Wig and method of manufacturing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

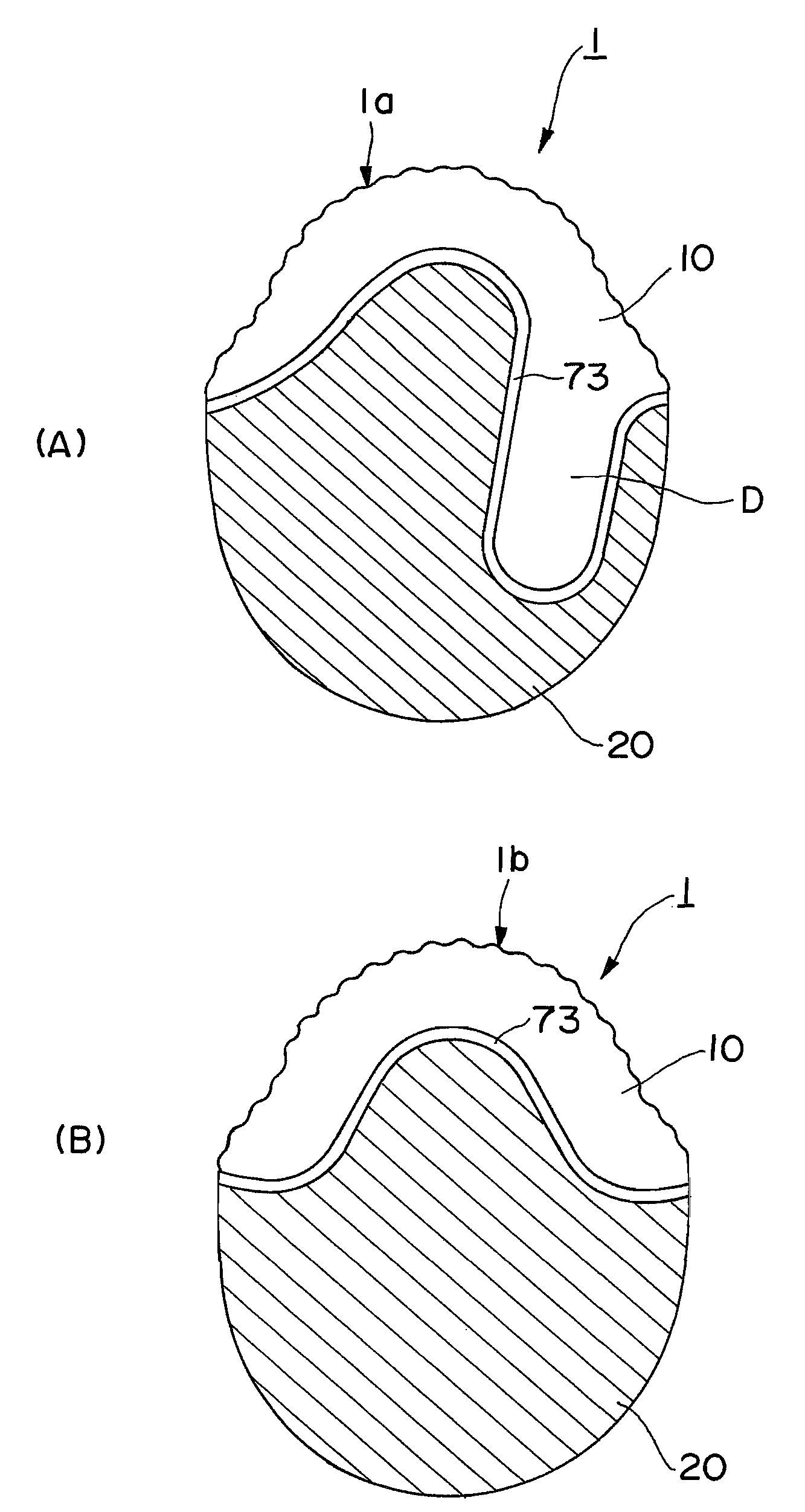

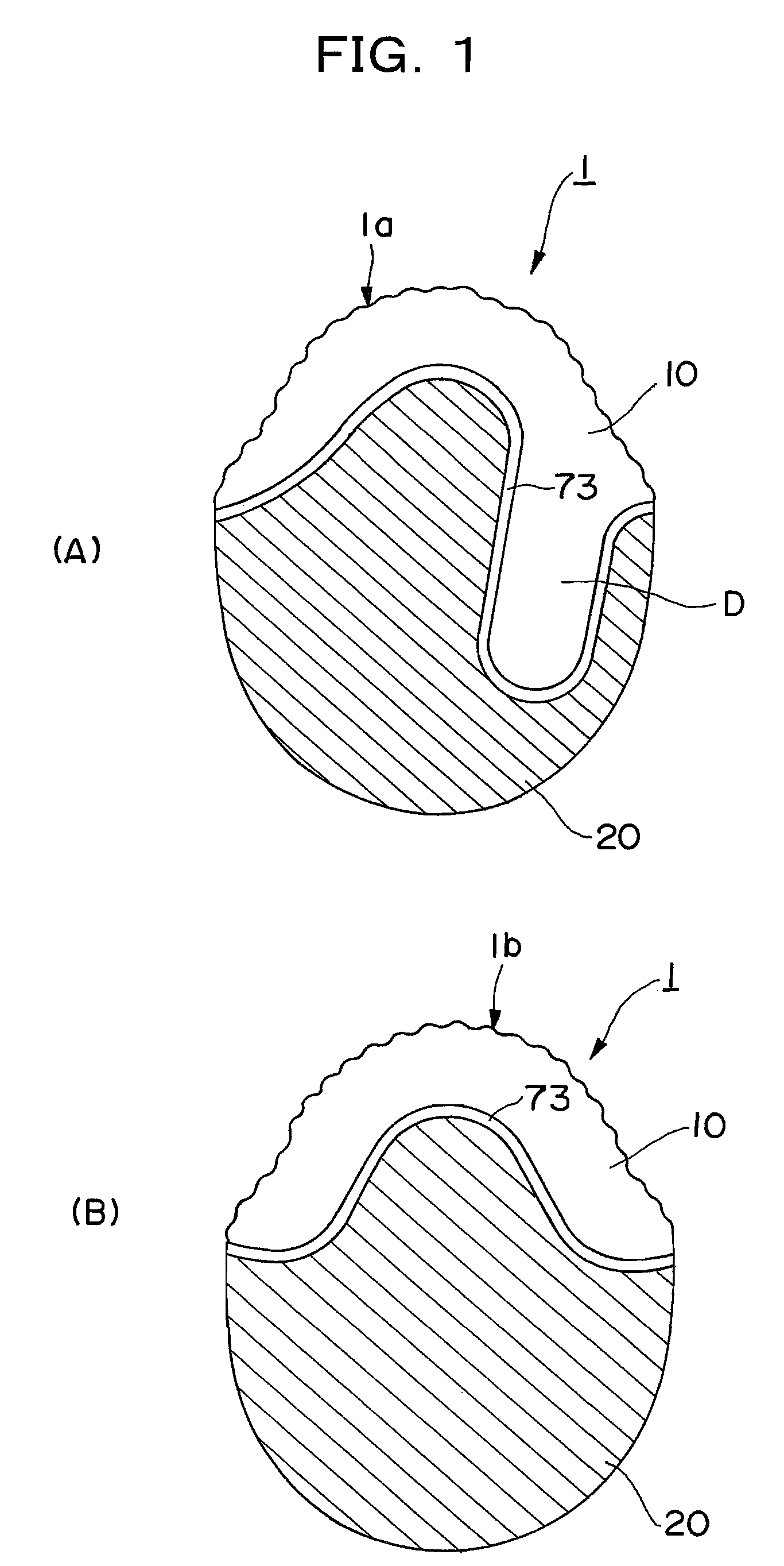

[0143]Explanation is made of the example of the method of manufacturing the wig in accordance with the embodiment of the present invention.

