Surface wave excitation plasma processing system

a plasma processing and surface wave technology, applied in plasma technology, energy-based chemical/physical/physico-chemical processes, electric discharge tubes, etc., can solve problems such as failure to obtain uniform plasma, and achieve uniform plasma generation over a large area stably, and prevent interference between adjacent dielectric members

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

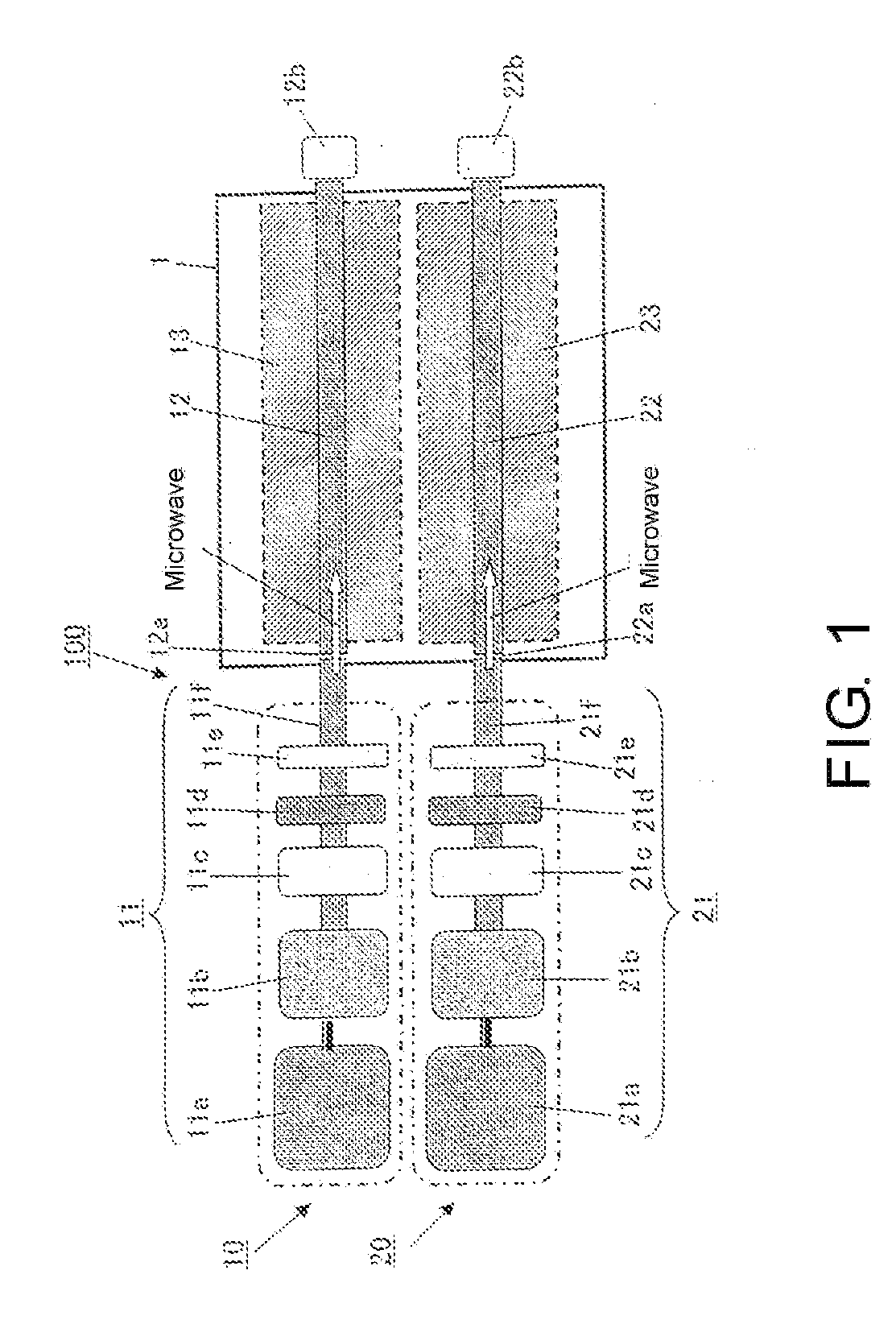

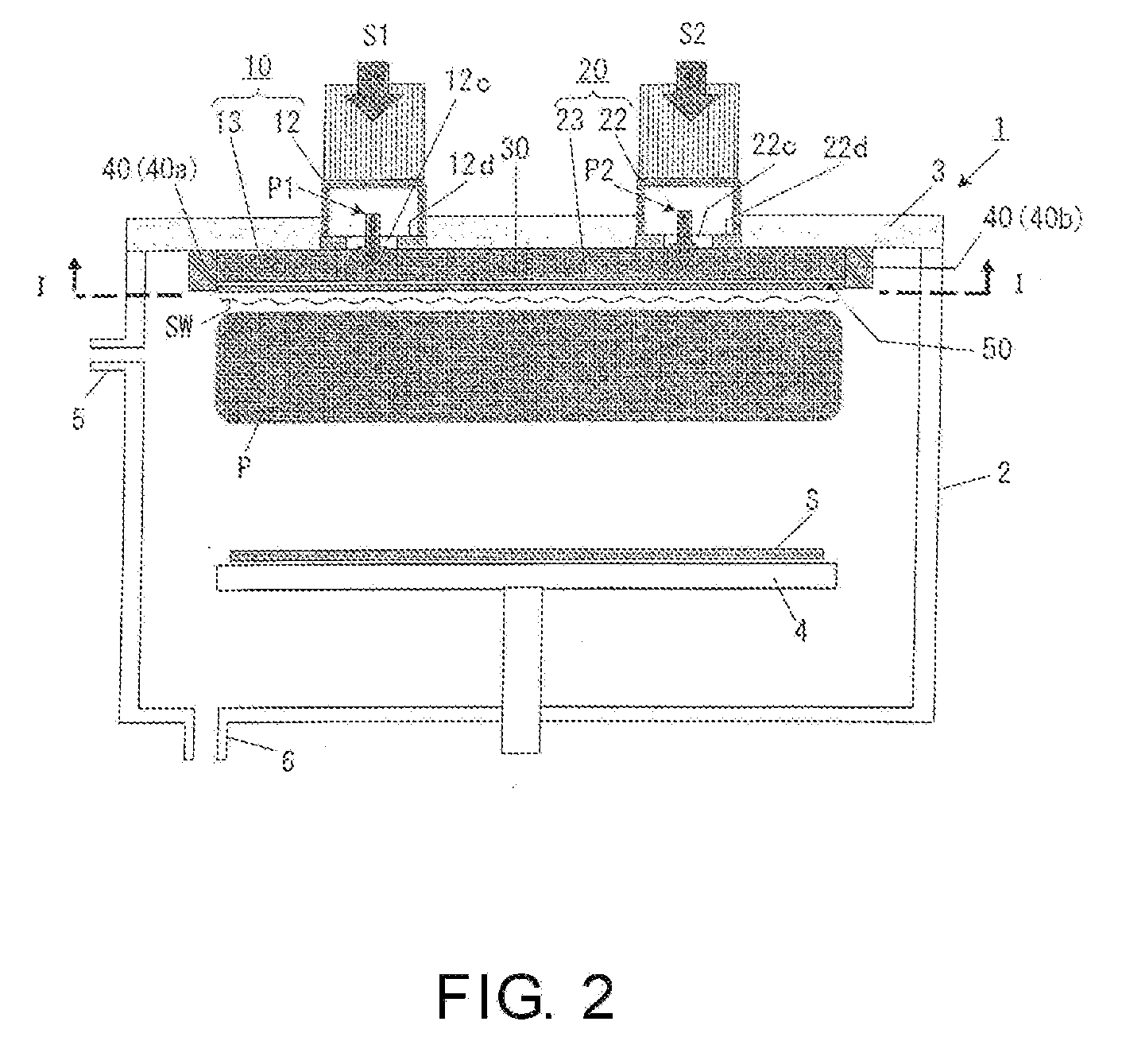

[0019]Hereinafter, a surface wave excitation plasma (SWP: Surface Wave Plasma) processing device (hereinafter briefly referred to as SWP processing device) according to an embodiment of the present invention is illustrated with reference to FIGS. 1-4. FIG. 1 is a plan view schematically showing a general structure of an SWP processing device according to an embodiment of the present invention. FIG. 2 is a cross-sectional view schematically showing structures of the main parts for an SWP processing device according to an embodiment of the present invention.

[0020]Referring to FIGS. 1 and 2, an SWP processing device 100 includes a chamber 1 and two plasma sources 10, 20. The chamber 1 is a sealed frame for performing plasma processing on a substrate to be processed. The plasma source 10 includes a microwave generator 11, a microwave waveguide 12, and a dielectric block 13. The microwave generator 11 has a high voltage power supply 11a, a microwave oscillator 11b, an insulator 11c, a di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com