Stackable bedding foundation having pocketed topper

a technology of bedding foundation and pocketed topper, which is applied in the field of nestable stackable bedding foundation, can solve the problems of increasing manufacturing costs, bulky spring assemblies, and costly shipping to the manufacturer for padding and covering thereto, so as to reduce the ultimate cost of the unit for the assembler, avoid the need for costly presses and ties, and quickly unload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

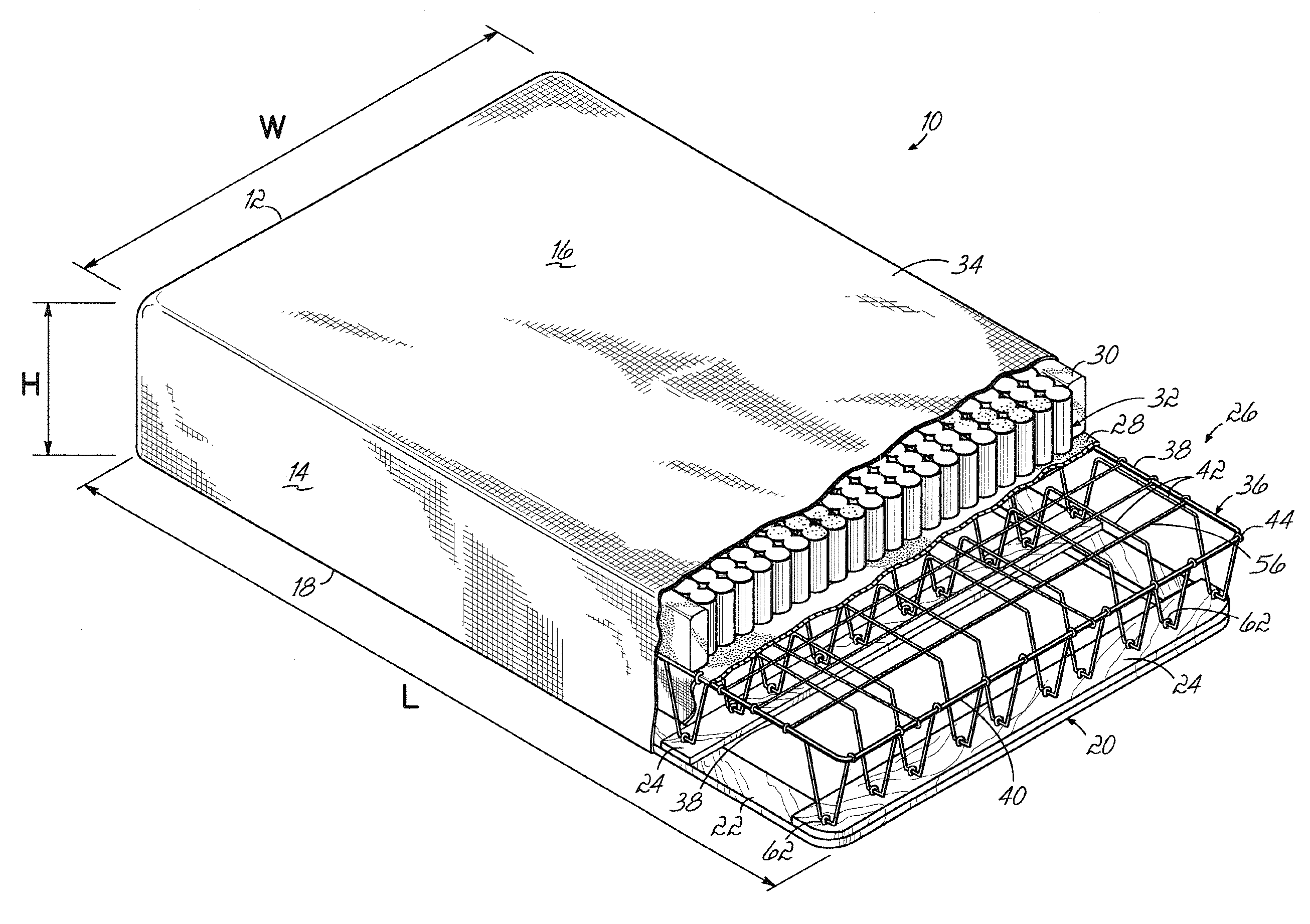

