Method and System For Retail Store Supply Chain Sales Forecasting and Replenishment Shipment Determination

a technology for retail stores and supply chains, applied in data processing applications, instruments, computing, etc., can solve the problems of not being able to meet the needs of retailers, systems are not able to process the large data volumes typical of most retail organizations, and manufacturing systems are not designed to deal with certain needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

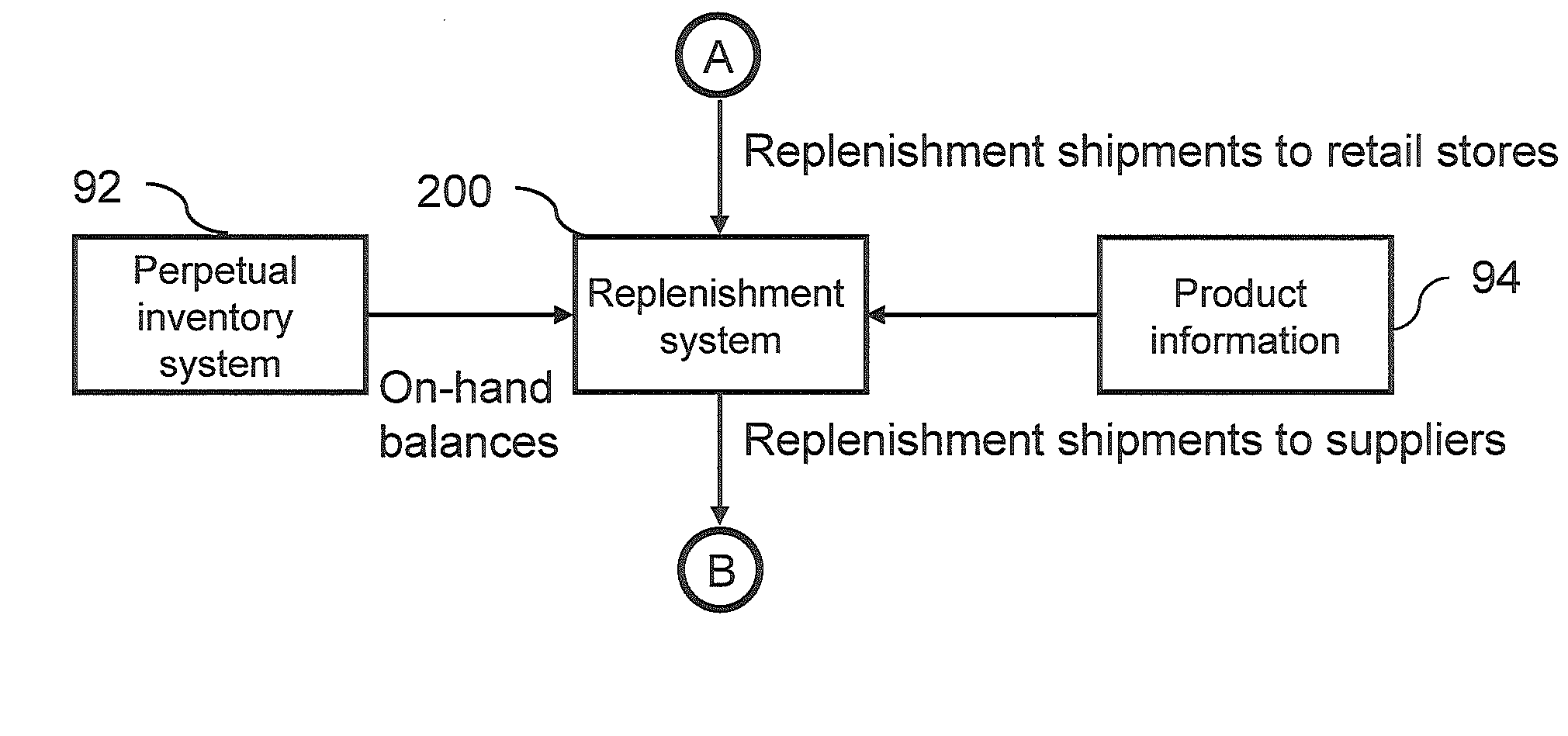

