Container with lid

a container and lid technology, applied in the field of containers with lids, can solve the problems of affecting the safety of use,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

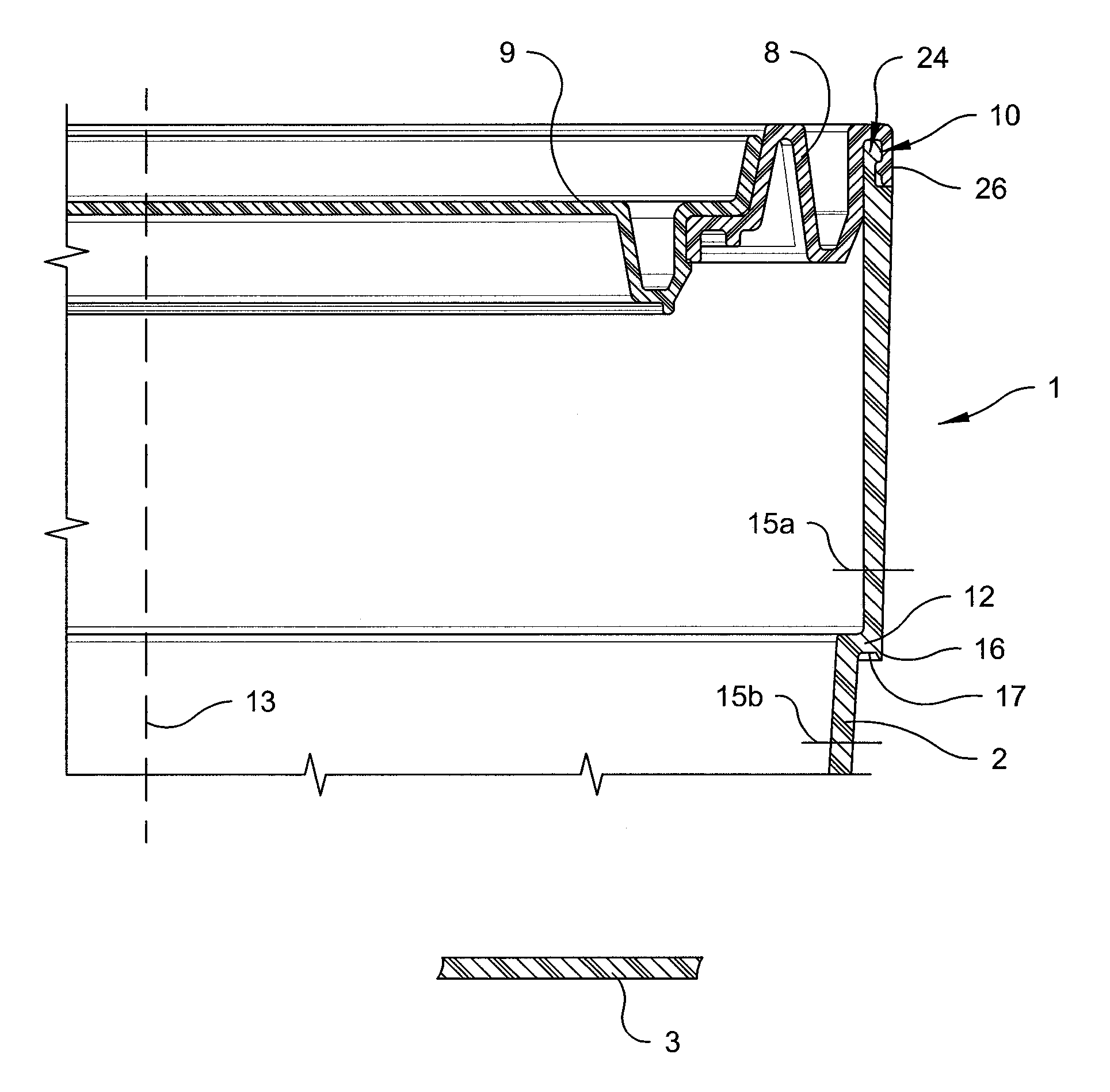

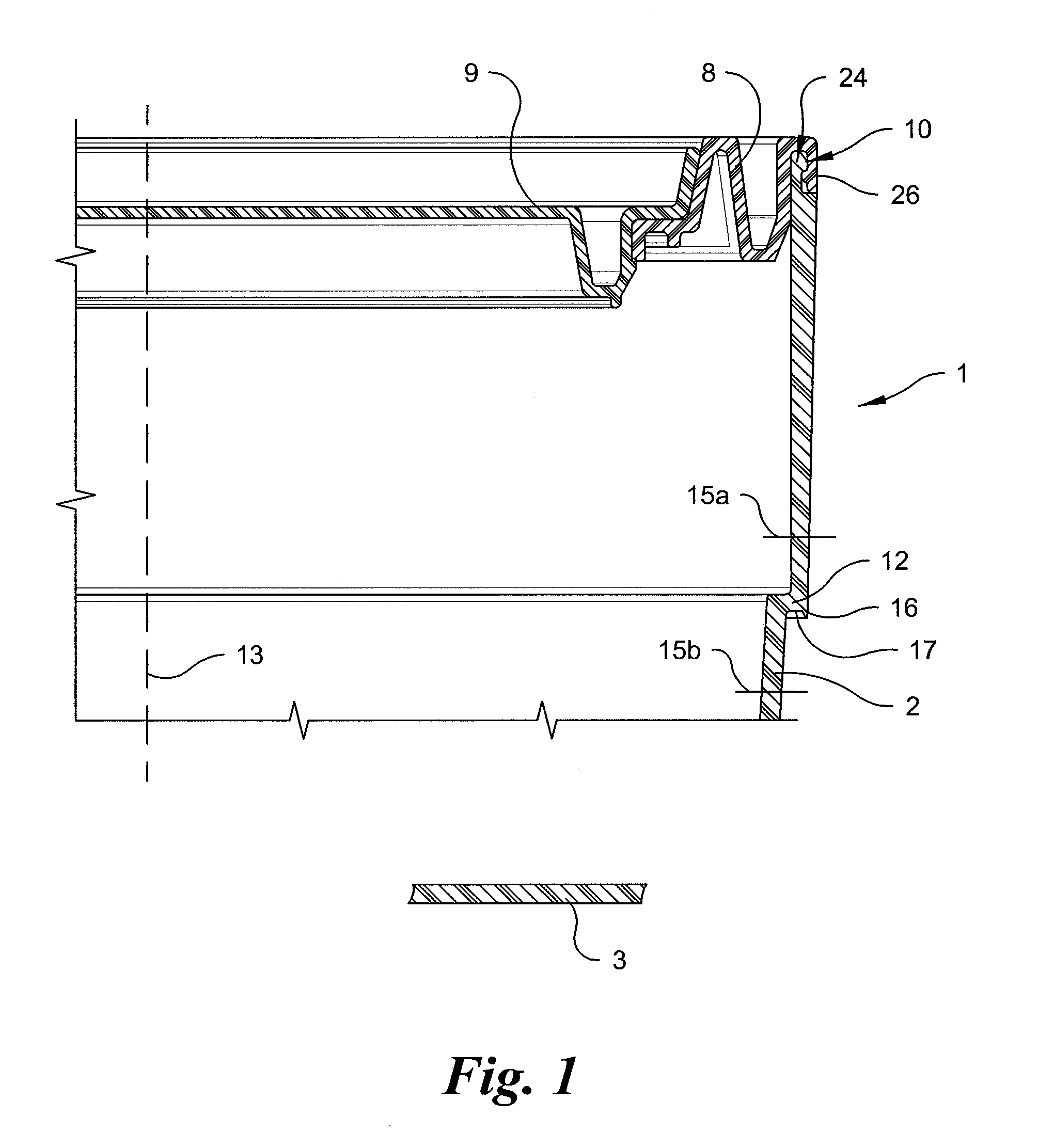

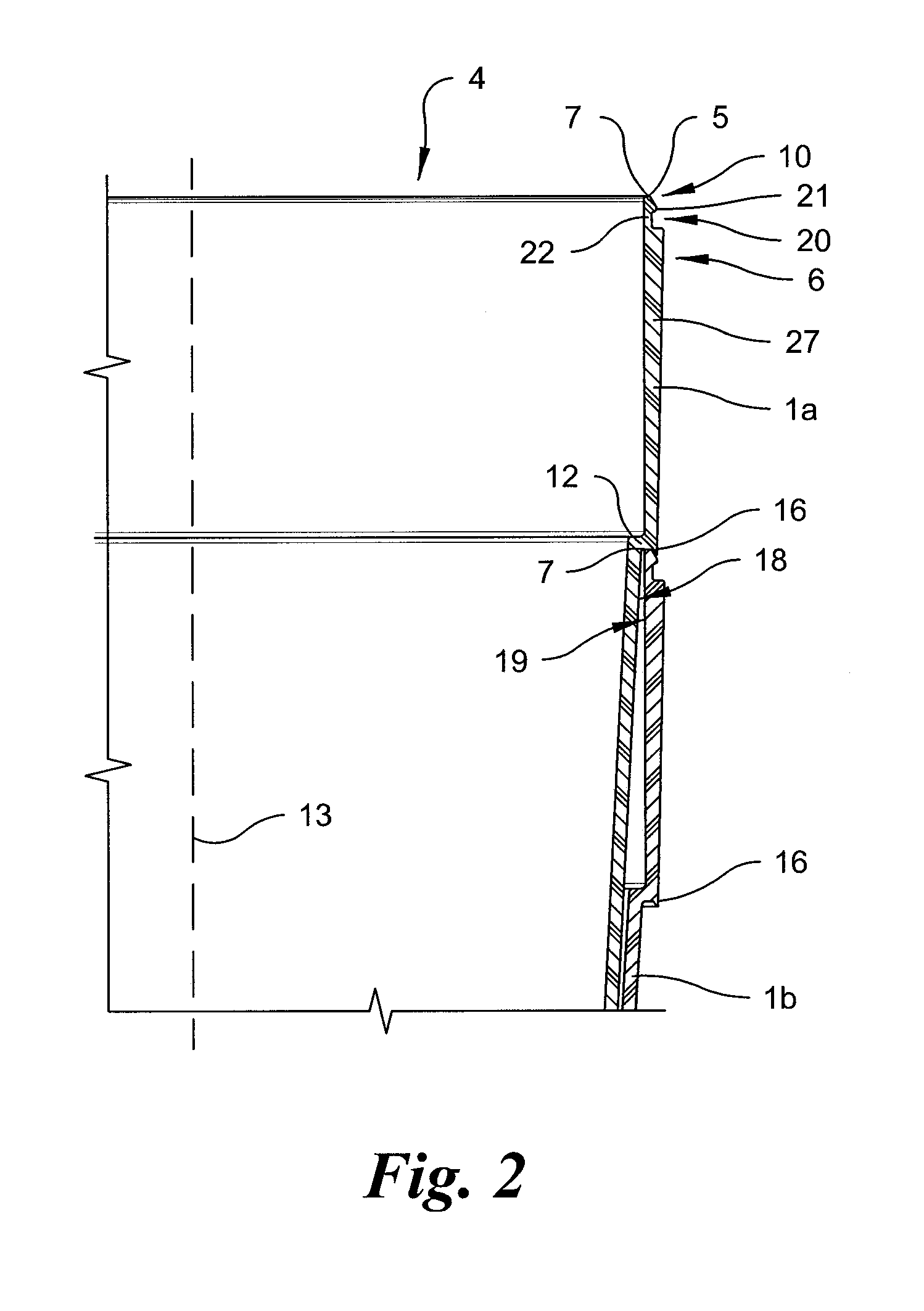

[0030]The container 1 according to one embodiment of the invention and illustrated in the FIGS. 1 to 4 includes a container wall 2, a container bottom 3 and a container opening 4, which is defined by an upper rim 5 of the container wall. In the upper part 6 of the container wall, namely in this embodiment on the upper edge 7 of the container, fixing means 10 for fixing a lid or an inwardly protruding peripheral frame 8, to which a lid 9 can be detachably fixed, are provided. The fixing means can be particularly constructed as a locking rim extending all around and, if need be, also as a number of locking protrusions distributed over the periphery of the container. The container wall 2 includes in its upper part below the fixing means an outwardly protruding shoulder 12. This shoulder can be formed on the inner surface of the container also in the form of a step or a radial offset or, if need be, the inner wall of the container at this position can also be formed substantially contin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| stack heights | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com