Radiating fin

a technology of radiating fins and fins, which is applied in the direction of basic electric elements, semiconductor devices, lighting and heating apparatus, etc., can solve the problems of large amount of waste materials produced in the manufacturing process, large amount of electrical elements that generate heat, and complicated and laborious manufacturing of radiating fins, so as to reduce waste, reduce manufacturing costs, and improve the effect of heat radiating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

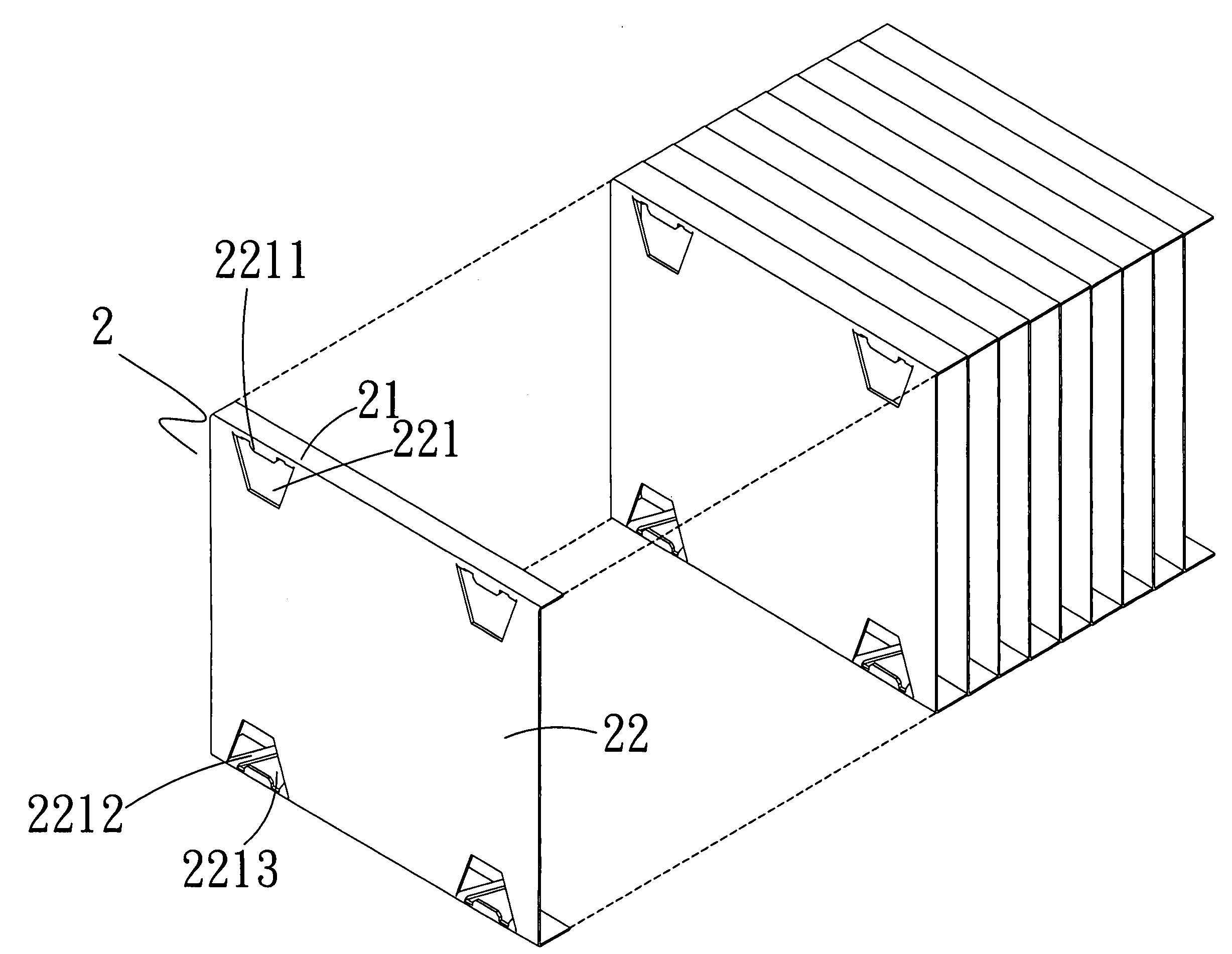

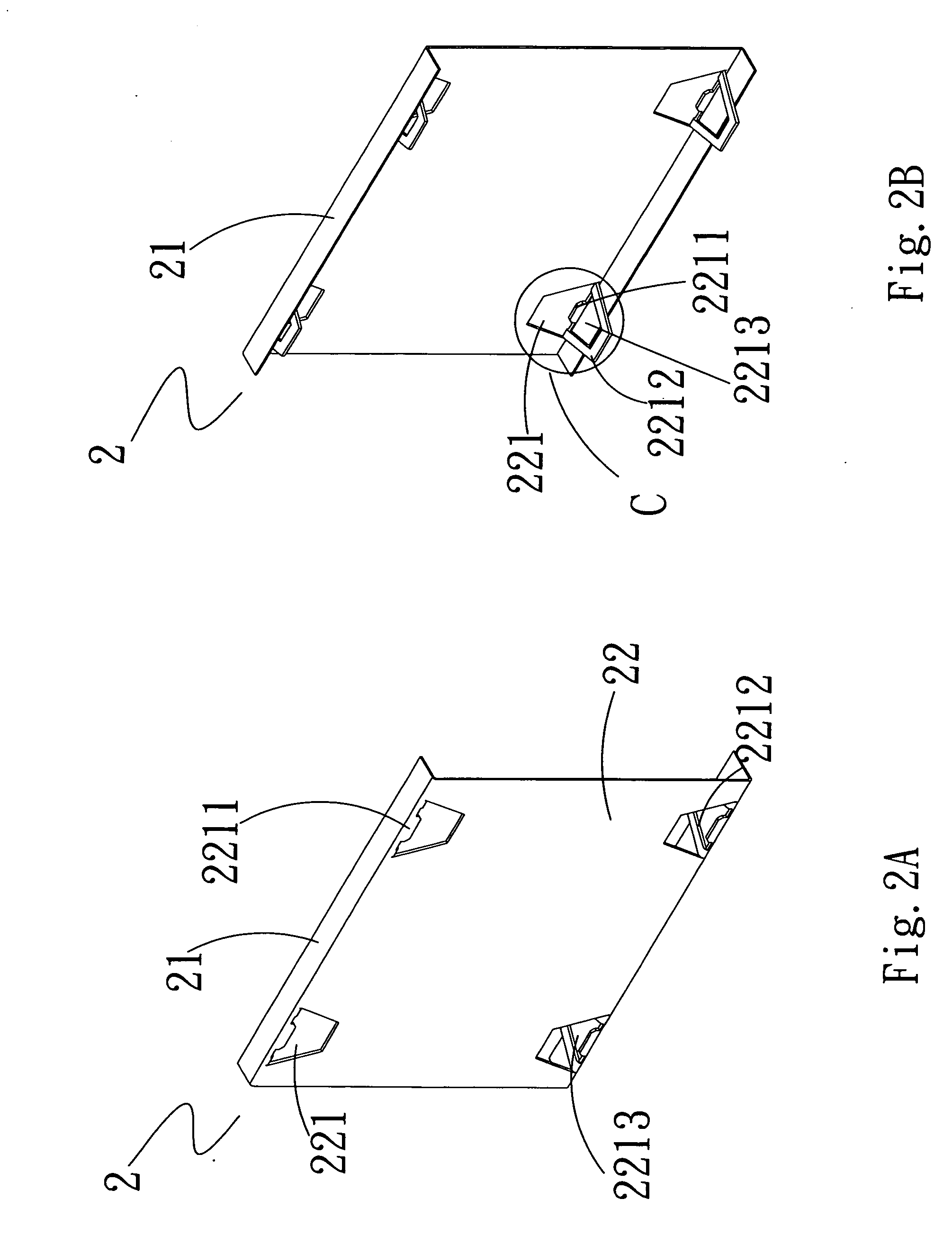

[0024]Please refer to FIGS. 2A and 2B that are front and rear perspective views, respectively, of a radiating fin 2 according to a preferred embodiment of the present invention, and to FIG. 2C that is an enlarged view of the circled area C of FIG. 2B. As shown, the radiating fin 2 of the present invention is made of a sheet material, and includes a flat surface 22 and two rearward extended flanges 21 formed along two opposite edges of the flat surface 22. The flat surface 22 is provided along the two edges adjacent to the flanges with a plurality of openings 221 each. In the preferred embodiment, each of the openings 221 has a trapezoidal configuration with a long base thereof adjacent to the flange 21. A lug 2211 is inward extended from the long base of the trapezoidal opening 221 by a short distance to locate in the same plane as the flat surface 22. In addition, a catch 2212 is rearward extended from the long base of the opening 221. In a preferred embodiment, the catch 2212 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com