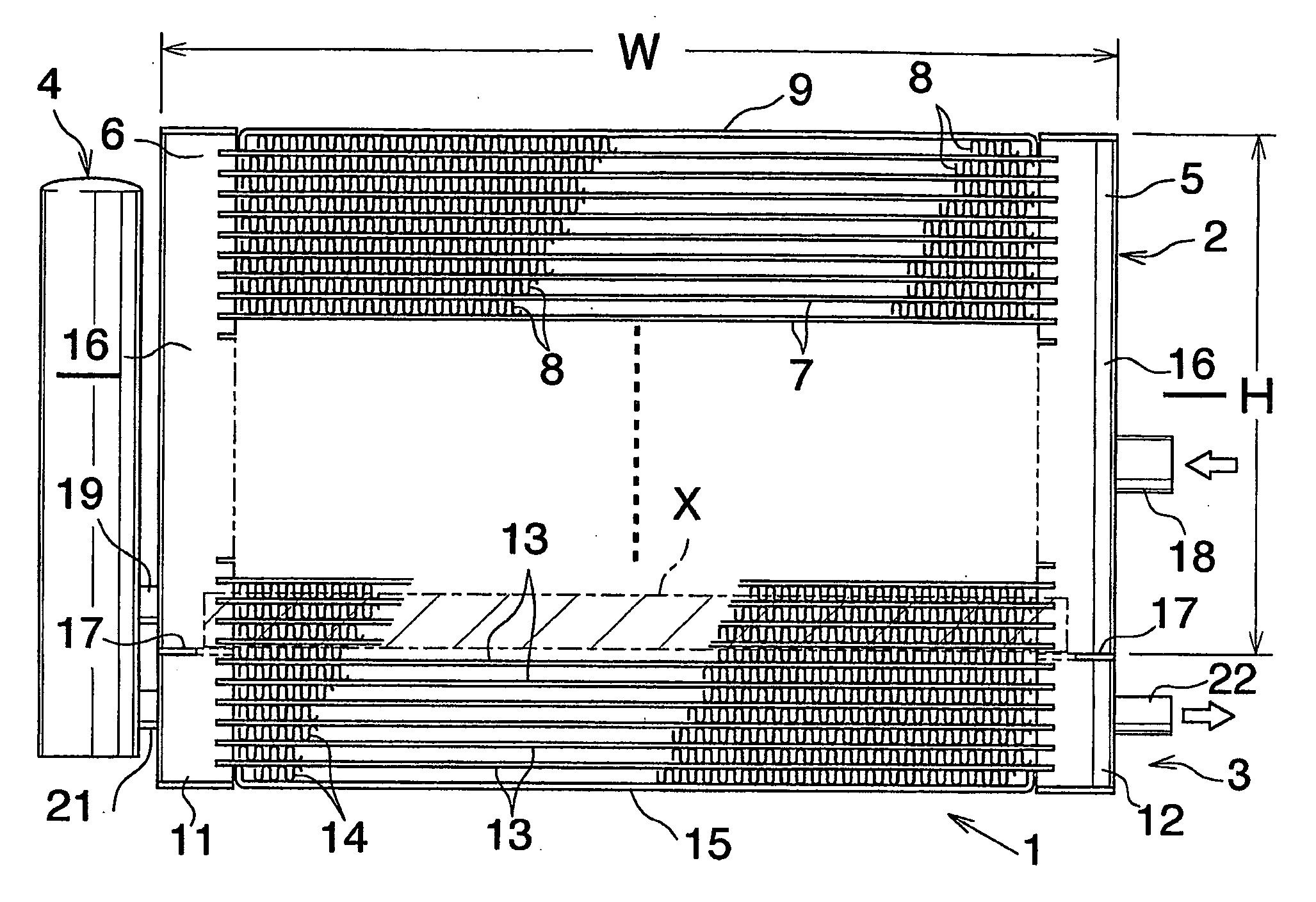

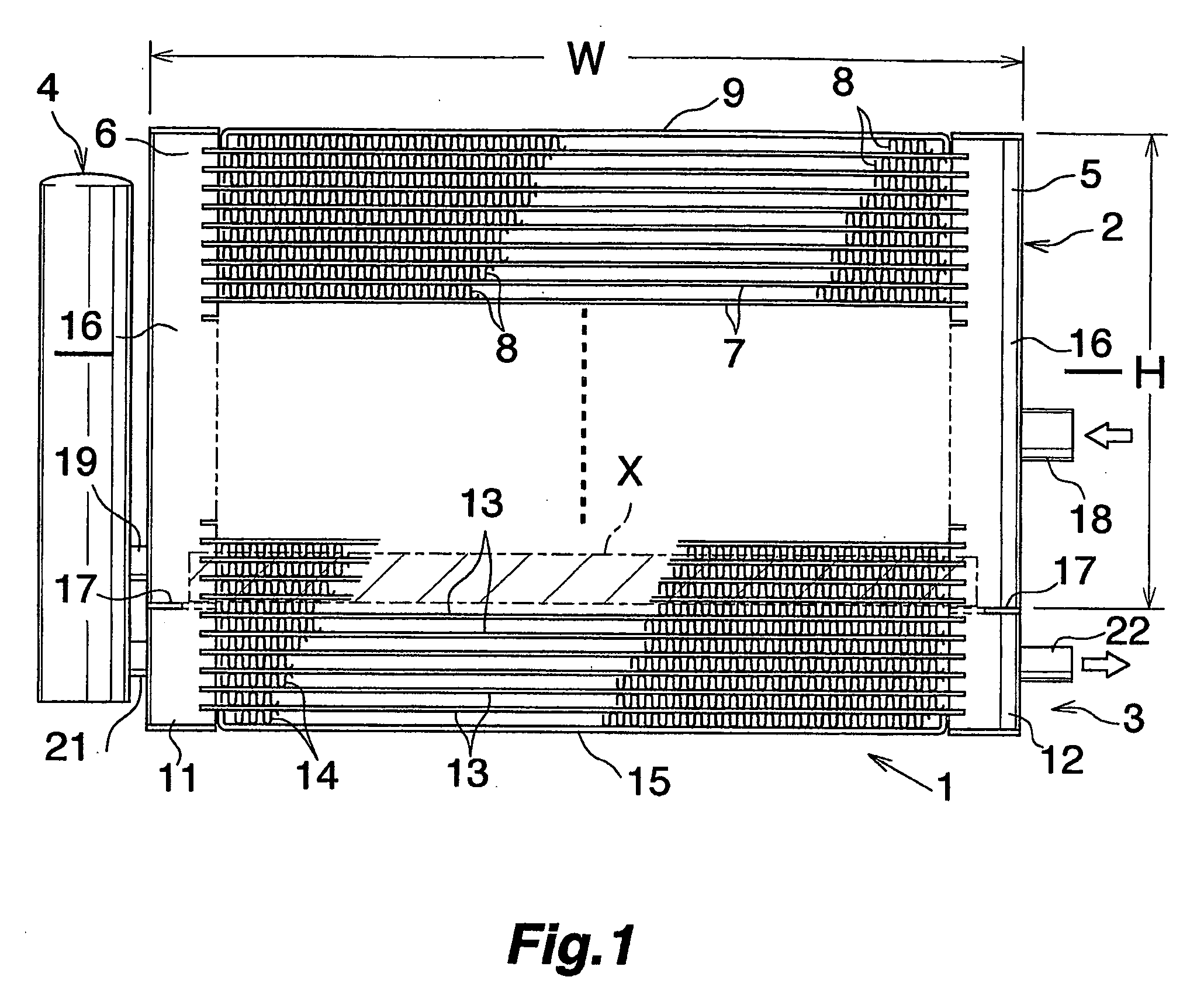

[0056]Used in this example was a heat exchanger 1 which was composed of a condenser portion 2 and a supercooler portion 3 having a combined overall height of 360 mm and an overall left-to-right width of 600 mm, and which was 300 mm in the height H of the condenser portion 2 and 43 in the total number of refrigerant tubes 7 of the condenser portion 2, 7 in the total number of refrigerant tubes 13 of the supercooler portion 3 and 21 in the number of refrigerant tubes 7 existing below the center, with respect to the vertical direction, of the refrigerant inlet 23 of the condenser portion 2 (see FIG. 1).