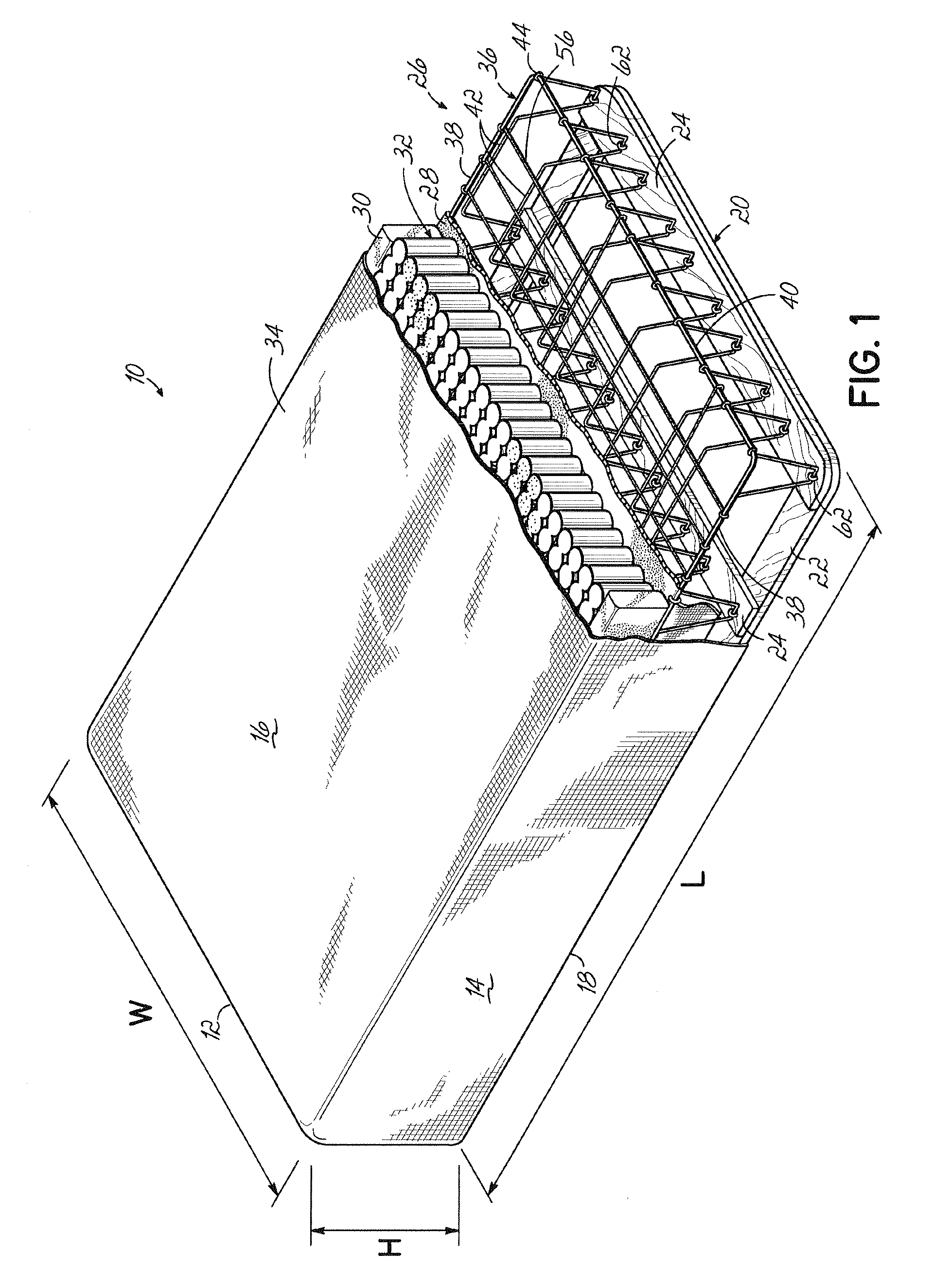

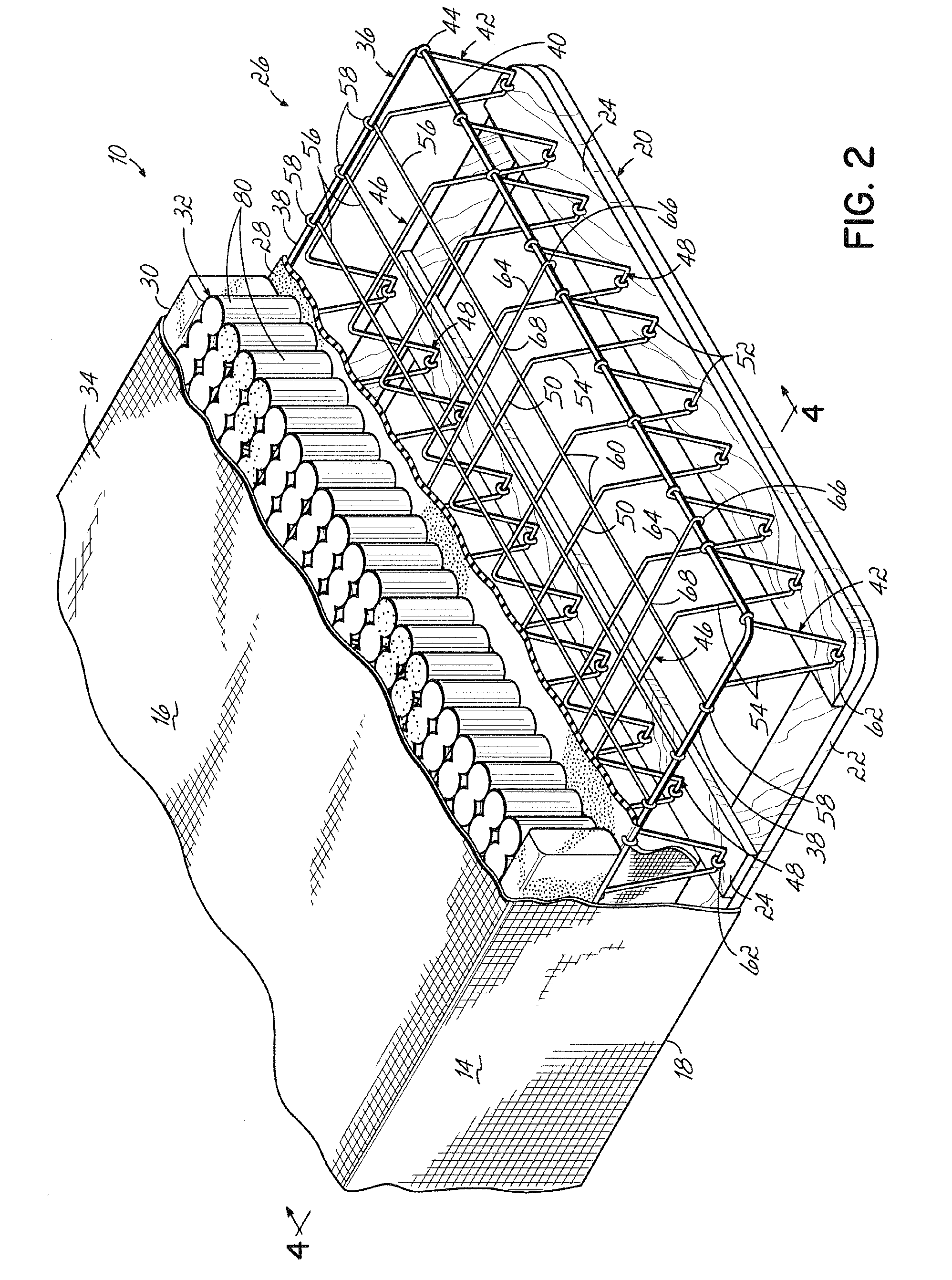

[0022]Referring first to FIG. 1, a bedding foundation or box spring 10 according to one embodiment of this invention is illustrated. The bedding foundation has a longitudinal dimension or length L defined as the distance between end surfaces 12 of the foundation; a transverse dimension or width W defined as the distance between side surfaces 14 of the foundation and a height H defined as the distance between upper and lower surfaces 16, 18, respectively, of the foundation 10.

[0023]The foundation 10 has a generally rectangular base 20 including a generally rectangular base frame 22 on which transverse slats 24 are attached. The base 20 is preferably made of wood but may be made of any suitable material such as plastic.

[0024]A nestably stackable spring assembly or wire core 26 is atop the base 12 and particularly the transverse slats 24. A cushioning pad 28 overlies the nestably stackable spring assembly 26, a border 30 is fixedly secured to the perimeter of the cushioning pad 28, a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com