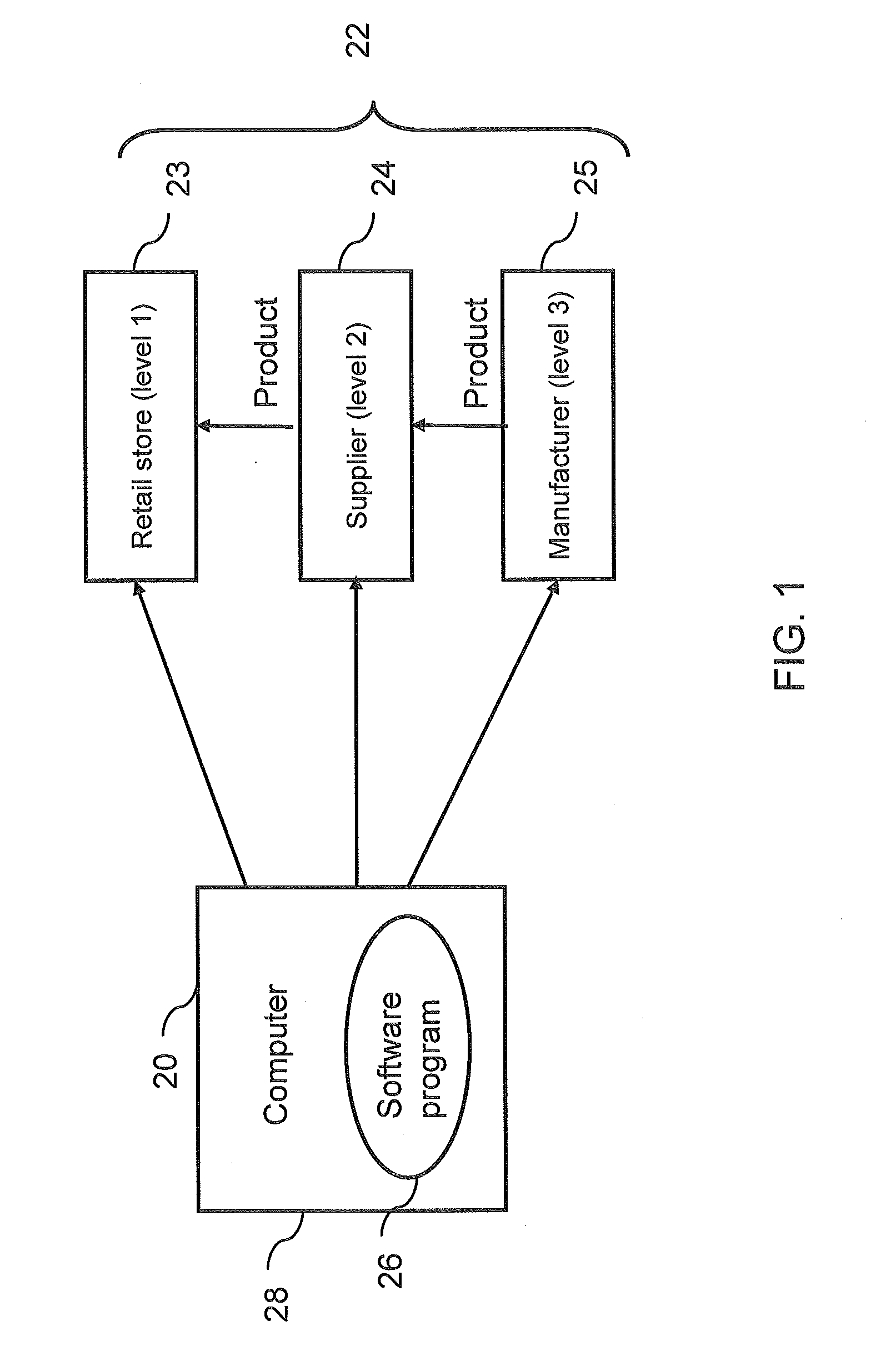

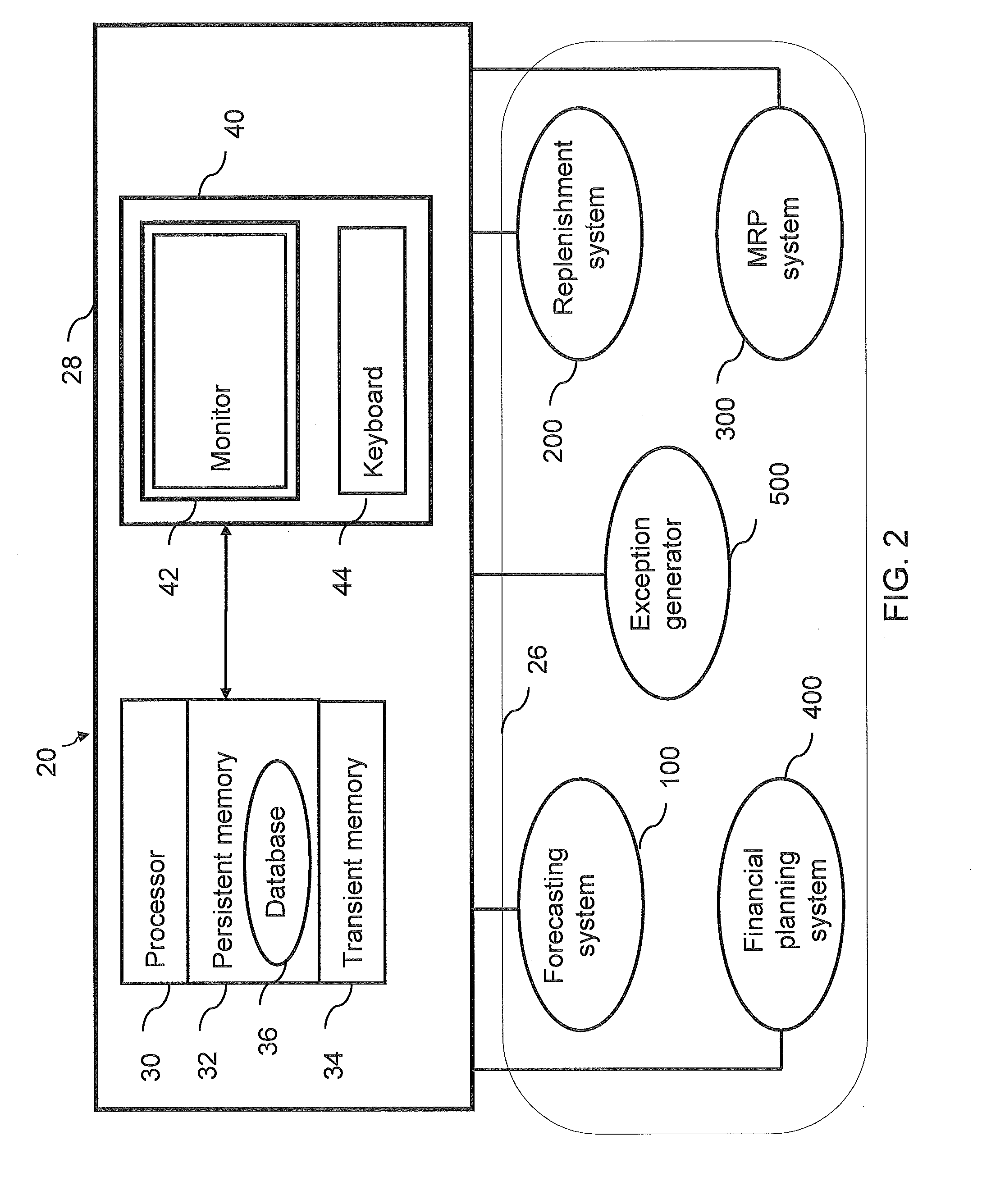

[0031]Referring to FIGS. 1 and 2, the present invention is a time-phased planning system 20 for use in a retail store supply chain 22 having one or more retail stores 23 (the first level in the supply chain), one or more suppliers 24 (the second level in the supply chain) and one or more manufacturers 25 (the third level in the supply chain). Retail store 23 can be a “bricks and mortar” store of any size or type, e.g., a small general store or a large “warehouse” store of a national chain. In addition, retail store 23 may be a so-called “clicks and bricks” store in which products are purchased on-line from a traditional store. Further, retail store 23 may be a pure e-commerce organization. Supplier 24 could be any one of the following facilities: a retail supplier, a satellite supplier, a retail depot, a wholesaler, an independent distributor, a manufacturer's supplier, or a manufacturer's plant. Manufacturer 25 could be any one of the following facilities: a manufacturer's distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com