example 2

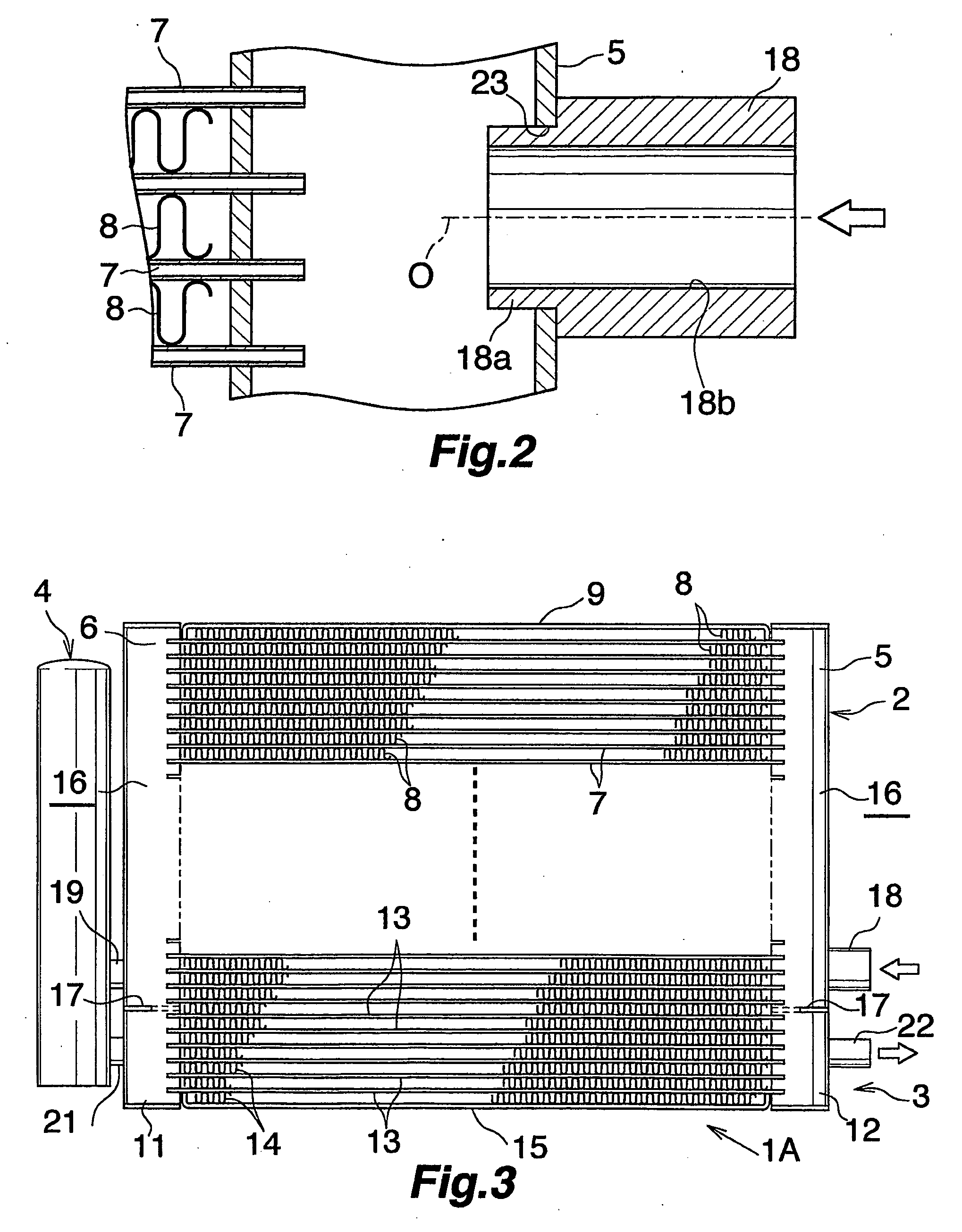

[0057]Used in this example was a heat exchanger 1A having the same construction as in Example 1 except that the condenser portion 2 had 7 refrigerant tubes 7 below the center O, with respect to the vertical direction, of the refrigerant inlet 23 (see FIG. 3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com