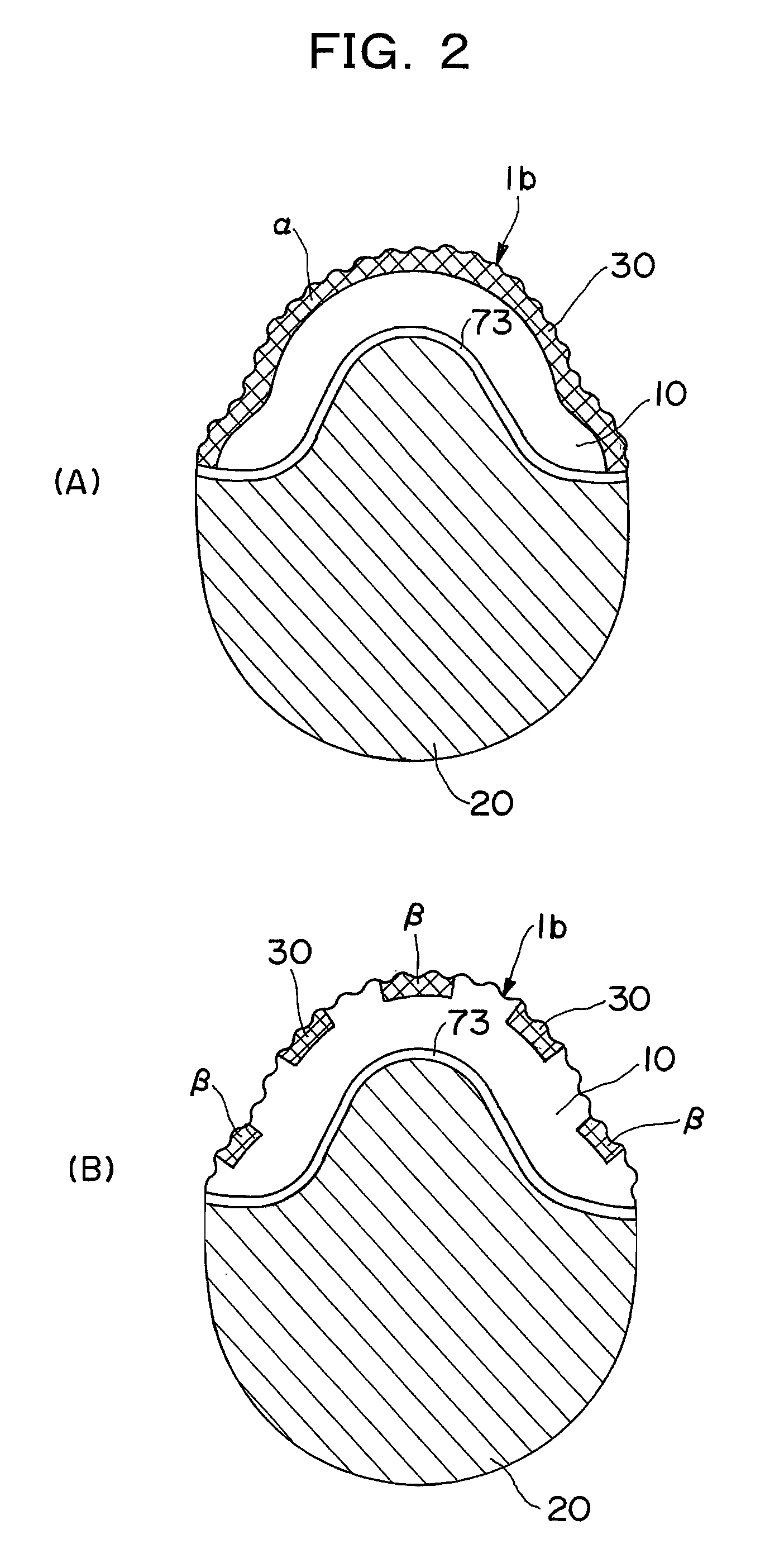

[0144]As a first step, the solution in which an urethane elastomer was dissolved in DMF and MEK and an antifungal agent was incorporated was coated on to a plaster pattern of a wig wearer's head shape prepared in advance, and dried at heating temperature 60° C. for one hour. Further on said plaster pattern, the urethane elastomer solution of the concentration lower than the previous urethane elastomer solution was coated, dried for 30 minutes at heating temperature 60° C. to form the ultra-thin artificial skin material 11 of about 0.07 mm thickness.

[0145]As a second step, into the solution in which an urethane elastomer was dissolved in DMF and MEK and an antifungal agent was incorporated, powdery silica (average particle diameter 3.1 μm to 4.1 μm) as a deglossing agent 6, an ultraviolet absorber, and an antioxidant were further incorporated to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com