Thermally conductive module

a technology heat pipes, applied in indirect heat exchangers, heat exchange apparatus, lighting and heating apparatus, etc., can solve the problems of increasing the cost of complex manufacturing processes, increasing the cost of thermally conductive modules, and reducing the thermally conductive effect, so as to increase the thermally conductive area of heat pipes, increase thermally conductive performance, and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]In cooperation with attached drawings, the technical contents and detailed description of the present invention are described thereinafter according to a number of preferable embodiments, not used to limit its executing scope. Any equivalent variation and modification made according to appended claims is all covered by the claims claimed by the present invention.

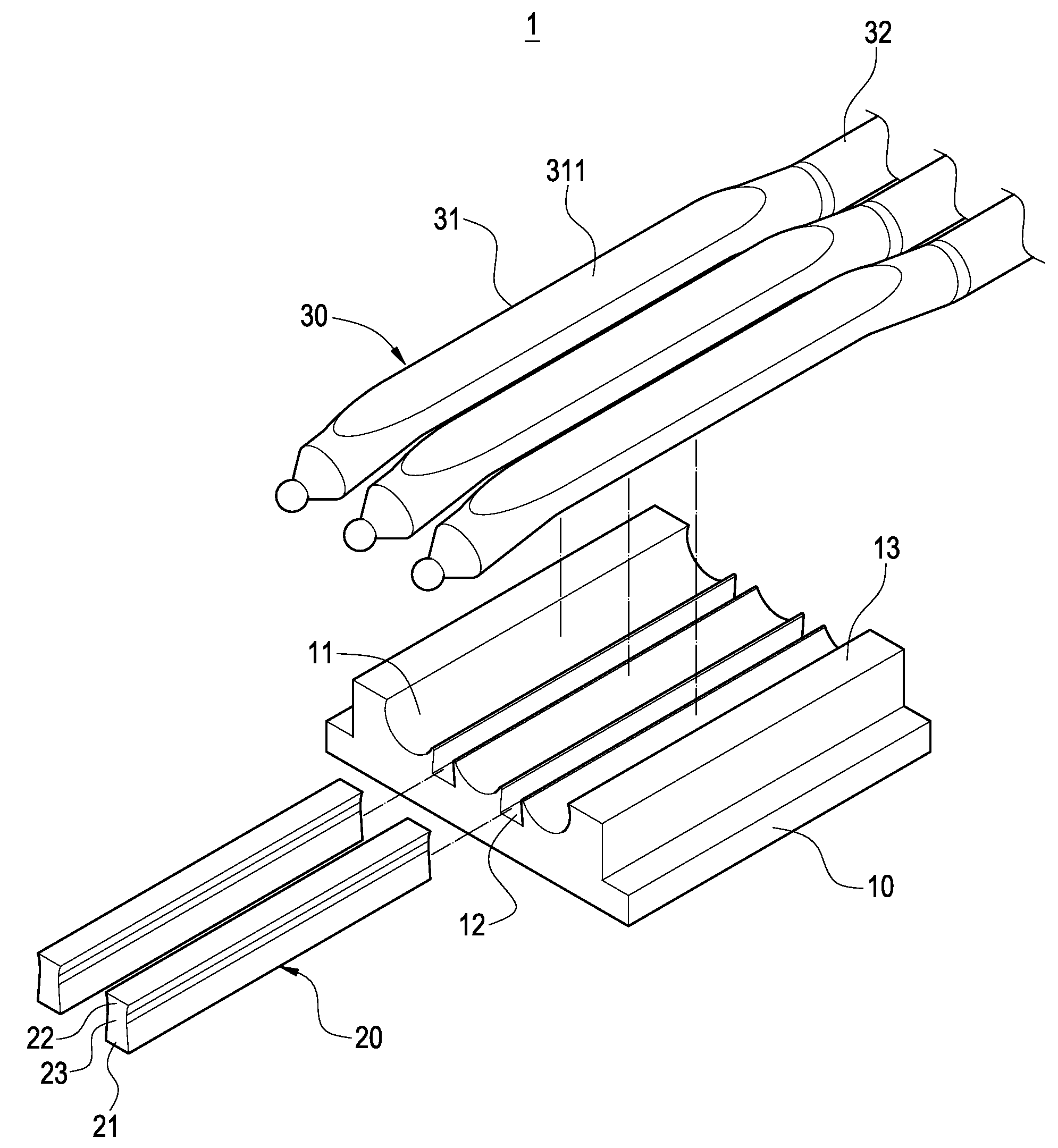

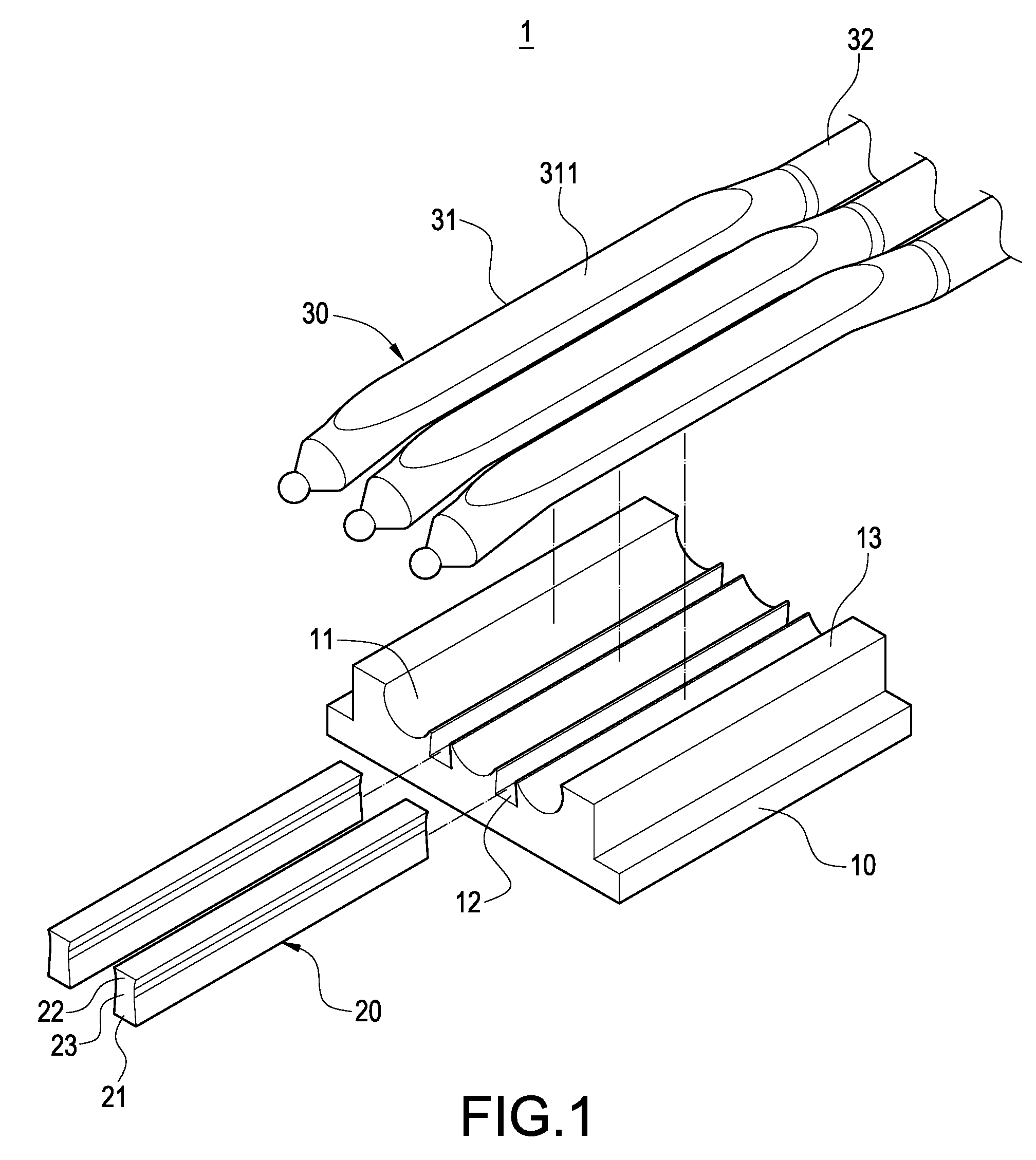

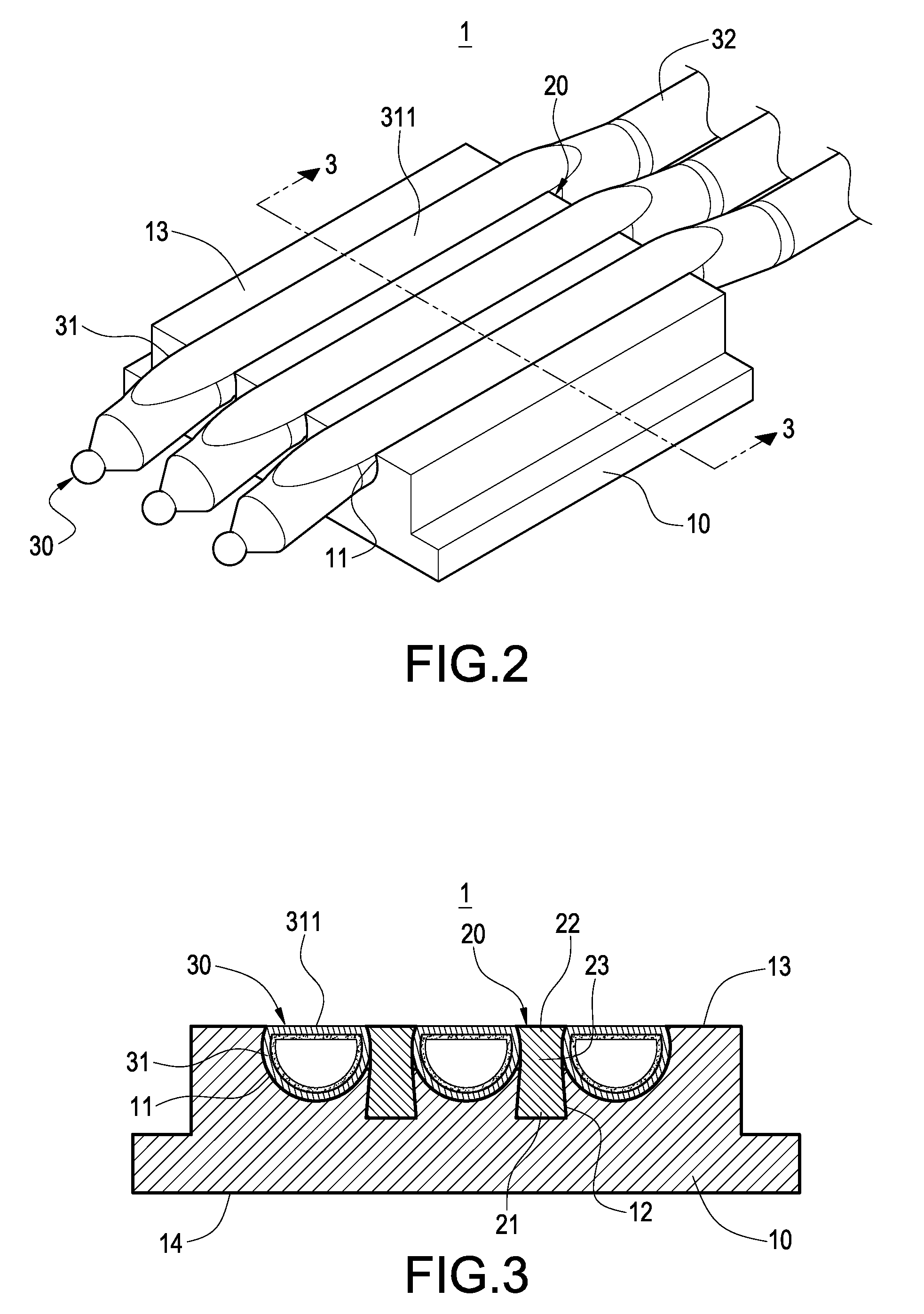

[0020]Please refer to FIG. 1 through FIG. 3. A thermally conductive module 1 according to the present invention is comprised of a base seat 1, a thermally conductive copper block 20 and a heat pipe 30.

[0021]The base seat 10 has a side face 13 and another side face 14 corresponding to the side face 13. An accommodation slot 11 is arranged on the side face 13 and a fixing slot 12 is arranged at a lateral side of the accommodation slot 11. The fixing slot 12 can be a dovetail slot. One or more cooling fins can be attached to another side face 14, as shown in FIG. 4. The base seat can be made by an aluminum extrusion or of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com