Overhead ventilation system incorporating a downwardly configured rear supply plenum with upward configured directional outlet and including baffle plates and dampeners incorporated into the plenum for evenly distributing an inlet airflow through the plenum outlet

a ventilation system and rear supply plenum technology, applied in the field of overhead ventilation systems, can solve the problems of increasing the cost of maintaining the desired interior air temperature, requiring further significant capacity, and introducing significant volumes of untreated air into the device, so as to reduce the velocity and evenly distribute the inlet flow, evenly distribute the intake flow, and reduce the effect of velocity and evenly distributed inlet flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

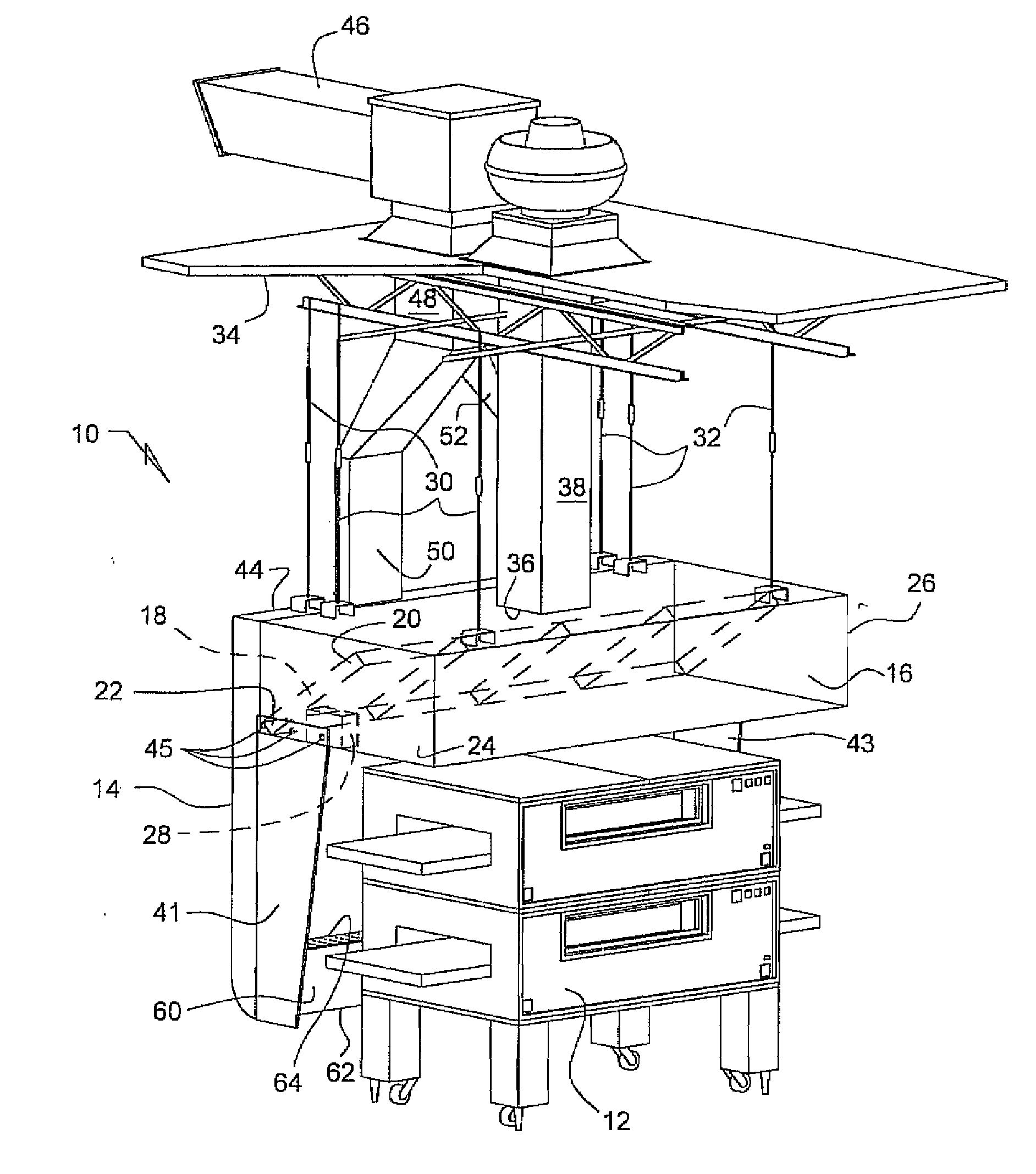

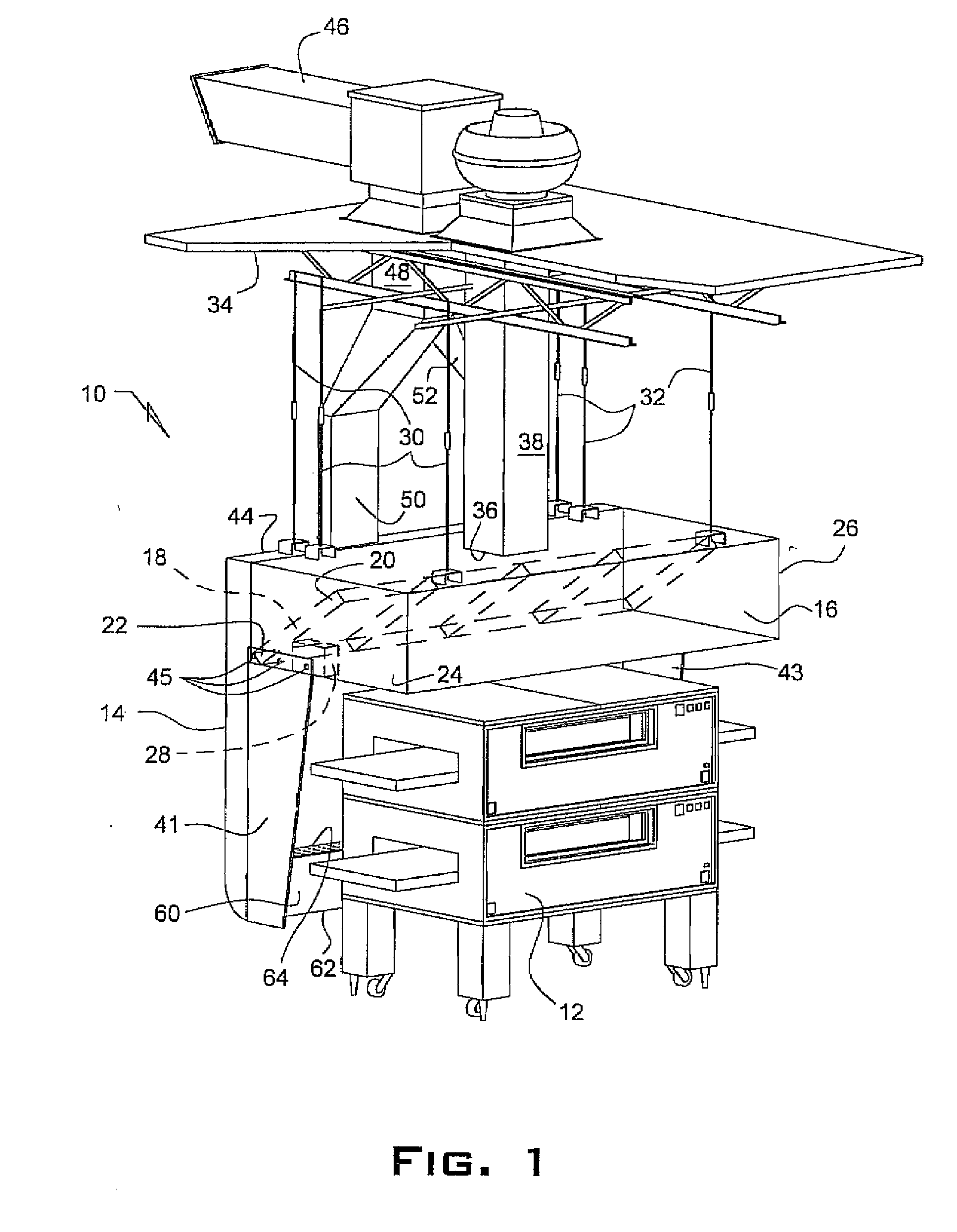

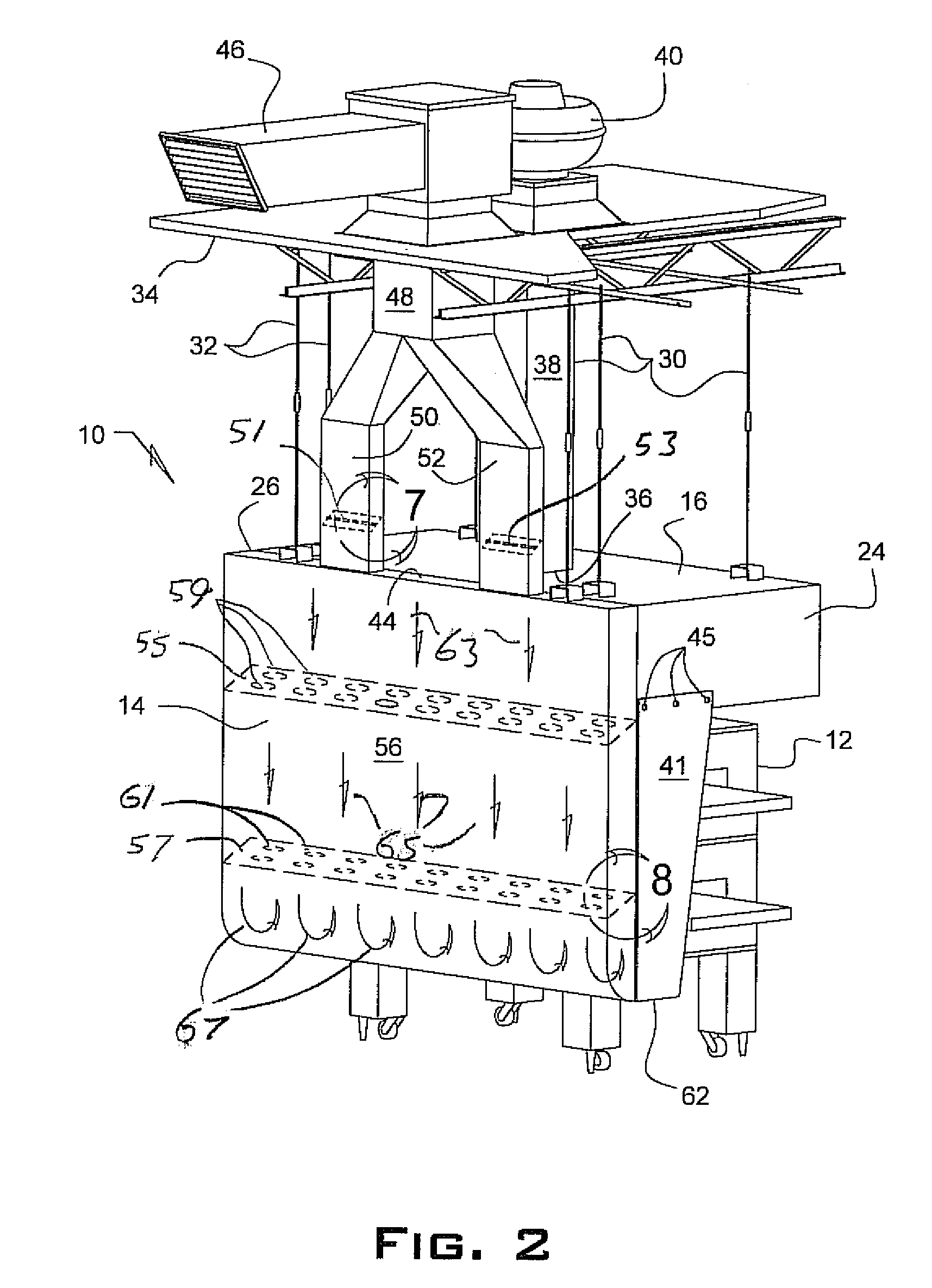

[0022]Referring now to FIG. 1, a first environmental view is generally shown at 10 in perspective of a ventilation system according to the present inventions in operative arrangement with respect to an item of conventional cooking equipment 12. As will be further described in additional detail, the present inventions include both an overall system, as well as a supply plenum (this defining a three dimensional and elongated module) 14 secured to an overhead hood 16 incorporated into the improved filter and ventilation system, and which is associated with the cooking appliance 12 to maintain a desired pressure balance, or equilibrium, within an enclosed space in which the appliance 12 is situated during filtration of the same. In particular, the plenum 14 operates in cooperation with the associated ventilation system in order to introduce, from an exterior location, a volume of raw untreated air for subsequent conditioning and conveyance to an inner hood perimeter, the same balancing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com