System and Method for Continuous Rapid Cooling of Molten Materials to Produce Uniformly-Shaped Solid Forms

a technology of molten materials and solid forms, which is applied in the direction of heat transfer modification, indirect heat exchangers, lighting and heating apparatus, etc., can solve the problems of large floor space and capital and space requirements of systems, and achieve the effect of rapid change of process and system, increasing productivity and/or forming rates, and providing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

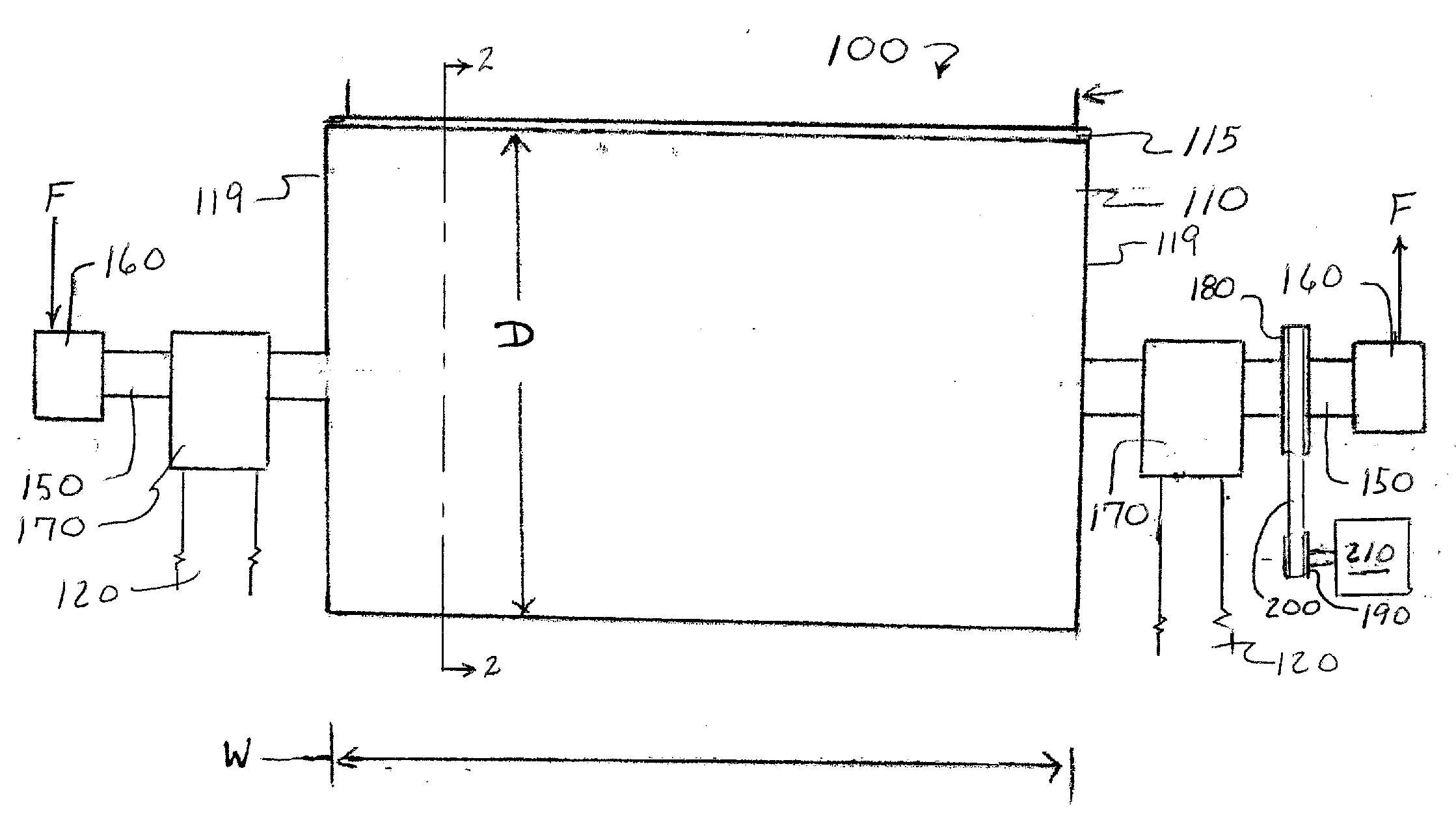

