Joint of parallel sandwich panels

a sandwich panel and parallel technology, applied in the field of joint of parallel sandwich panel, can solve the problems of low building cost, scarce natural resources and raw materials, and difficult to meet the needs of construction, and achieve the effects of less labor intensity, less weight, and reduced construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

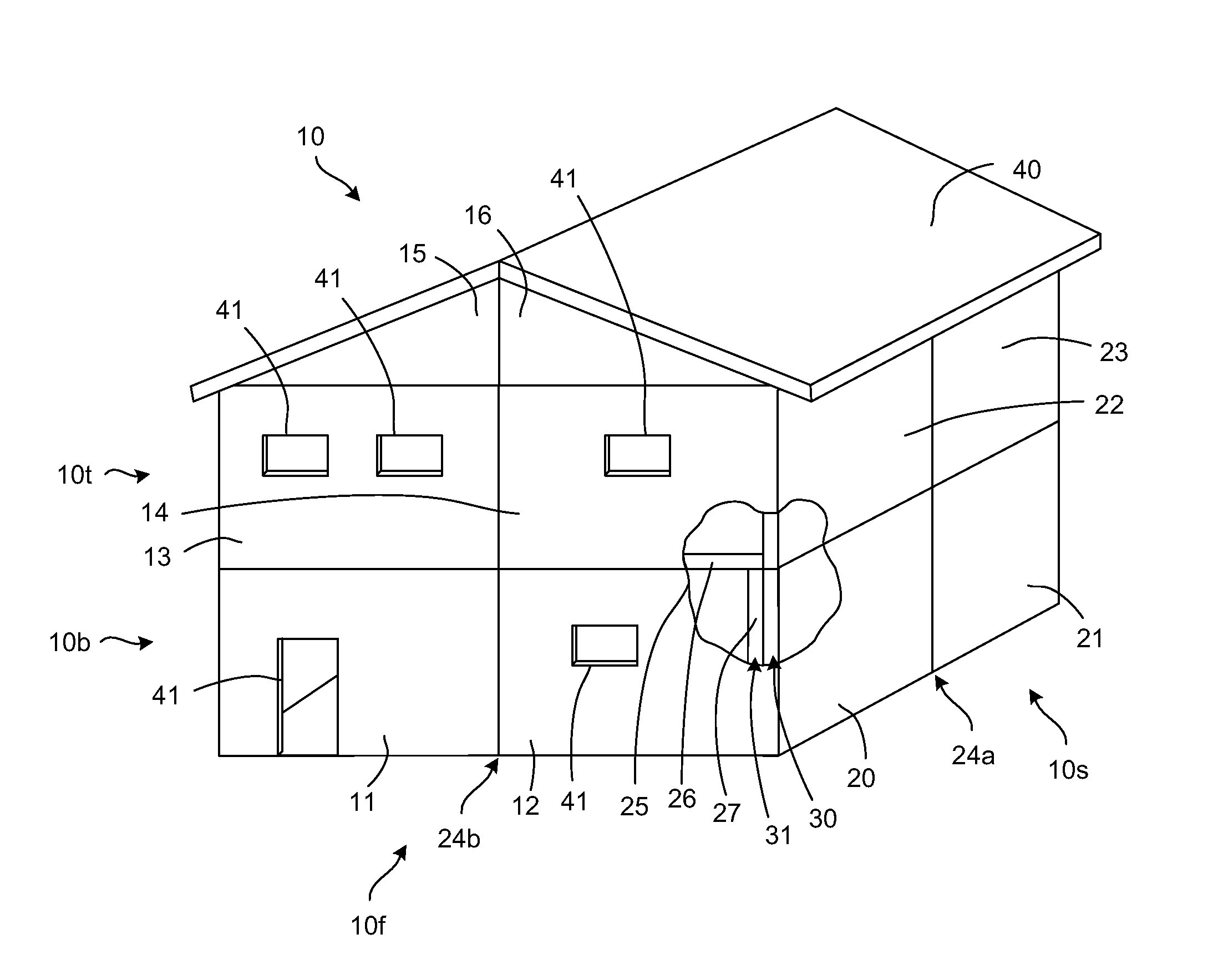

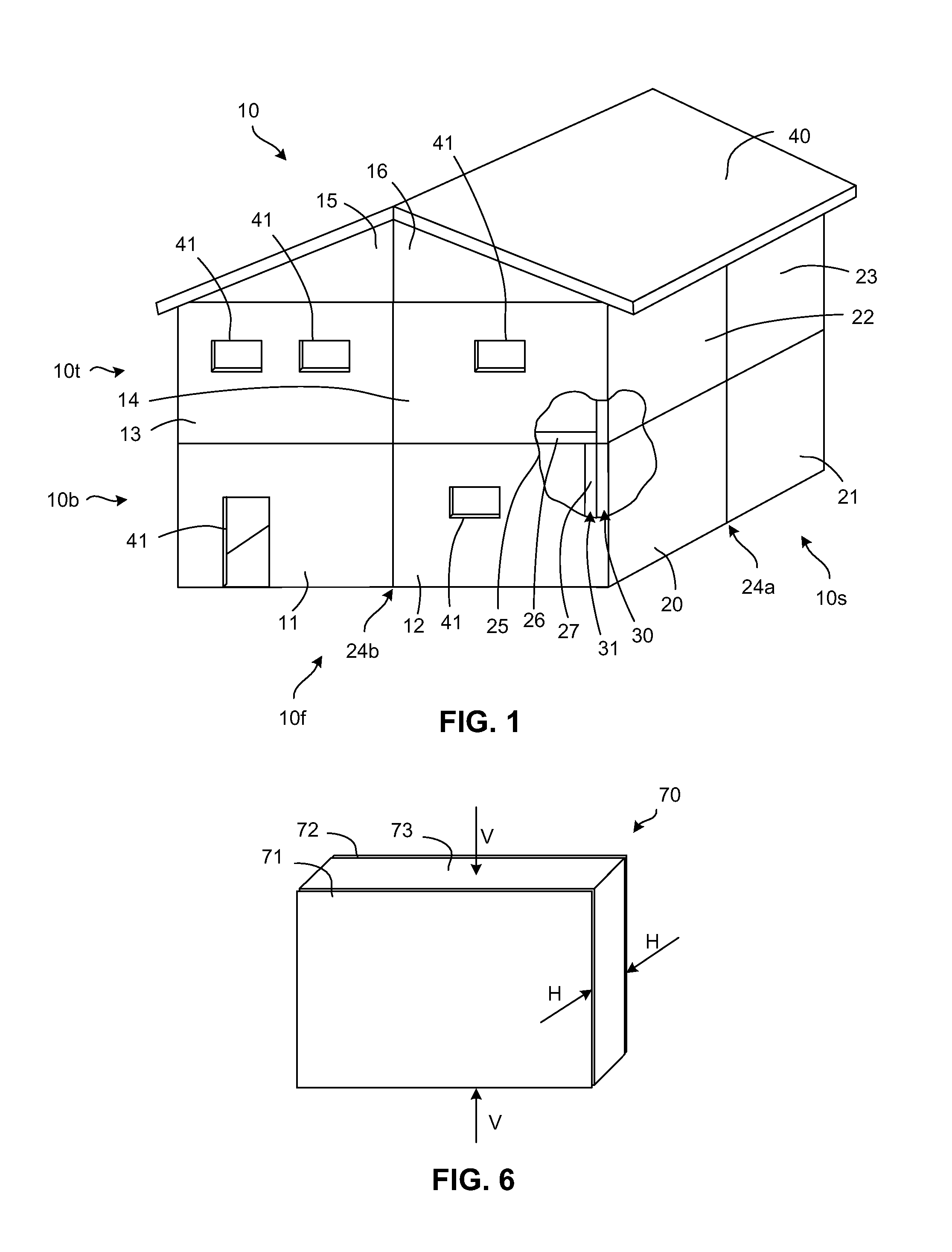

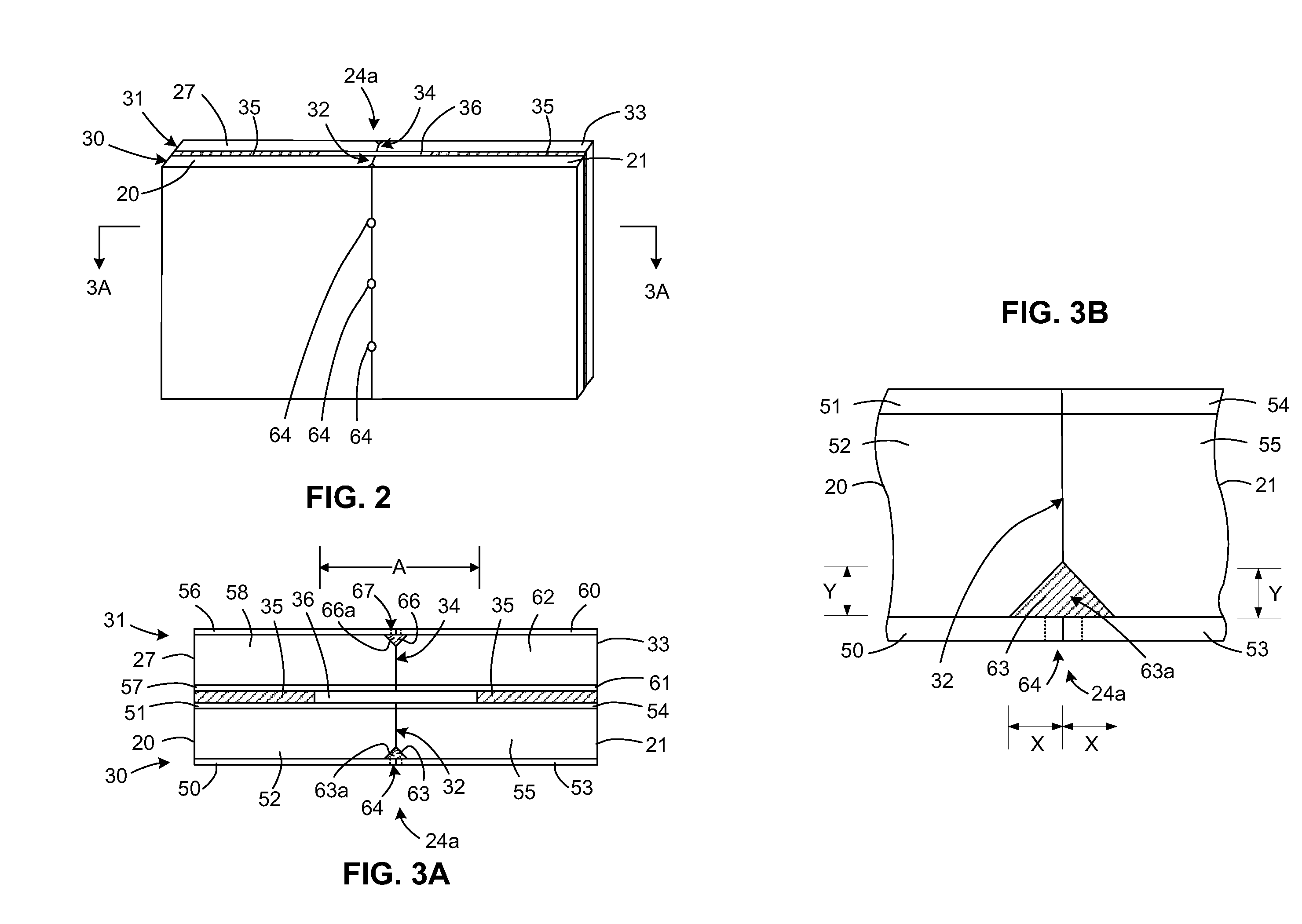

[0041]In the detailed description that follows, like components have been given the same reference numerals regardless of whether they are shown in different embodiments of the invention. To illustrate the present invention in a clear and concise manner, the drawings may not necessarily be to scale and certain features may be shown in somewhat schematic form. Certain terminology is used herein to describe the different embodiments of the invention. Such terminology is used for convenience when referring to the figures. For example, “upward,”“downward,”“above,”“below,”“left,” or “right” merely describe directions in the configurations shown in the figures. Similarly, the terms “interior” and exterior” or “inner” and “outer” may be used for convenience to describe the orientation of the components in the figures. The components can be oriented in any direction and the terminology should therefore be interpreted to include such variations. The dimensions provided herein are exemplary i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com