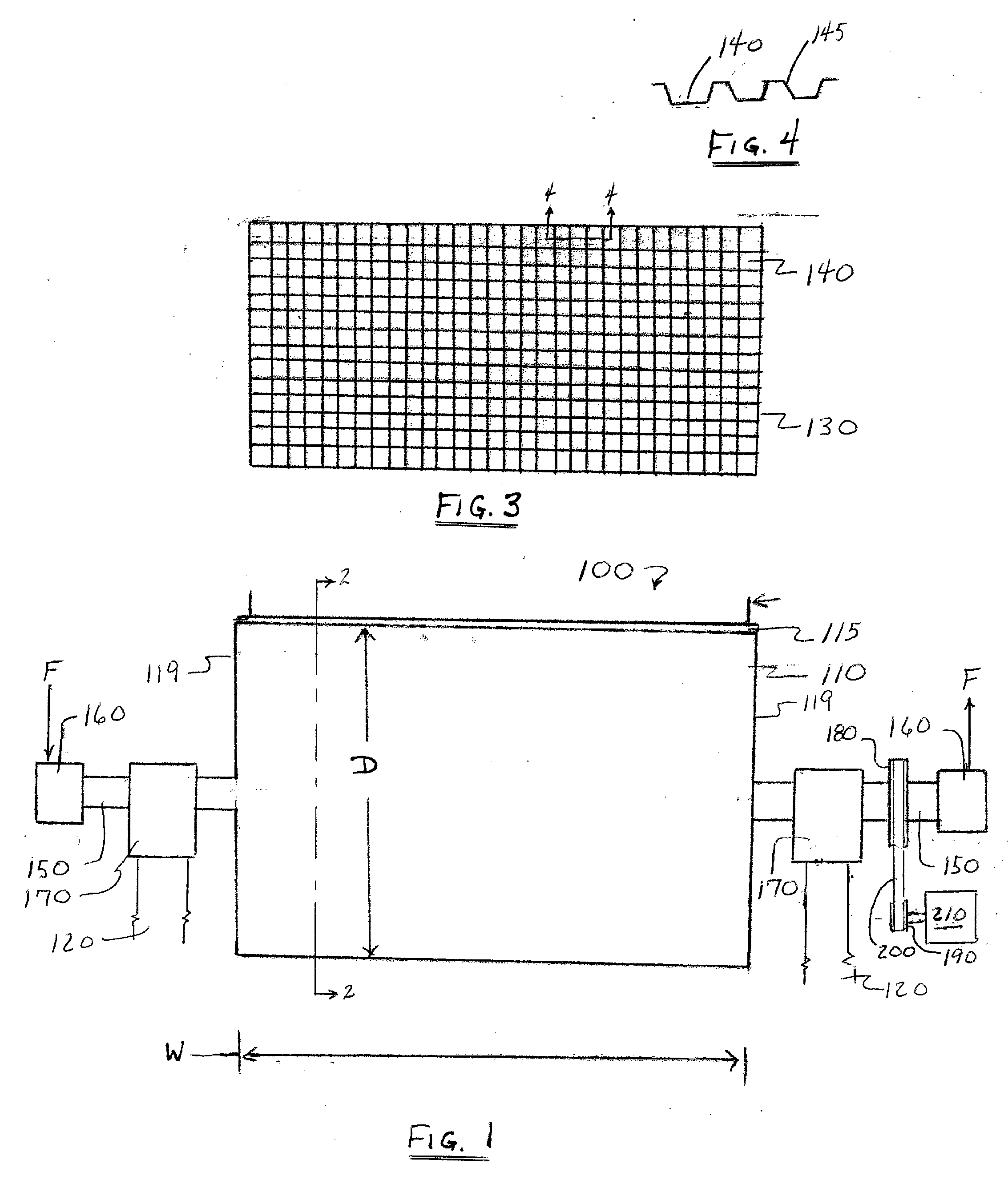

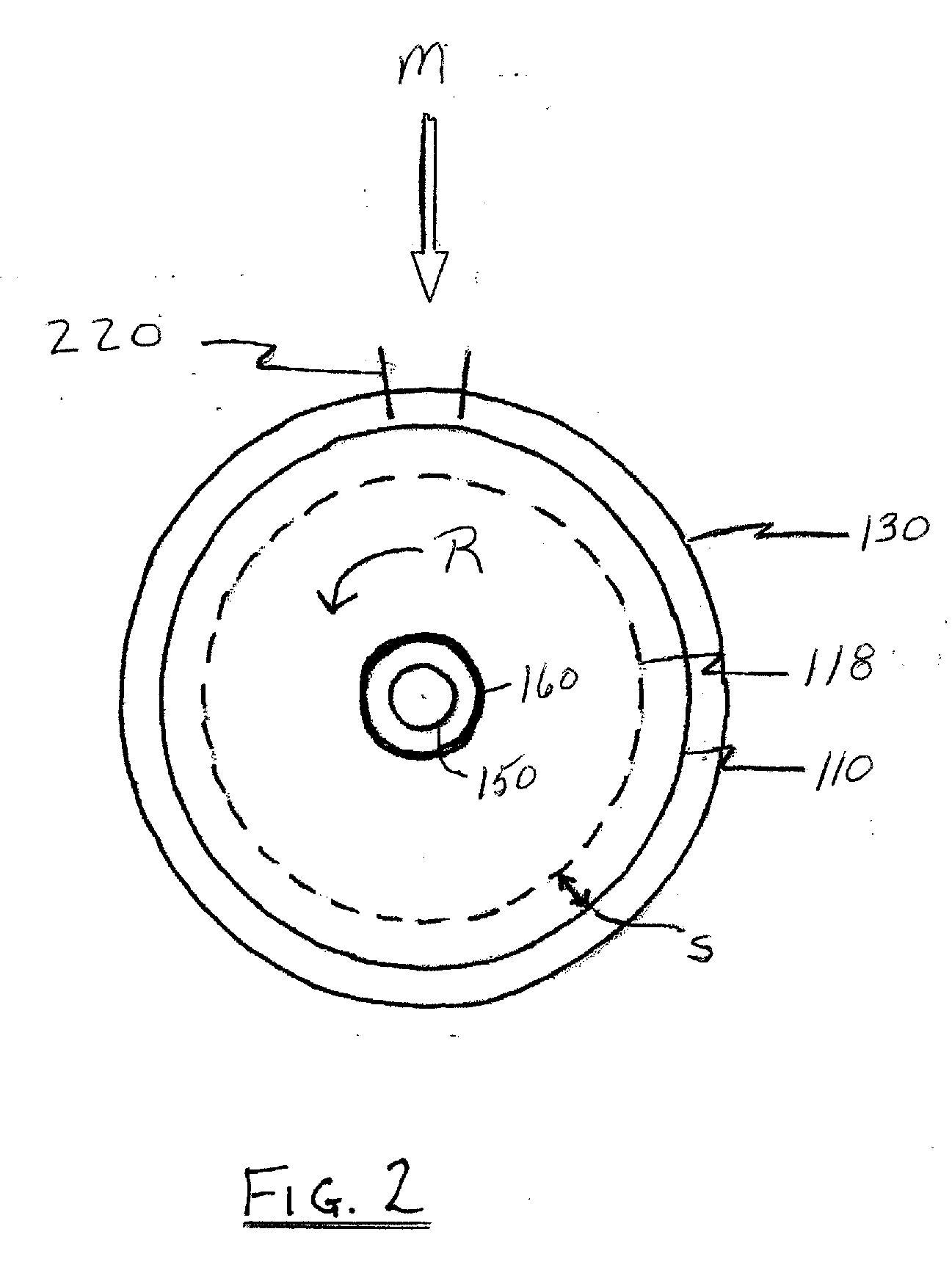

[0023]In describing preferred embodiments of the system and method of the present disclosure illustrated in the drawing Figures, specific terminology is employed for the sake of clarity. The claimed invention, however, is not intended to be limited to the specific terminology so selected, and it is to be understood that each specific element includes all technical equivalents that operate in a similar manner to accomplish a similar purpose.

[0024]It will be further understood that the terms, “chemical,” and “material,” and their respective plural forms, as used herein, are intended to describe any of a variety of those organic and / or inorganic chemicals, compounds, materials, composites, emulsions, solutions, and the like, that go through a phase change from a fluid form, and typically a molten fluid form, to become a solid upon cooling. By way of non-limiting example, such materials might comprise glues, adhesives, plastics, and the like.

[0025]The invention disclosure set forth here...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat transfer | aaaaa | aaaaa |

| heat | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap