Patents

Literature

48results about How to "More elastic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

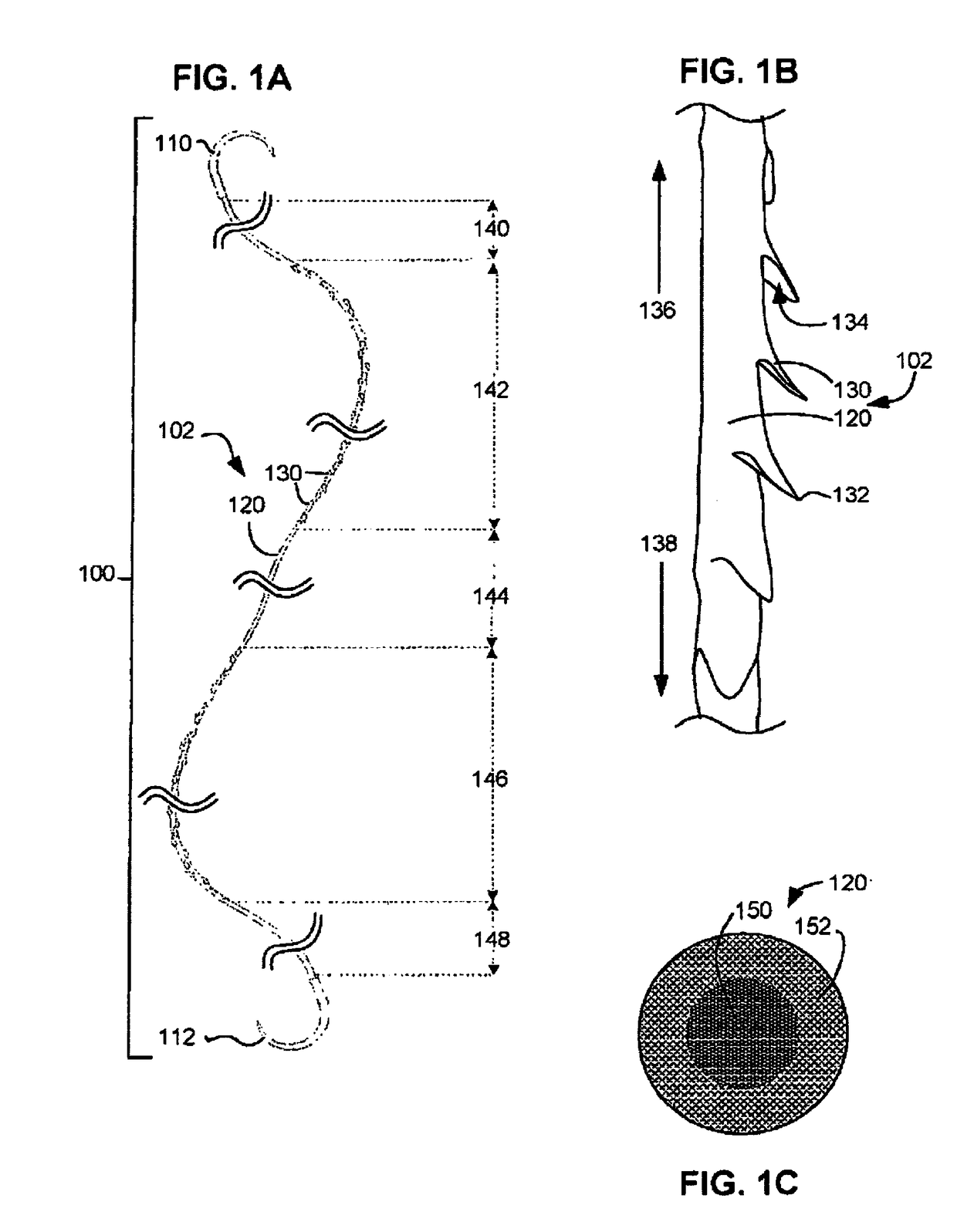

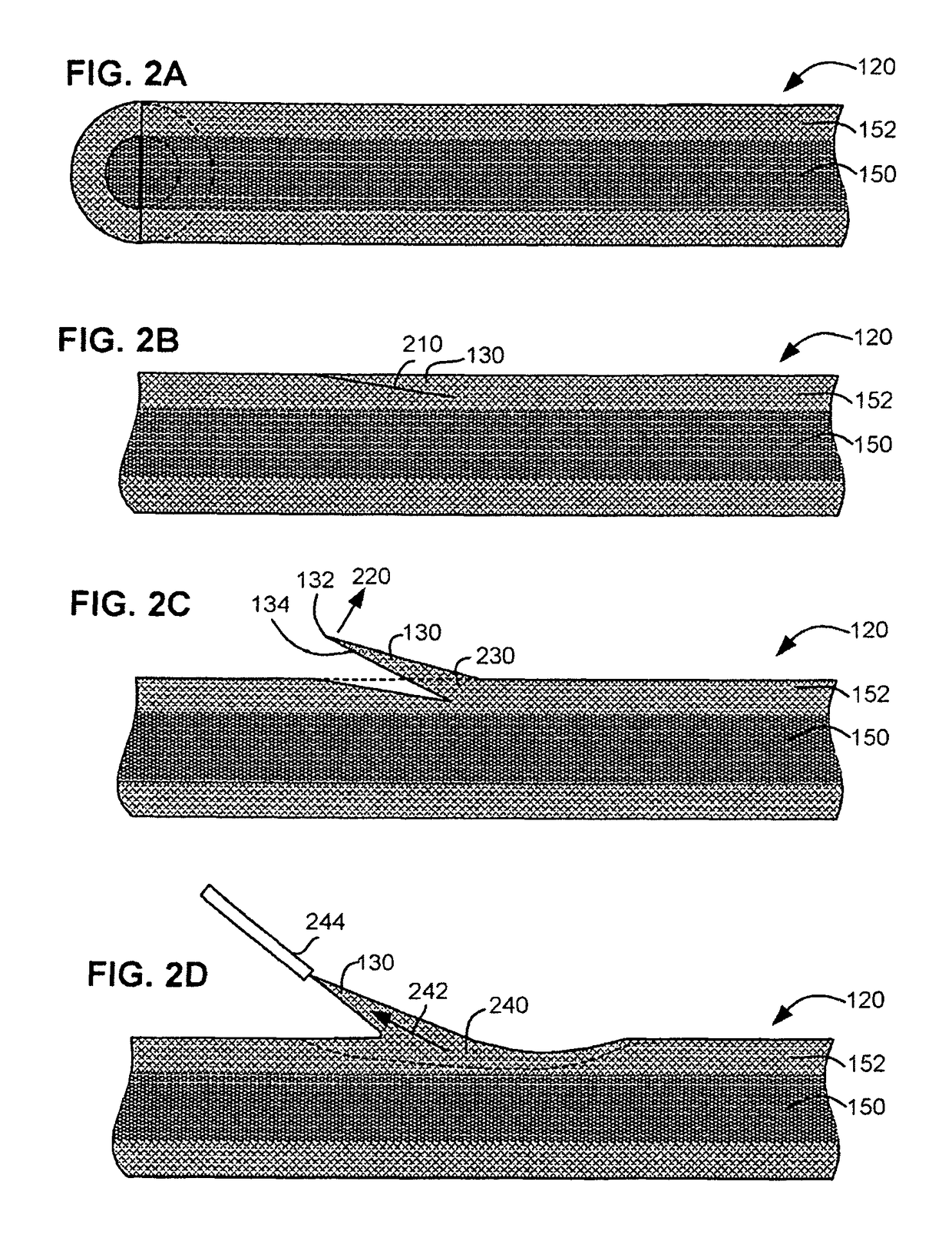

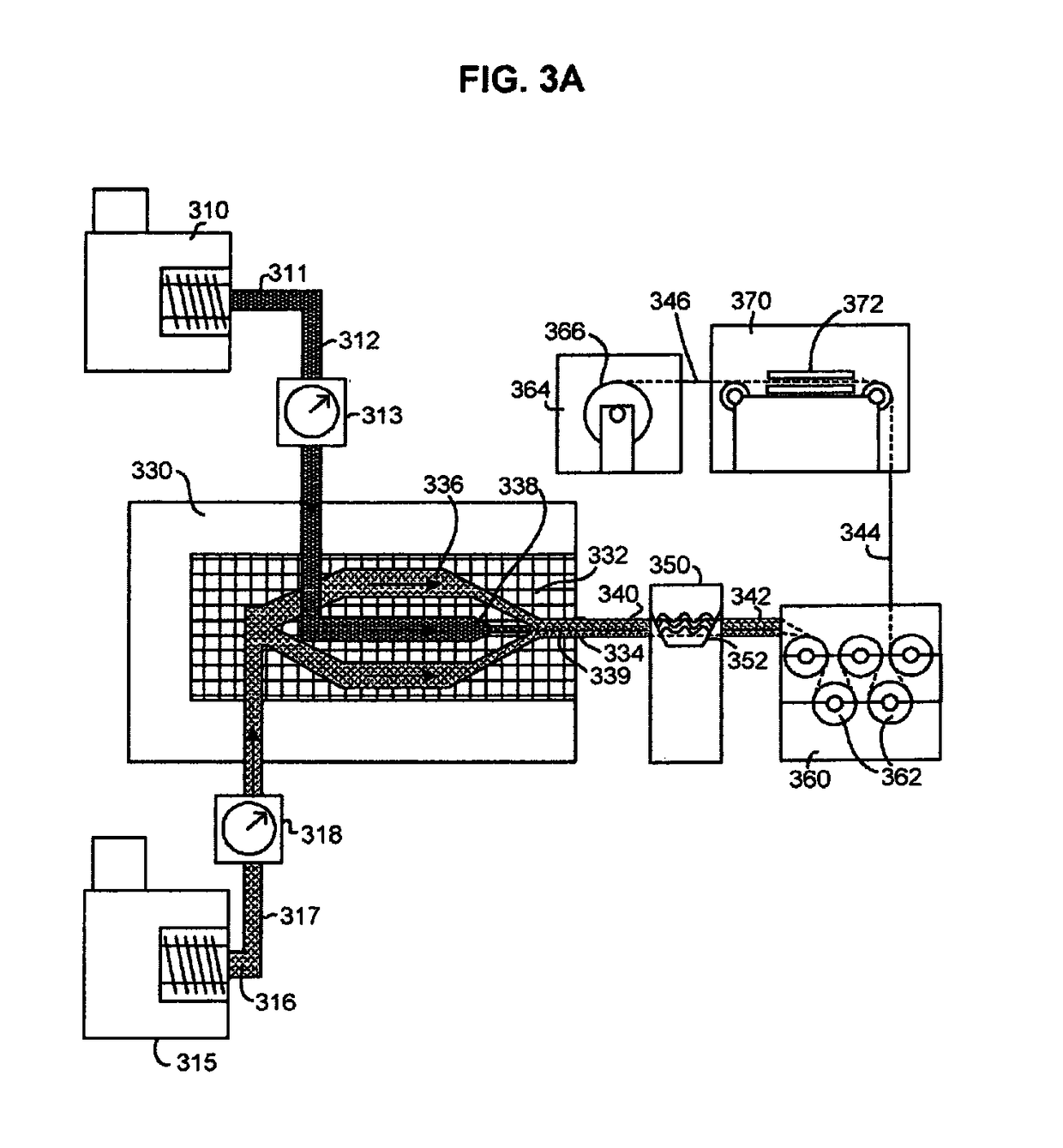

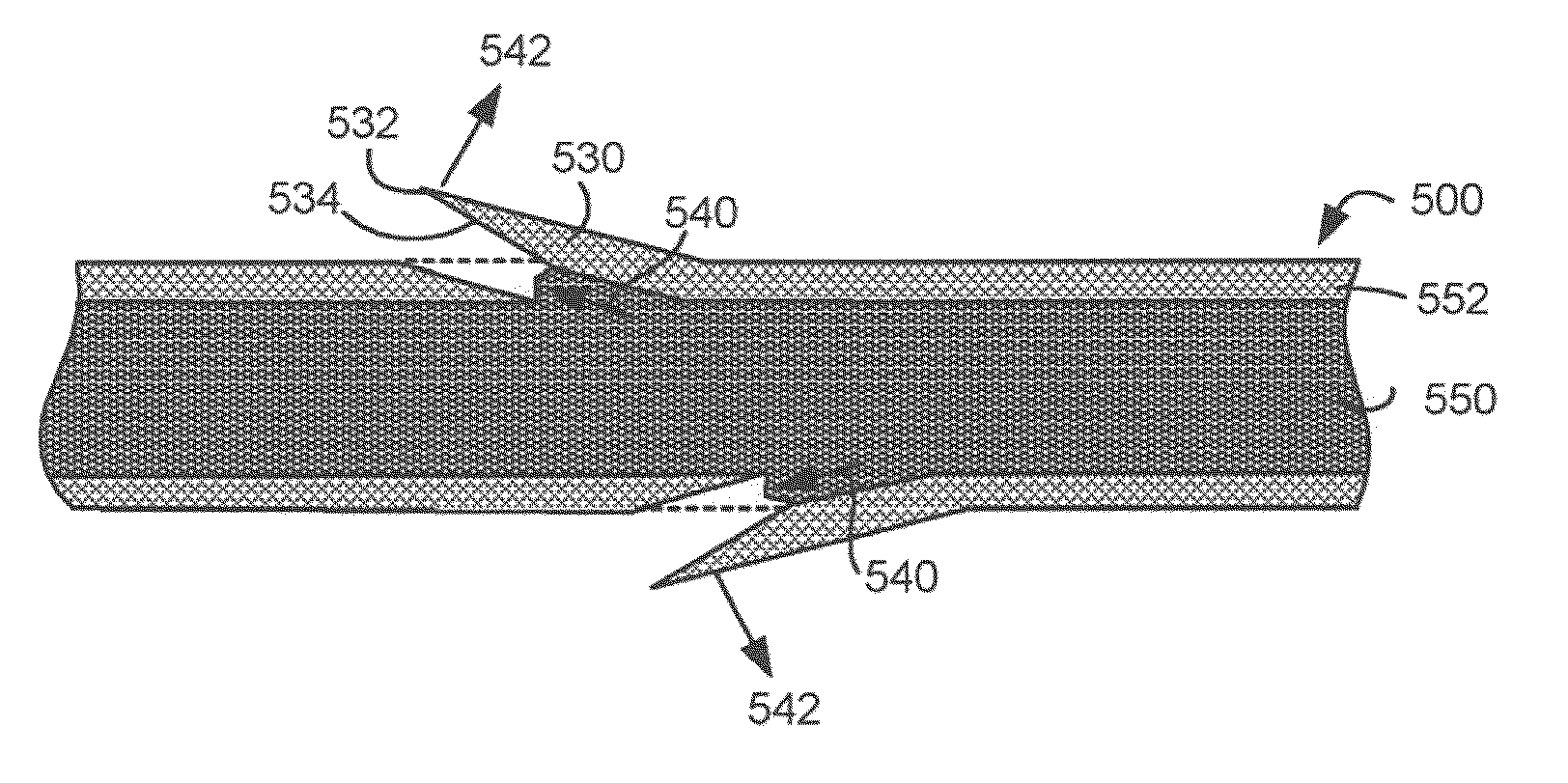

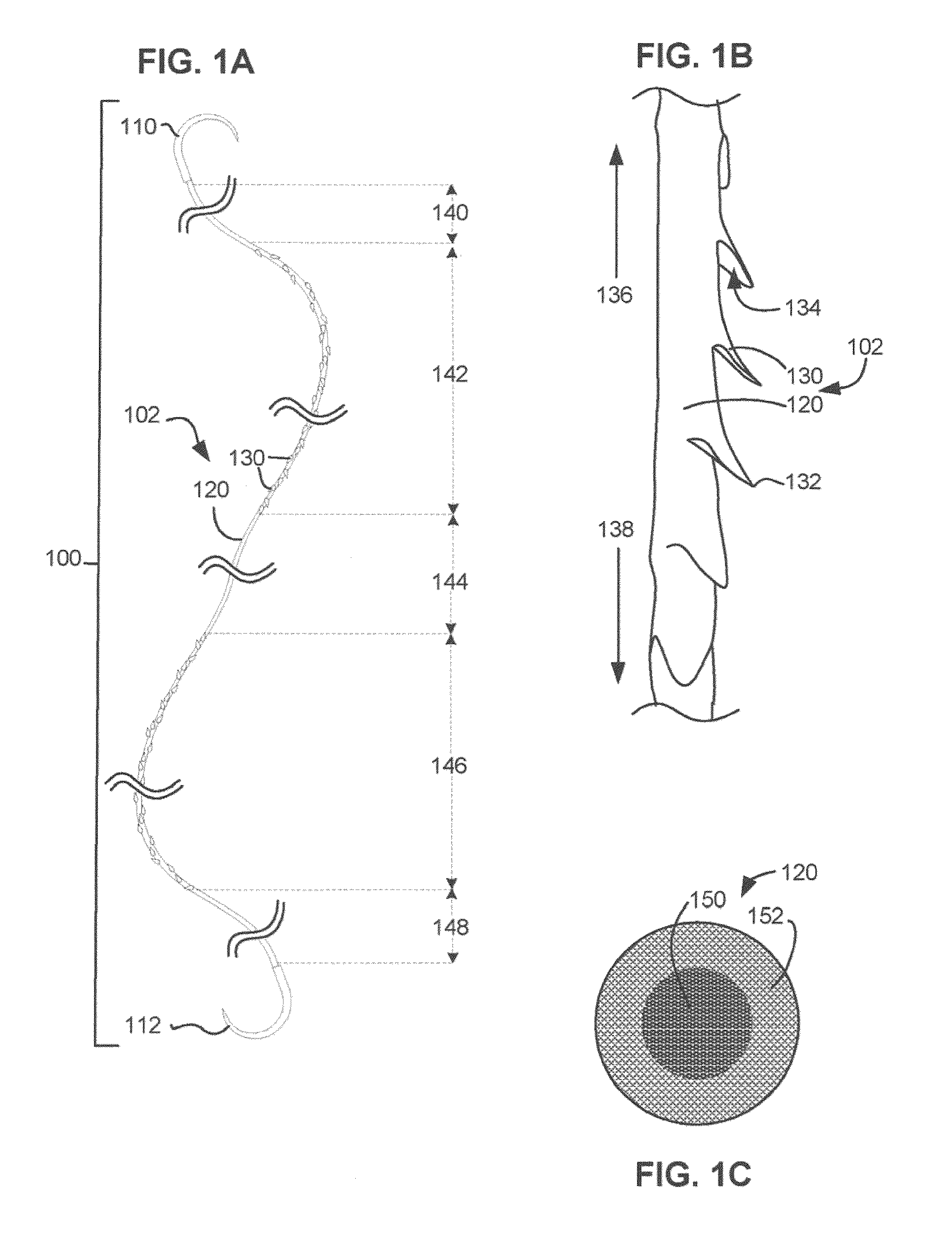

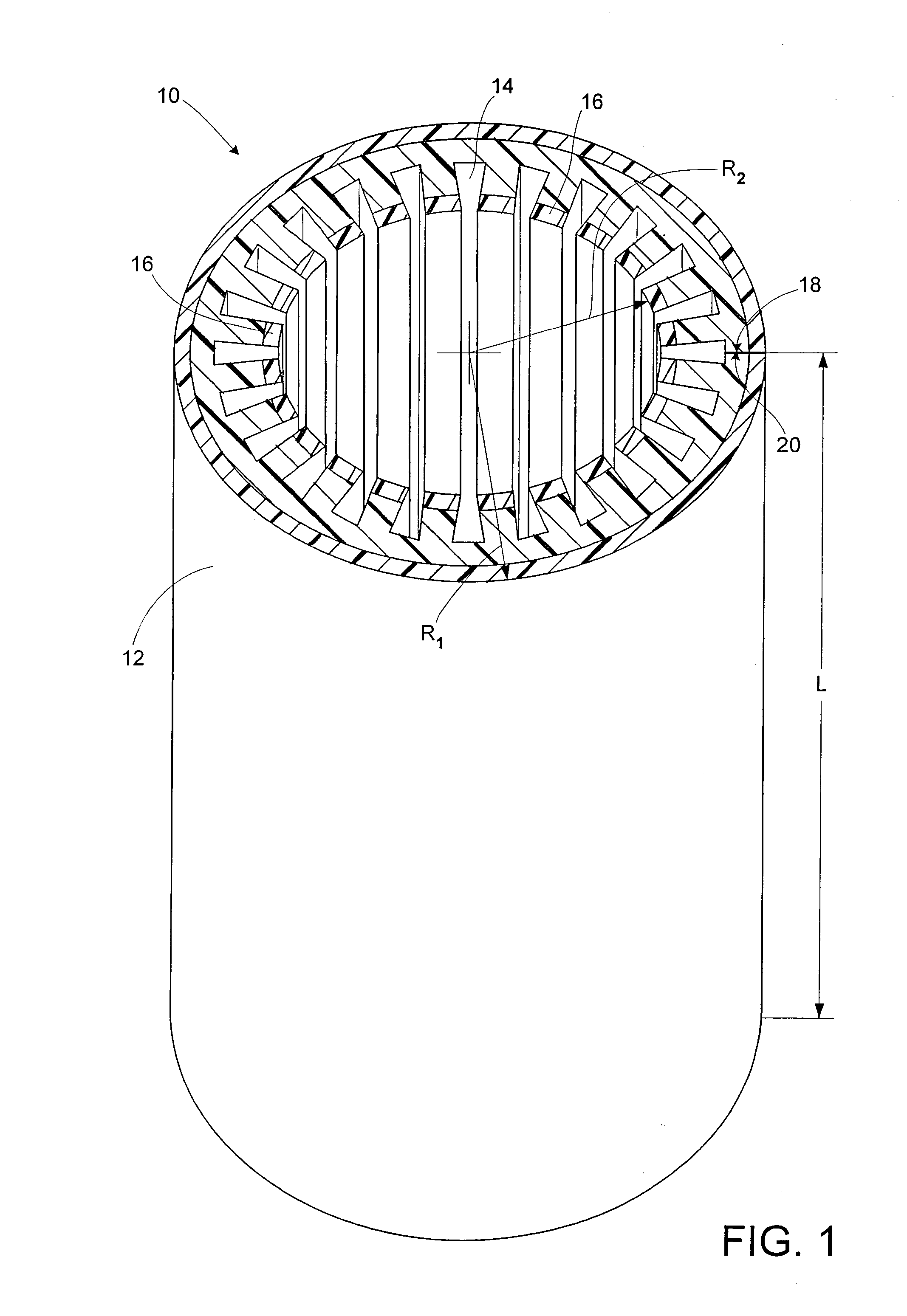

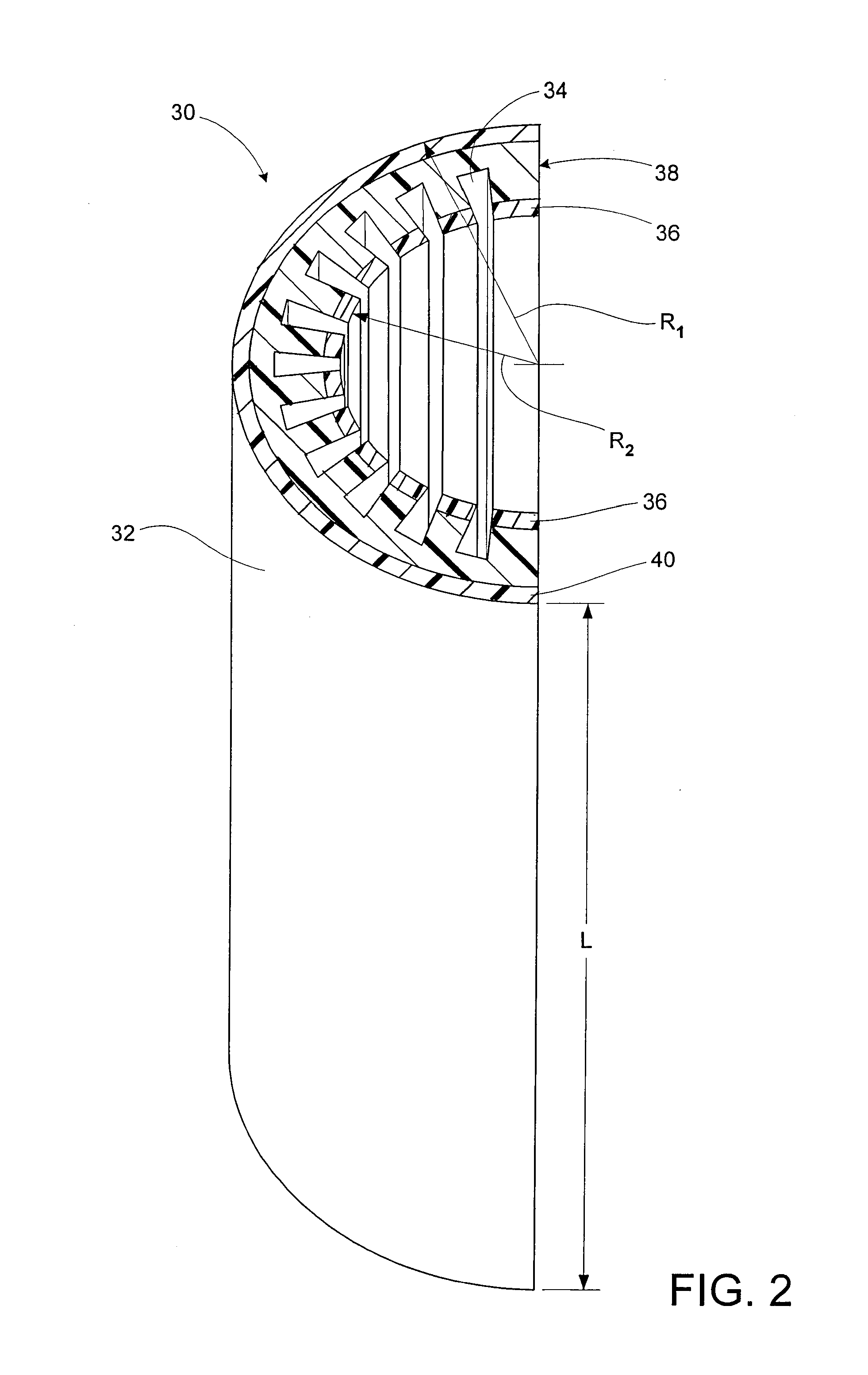

Composite self-retaining sutures and method

ActiveUS8118834B1Improved self-retaining suturesImprove abilitiesSuture equipmentsSurgical needlesUltimate tensile strengthMaterials science

Owner:ETHICON INC

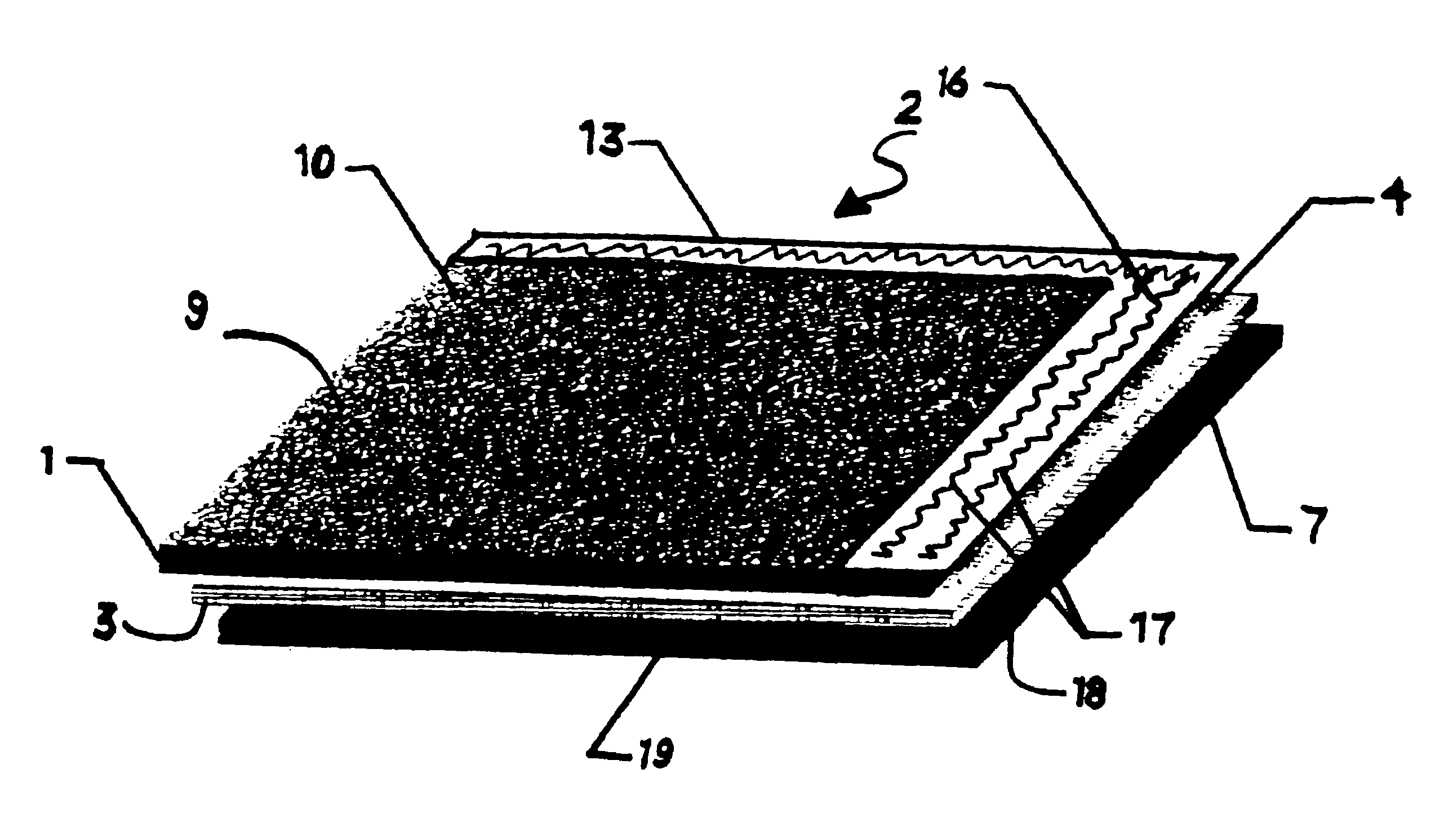

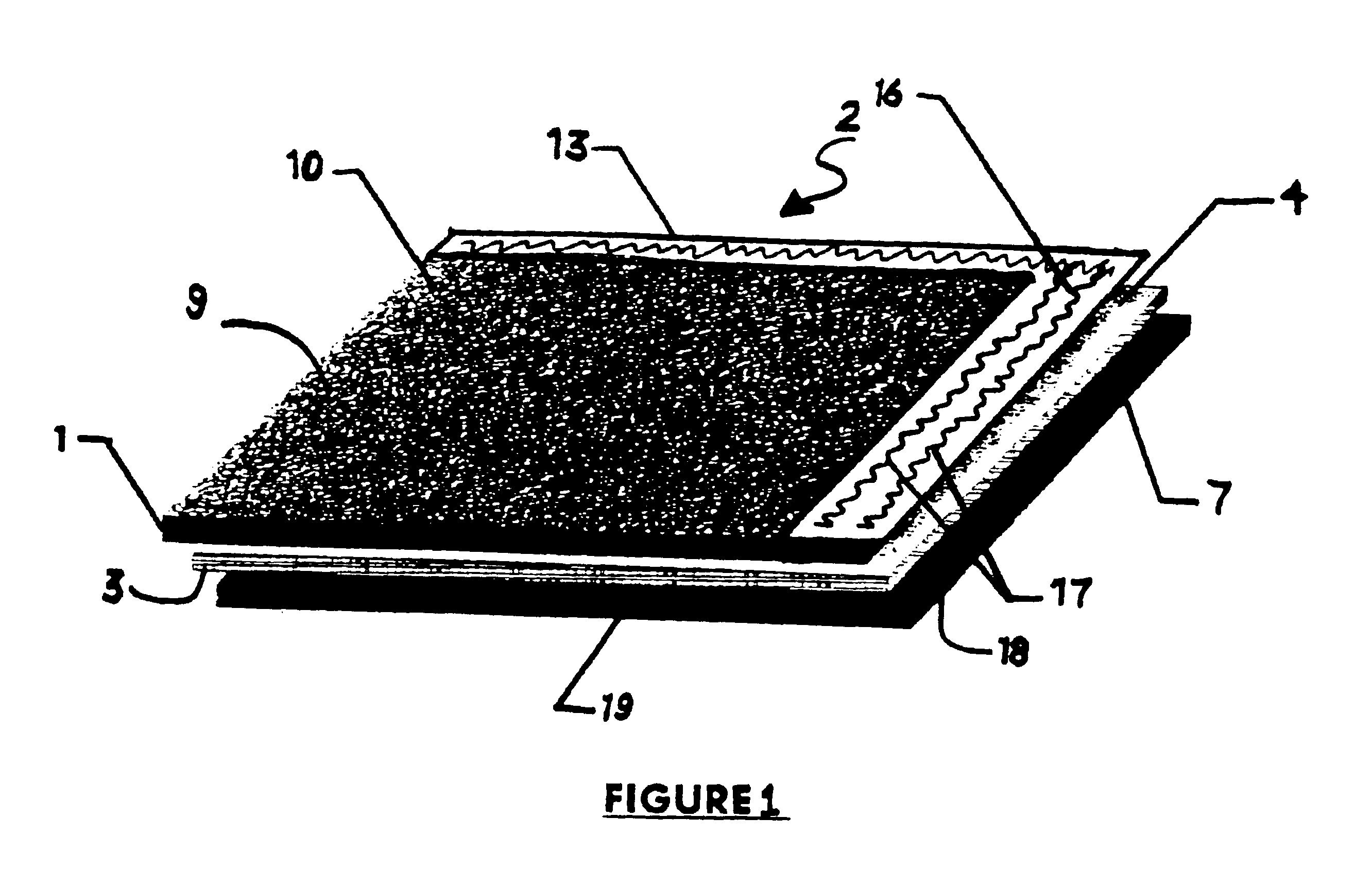

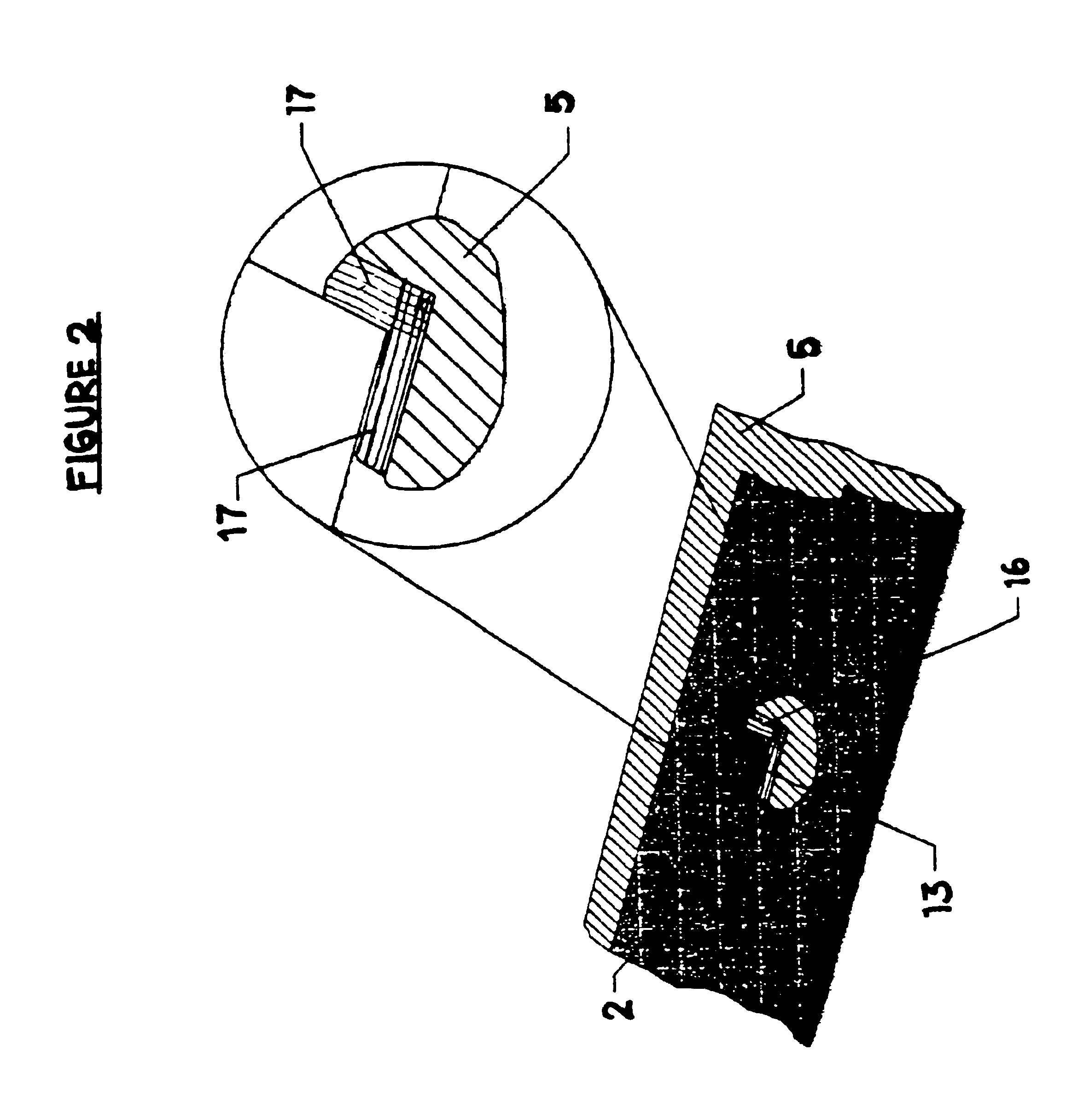

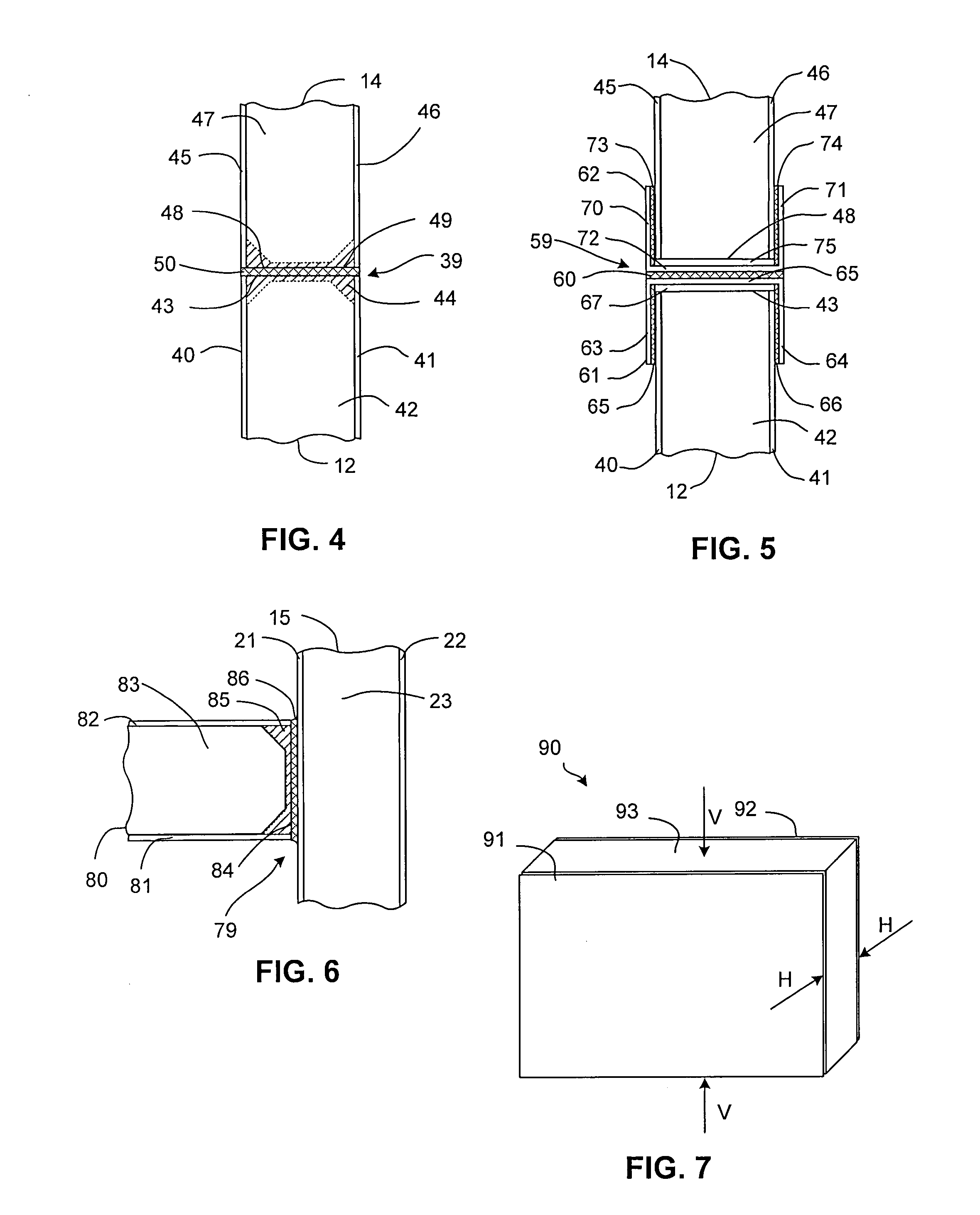

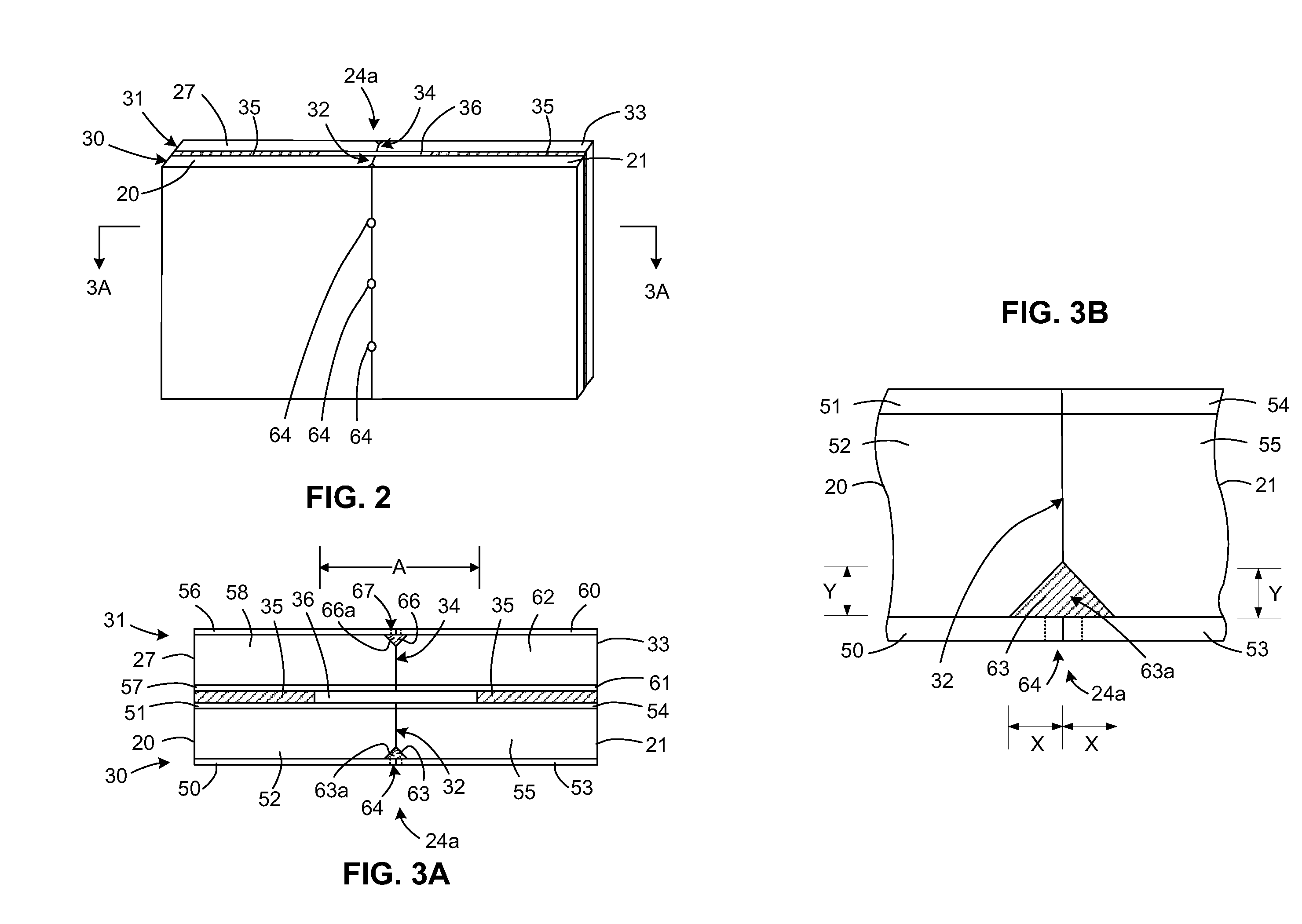

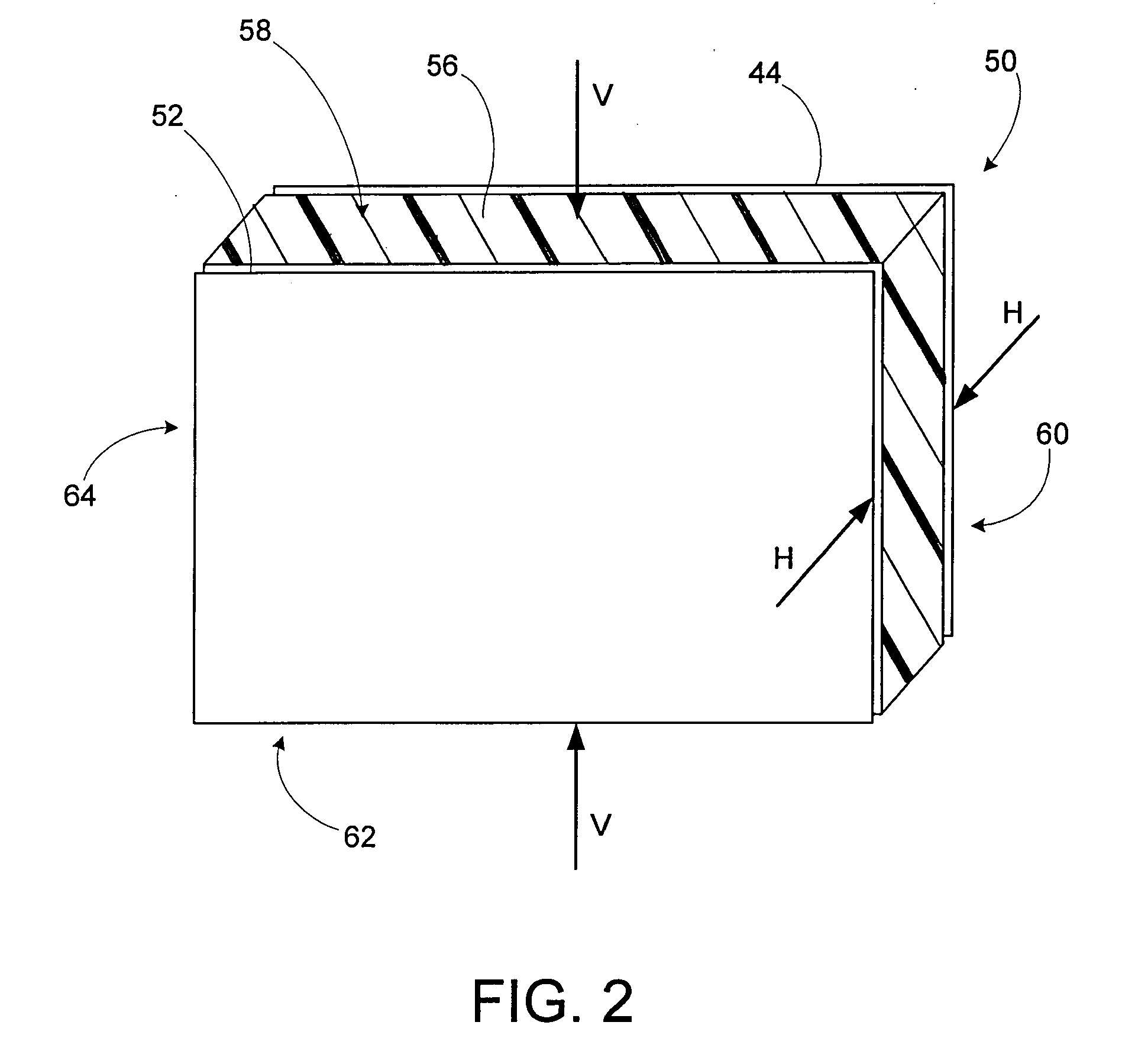

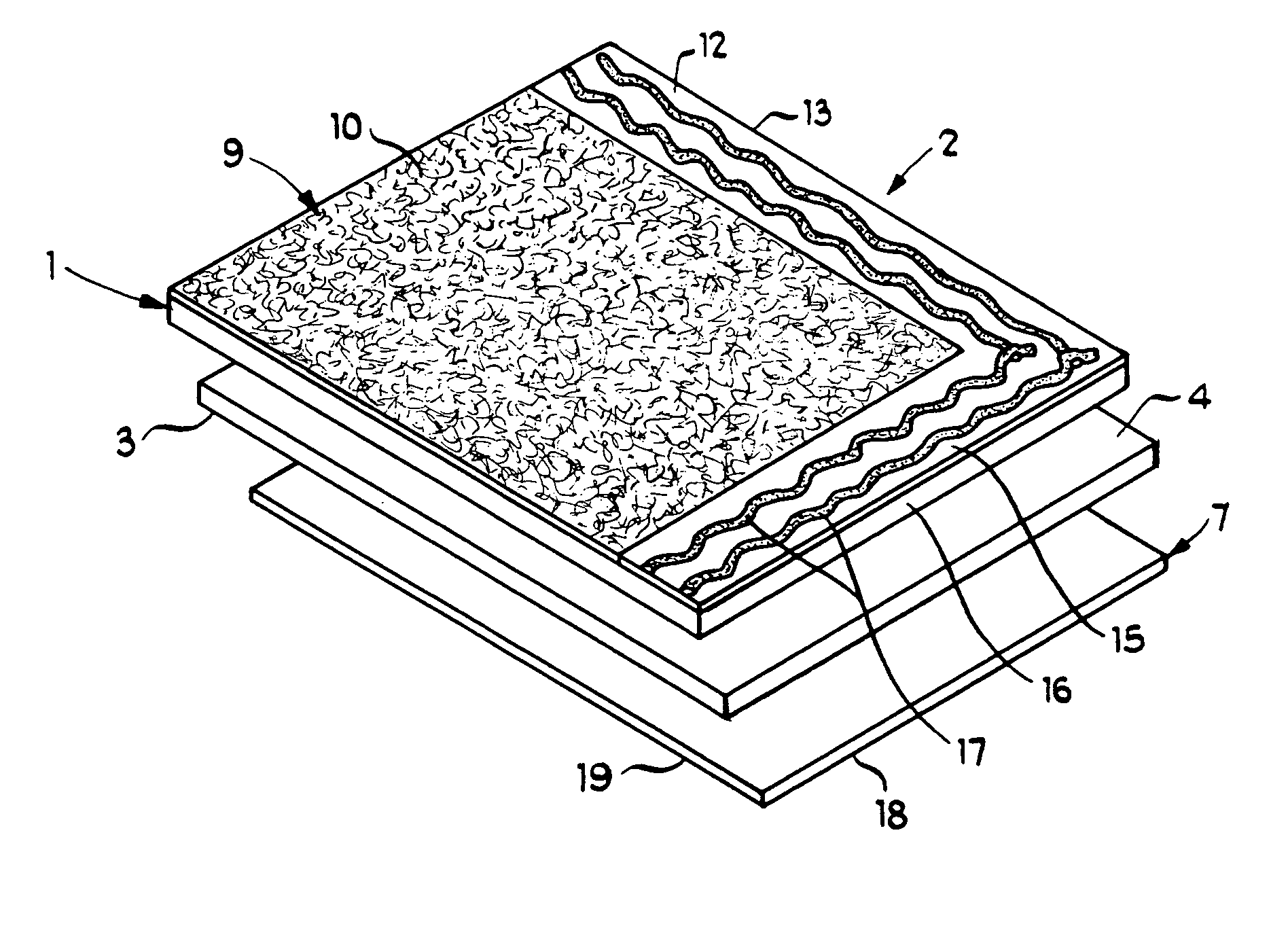

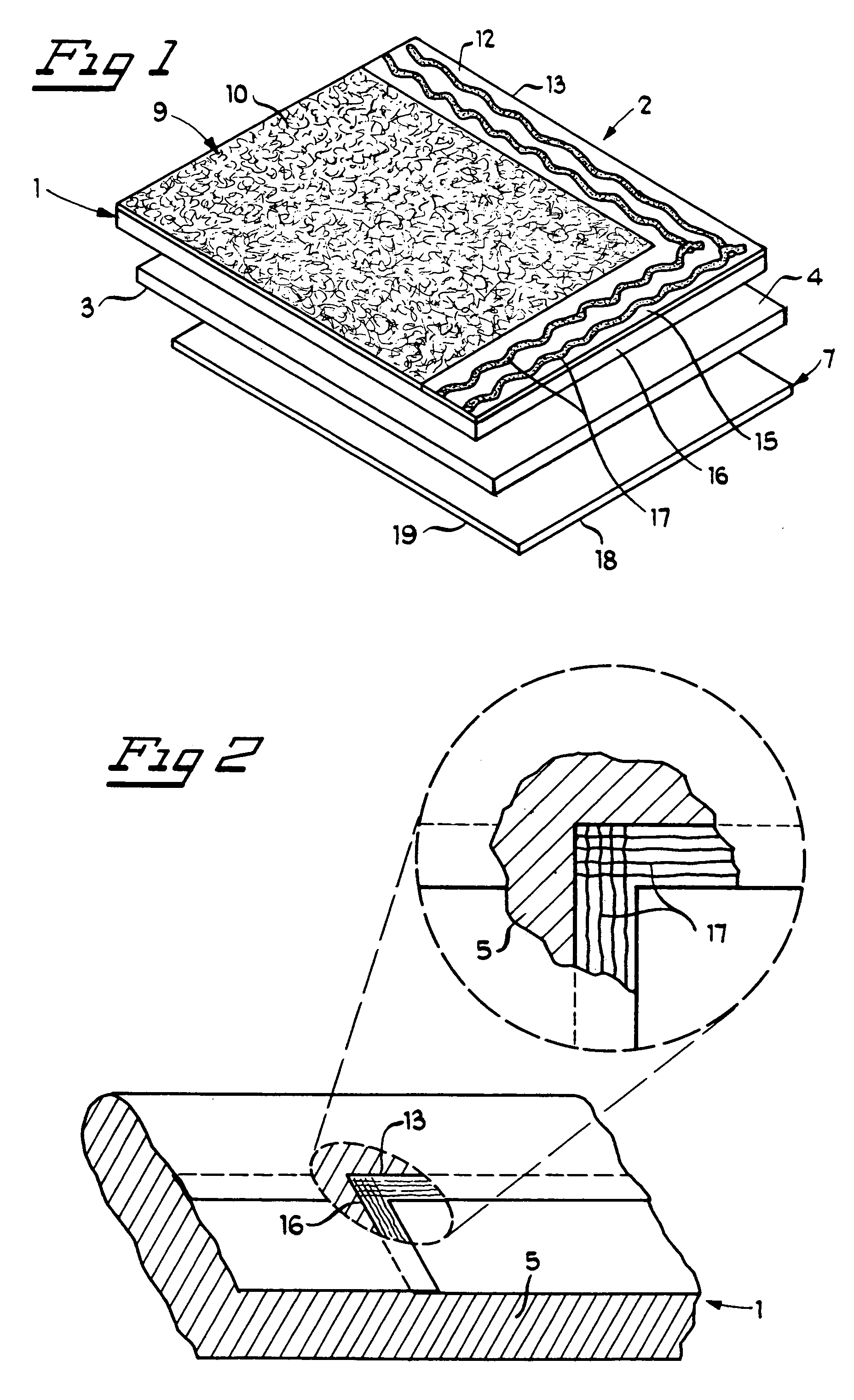

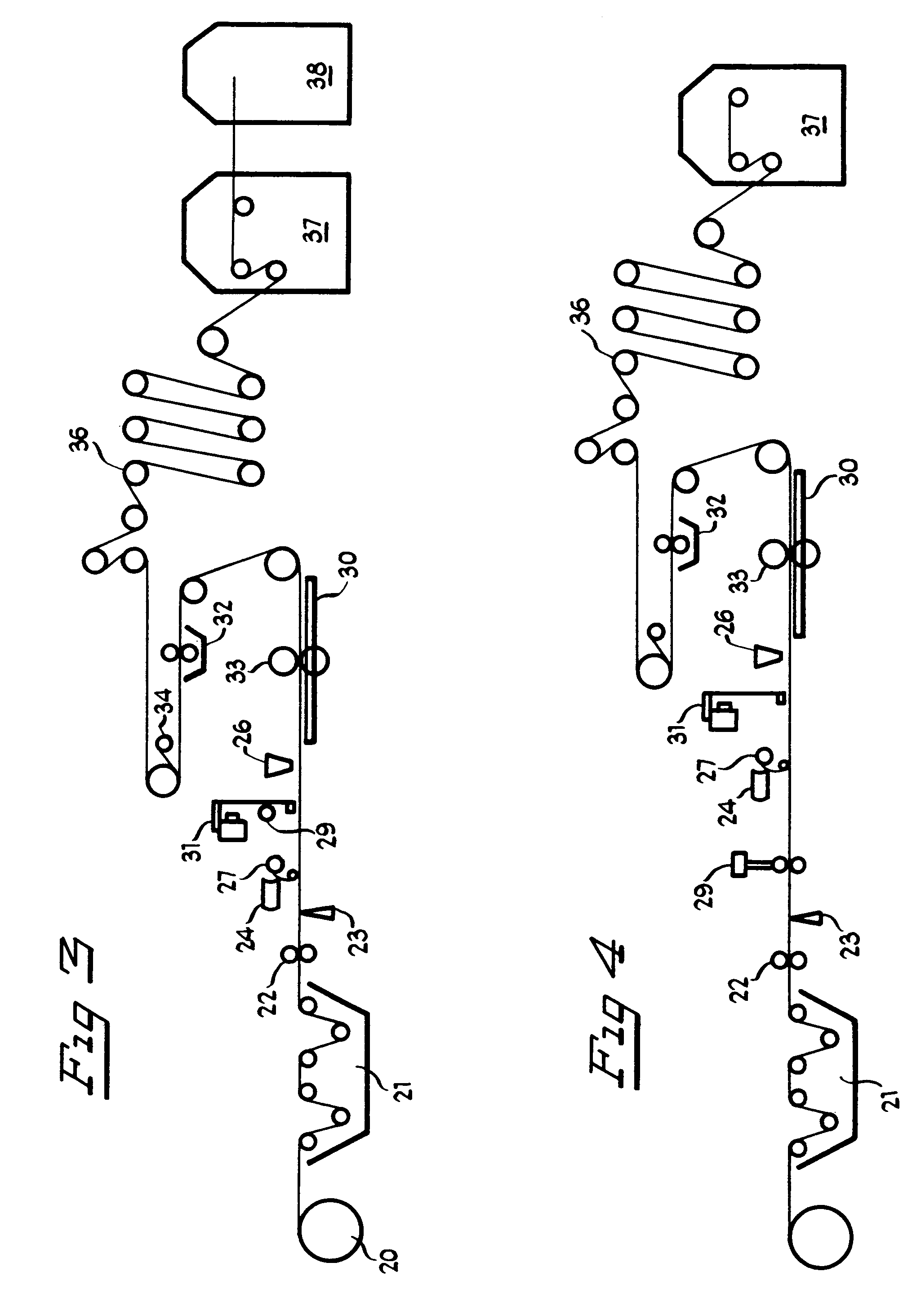

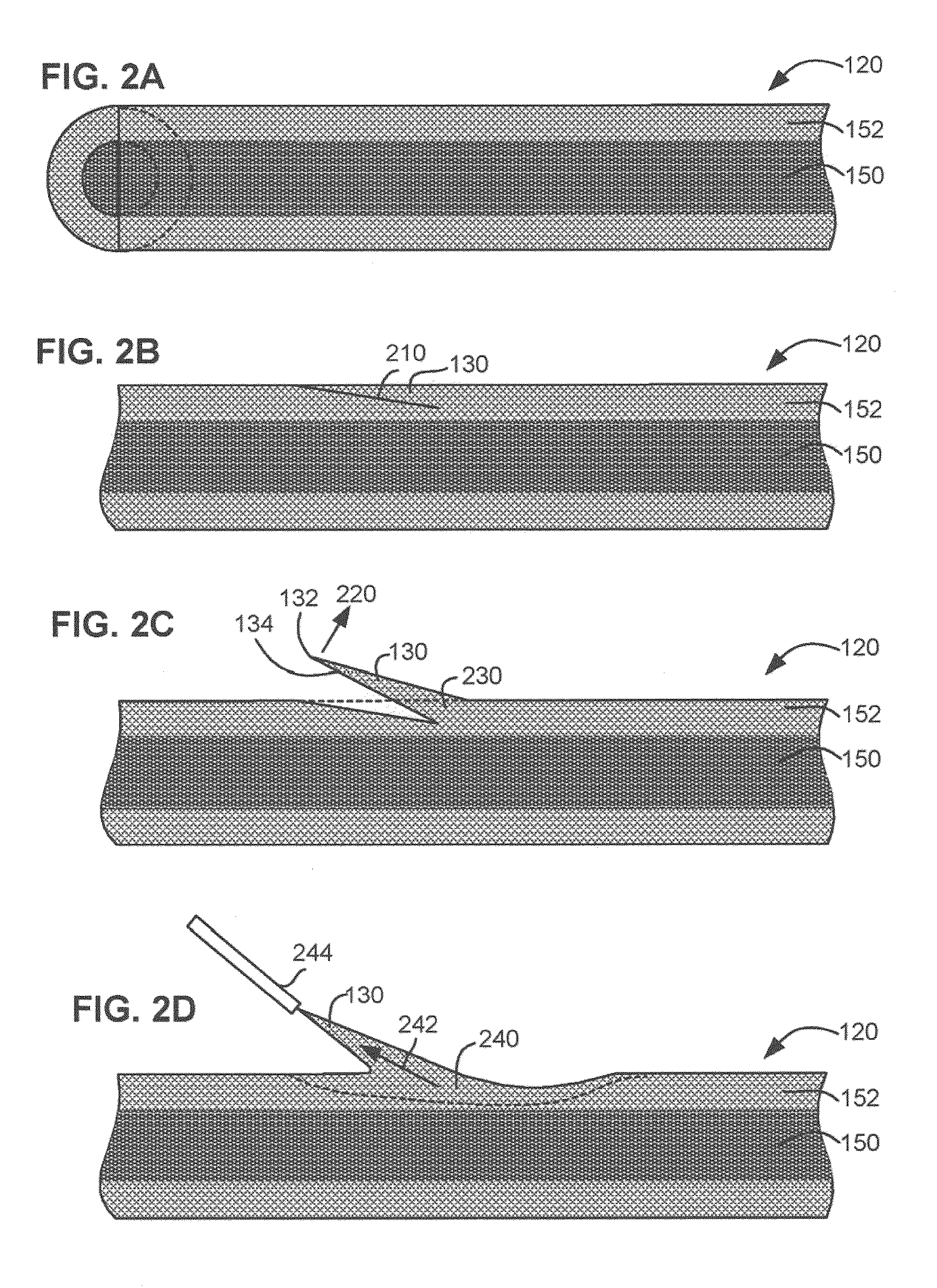

Modified bitumen roofing membrane with enhanced sealability

InactiveUS6924015B2Reduce the possibilityImprove the noise reduction effectTreadsRoof covering using flexible materialsThermoplasticEngineering

A self-adhering modified bituminous roof covering composite that comprises a thermoplastic (APP), elastomeric (SBS) or TPO modified bitumen compound on the front side, and a factory-applied self-adhesive compound on the back side of a reinforcement carrier sheet, with factory-applied tracts of adhesive on the side lap and end lap sections of each roll to enhance adhesion. A method of manufacturing such composite comprising coating an APP or SBS or TPO compound on the upper surface and affixing a self-adhesive compound to the lower surface of a reinforcement carrier support sheet, coating an adhesive on the side lap and end lap areas, applying a release liner to the tacky self-adhesive layer, and applying release films to the side and end laps during manufacture, stripping the release liner, selvage release film and end lap film from the membrane immediately prior to use, subsequently placing the exposed self-adhesive side of the membrane directly on to the end lap areas and side lap areas of adjacent rolls and applying force directly to the sheet to enhance the bond between the two sheets, resulting in a continuous roof covering. The present invention relates generally to residential and commercial roofing membranes.

Owner:POLYGLASS

Electroactive polymer coatings for corrosion control

InactiveUS6150032APromote formationTolerant to scratch damageConductive materialSynthetic resin layered productsConductive polymerDouble stranded

An anti-corrosive polymeric complex which is comprised of a plurality of double-stranded molecular complexes. Each of the molecular complexes are comprised of a strand of a conductive polymer and a strand of a copolymer. The strands of the polymeric complex are non-covalently bonded to each other along the contour of the strands to form a side-by-side, twisted, double-stranded configuration.

Owner:BOARD OF GOVERNORS FOR HIGHER EDUCATION STATE OF RHODE ISLAND & PROVIDENCE PLANTATIONS

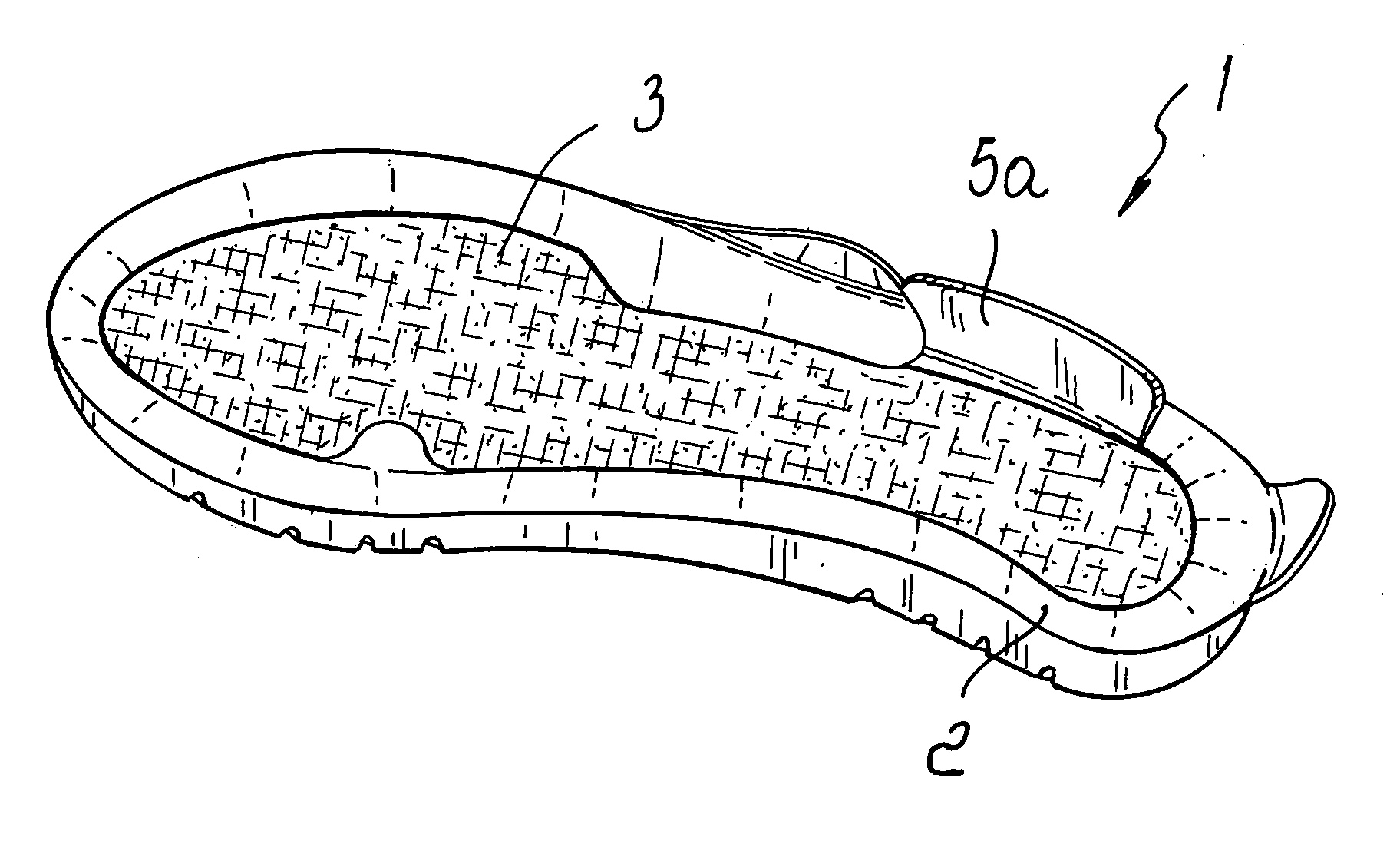

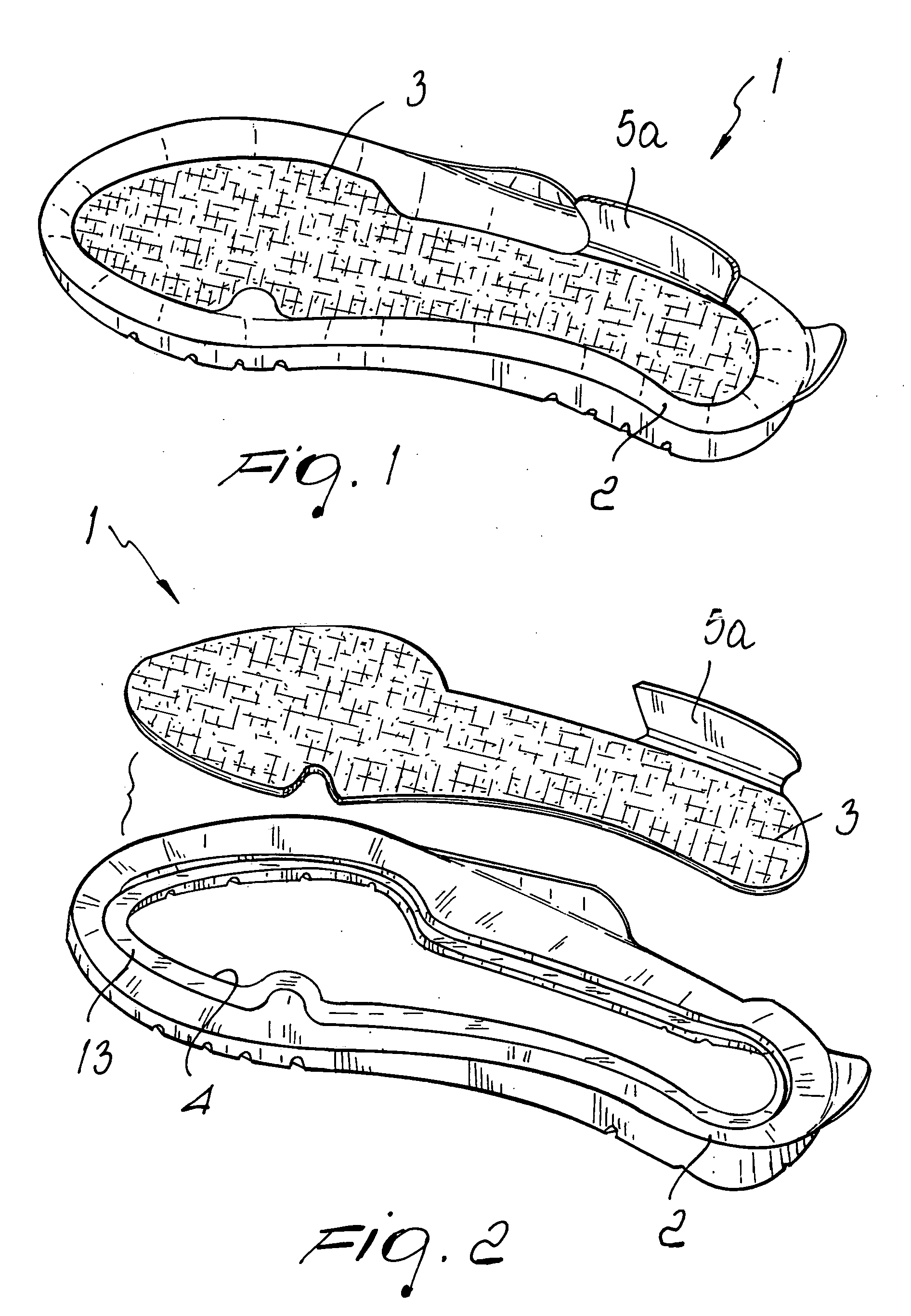

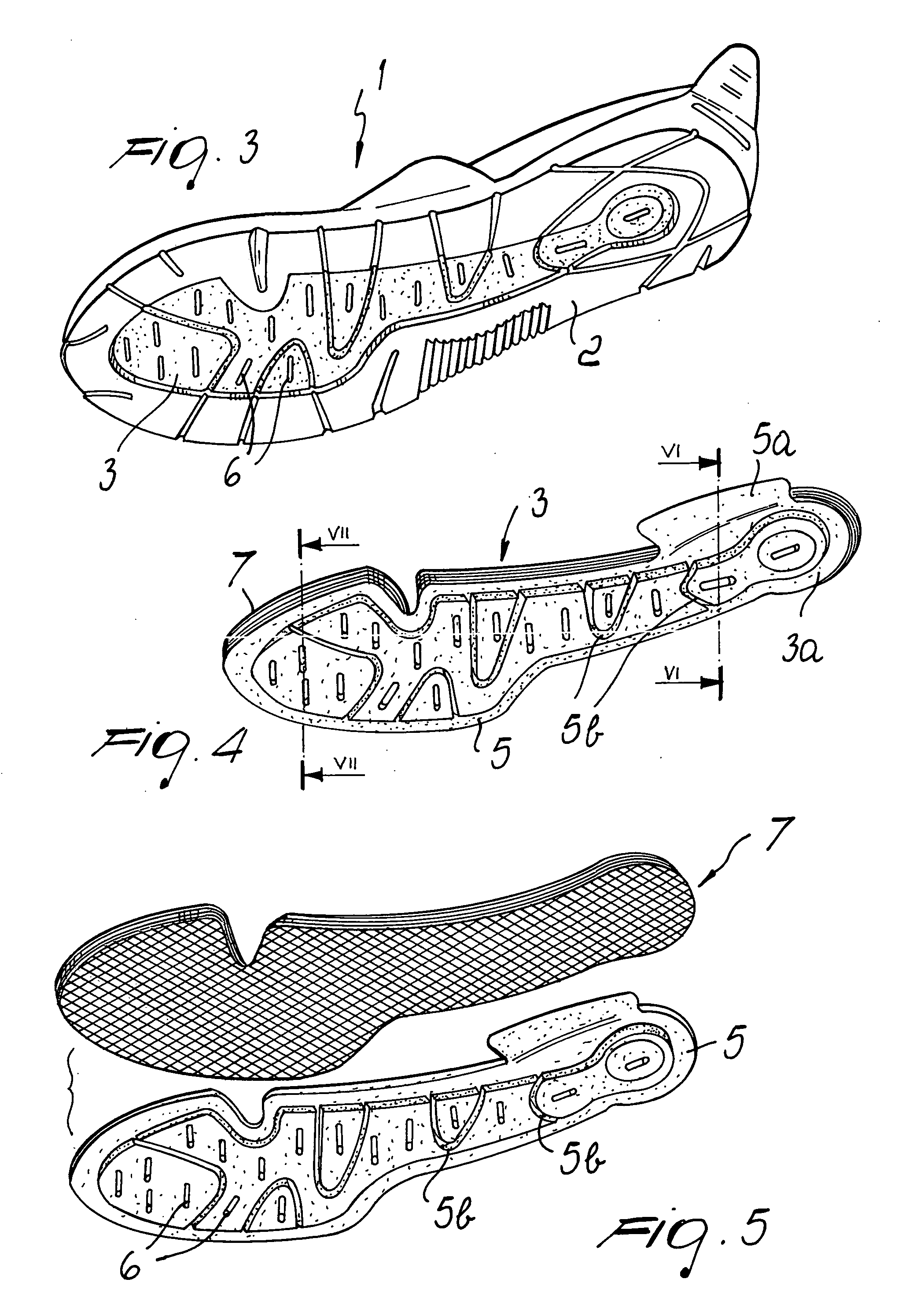

Sole for shoes

InactiveUS20050229431A1Easy and comfortable walkingMore elasticSolesDomestic footwearRubber materialBiomedical engineering

A sole for shoes comprising a sole base body, the sole base body having at least one cutout that is closed at least partially by at least one multilayer sheet insert; the insert has, in its lower part intended to be directed toward the ground, a layer made of rubber material, which is molded directly by direct microinjection onto the remaining part of the multilayer sheet insert.

Owner:CALZATURIFICIO MONTEROSA

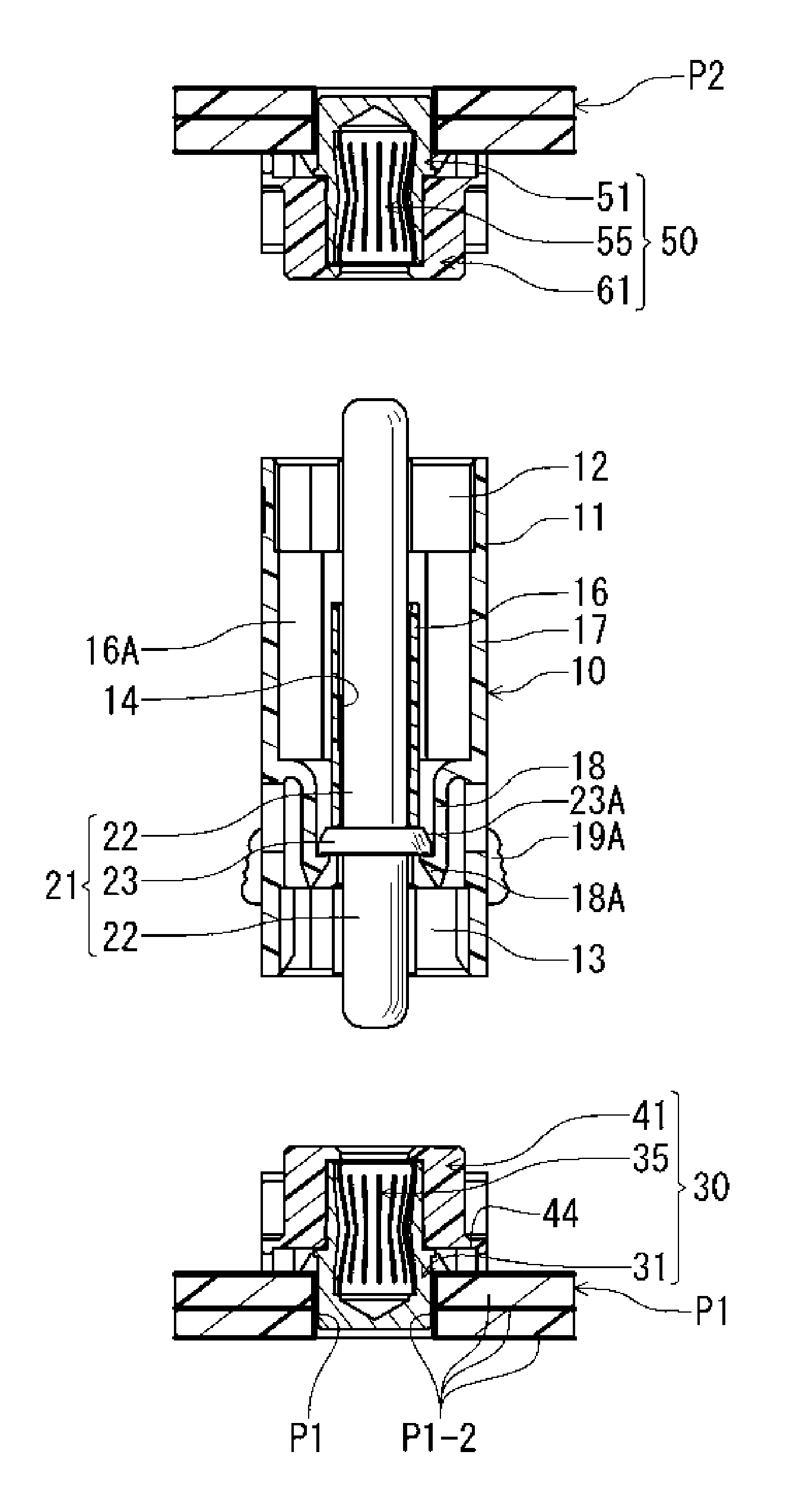

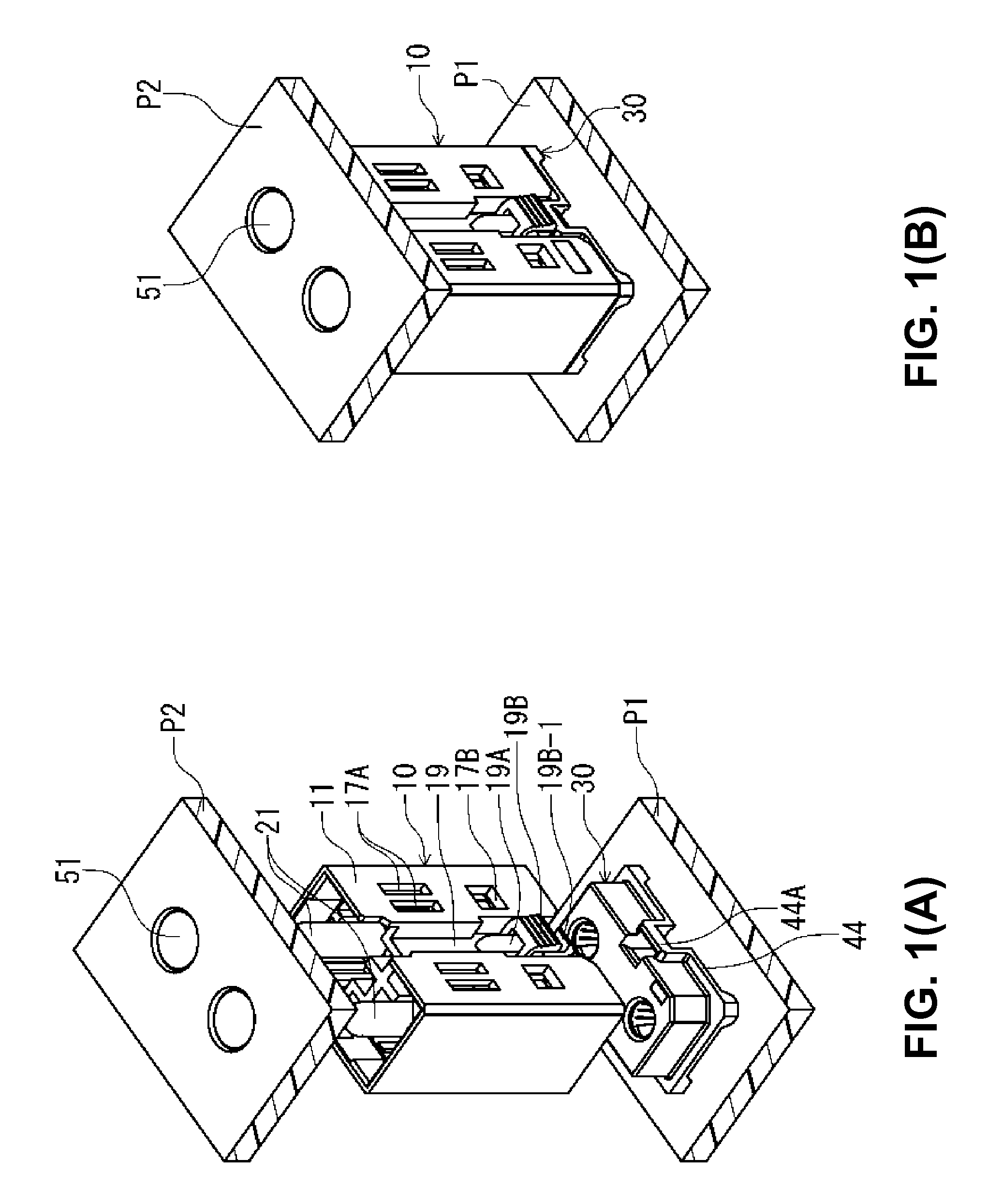

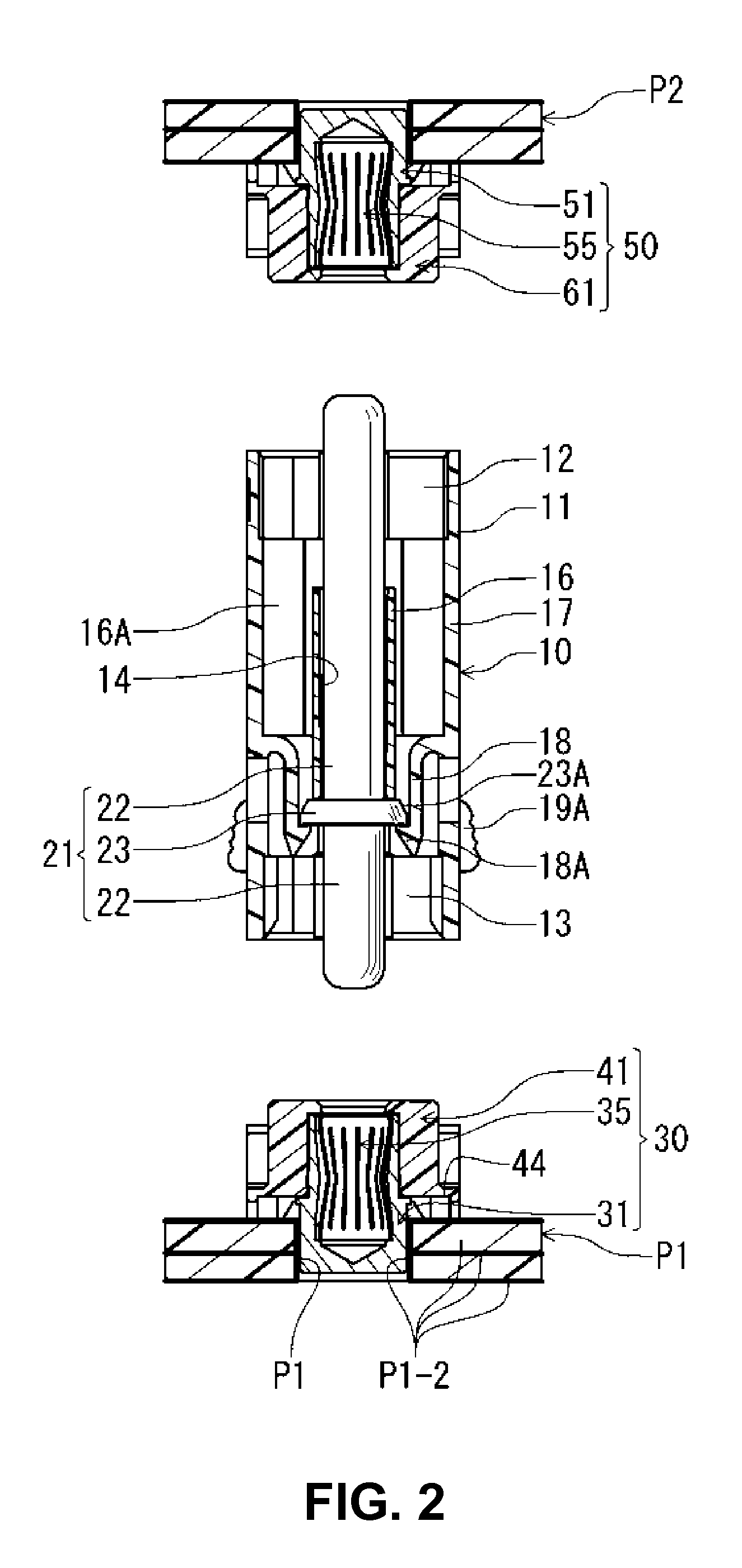

Electrical connector assembly

ActiveUS8734167B2Prevent the elastic tubular member retainedMore elasticCoupling device detailsPrinted circuitsEngineeringElectrical connector

An electric connector assembly includes an intermediate connector for connecting the first attaching connector to the second attaching connector. The intermediate connector includes a power source terminal. The first attaching connector includes a first receiving terminal for contacting with the power source terminal, and the second attaching connector includes a second receiving terminal for contacting with the power source terminal. One of the first receiving terminal and the power source terminal and one of the second receiving terminal and the power source terminal include a metal cylindrical member capable of elastically deforming in a radial direction. Therefore, the power source terminal can incline and move in the radial direction at an arbitrary angle along a circumferential direction around an axial line of the power source terminal. The elastic cylindrical member includes a circumference elastically contacting with the power source terminal, the first receiving terminal, and the second receiving terminal.

Owner:HIROSE ELECTRIC GROUP

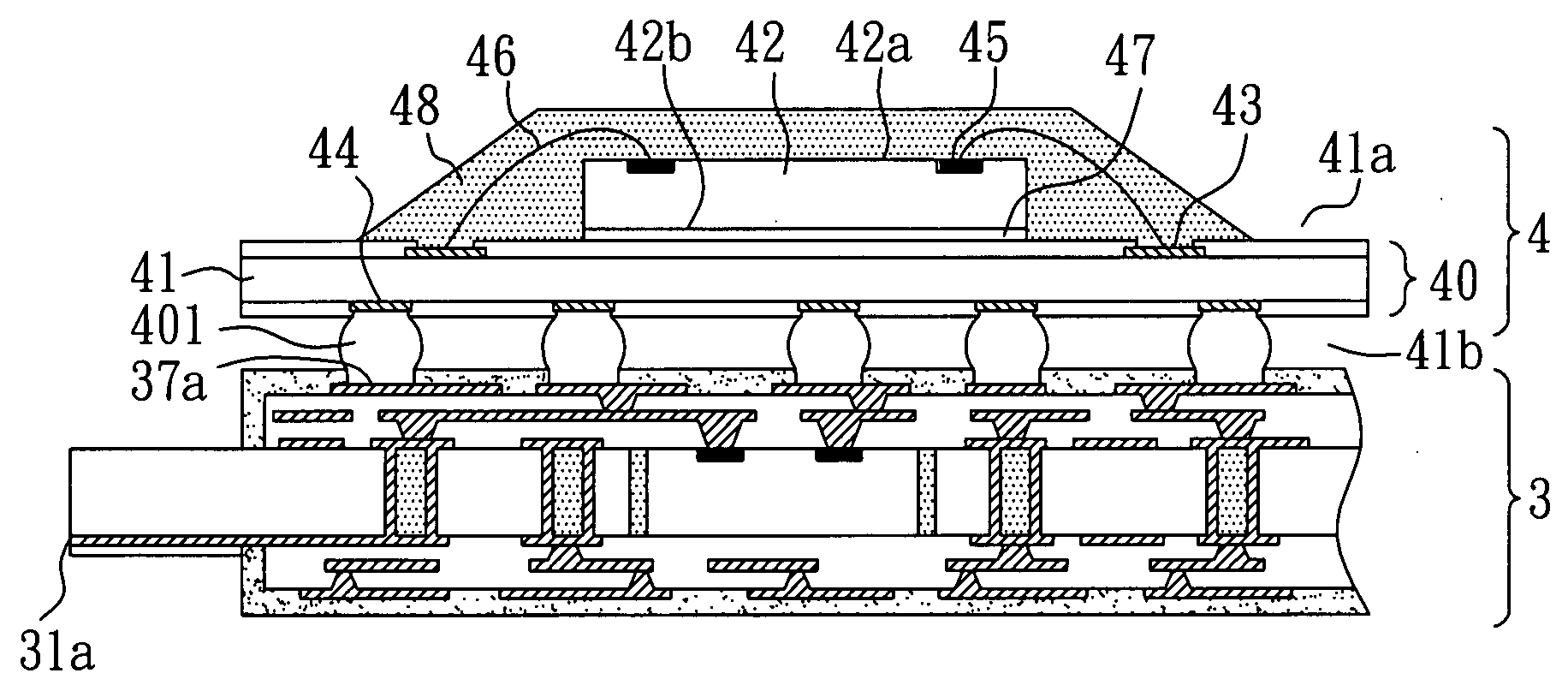

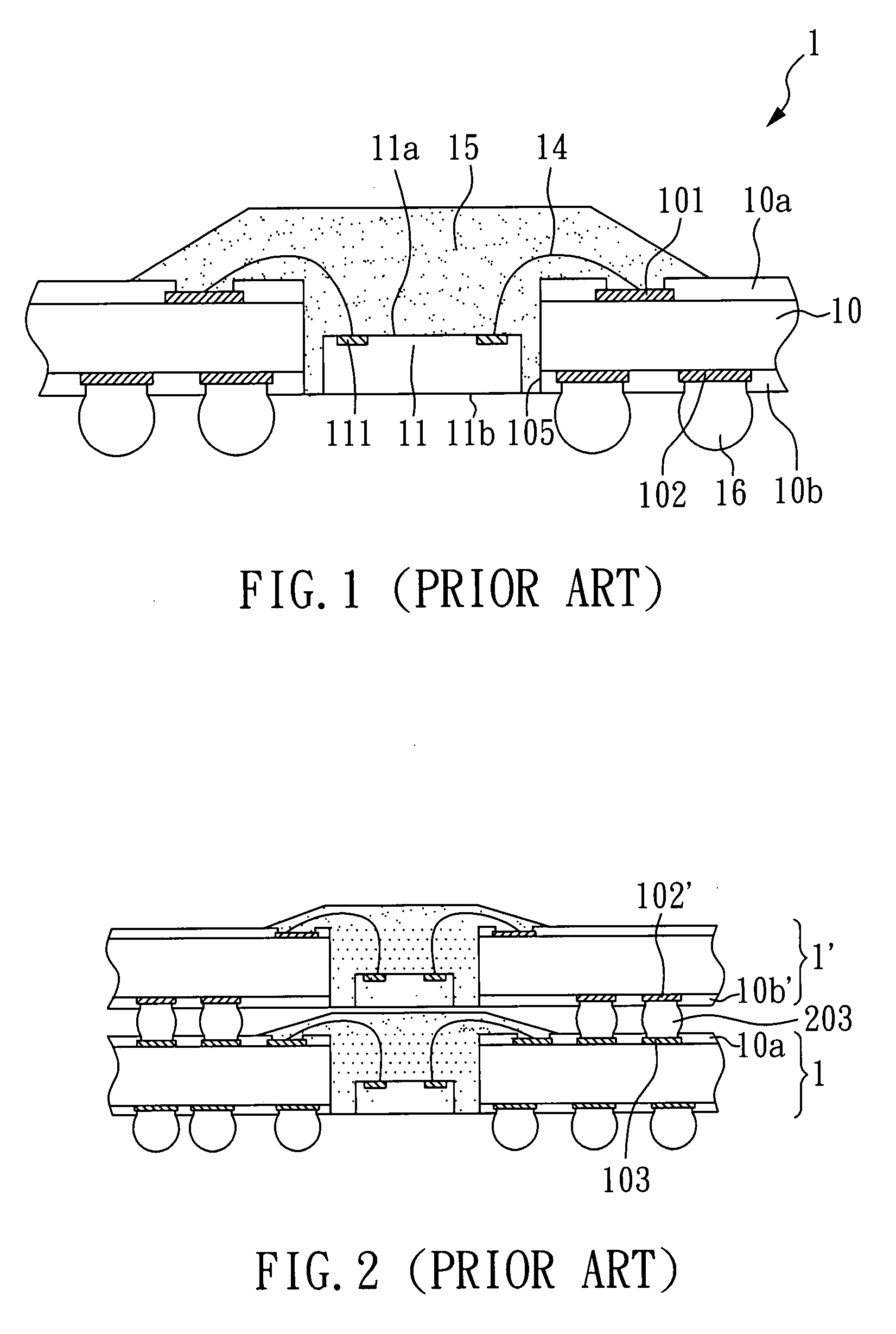

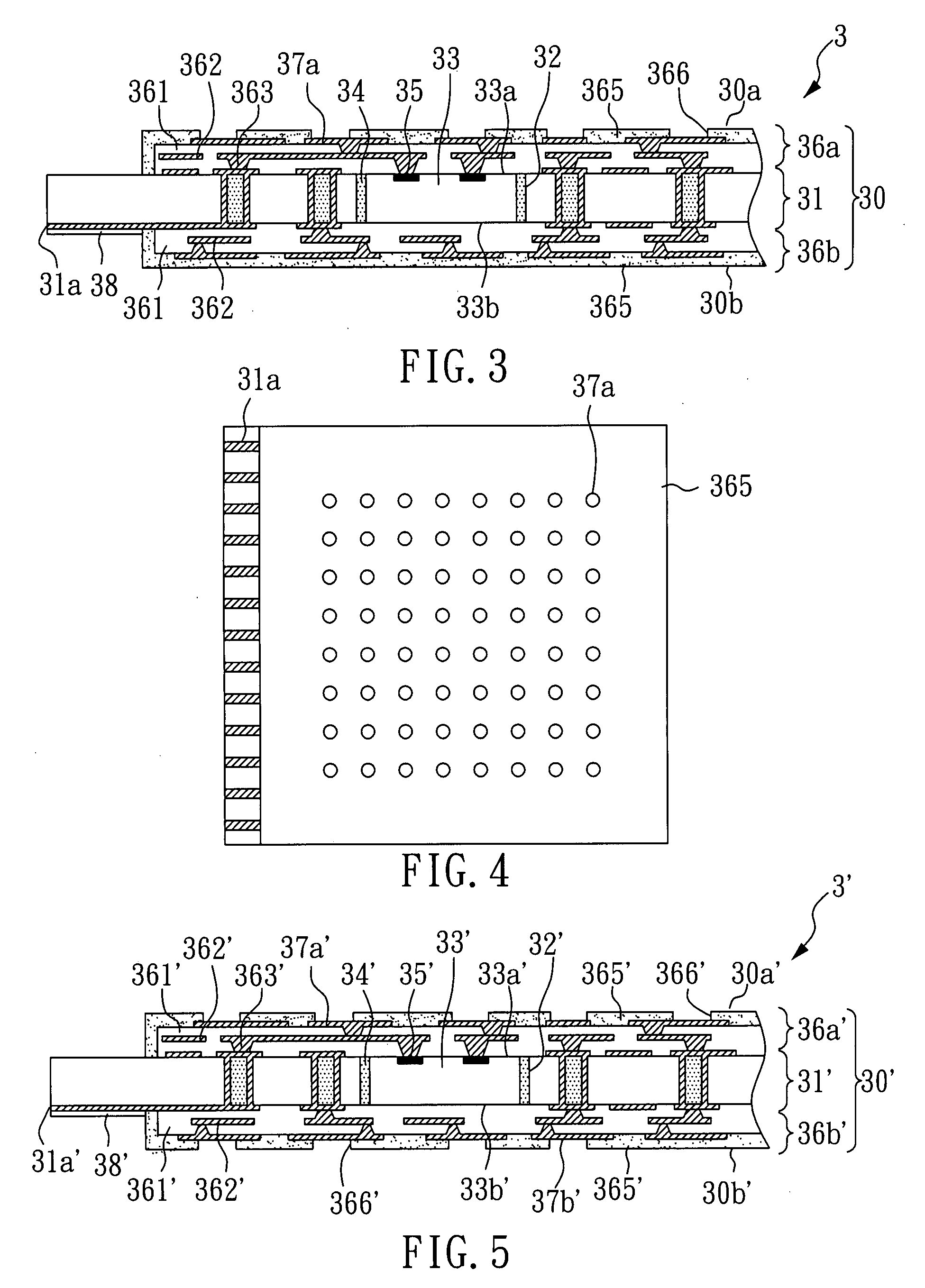

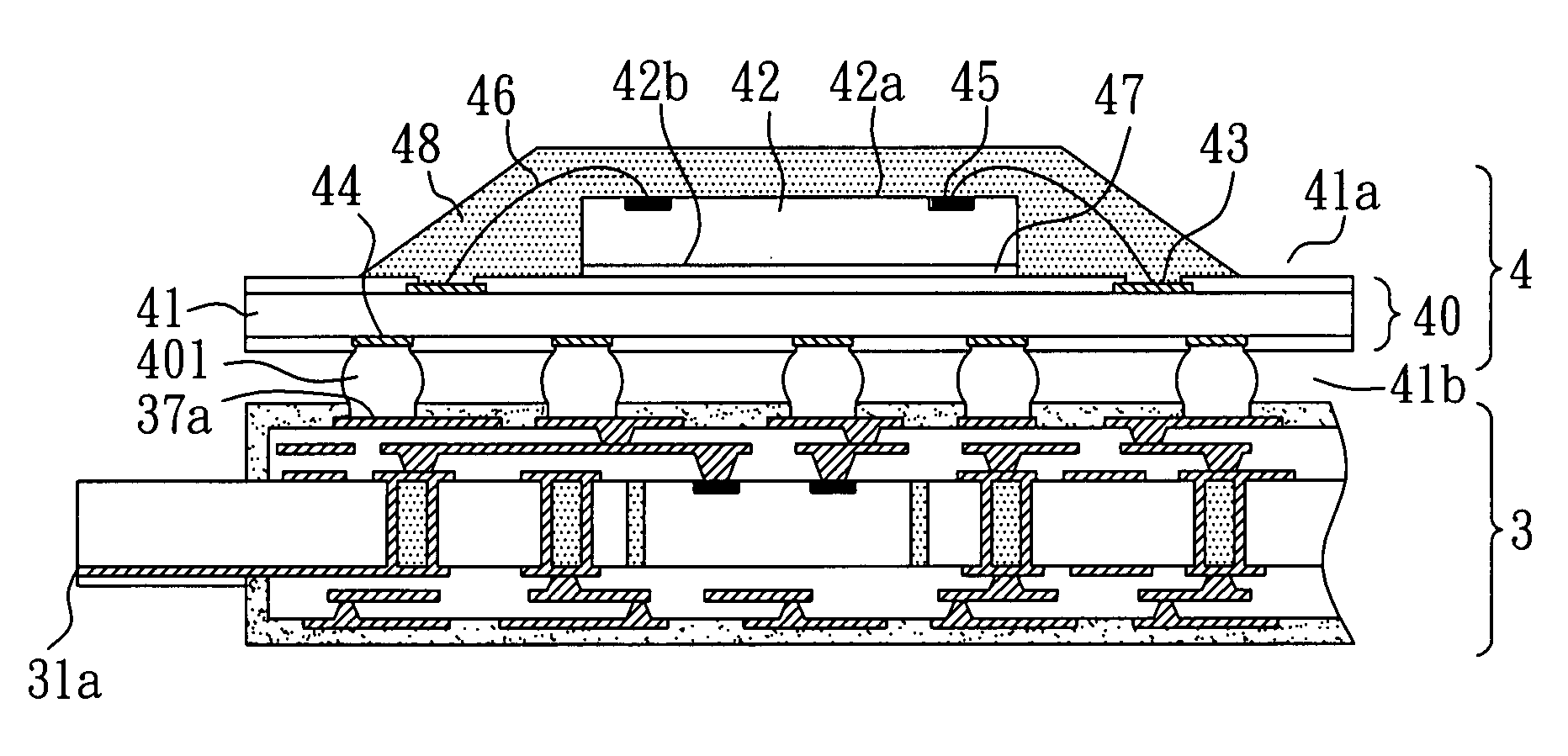

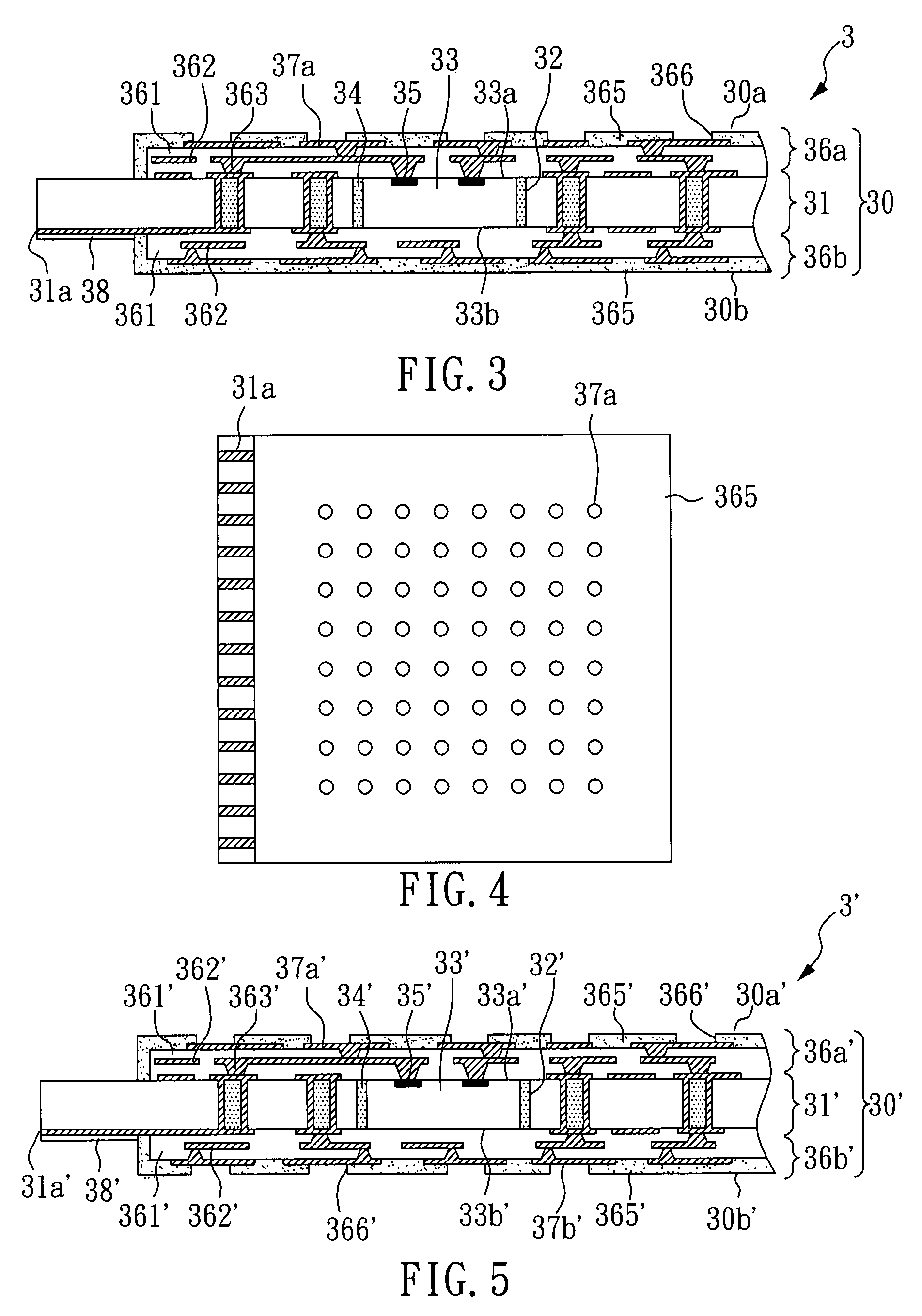

Stacked package module

ActiveUS20080246135A1Size moreMore elasticSemiconductor/solid-state device detailsPrinted circuit aspectsSolder ballEngineering

A stacked package module is disclosed, which comprises: a first package structure comprising a first circuit board with a first chip embedded therein, wherein the first chip has a plurality of electrode pads; the first circuit board comprises a first surface, an opposite second surface, a plurality of exposed electro-connecting ends, a plurality of first conductive pads on the first surface, a plurality of conductive vias, and at least one circuit layer, therewith the electrode pads of the first chip electrically connecting to the electro-connecting ends and the first conductive pads directly through the conductive vias and the circuit layer; and a second package structure electrically connecting to the first package structure through a plurality of first solder balls to make a package on package. The stacked package module of this invention has characters of compact size, high performance, high flexibility, and detachability.

Owner:UNIMICRON TECH CORP

Stacked package module and board having exposed ends

ActiveUS7968991B2Size moreMore elasticSemiconductor/solid-state device detailsPrinted circuit aspectsSolder ballComputer module

Owner:UNIMICRON TECH CORP

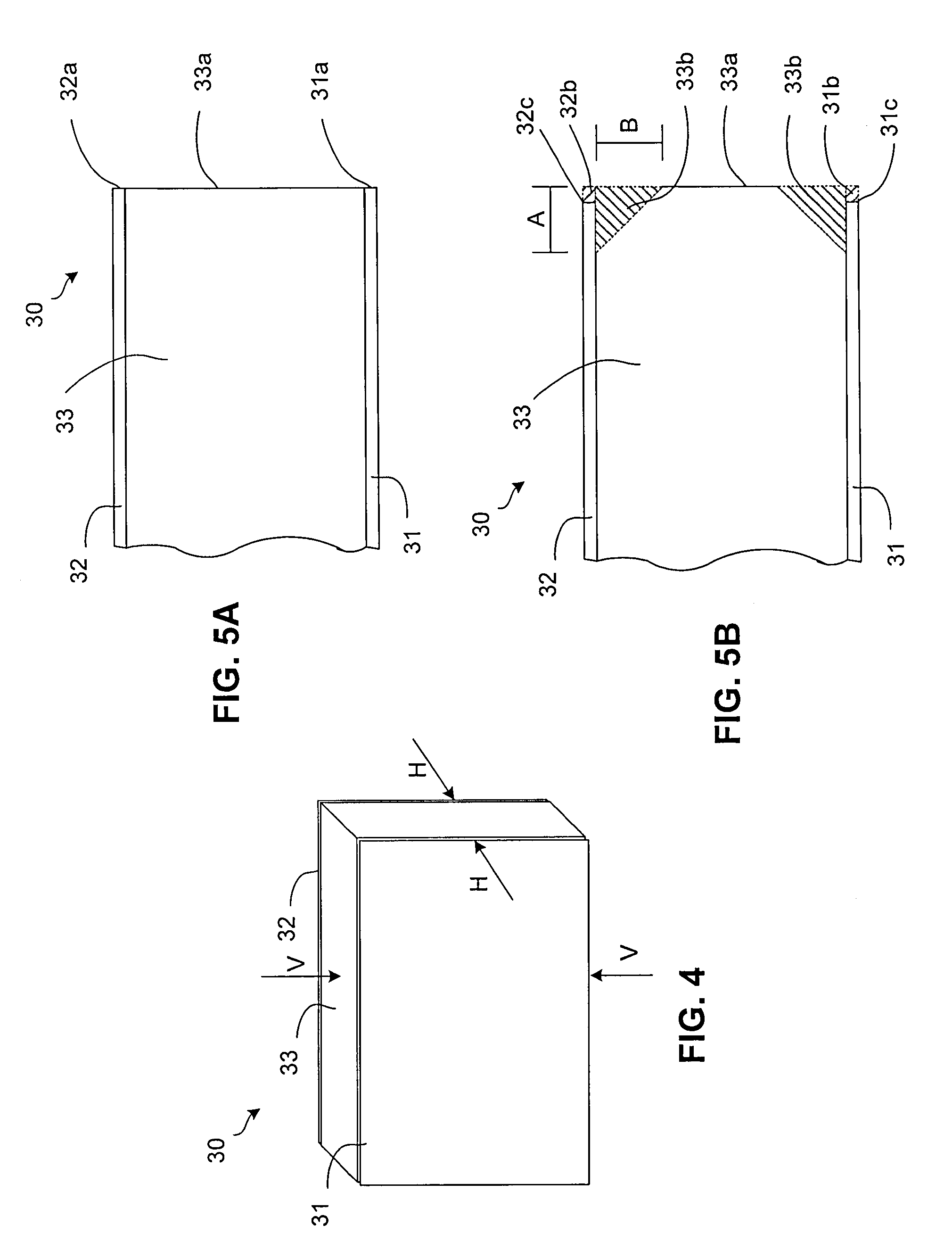

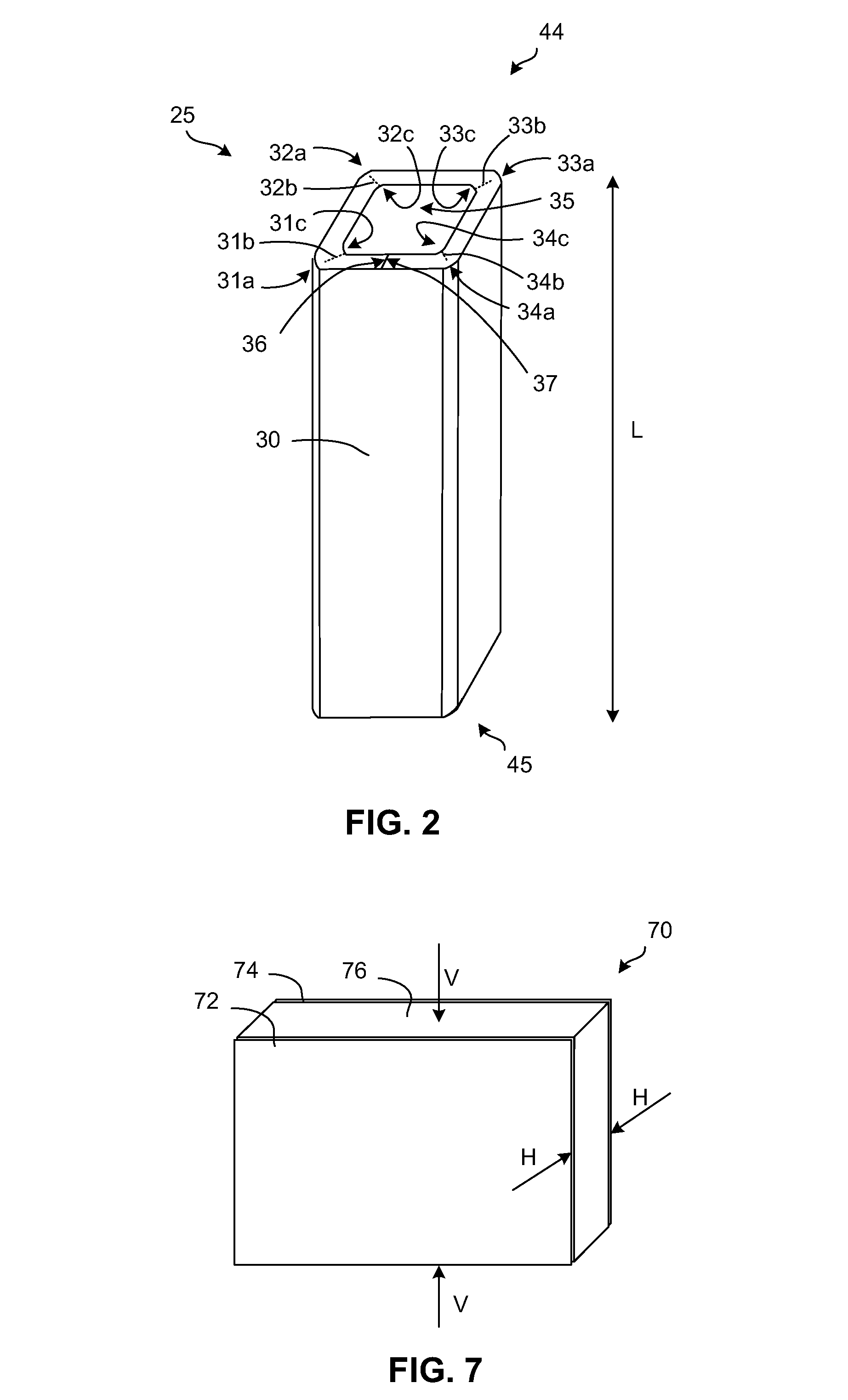

Sandwich panel with closed edge and methods of fabricating

InactiveUS20090255213A1Great strength to weight ratioLight weightLaminationLamination apparatusEngineeringSandwich panel

The edge of a construction element, such as a sandwich panel having a core and two outer layers, is closed such that forces acting on the construction element are directed to the outer layers and generally not through the panel core. A portion of the core may be removed to define a cavity within the construction element. A bonding material closes the edge by filling the cavity and forming a new edge that is substantially coplanar to the edges of the outer layers. The edge also can be closed by inserting the edge into a U-profile bracket and connecting the outer layers of the panel to side walls of the U-profile bracket.

Owner:MILLPORT ASSOC

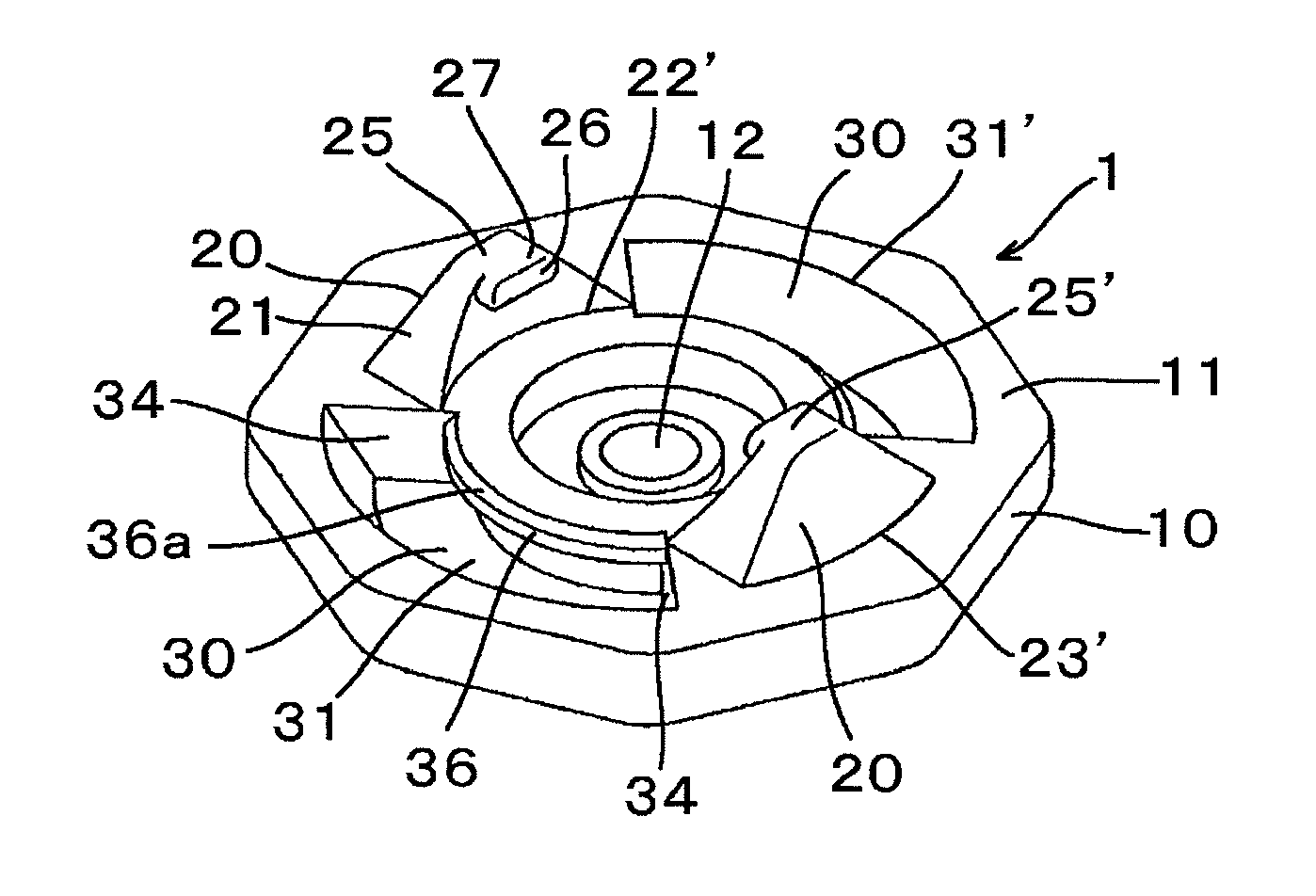

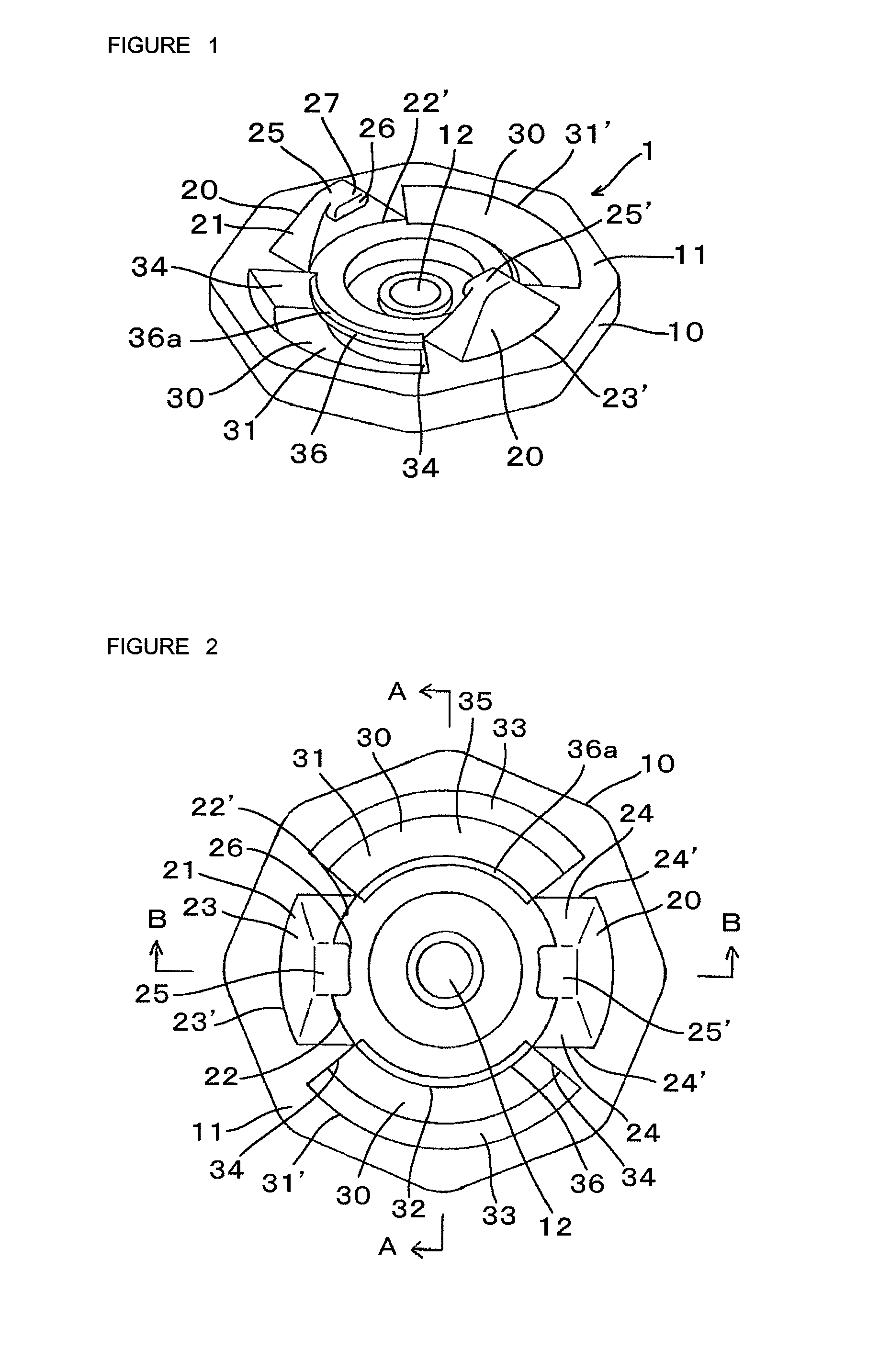

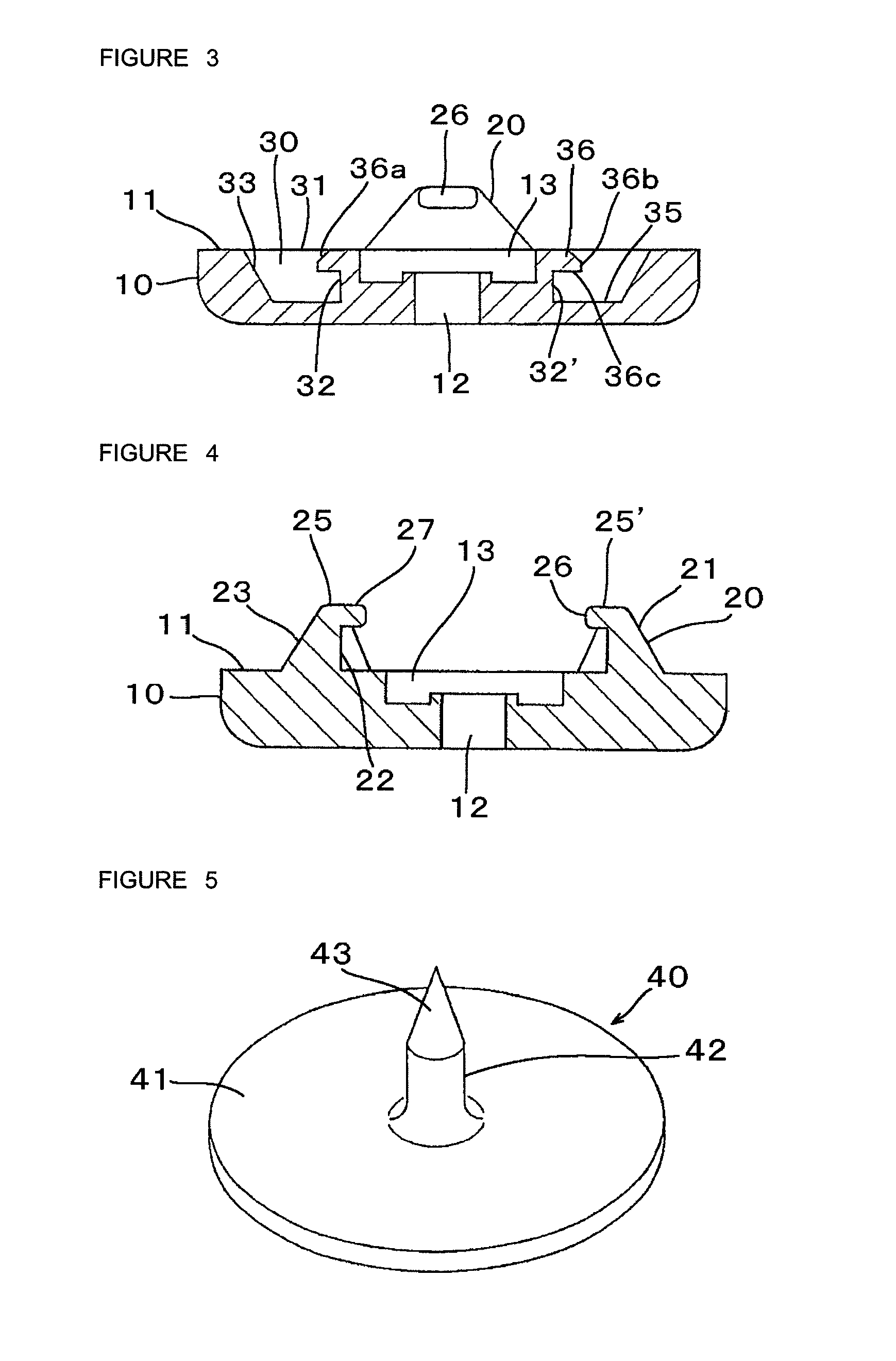

Snap button

ActiveUS8484813B2Little strengthMore elasticSnap fastenersRopes and cables for vehicles/pulleyEngineering

Owner:YKK CORP

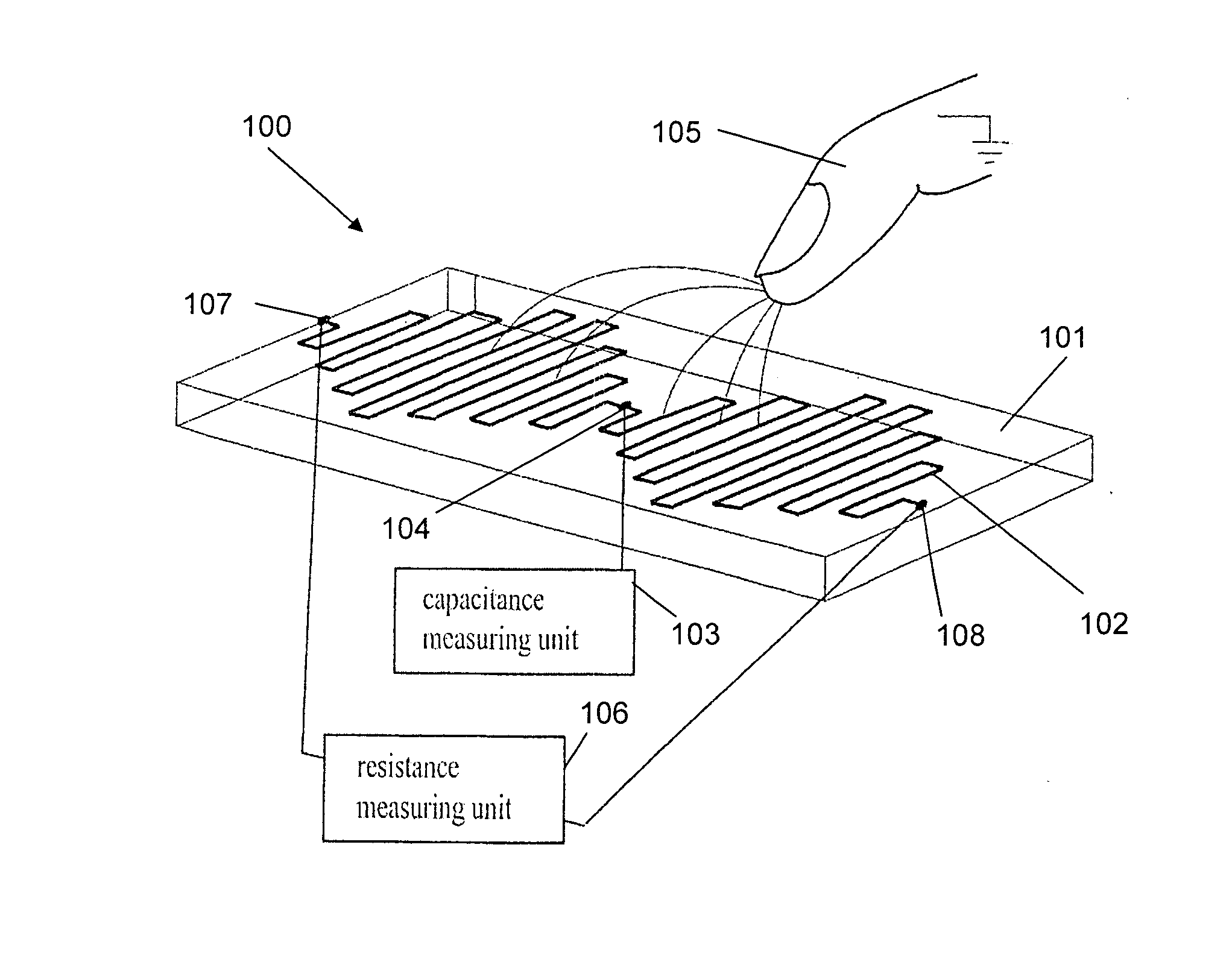

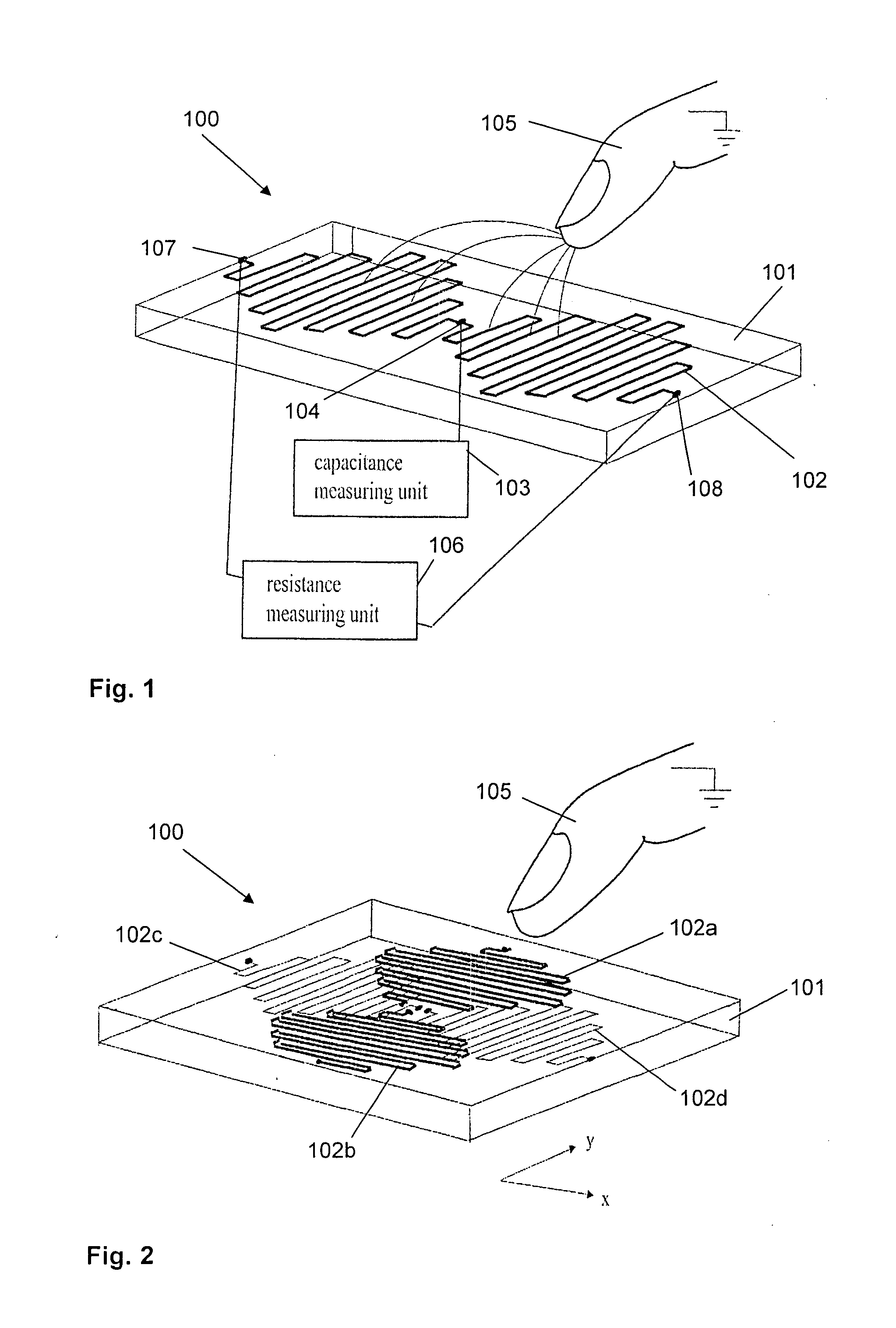

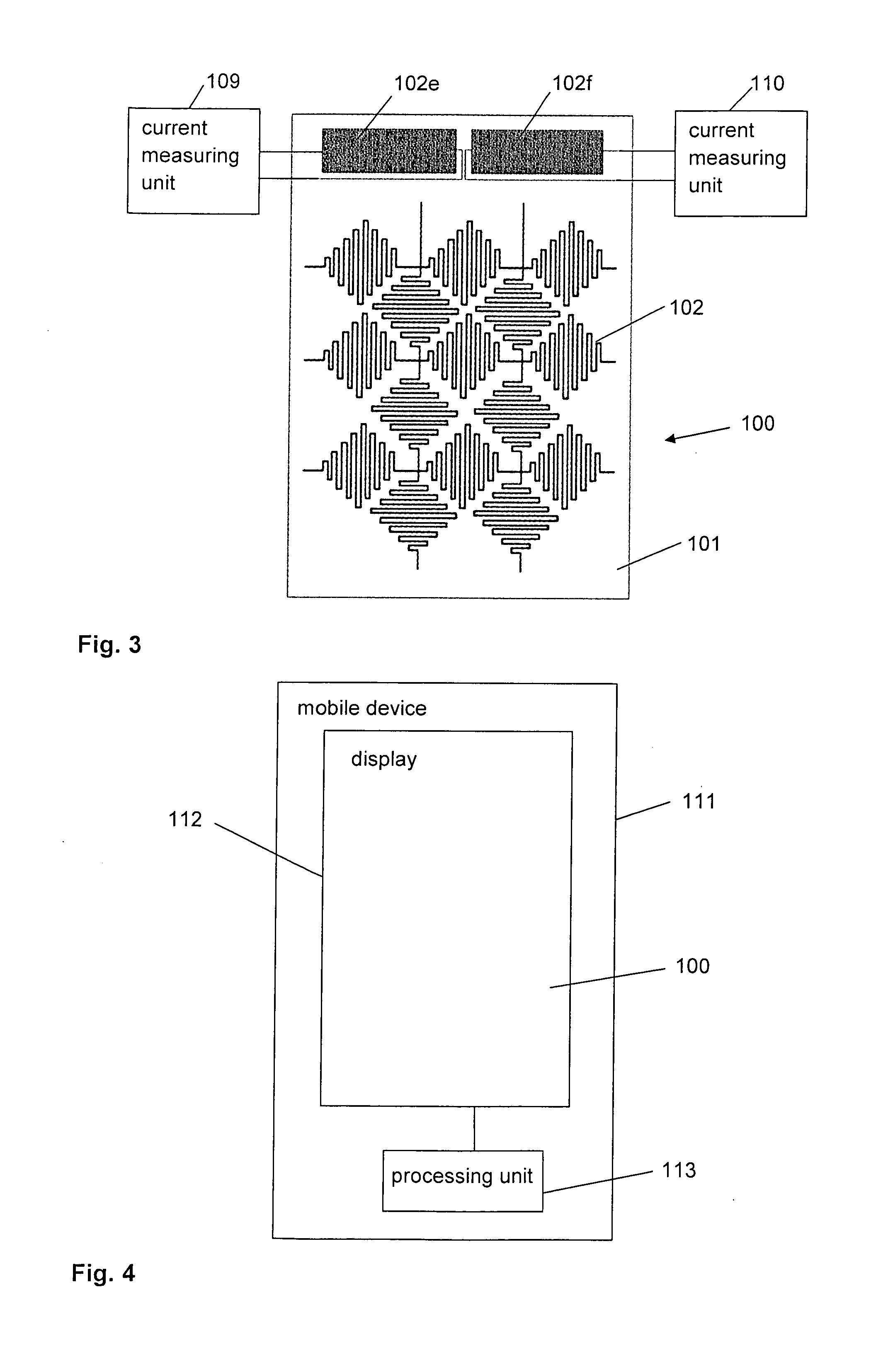

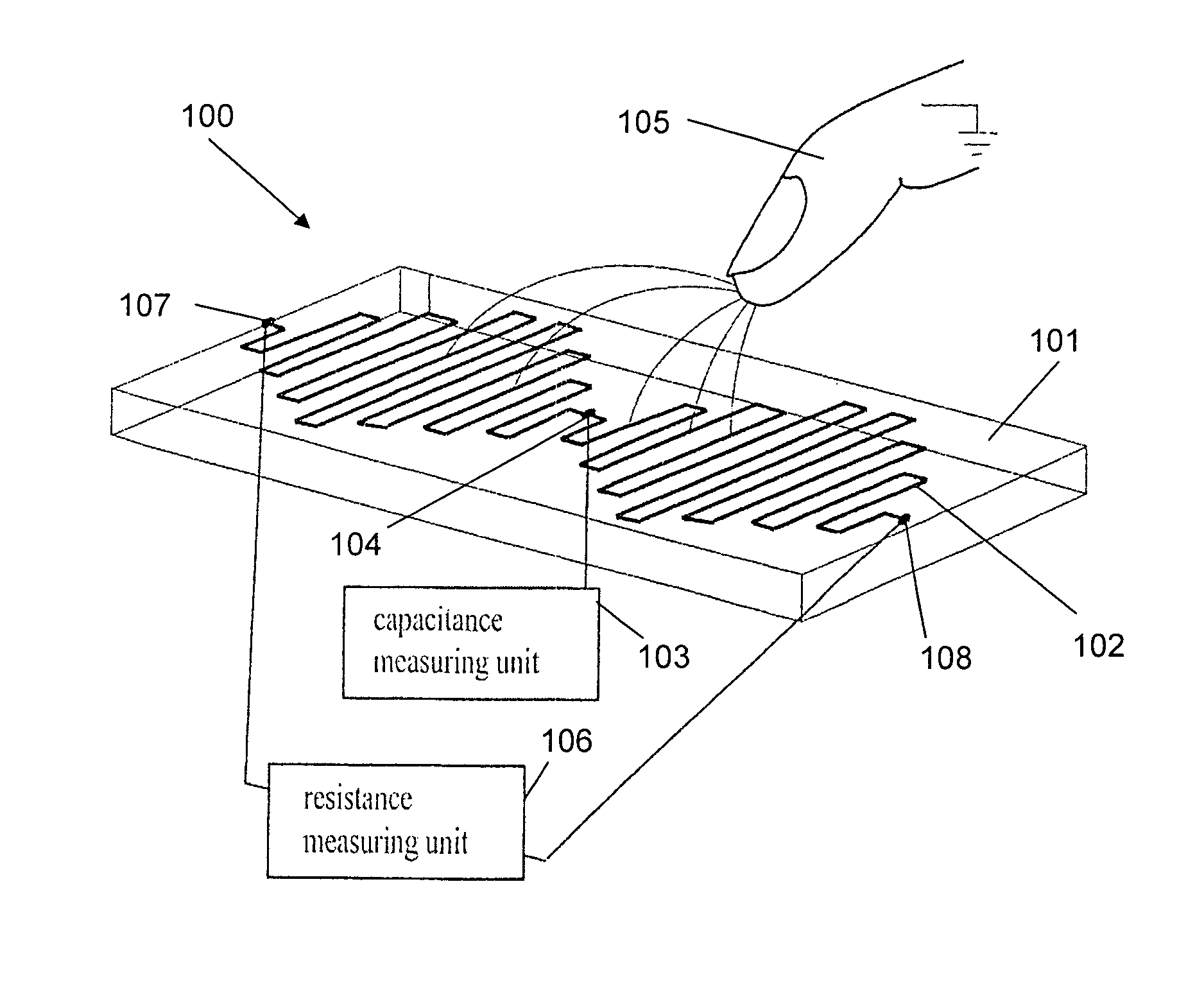

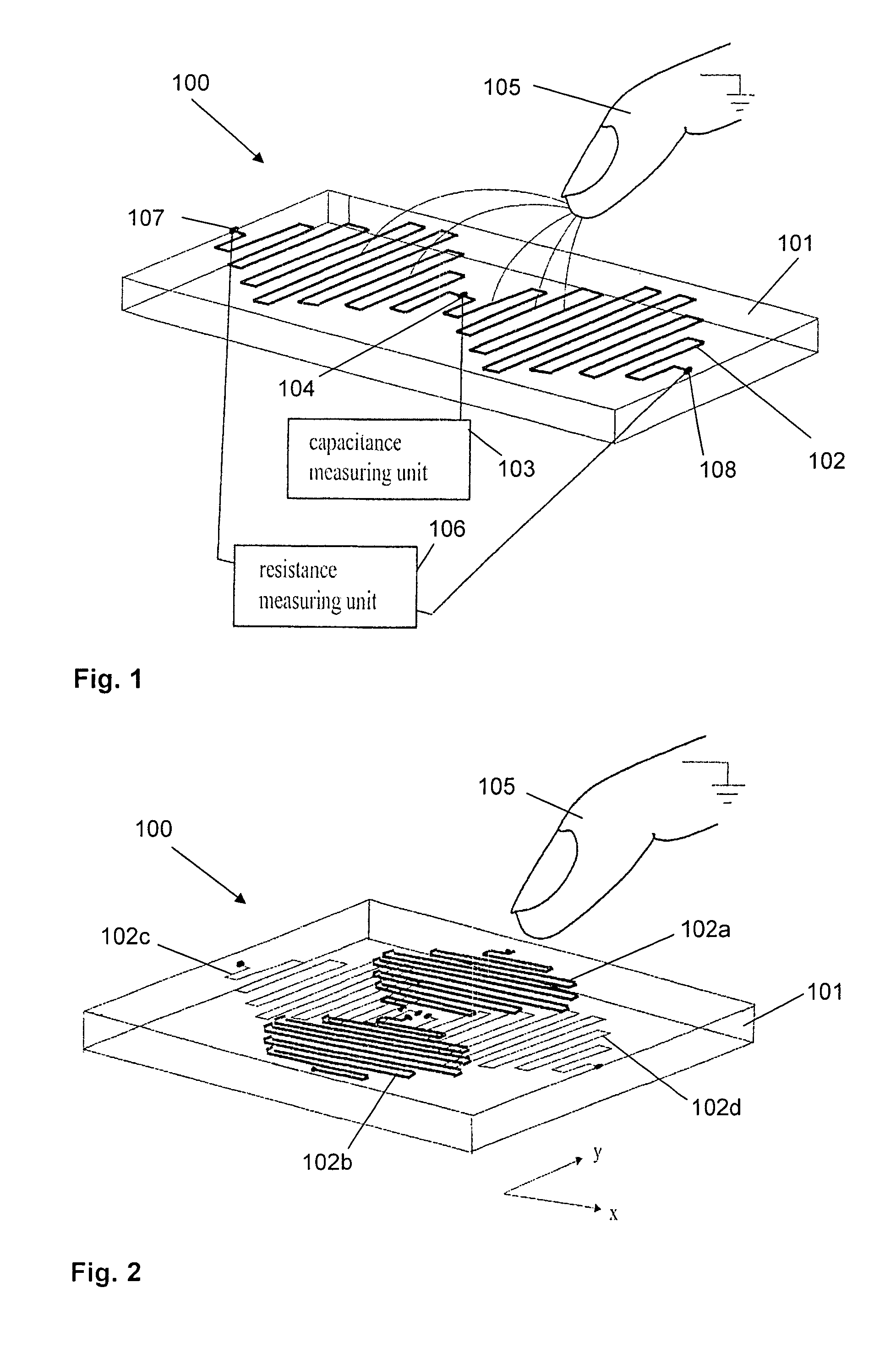

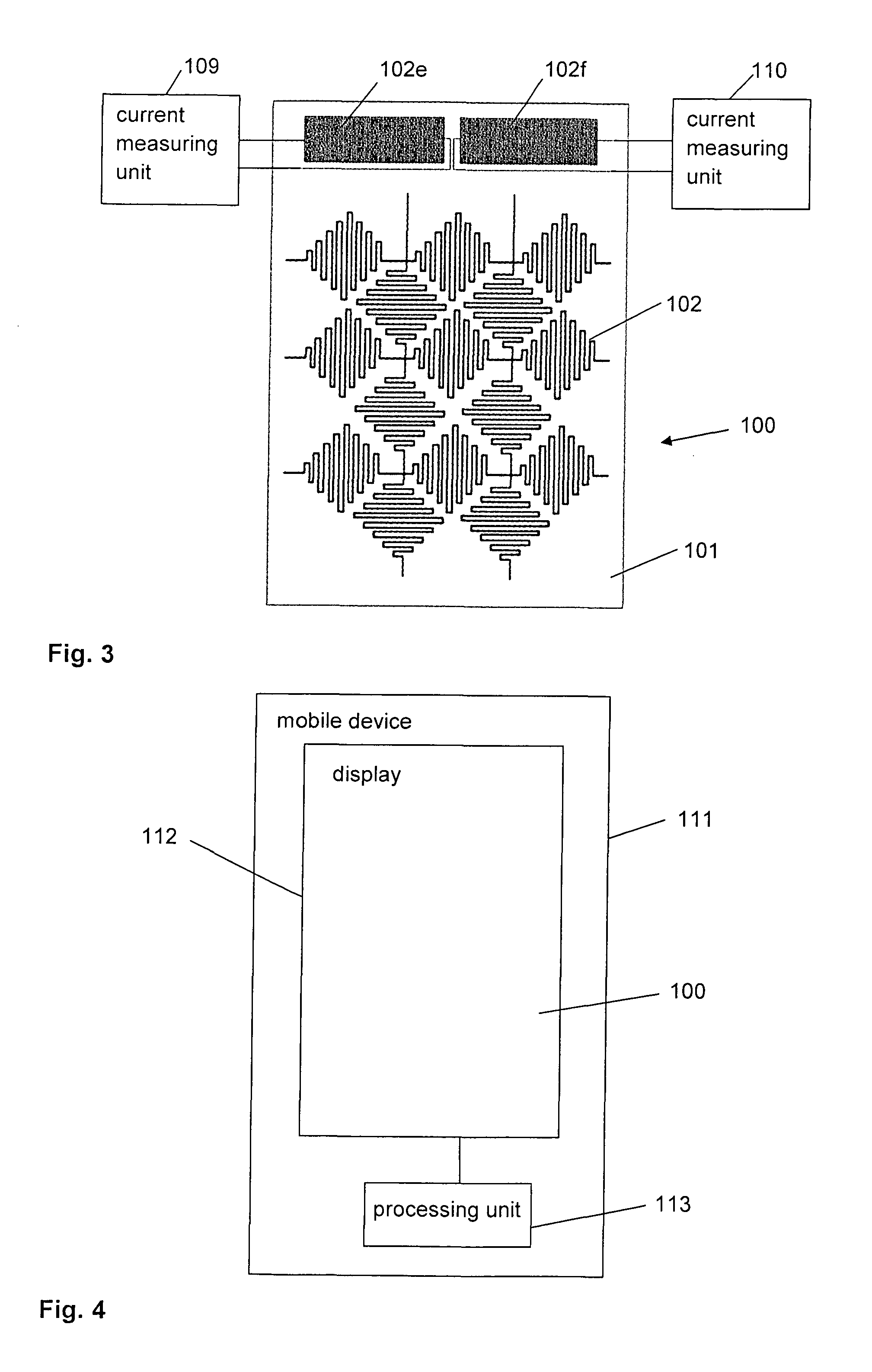

Force sensitive touch sensor

ActiveUS20140216174A1Accurate force measurementWider toleranceForce measurement using piezo-resistive materialsApparatus for force/torque/work measurementElectrical resistance and conductanceSensitive touch

A force sensitive touch sensor (100) is provided. The sensor (100) comprises an insulating support layer (101) and an electrically conductive sensor structure (102). The electrically conductive sensor structure (102) comprises a piezoresistive material and is configured to provide a resistance varying in response to a force being applied to the insulating support layer (101). The piezoresistive material comprises graphene.

Owner:SONY CORP

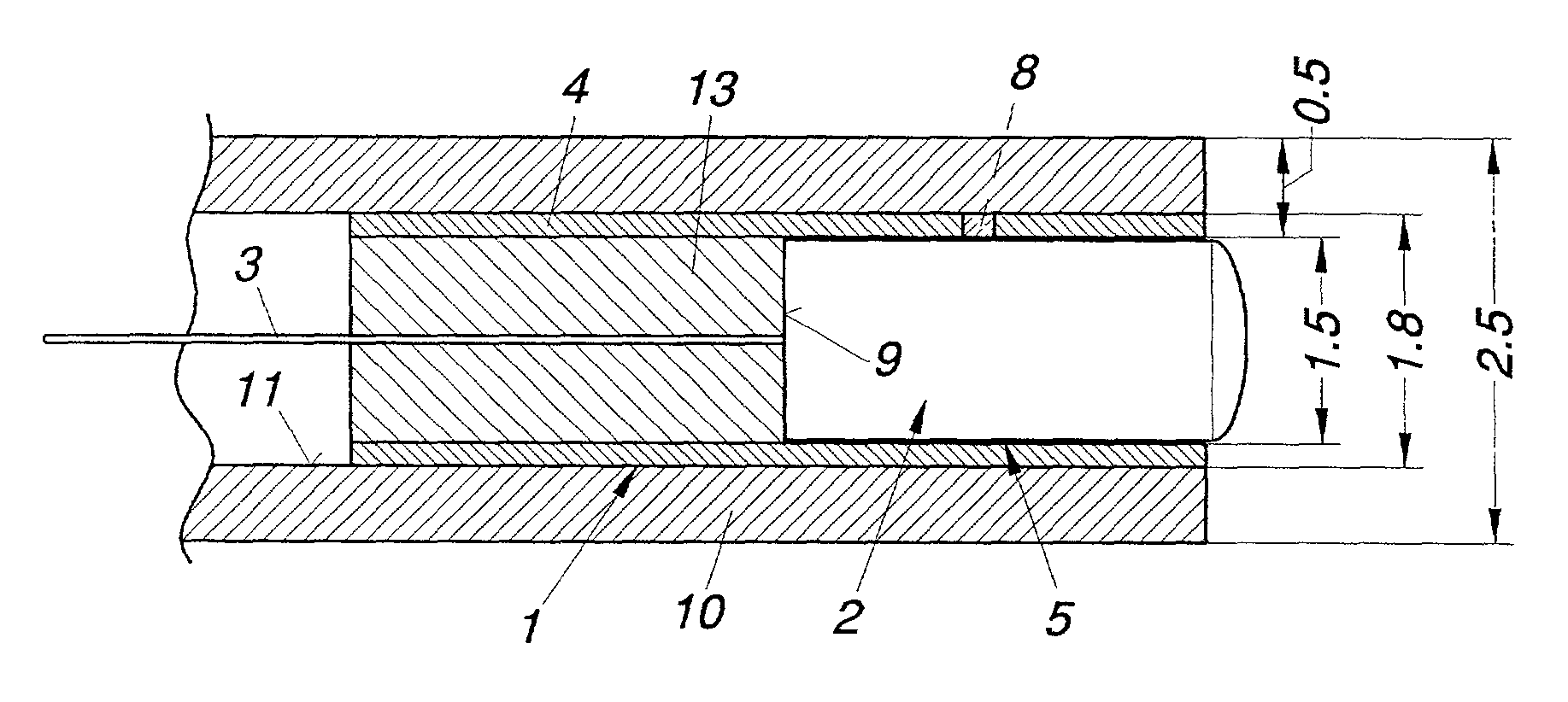

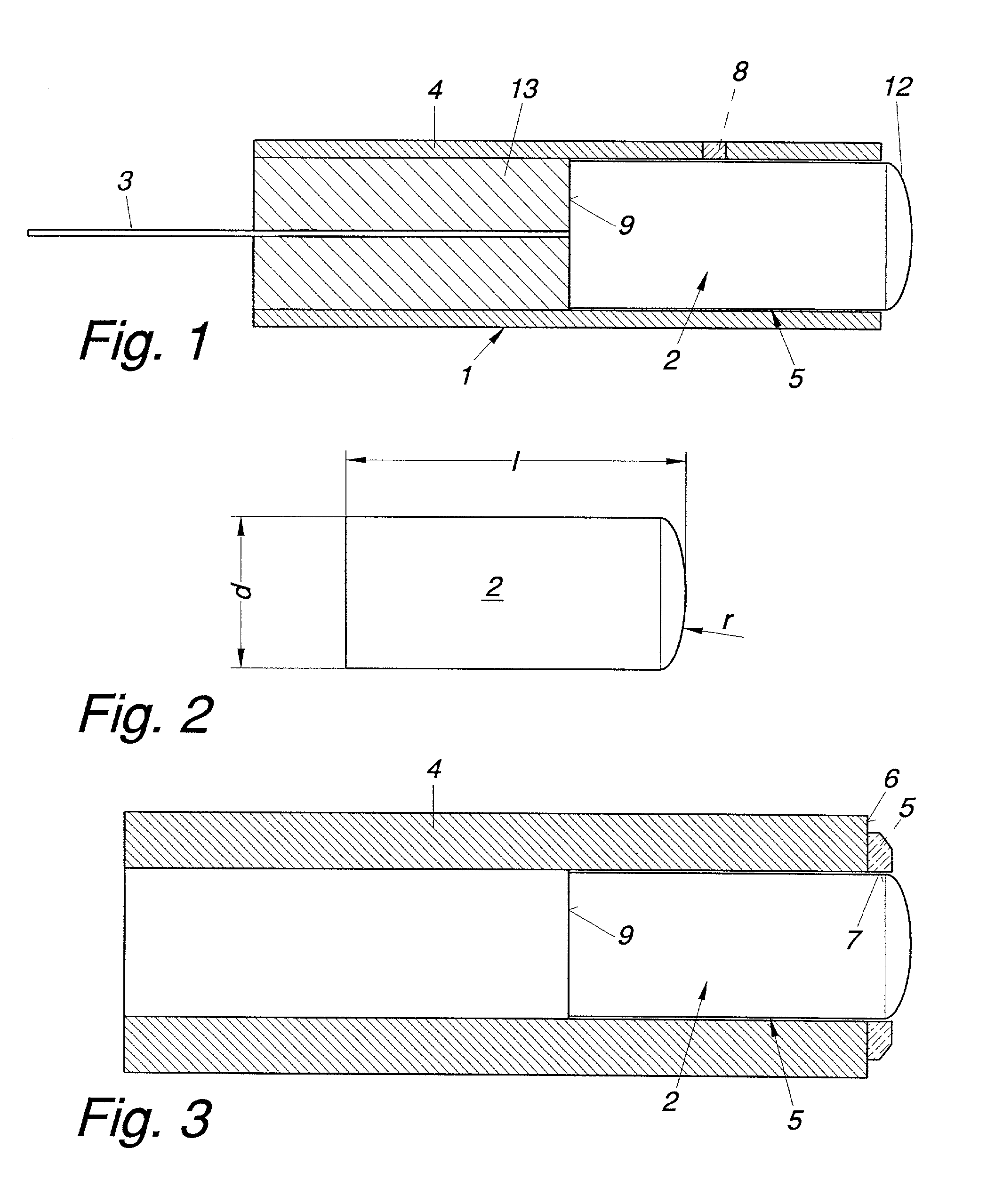

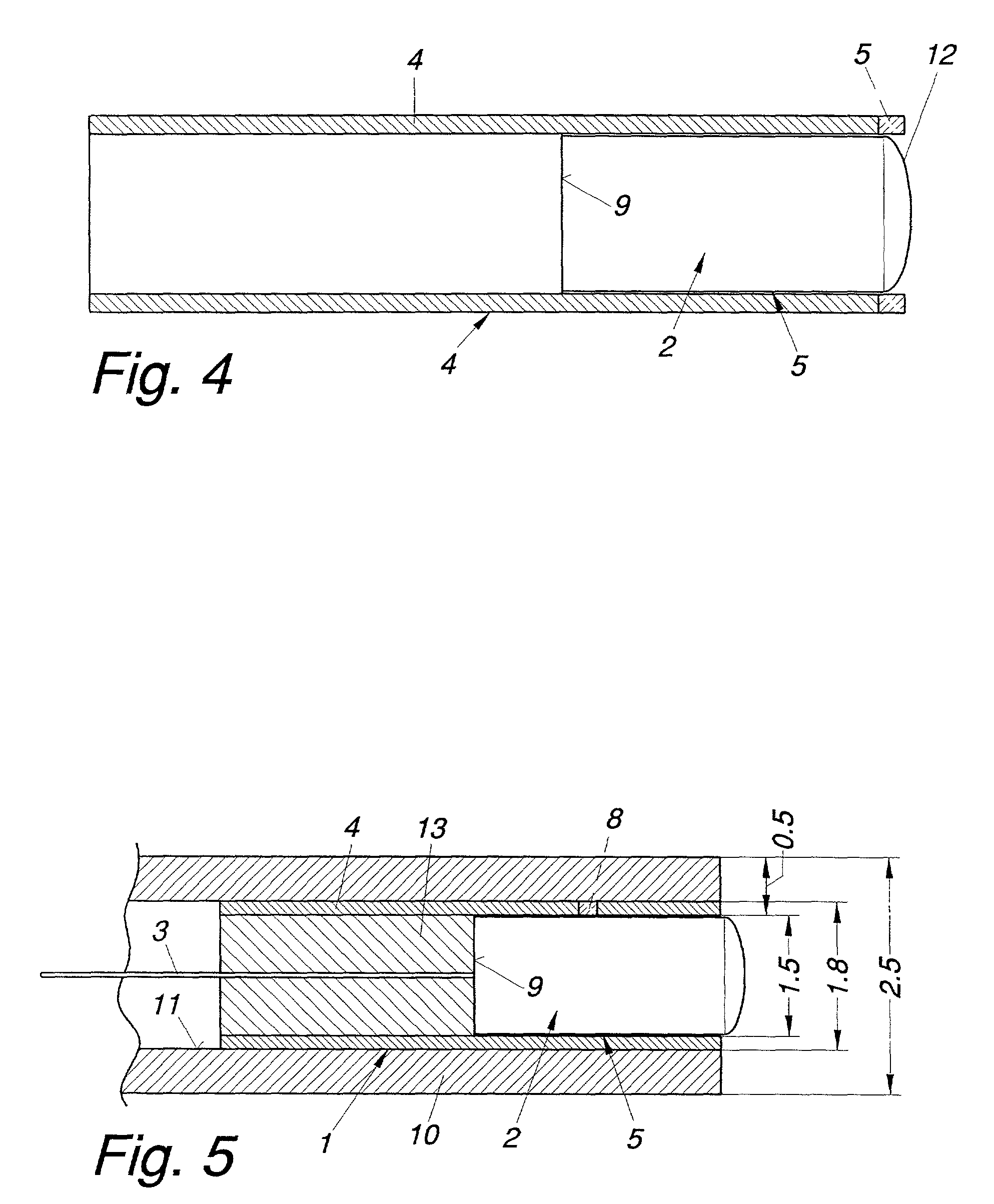

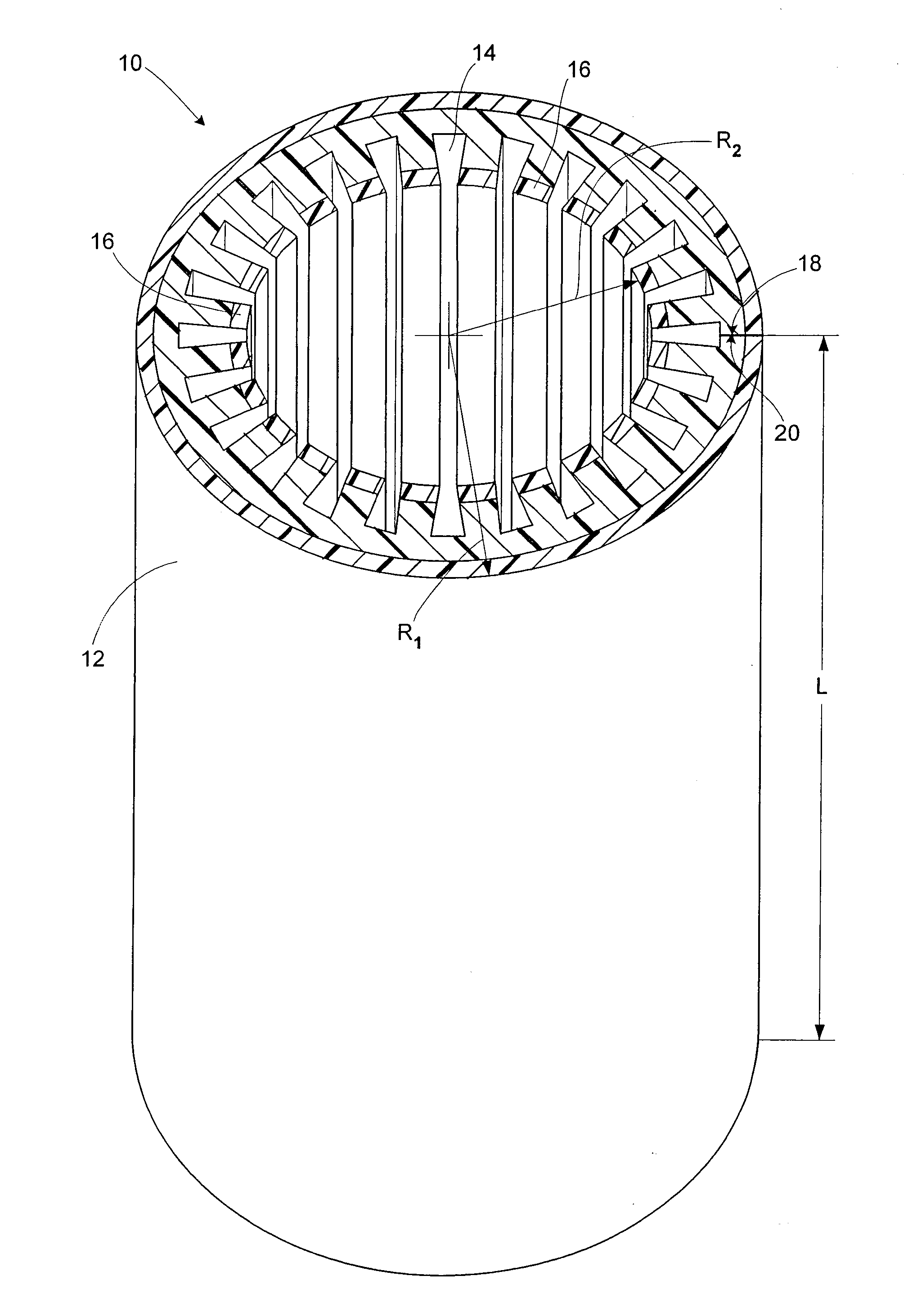

Optical sensor or emitter used for monitoring combustion processes

InactiveUS7007547B2Simple manufacturing processMore elasticInternal-combustion engine testingPhotometryCombustion chamberFiber bundle

An optical sensor or emitter (1) used for monitoring combustion processes in a combustion chamber is provided with an optical element (2) on a side facing the combustion chamber and an optical fiber or fiber bundle (3) on a side opposite the combustion chamber, the optical element and optical fiber / fiber bundle being jointly held in a metal sleeve (4). An annular gap filled with solder material (5) is provided between the optical element (2) and the inside of the metal sleeve (4).

Owner:AVL LIST GMBH

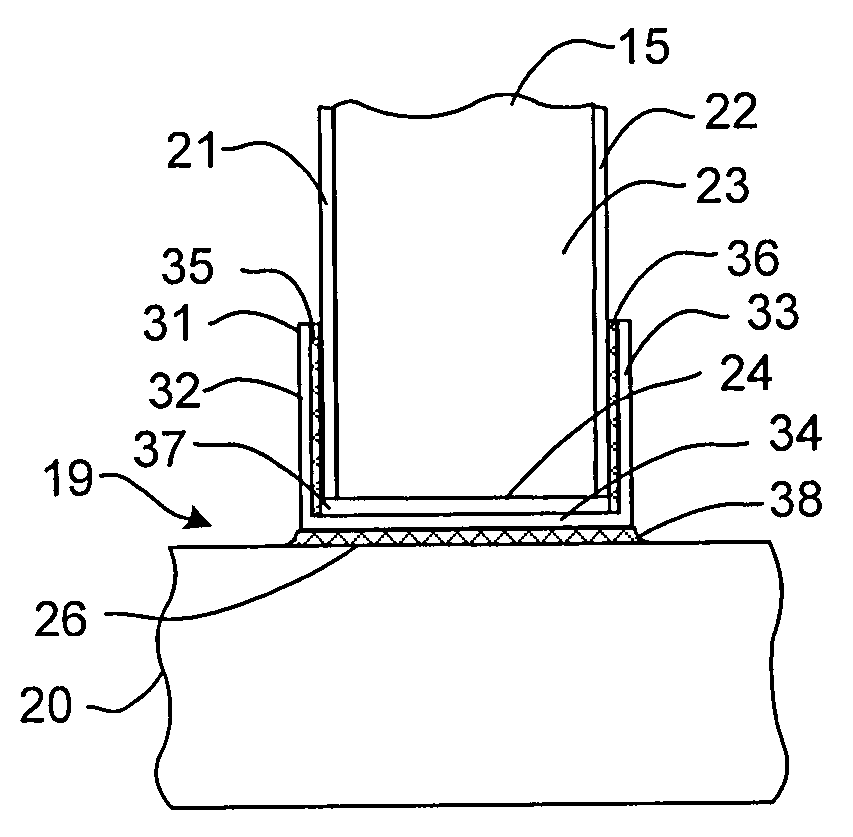

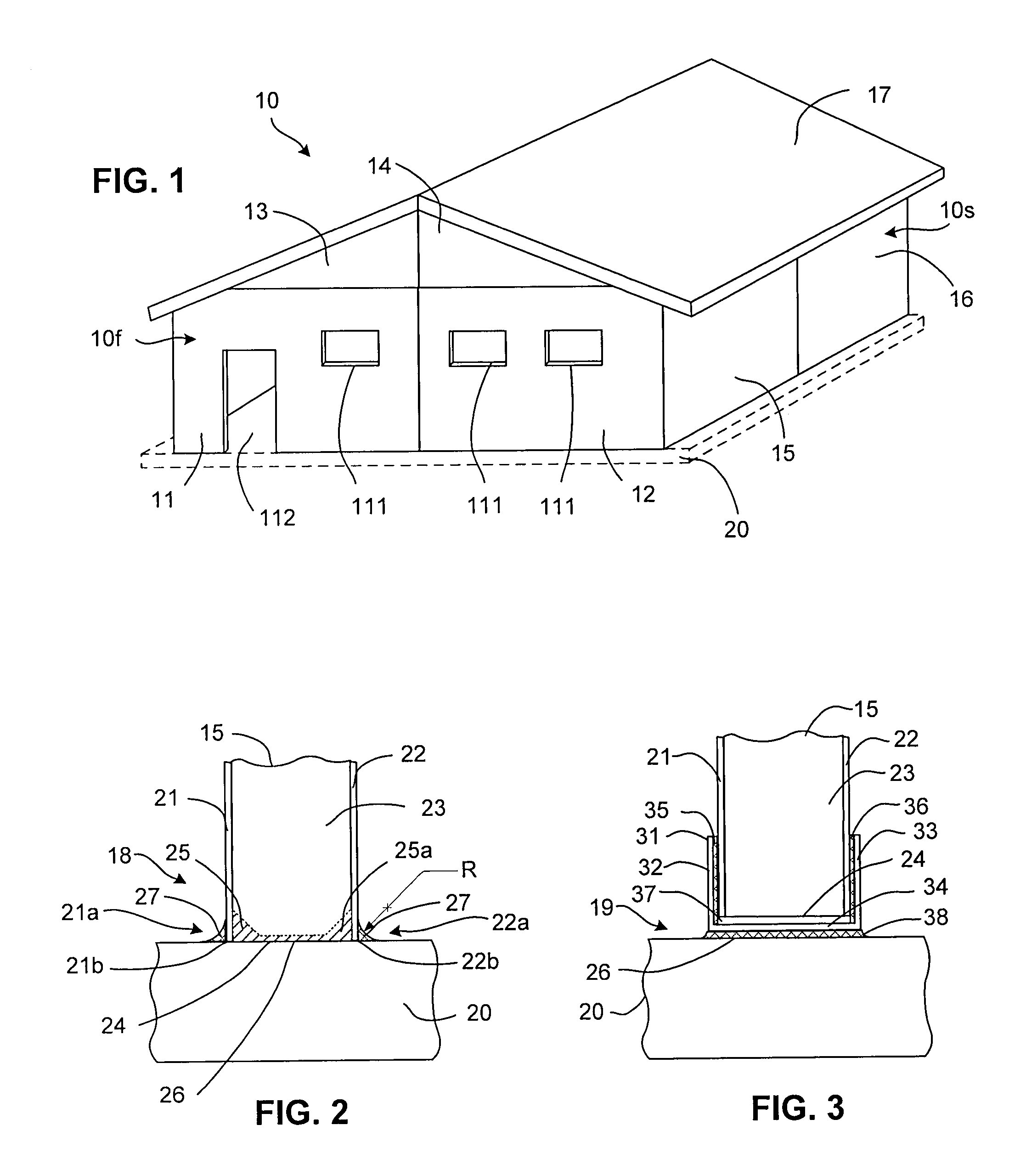

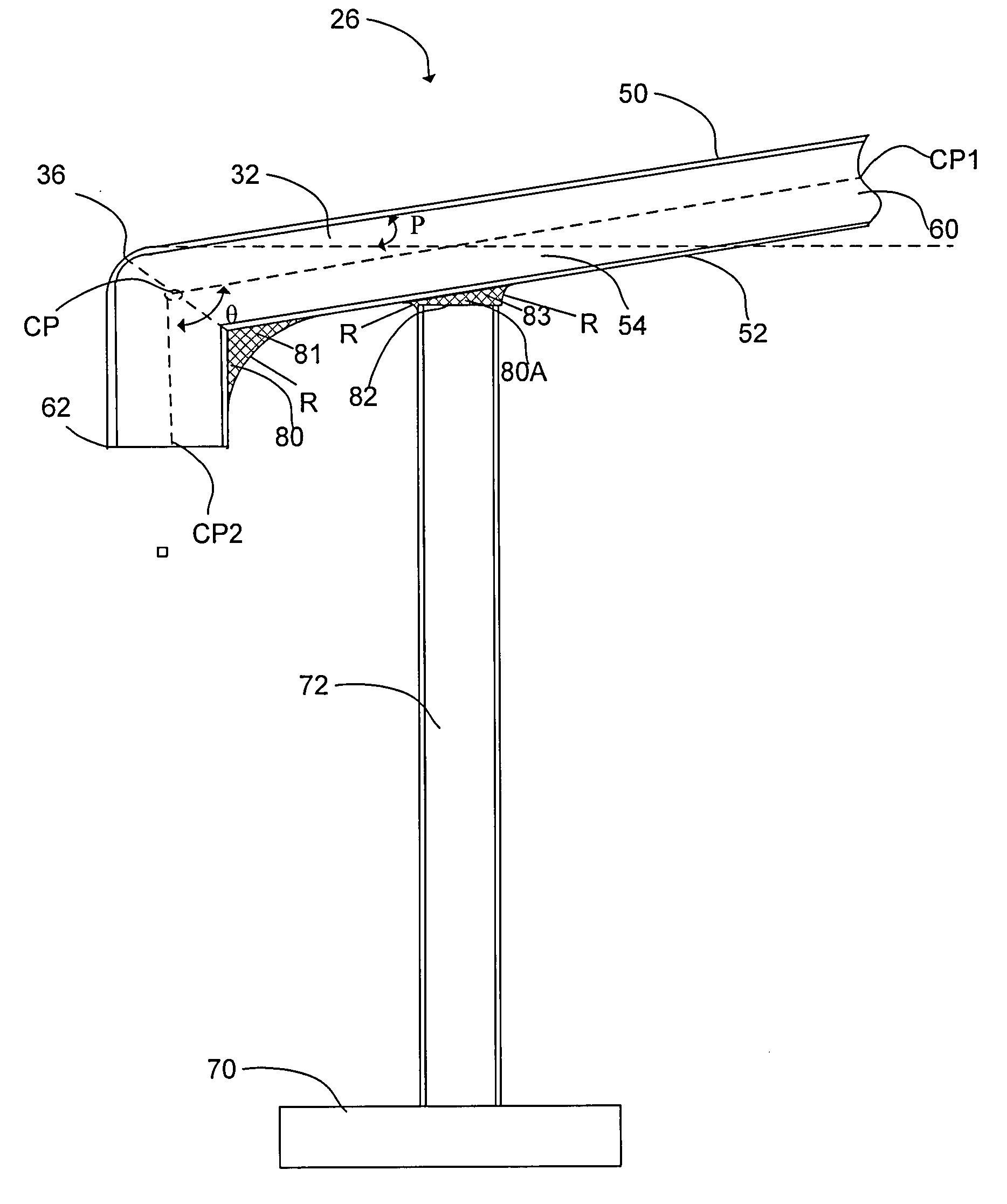

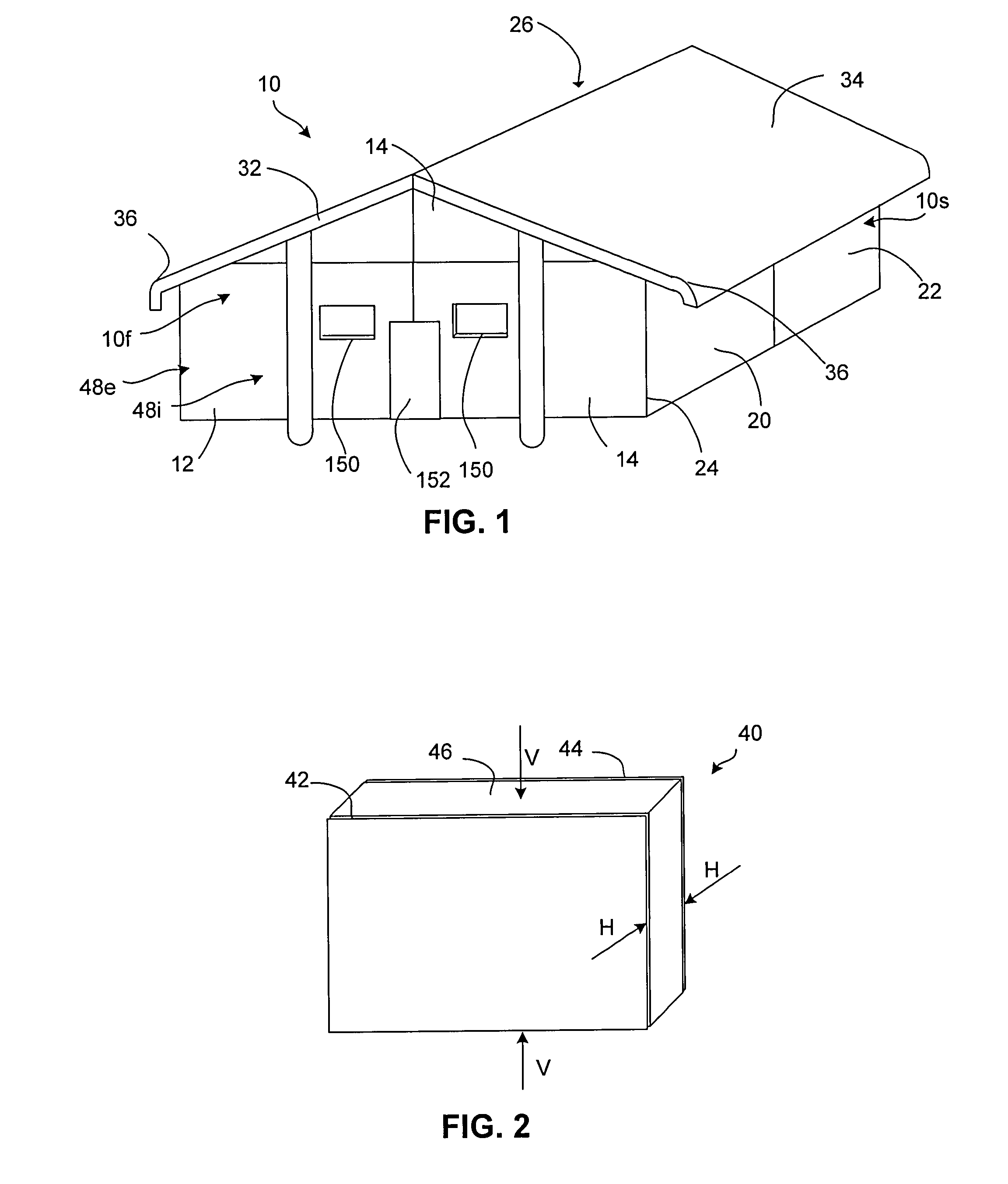

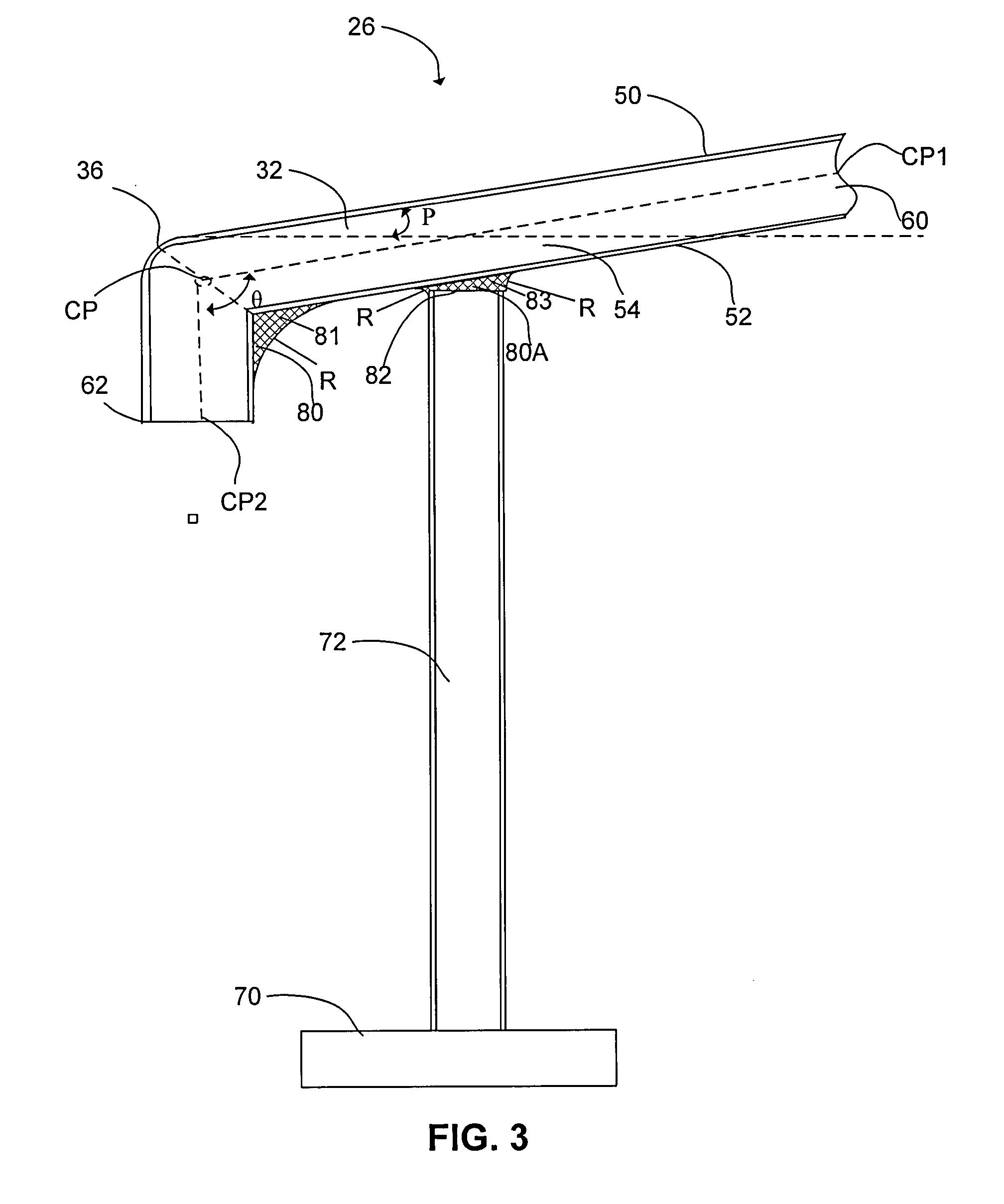

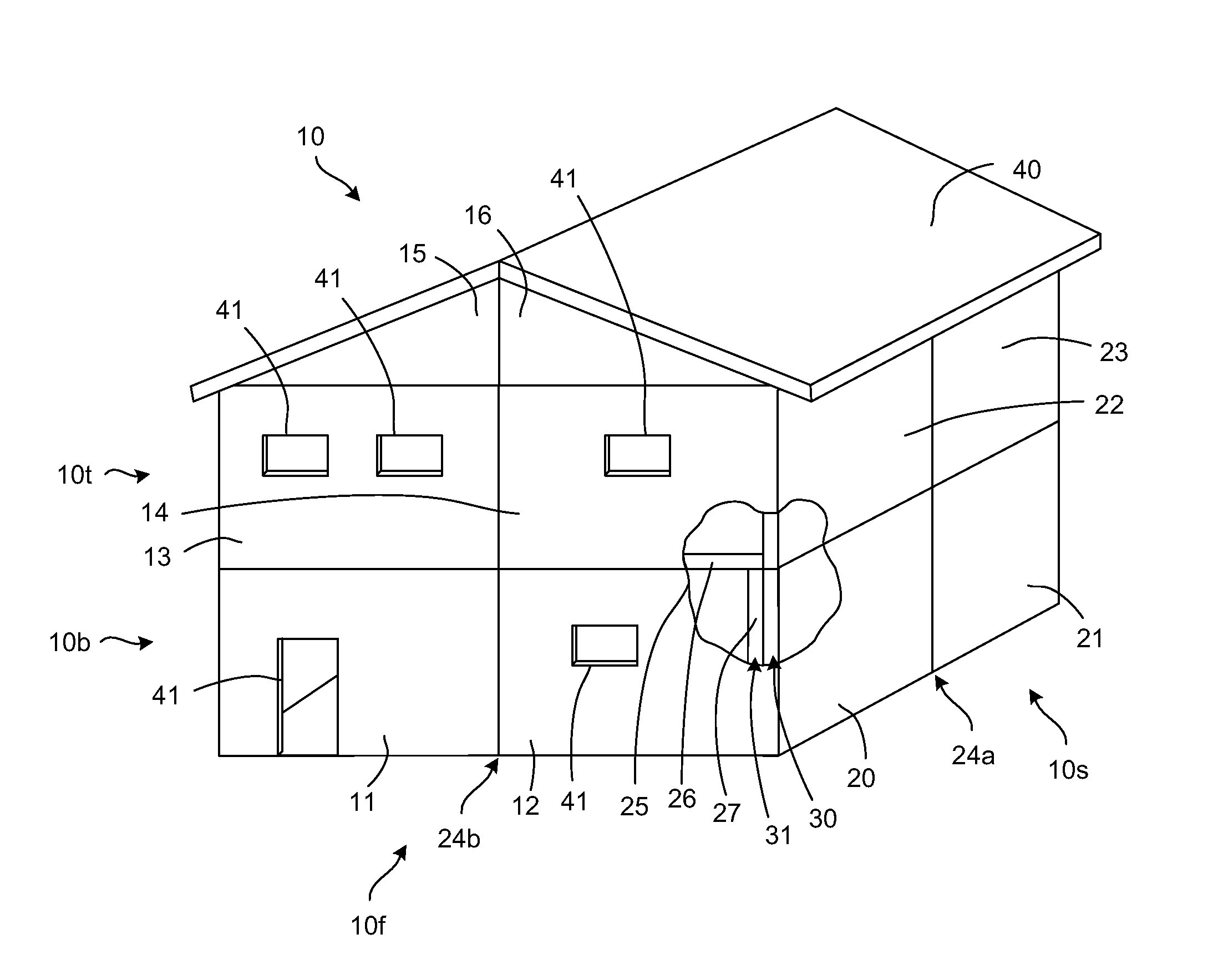

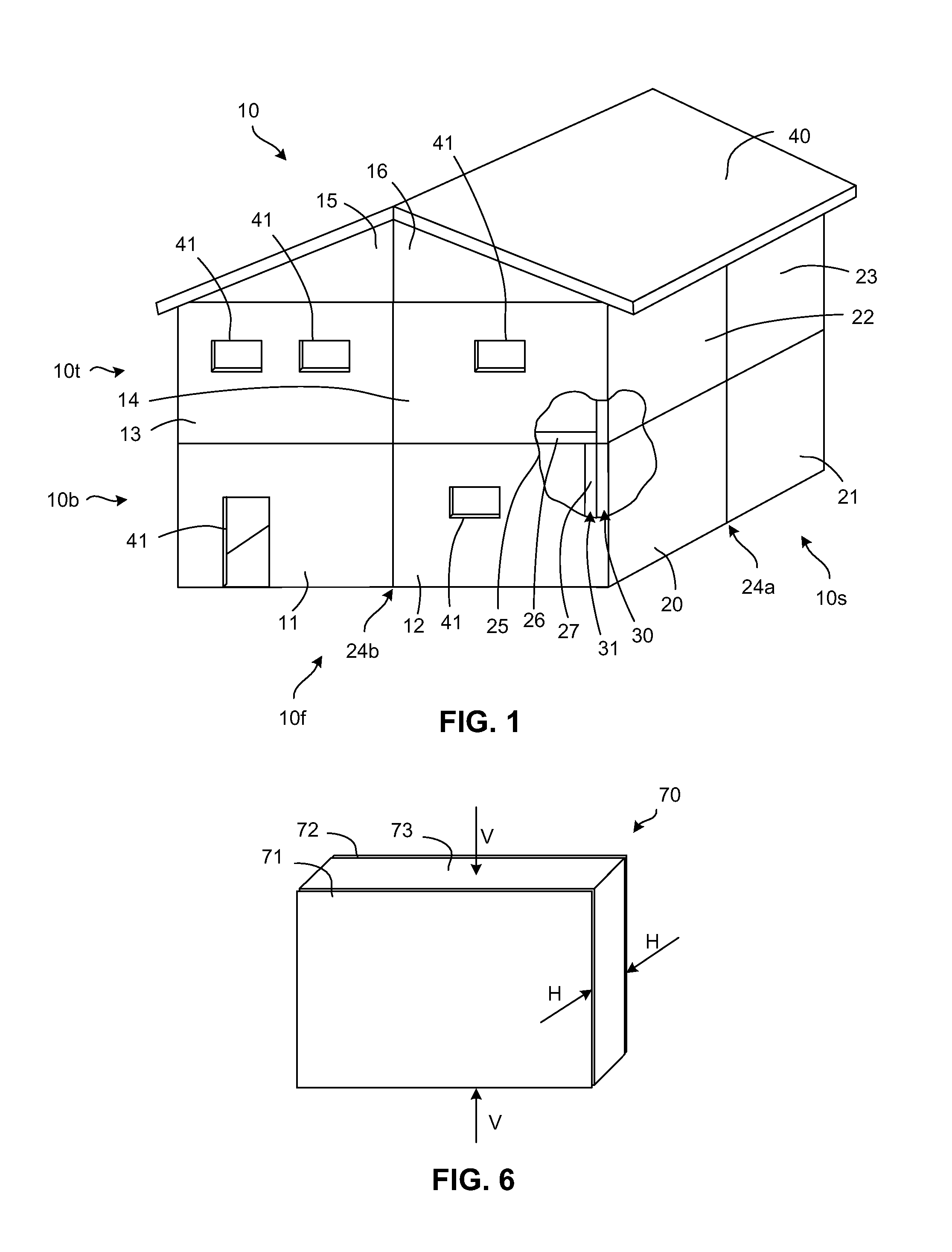

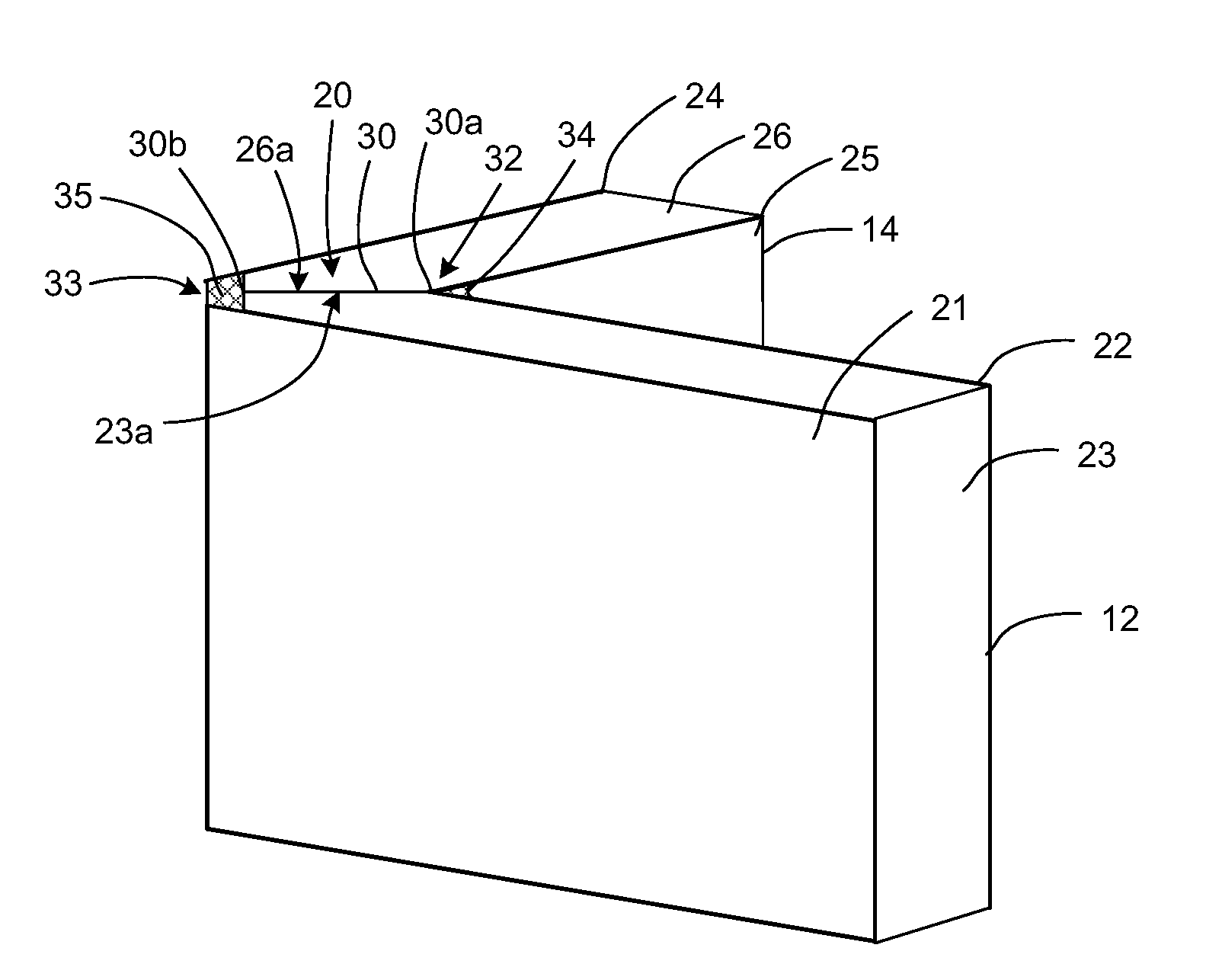

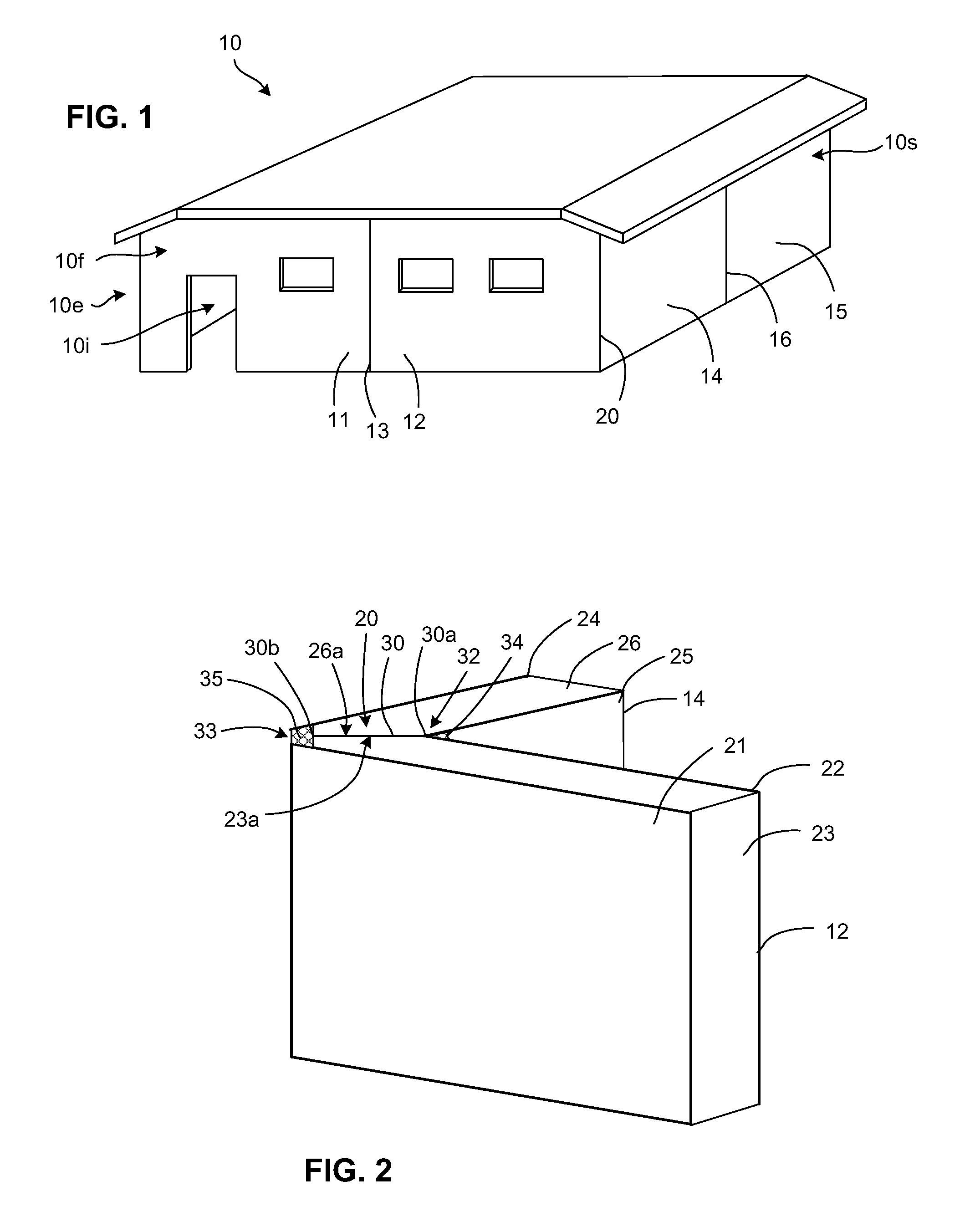

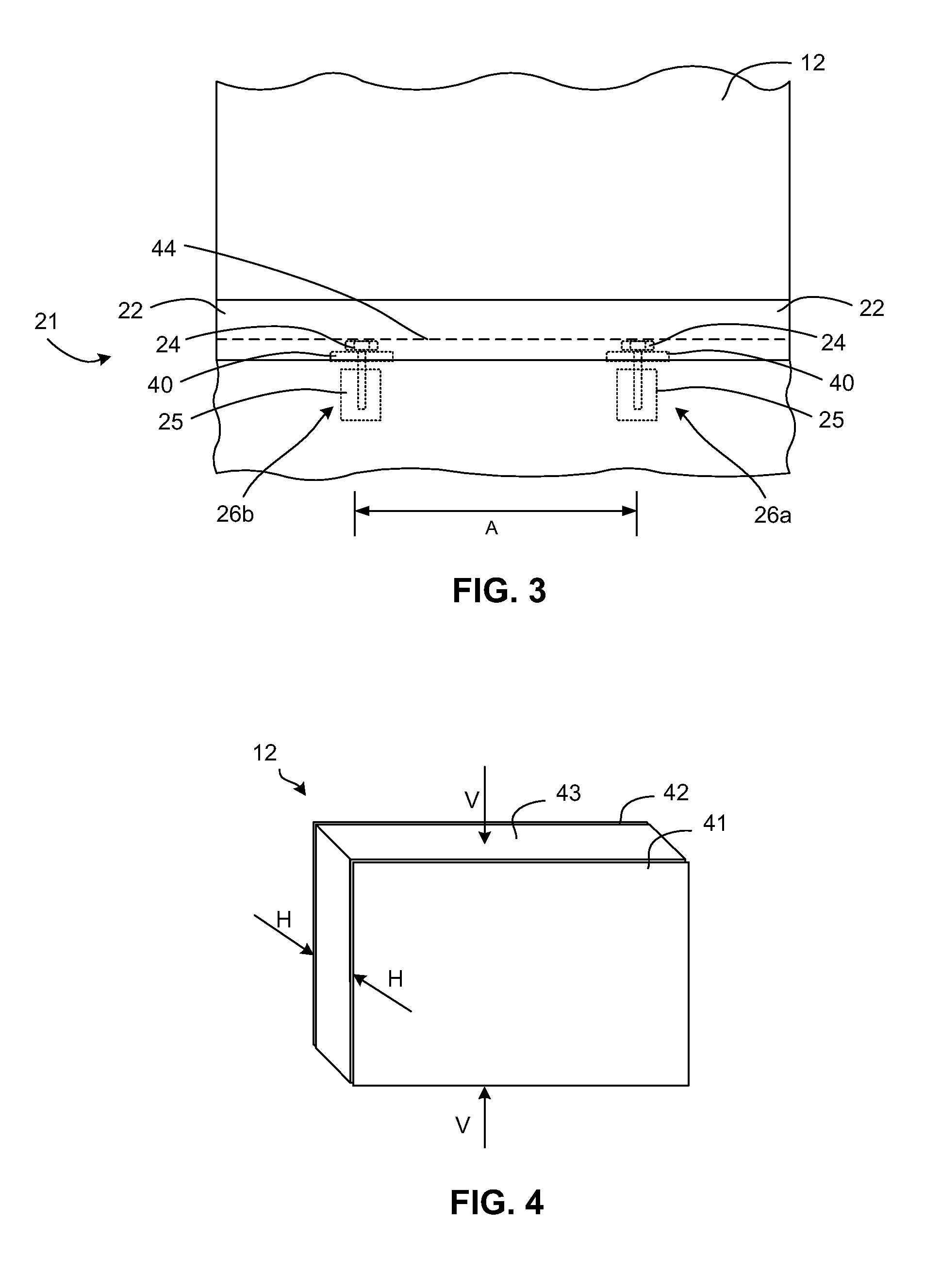

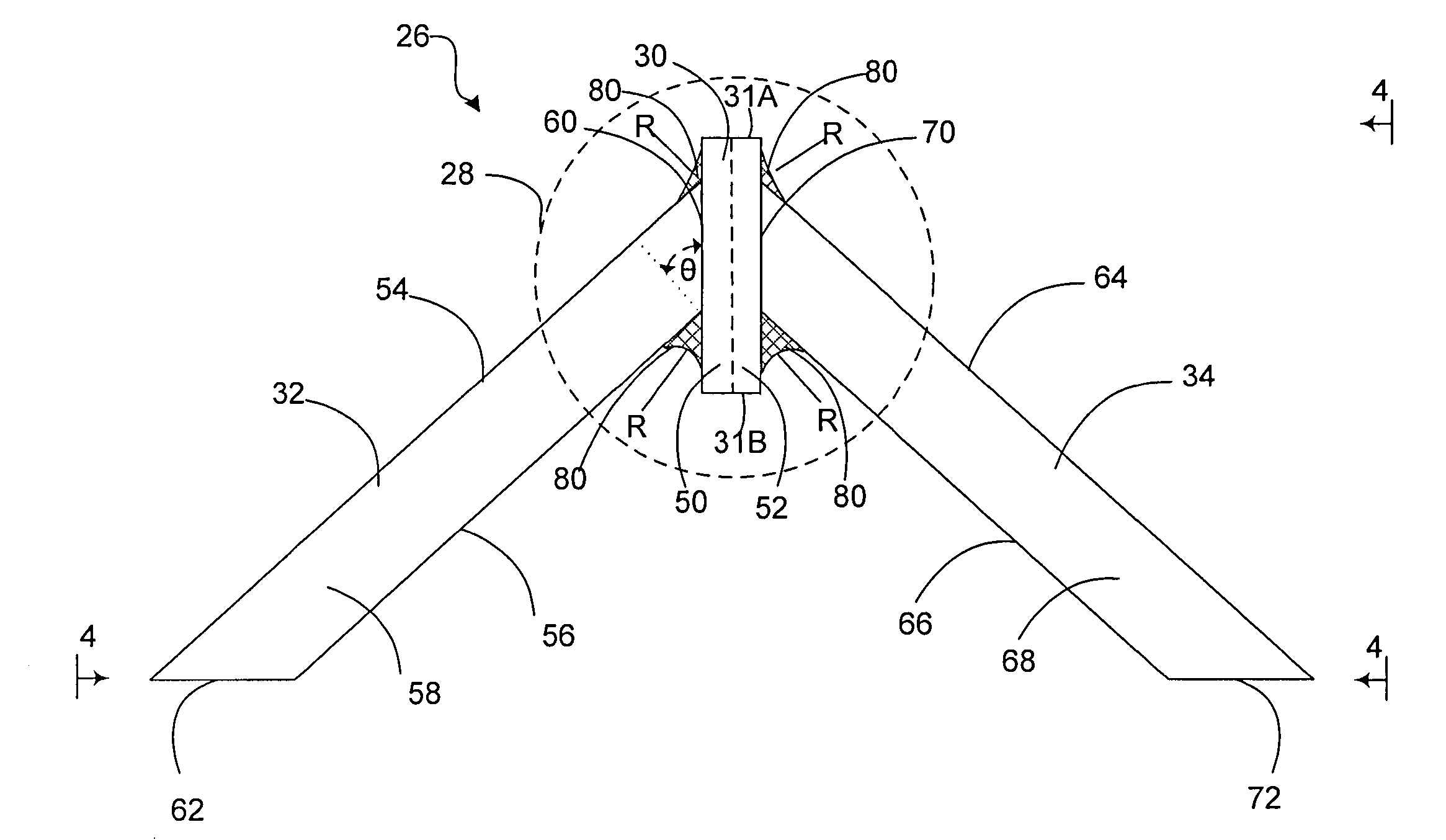

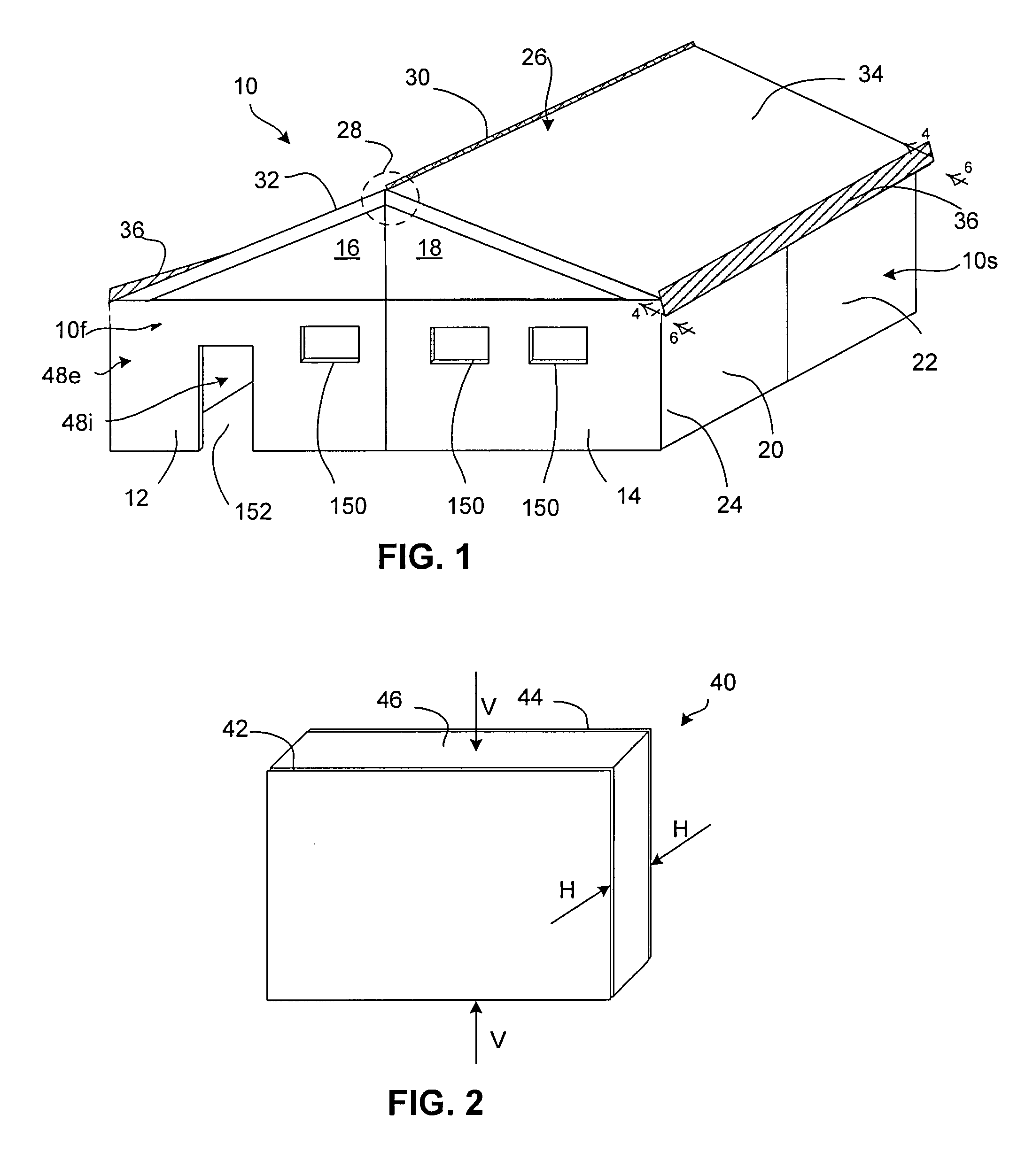

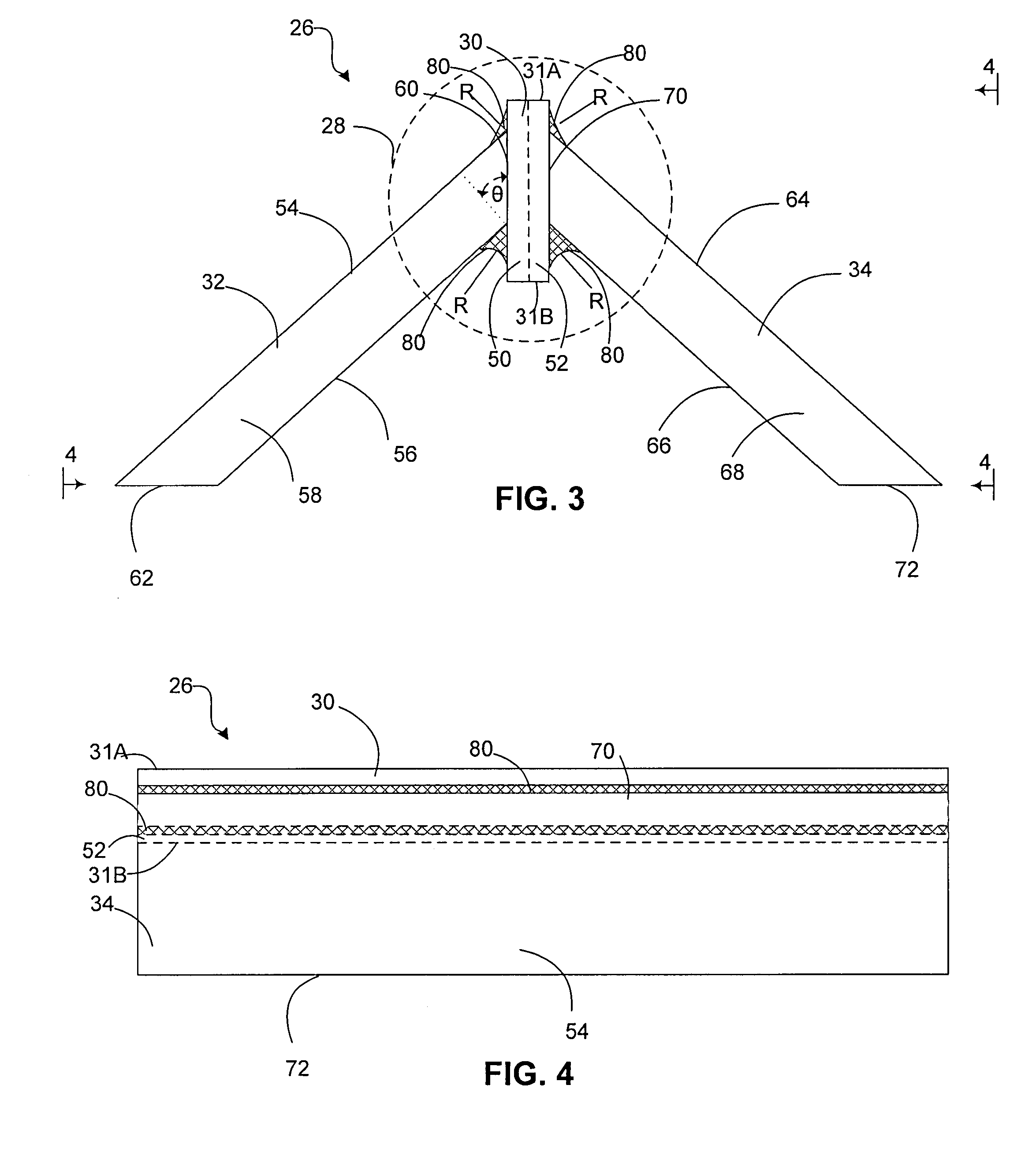

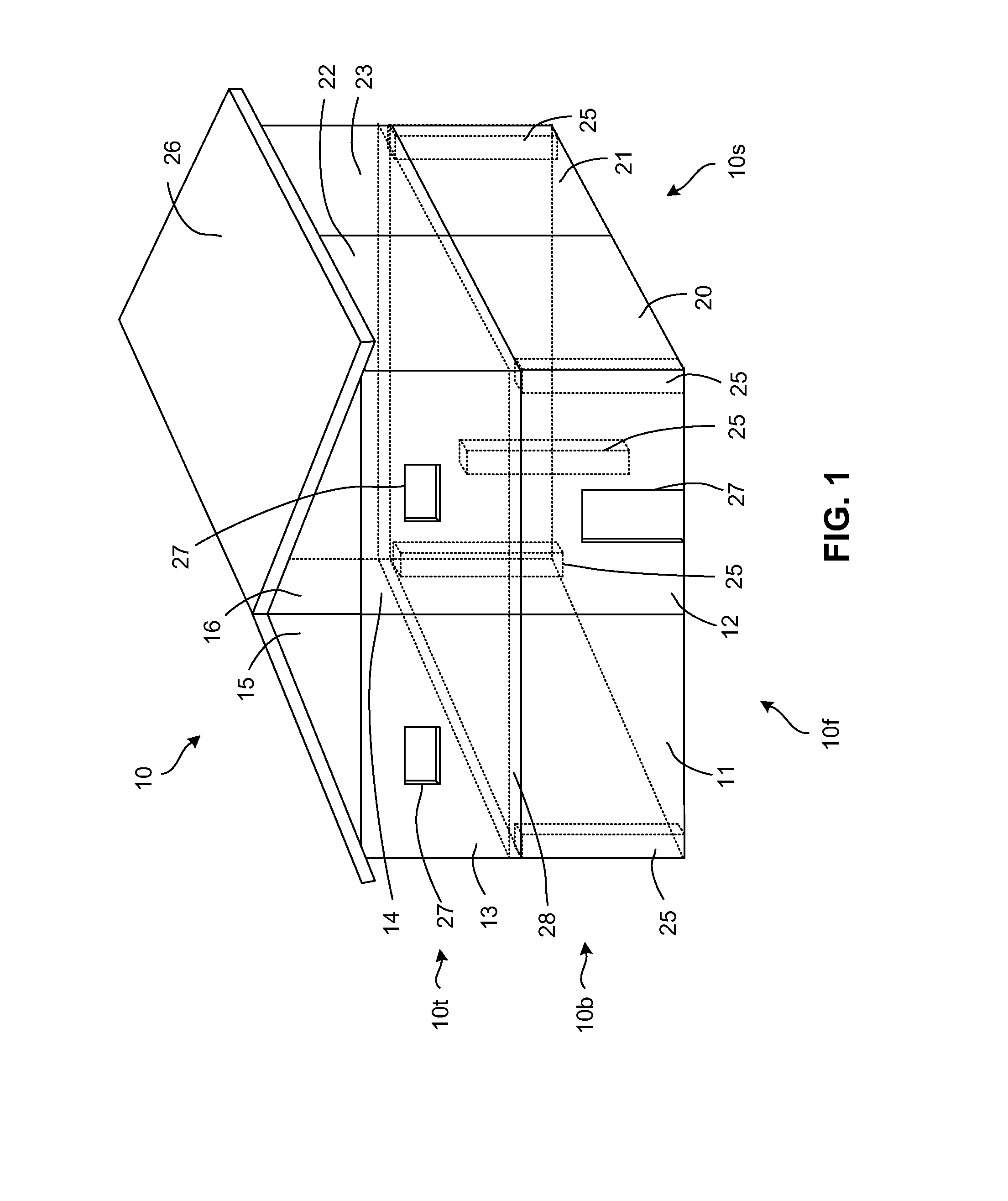

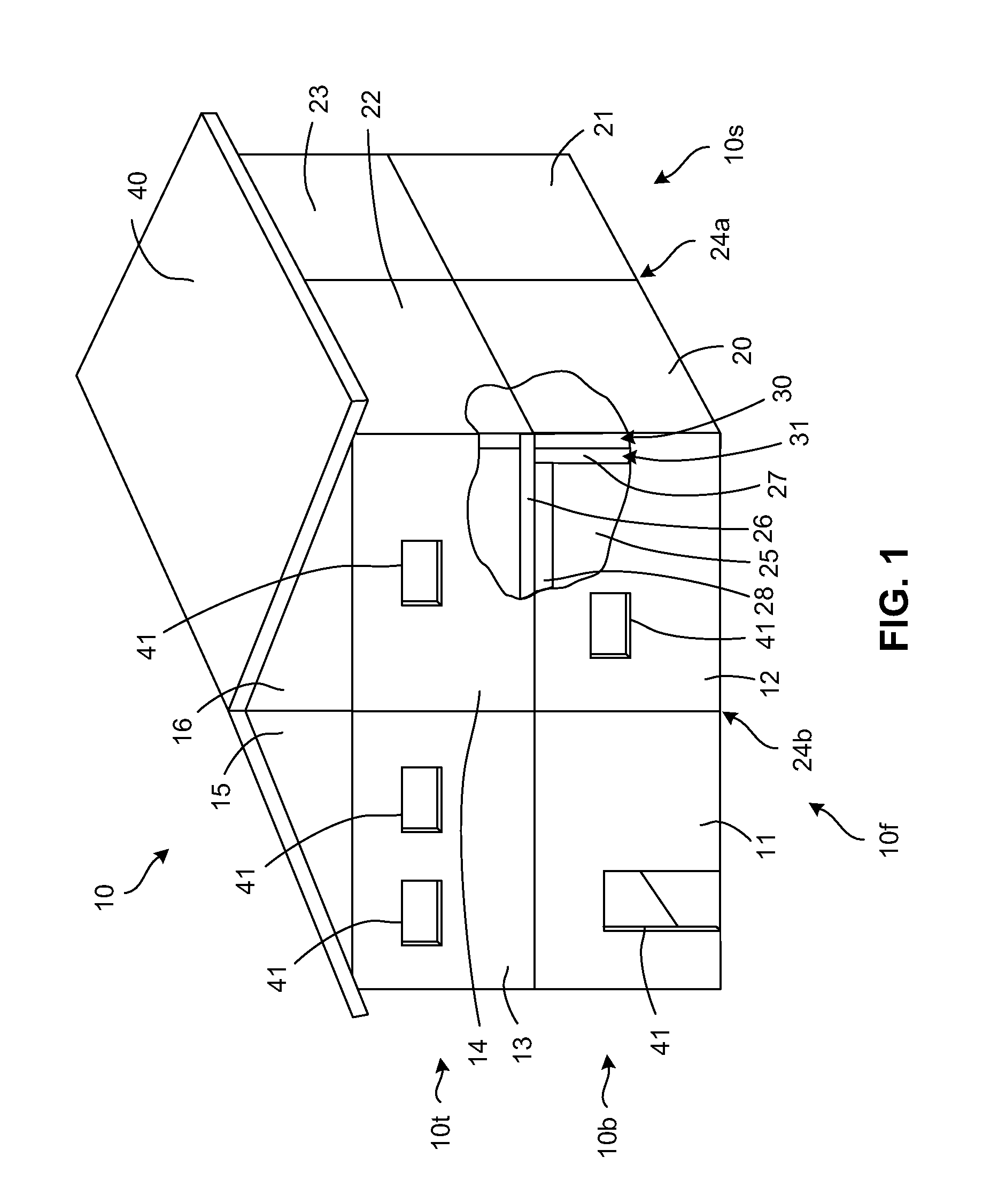

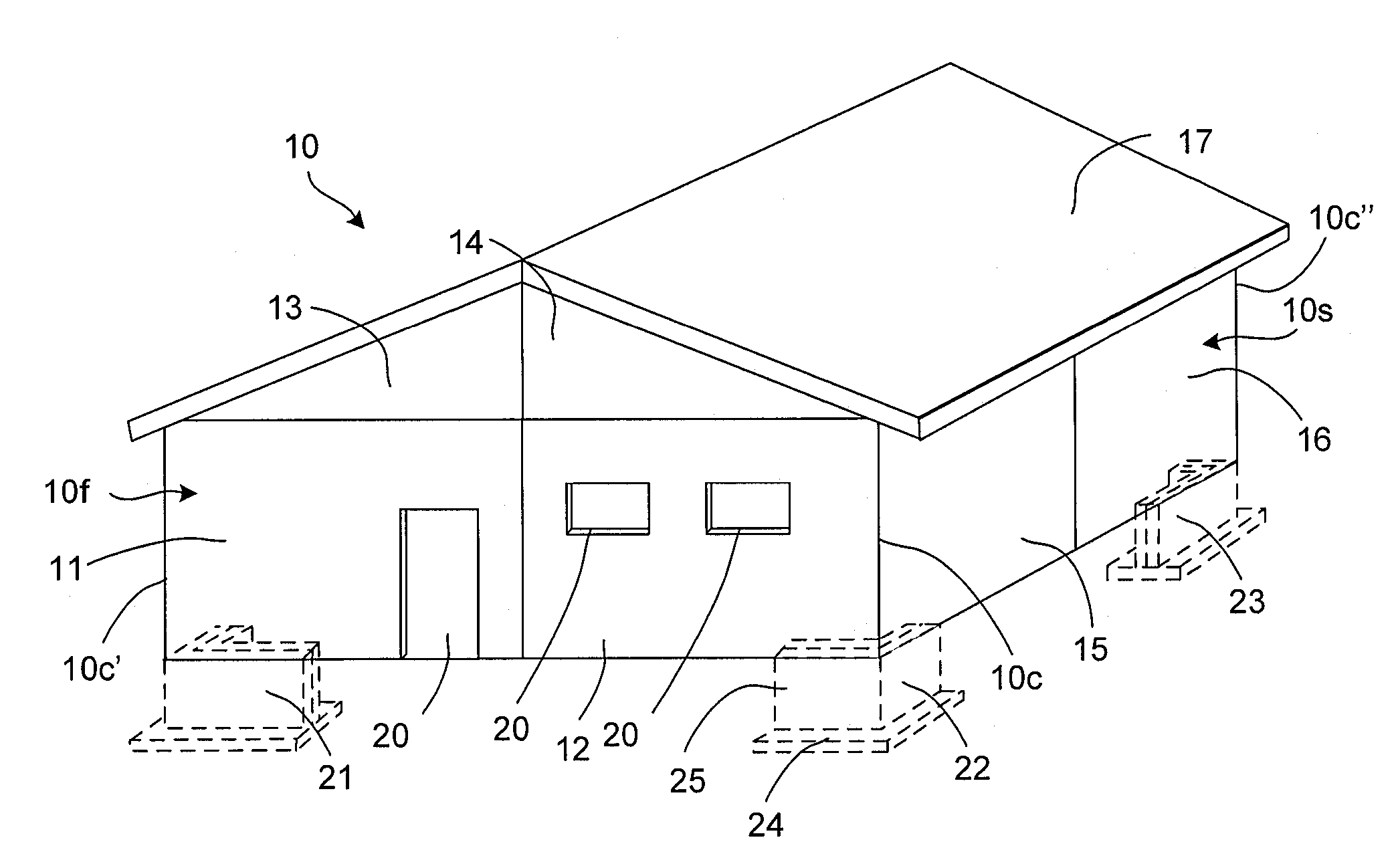

Building roof structure having a round corner

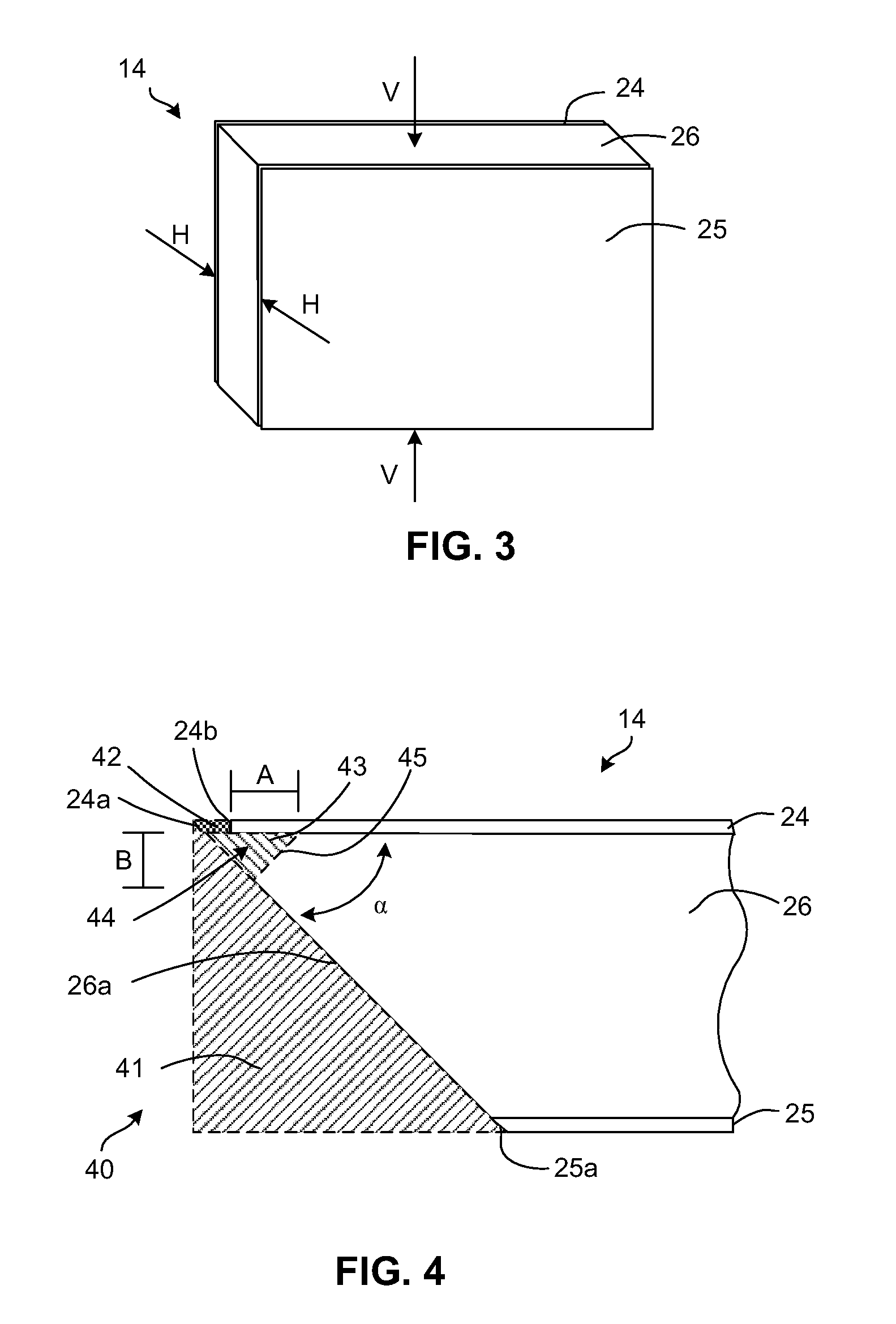

InactiveUS20100005732A1Great strength to weight ratioLight weightRoof covering using slabs/sheetsBuilding roofsEngineeringSandwich panel

A roof structure may be made with one or more sandwich panels having a round corner and installed with a drainage slope (e.g., 5-10 degree) to facilitate removal of liquid (e.g., water, rain, snow, sleet, etc.) from the roof structure. The round corner may have any desired curvature and / or angle for establishing a drainage area. A bonding material may be used to secure and / or seal the underlying interface of the round corner. The roof structure may be secured to an exterior wall by the bonding material.

Owner:MILLPORT ASSOC

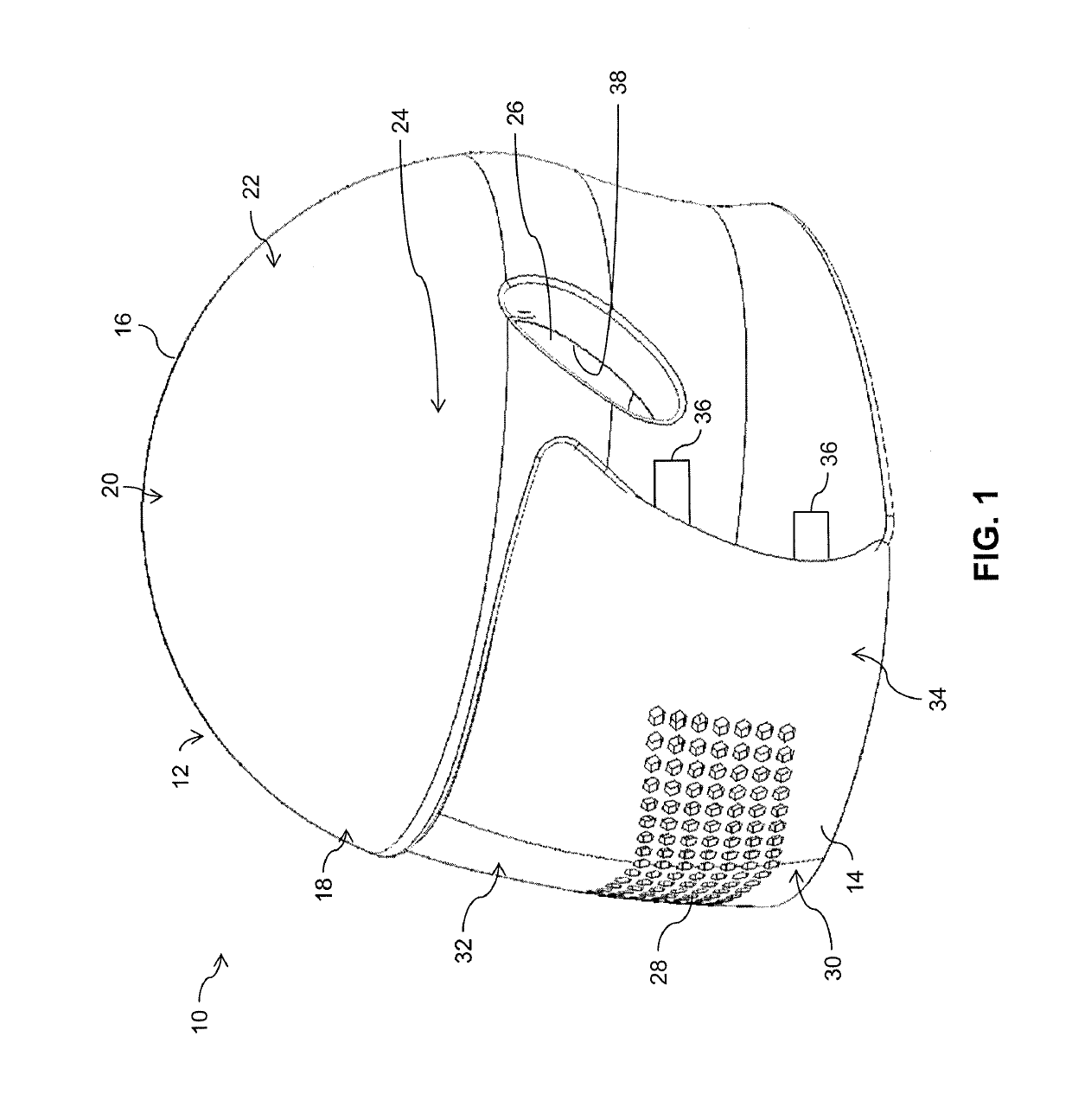

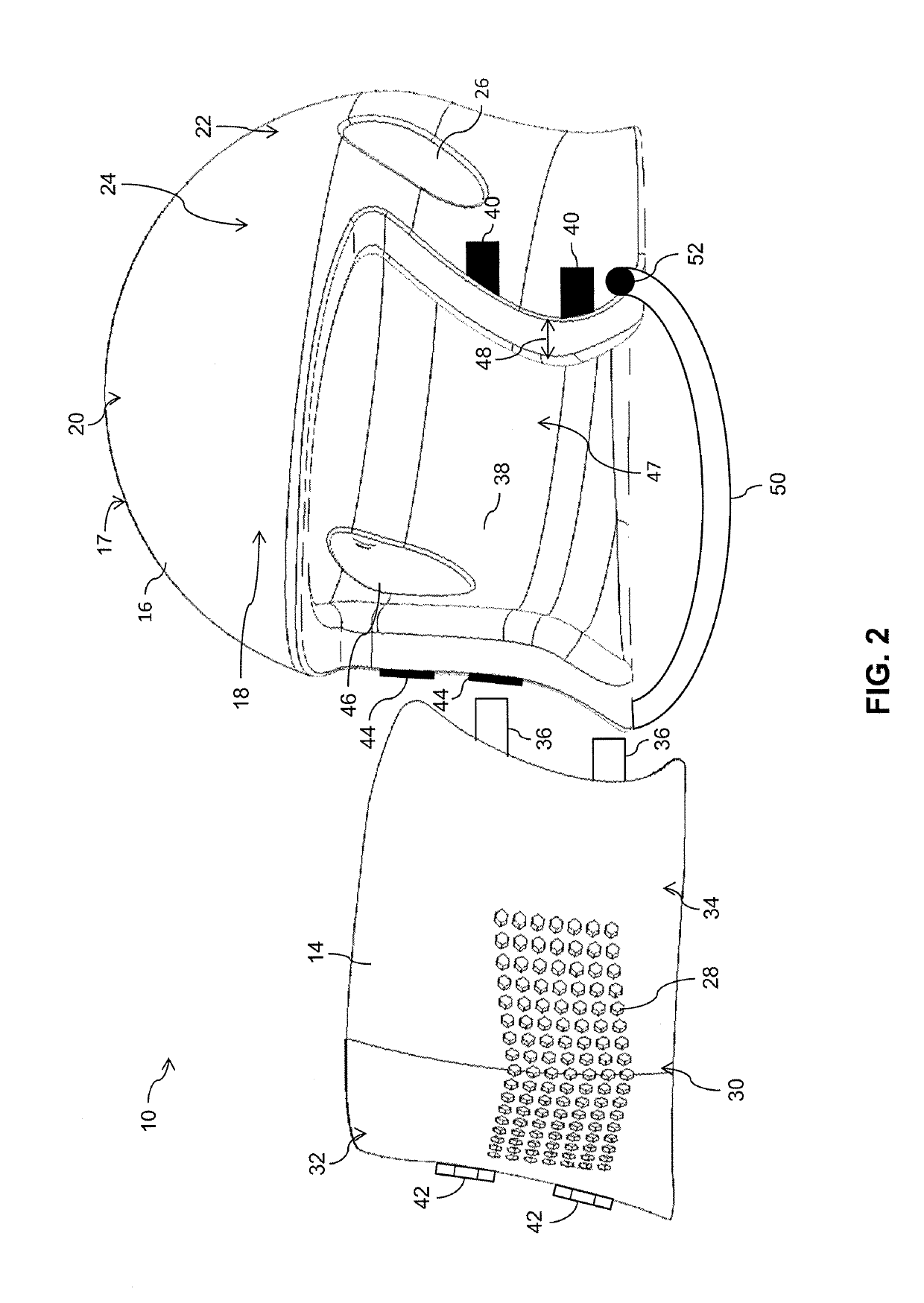

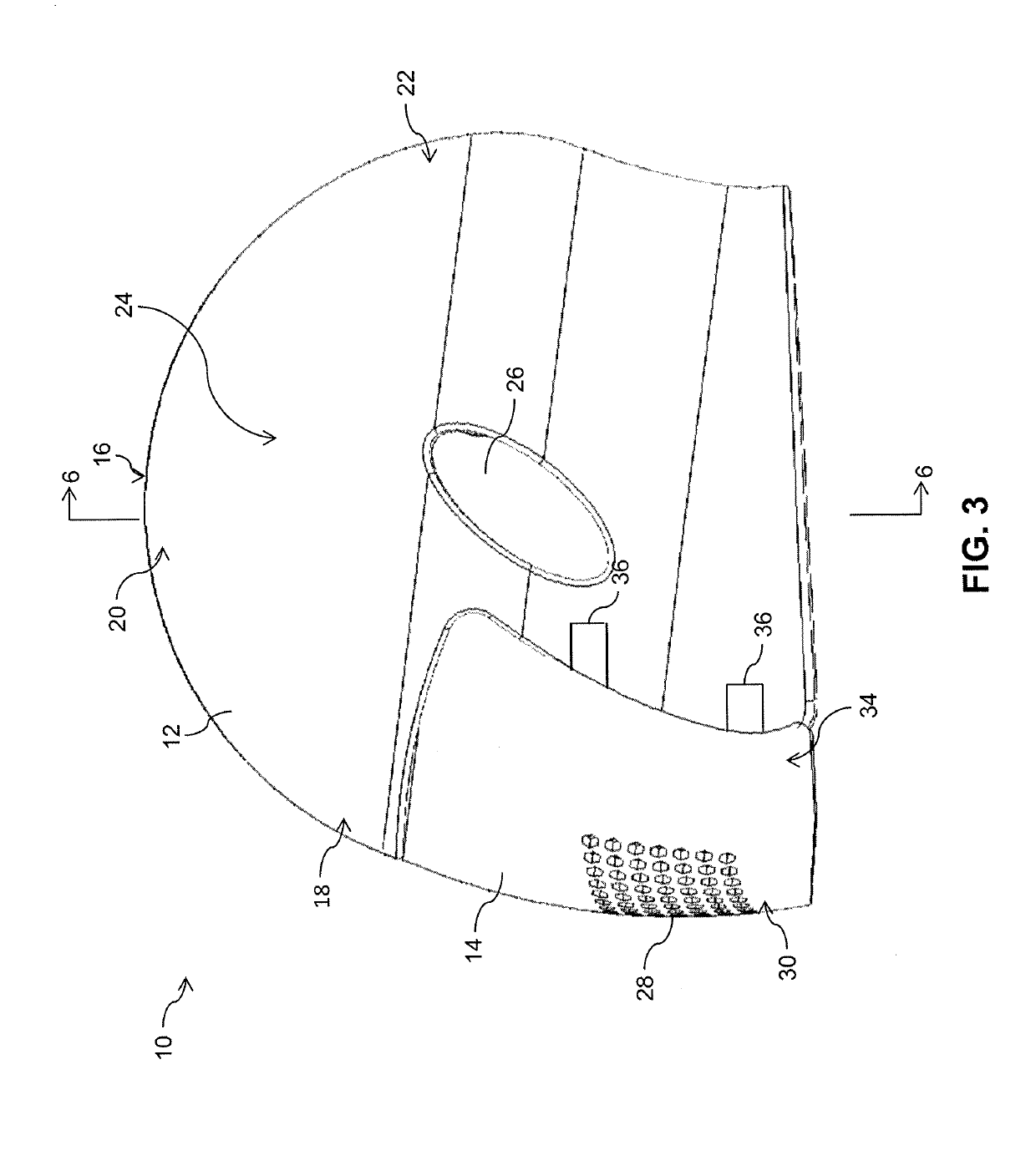

Shock Reducing Helmet

PendingUS20190133235A1Reduction in headform accelerationImprove protectionHelmetsHelmet coversFiberCarbon fibers

A shock reducing helmet includes a helmet body made of an outer and inner shell, ear openings, and face shield or visor that connects flush to the helmet body.The outer shell is formed from the strongest and lightest weight materials, such as polycarbonate, or other plastics, Kevlar, carbon fiber, or metal, to provide a high strength to weight ratio and minimize fracture.The inner chamber includes shock absorbing structures made from materials such as a nickel-titanium shape-memory alloy, polycarbonate, other plastics, Kevlar, carbon fiber, or metal. Some variants have a viscous or gaseous layer around the springs to increase stability upon linear and rotational impact.The face shield or visor is made of a clear polycarbonate that connects flush with the outer shell to eliminate visibility interference and rotational injuries caused by competitors pulling the metal bars commonly present in football helmets.

Owner:GRIM GREGORY A

Joint of parallel sandwich panels

InactiveUS20100050549A1Great strength-to-weight ratioLight weightBuilding roofsFloorsDouble wallEngineering

A number of multi-panel wall segments are connected together in a parallel orientation with bonding material to form a double wall segment. The connections between the multi-panel wall segments are bridged at a joint between the segments. In one embodiment, the connections between the multi-panel wall segments are bridged by a reinforcement member that extends on both sides of the connection between the sandwich panels of the multi-panel wall segments. In another embodiment, the joint is bridged an offset between the connections of the sandwich panels multi-panel wall segments to form a discontinuous joint. The bridged joint increases the rigidity and stiffness of the wall and also transfers loads between the multi-panel wall segments.

Owner:MILLPORT ASSOC

Straight joint for sandwich panels and method of fabricating same

InactiveUS20090255204A1Great strength to weight ratioLight weightWallsMaterial gluingThermal bridgeEngineering

Owner:MILLPORT ASSOC

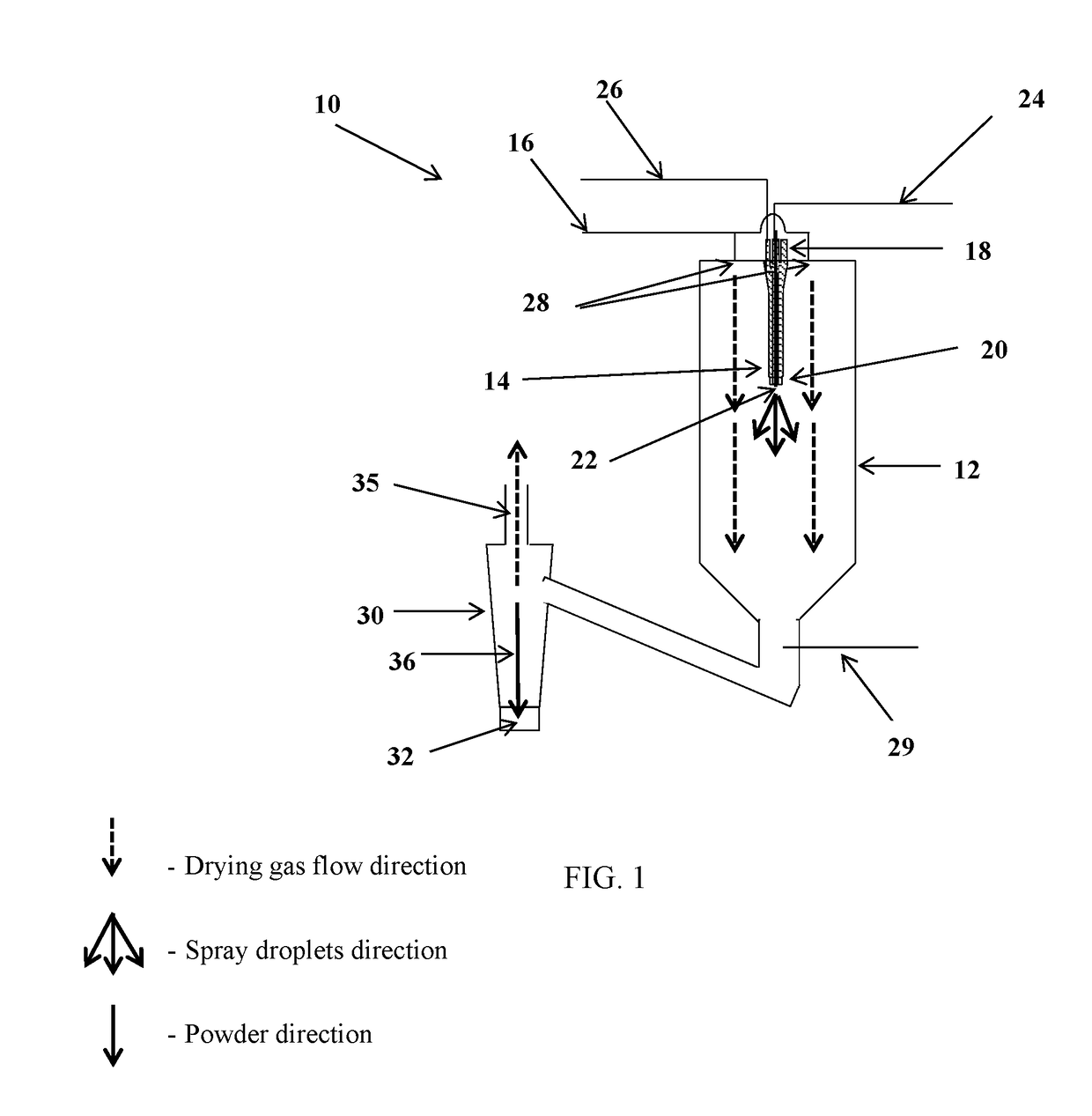

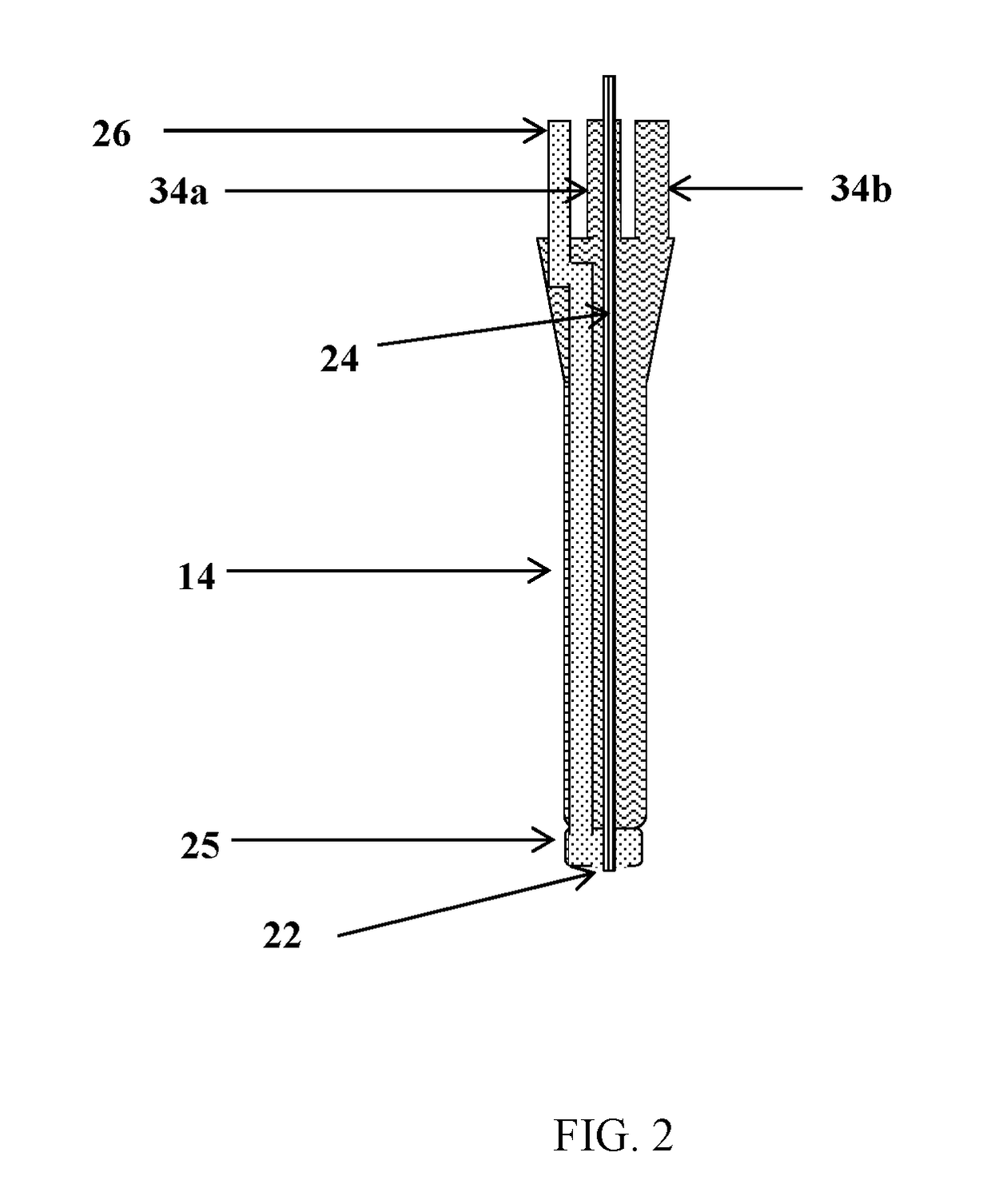

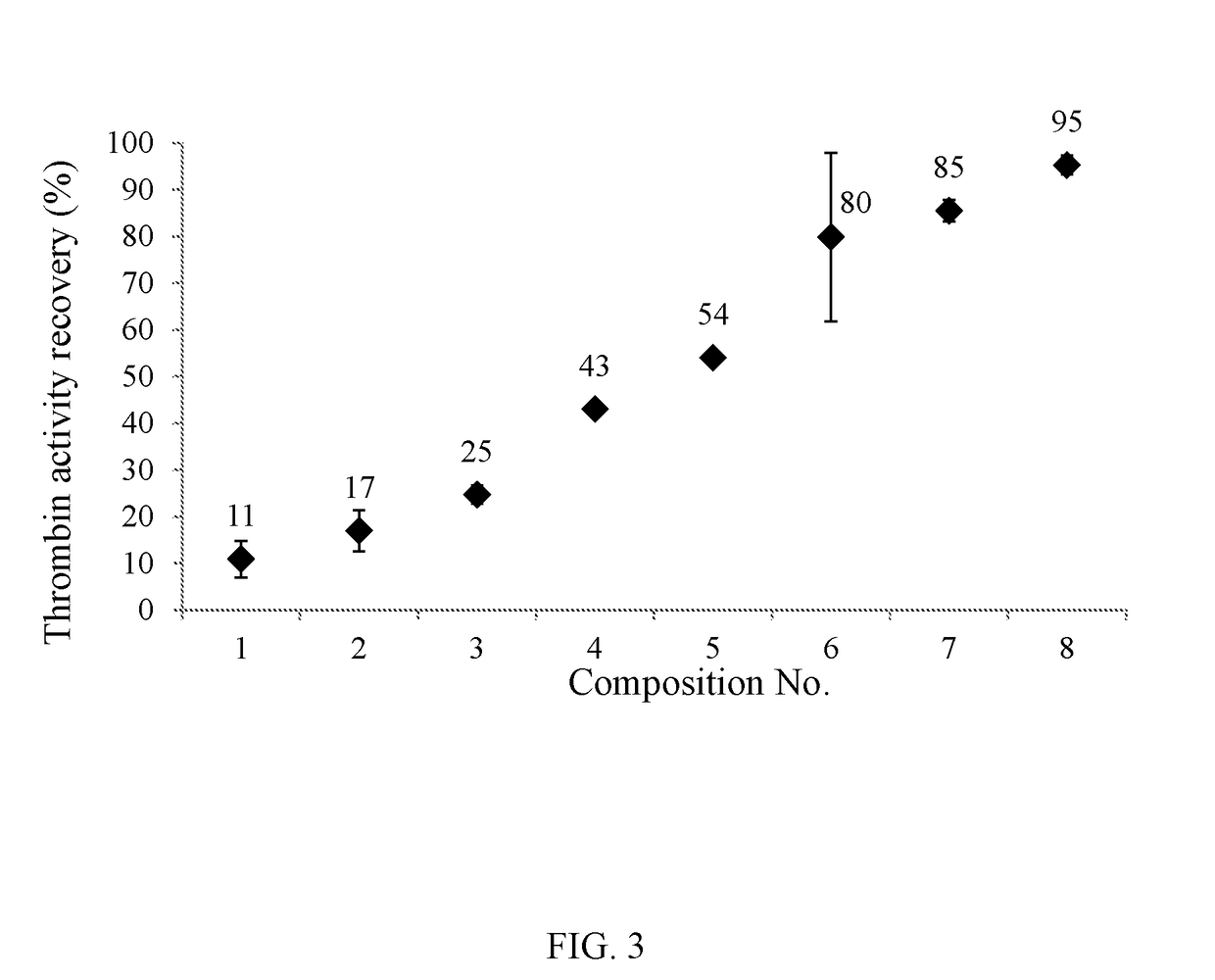

Thrombin microcapsules, preparation and uses thereof

ActiveUS20170157222A1Reduce moistureIncrease drying speedPeptide/protein ingredientsGranular deliveryMedicineThrombin activity

Provided are spray-dried thrombin powders comprising microcapsules, methods of preparation and uses thereof.

Owner:OMRIX BIOPHARM

Force sensitive touch sensor

ActiveUS9417141B2No expensiveHigh transparencyForce measurement using piezo-resistive materialsForce measurement by elastic gauge deformationElectrical resistance and conductanceSensitive touch

A force sensitive touch sensor (100) is provided. The sensor (100) comprises an insulating support layer (101) and an electrically conductive sensor structure (102). The electrically conductive sensor structure (102) comprises a piezoresistive material and is configured to provide a resistance varying in response to a force being applied to the insulating support layer (101). The piezoresistive material comprises graphene.

Owner:SONY CORP

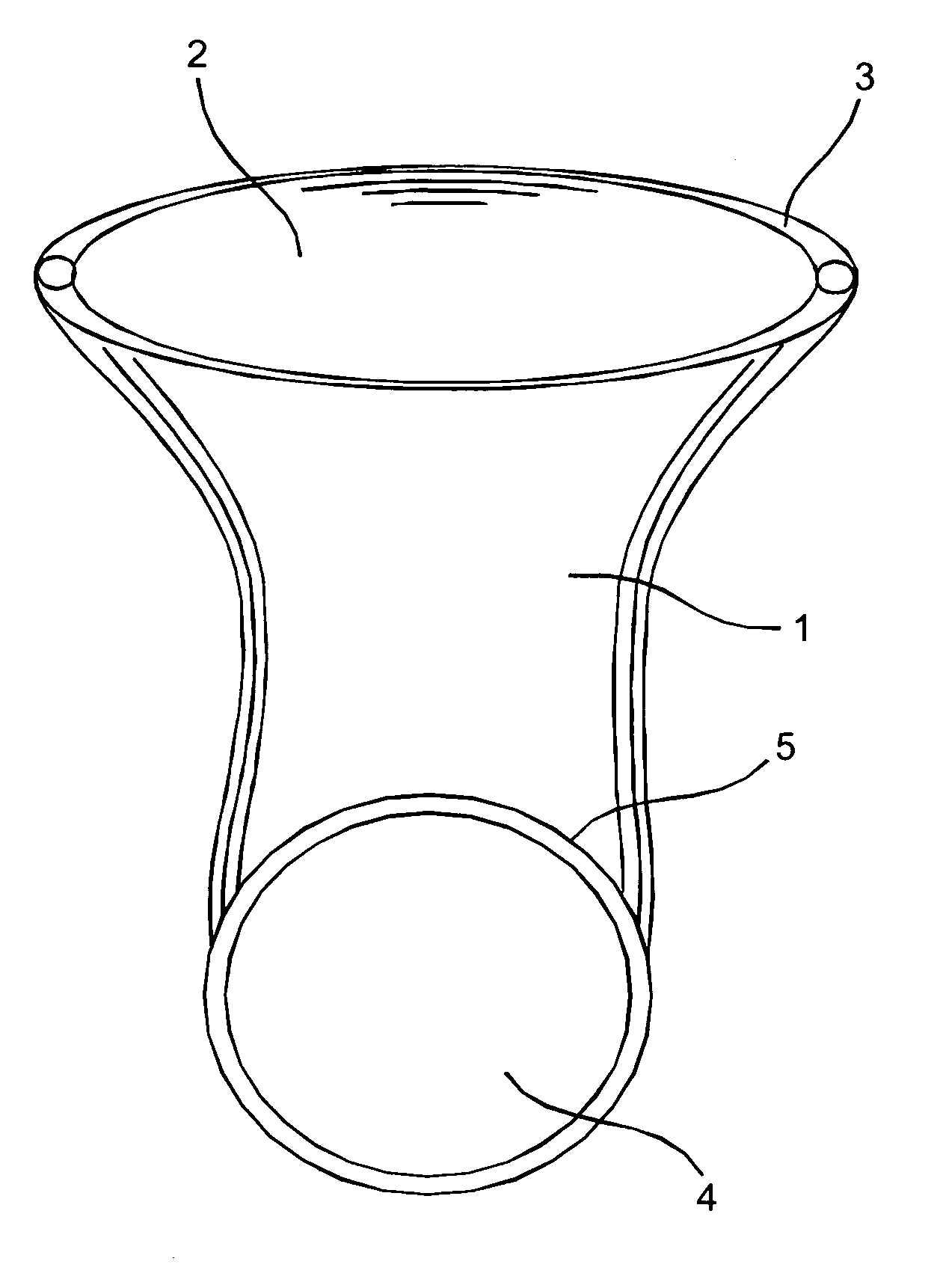

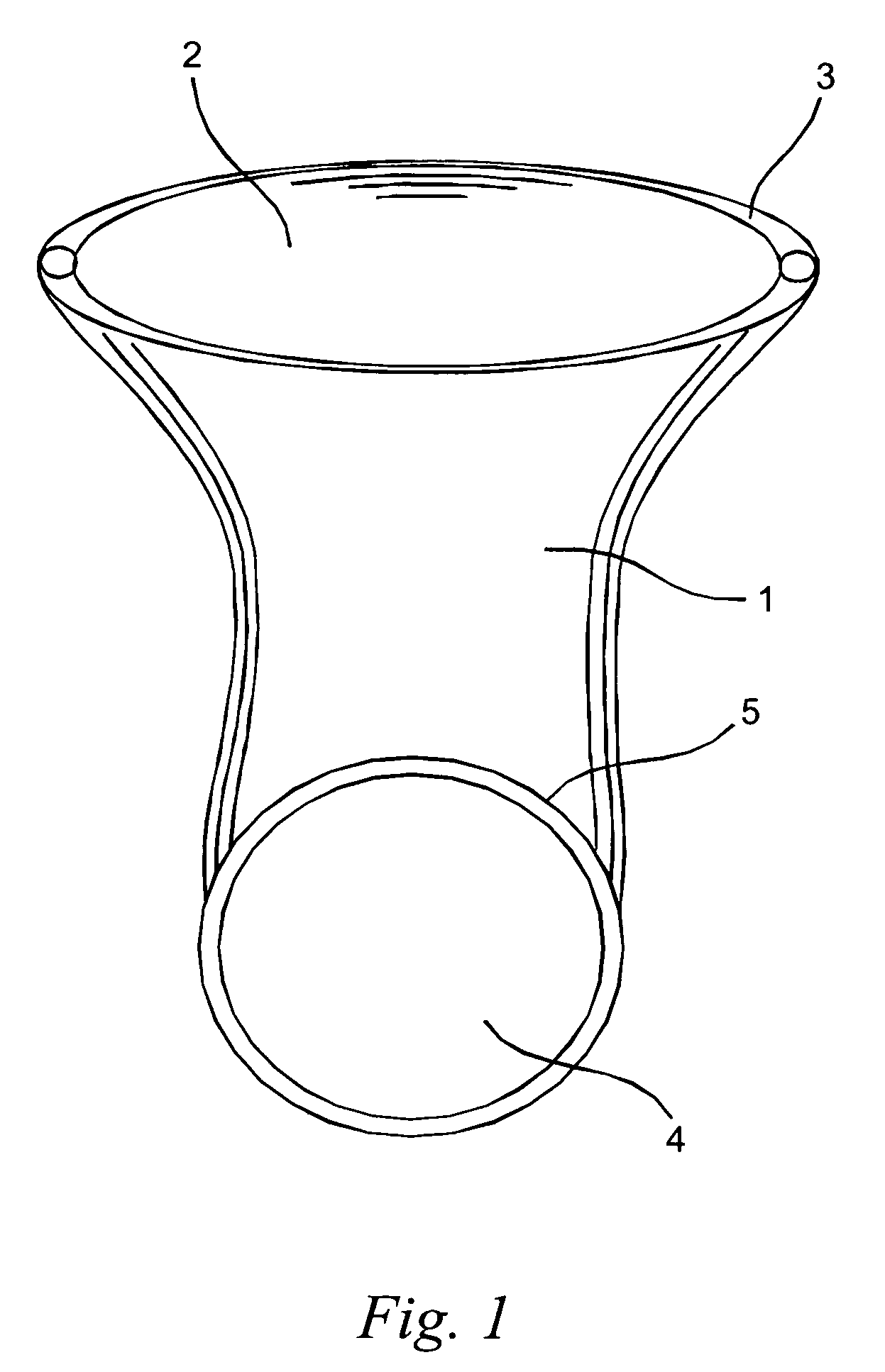

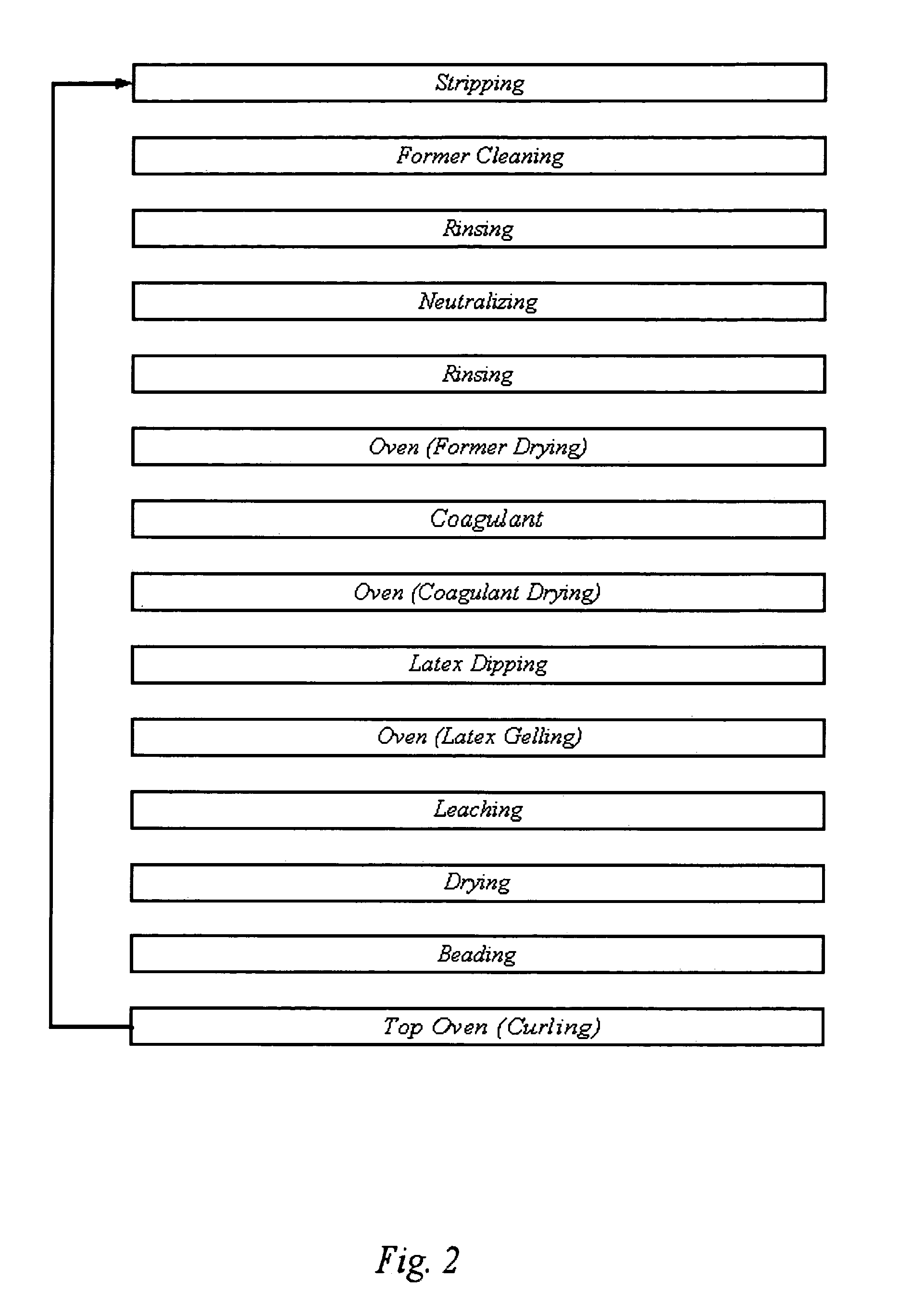

Contraceptive sheath with integrated bead construction

A female condom and an improved method for manufacturing a female condom is disclosed. The invention provides a device that is effective in both acting as a contraceptive and inhibiting the transmission of disease during coitus. The invention employs synthetic latex in an efficient and cost effect manufacturing method that results in an improved product.

Owner:VERU INC

Angle joint for sandwich panels and method of fabricating same

InactiveUS20090282777A1Great strength to weight ratioLight weightBuilding componentsHeat transmissionSandwich panel

An angle joint between two sandwich panels, wherein the sandwich panels each have a first outer layer and a second outer layer spaced from the first outer layer by a panel core, and an angle edge including an edge portion of the panel core and an edge portion of the first outer layer. The joint has an interface between the panel cores and the interface has an entranceway at an inner corner comprised of the edge portions of the first outer layers. A cavity in the panel cores is defined by a portion of the second outer layers and a portion of each panel core. The cavity spans across a second entranceway to the interface between panel cores. Bonding material applied in the cavity and at the inner corner connects the sandwich panels together in a manner that maintains an area of dead air space at the interface to inhibit or to reduce thermal transmissions across the joint.

Owner:MILLPORT ASSOC

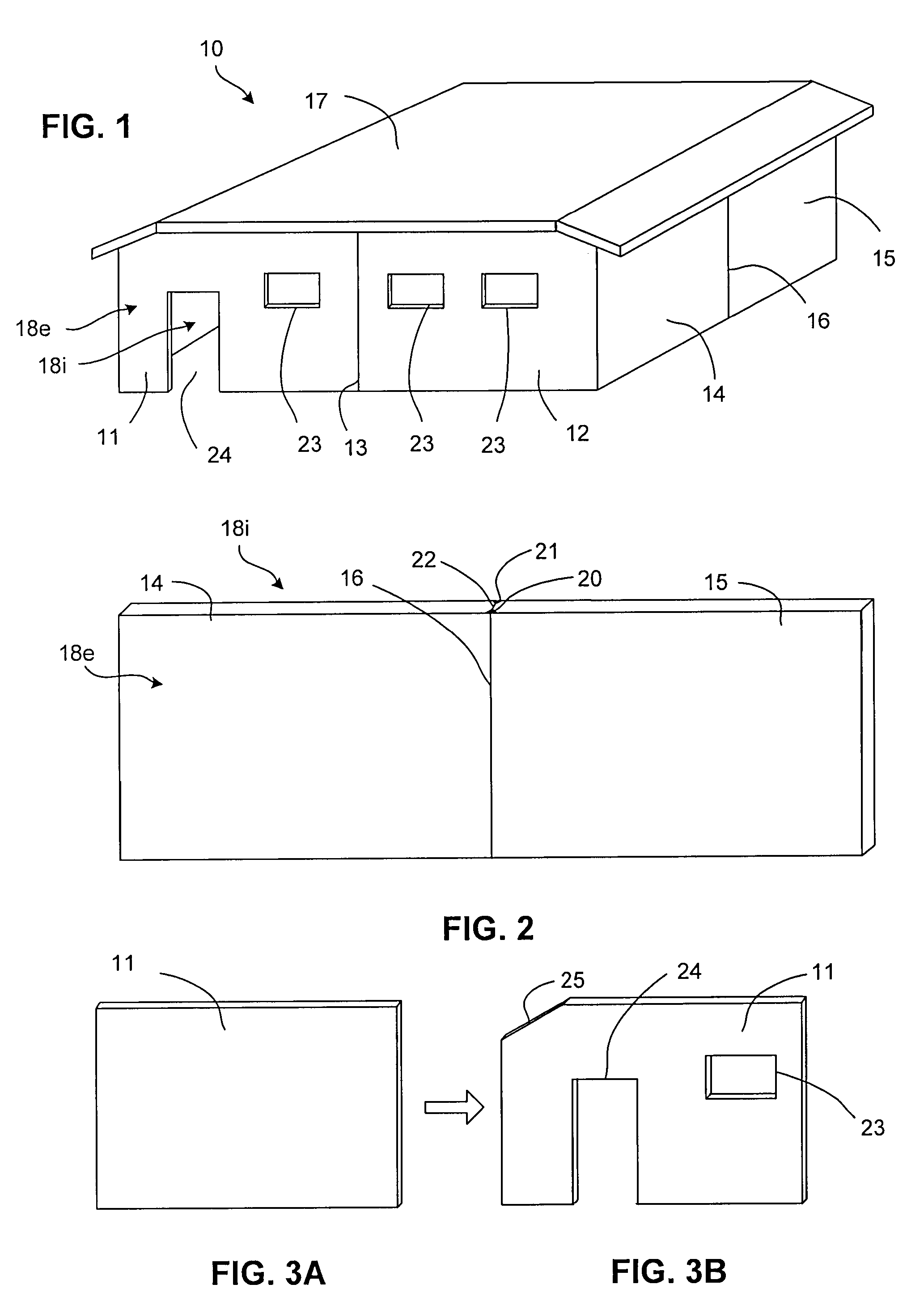

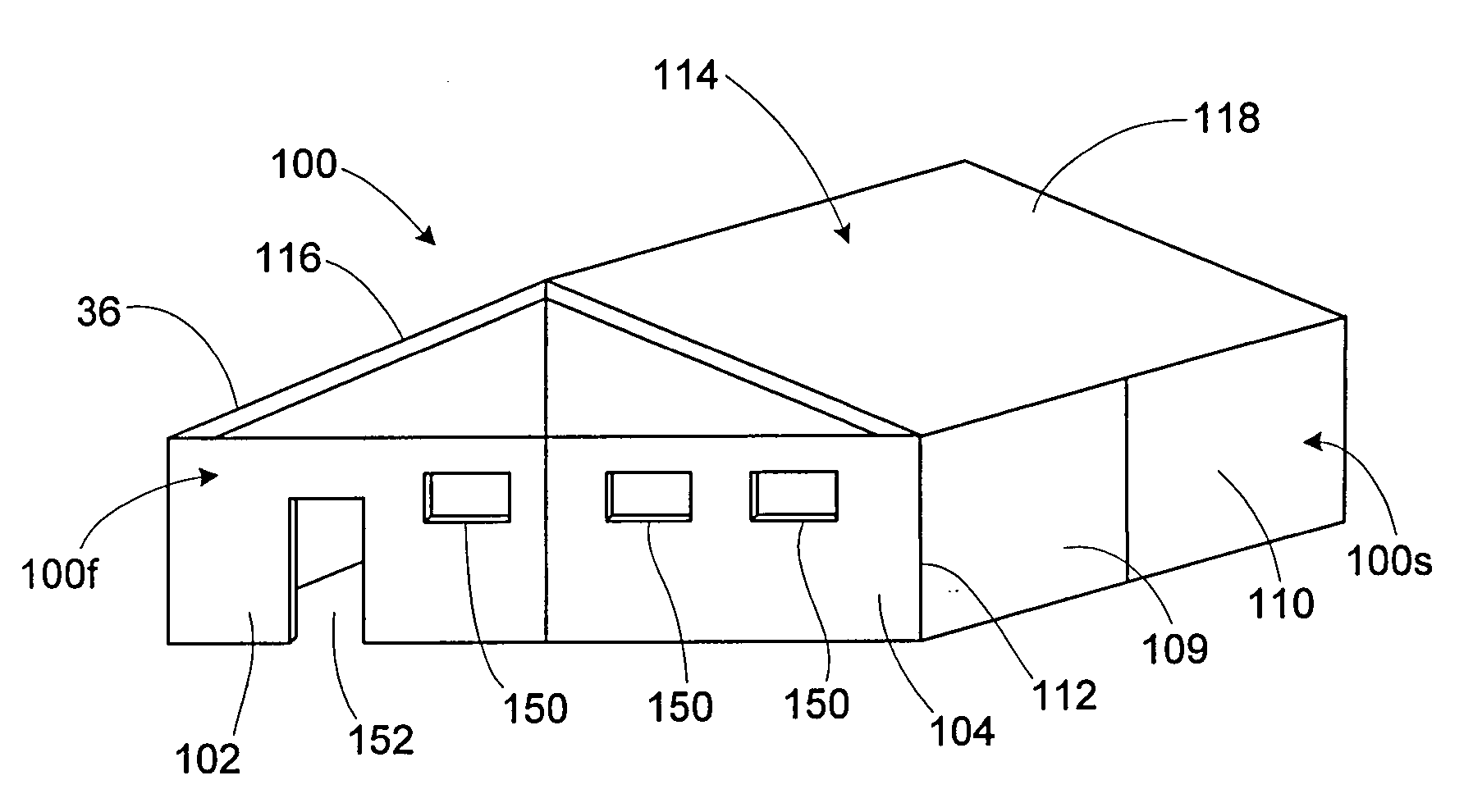

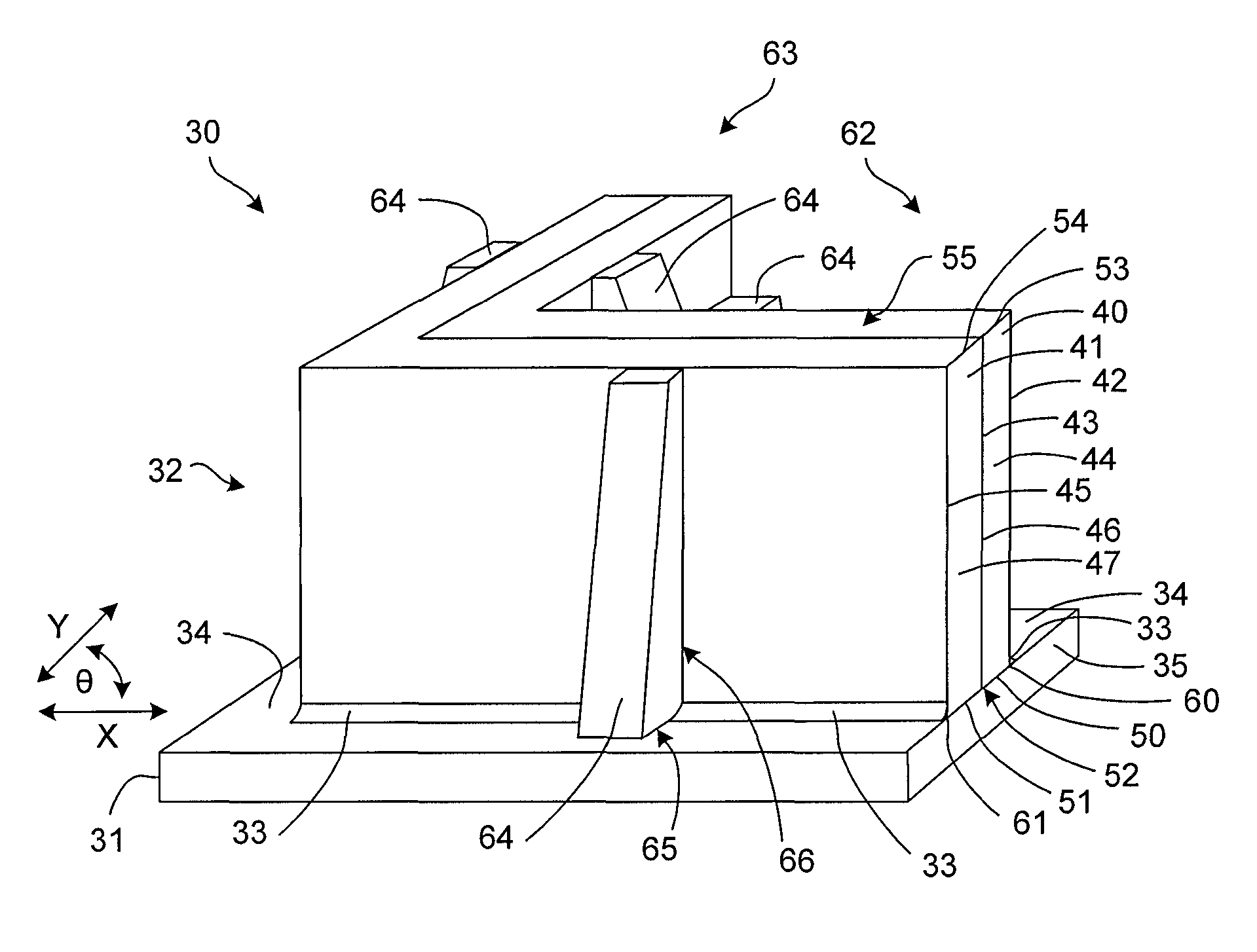

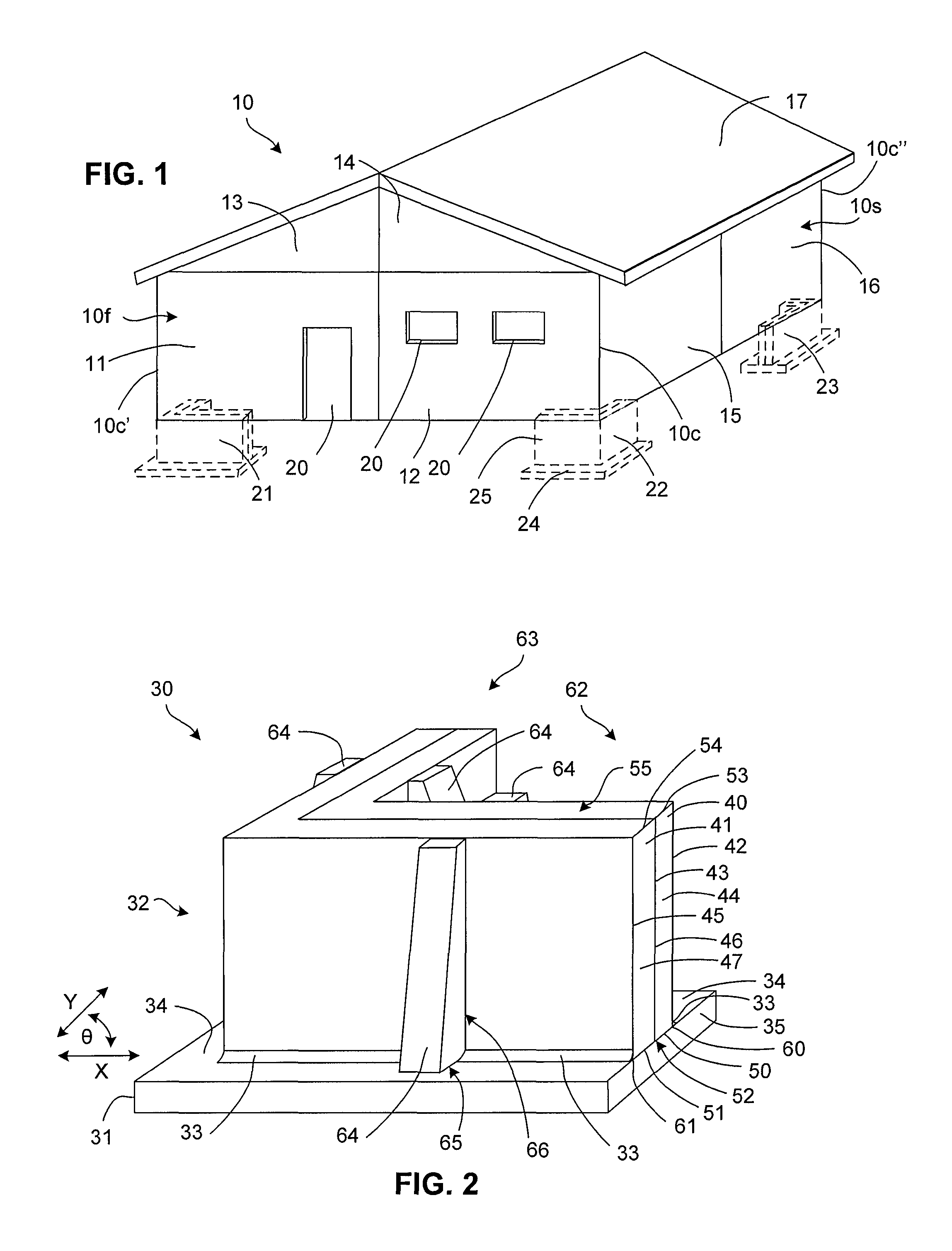

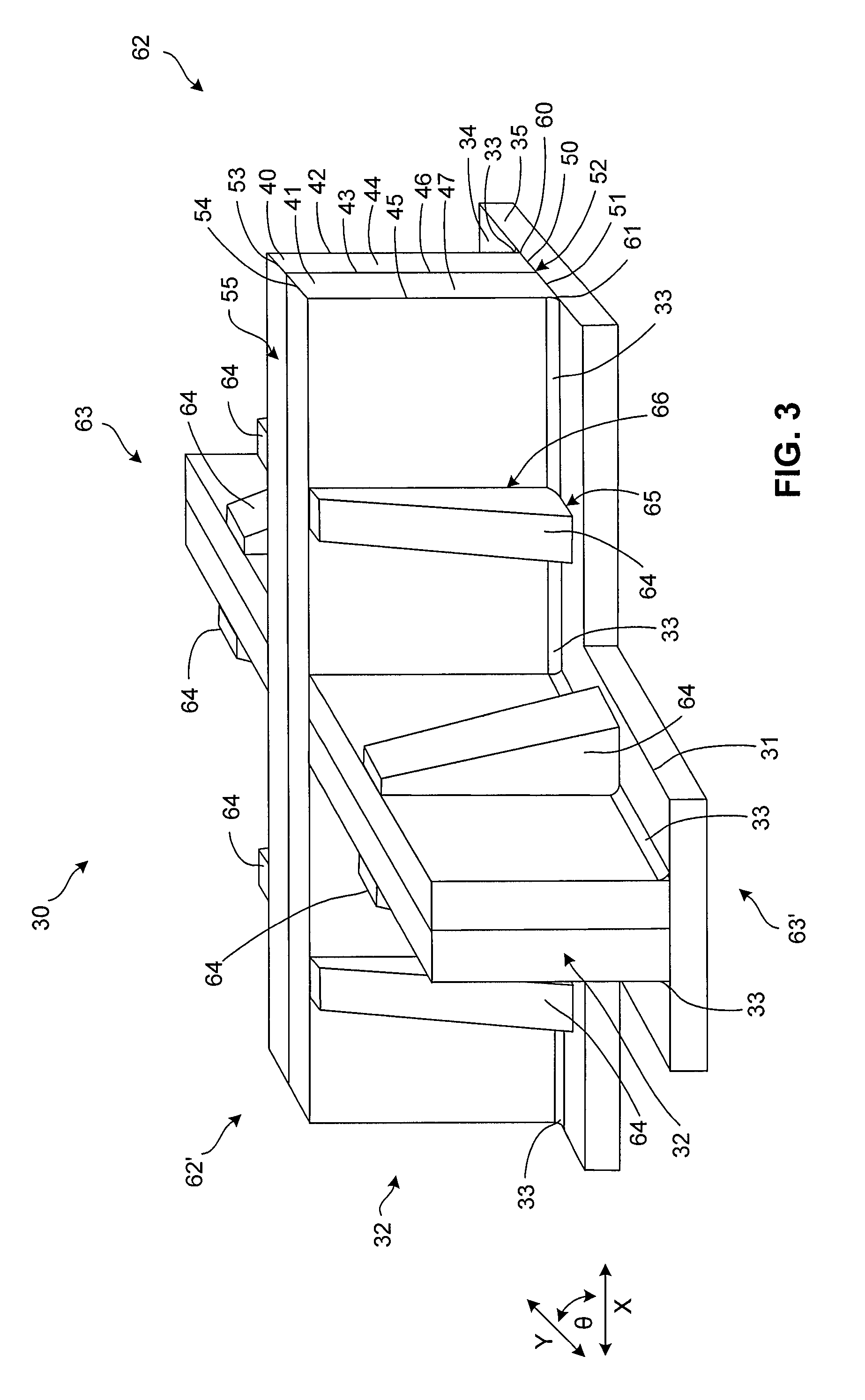

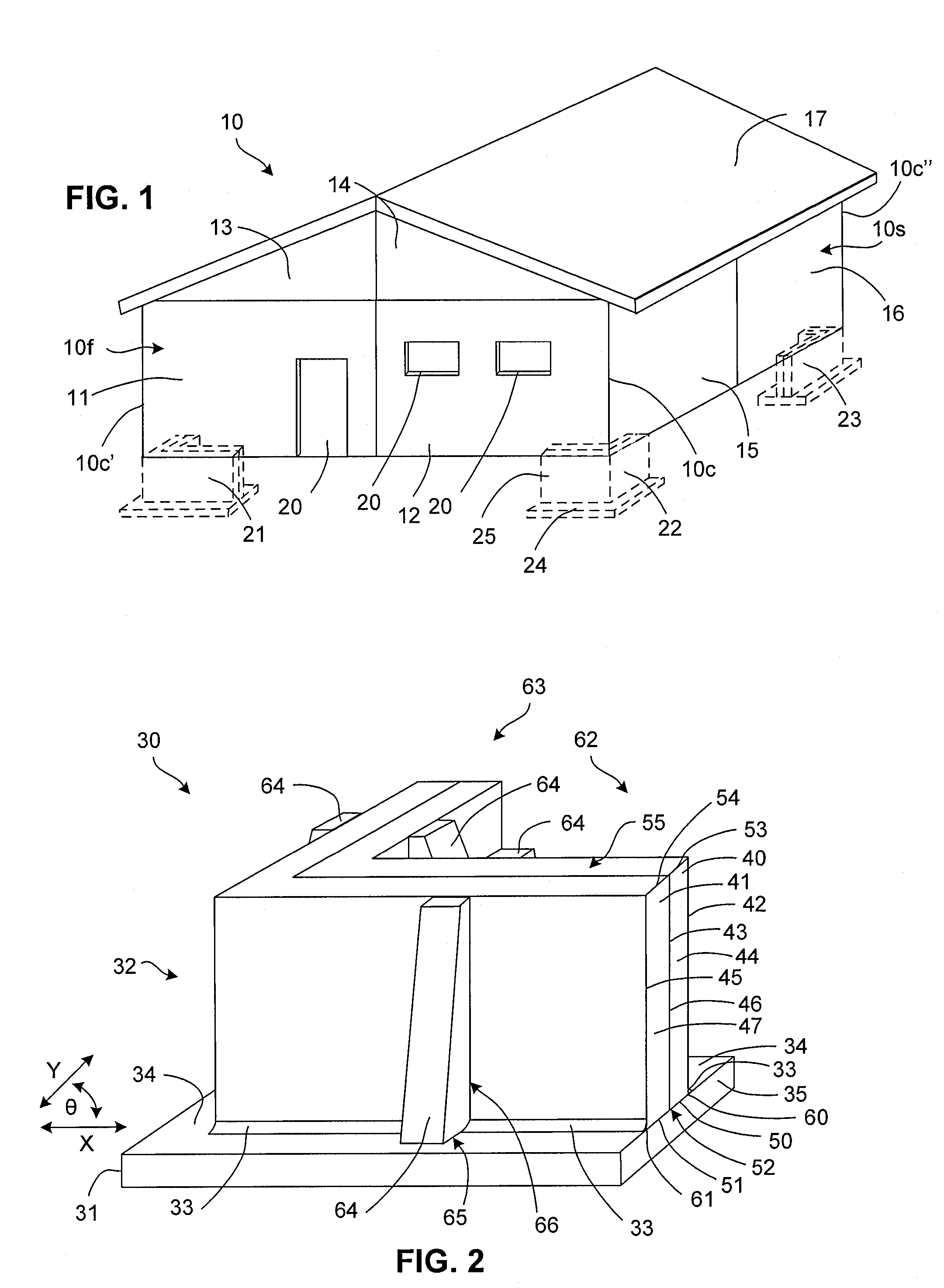

System and method of forming at least a portion of a reinforced roof structure from sandwich panels

InactiveUS20100050542A1Great strength-to-weight ratioLight weightBuilding roofsRoof coveringEngineeringSandwich panel

A roofing system includes a first sandwich panel, a second sandwich panel and a support panel. The first sandwich panel, which forms at least a portion of the roof structure, has a first outer layer and a second outer layer spaced from the first outer layer by a panel core. The first sandwich panel includes a first angle edge, which includes an edge portion of the panel core and an edge portion of at least the first outer layer. The second sandwich panel includes a first outer layer and a second outer layer spaced from the first outer layer by a second panel core, wherein the edge portion of the first sandwich panel is supported, at least in part, by one or more outer surface Depending on the length of the roofing system and / or other design criteria, the roofing system includes one or more support panels secured between the first sandwich panel and the second sandwich panel to provide additional support for the roof structure.

Owner:MILLPORT ASSOC

Modified bitumen roofing membrane with enhanced sealability

InactiveUS20060062954A1Good flexibilityMore elasticRoof covering using flexible materialsTextiles and paperThermoplasticCompound (substance)

Owner:ZANCHETTA NATALINO

Composite self-retaining sutures and method

ActiveUS9044225B1Improved self-retaining suturesImprove abilitiesSuture equipmentsSurgical needlesUltimate tensile strengthMaterials science

Owner:ETHICON INC

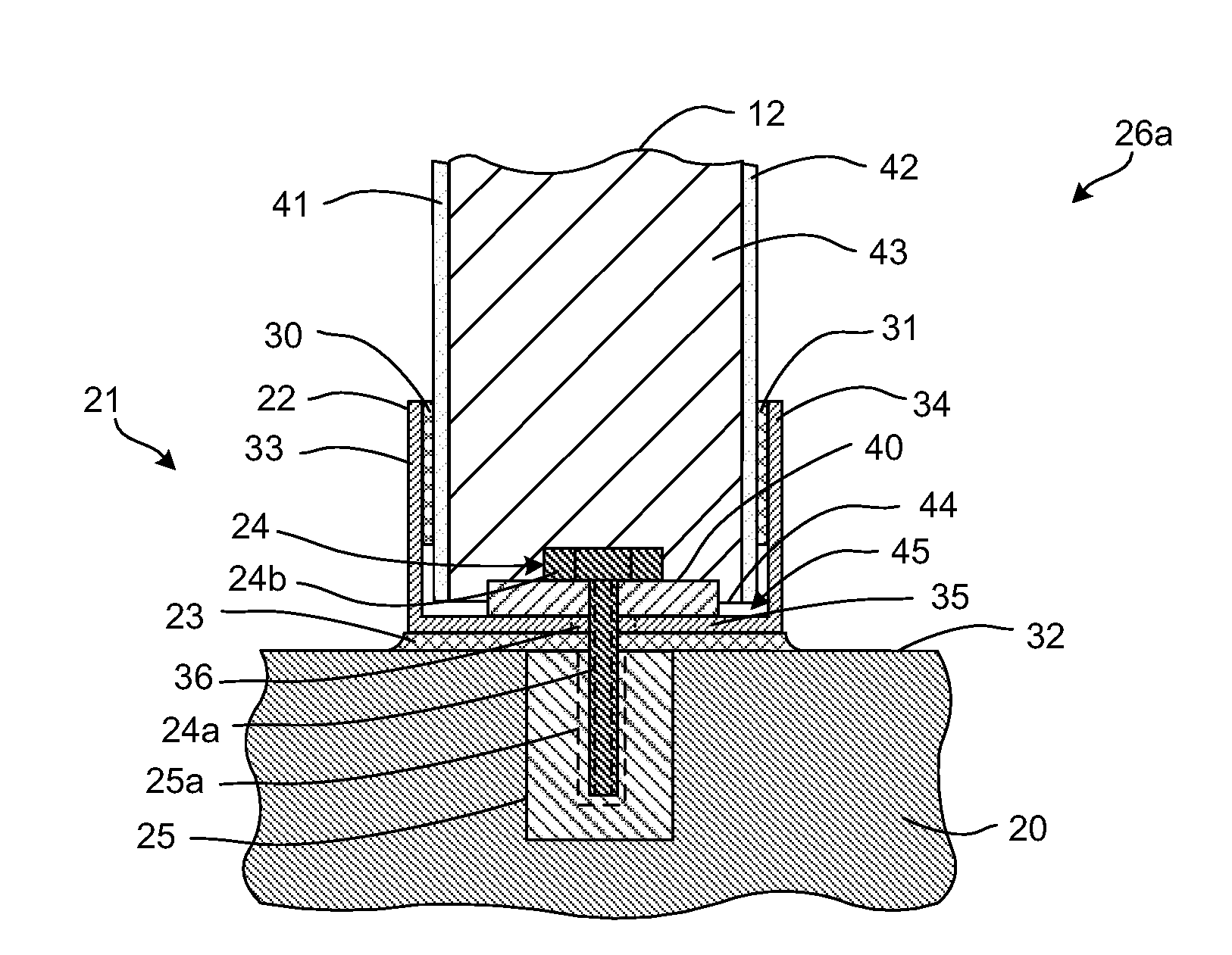

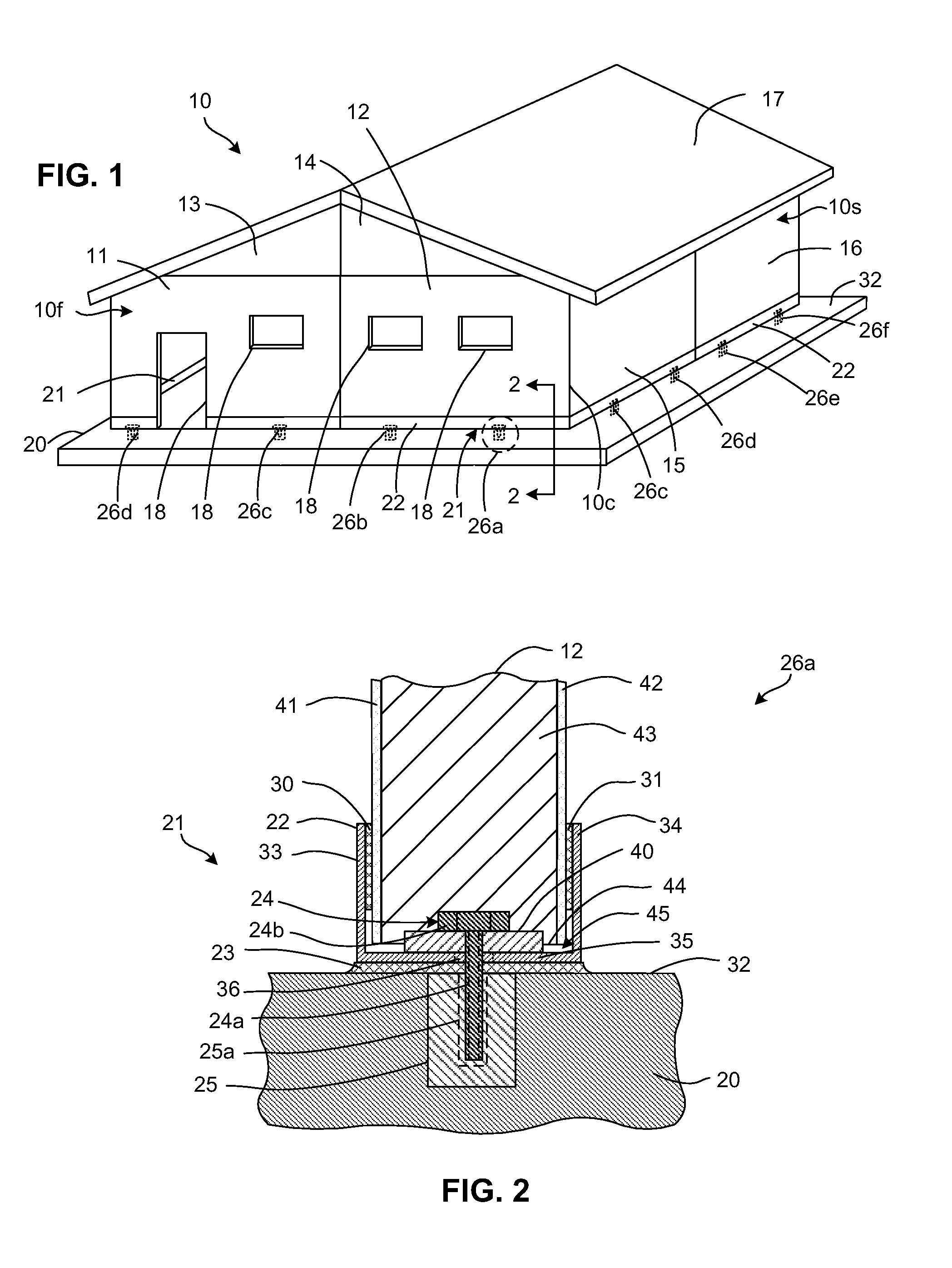

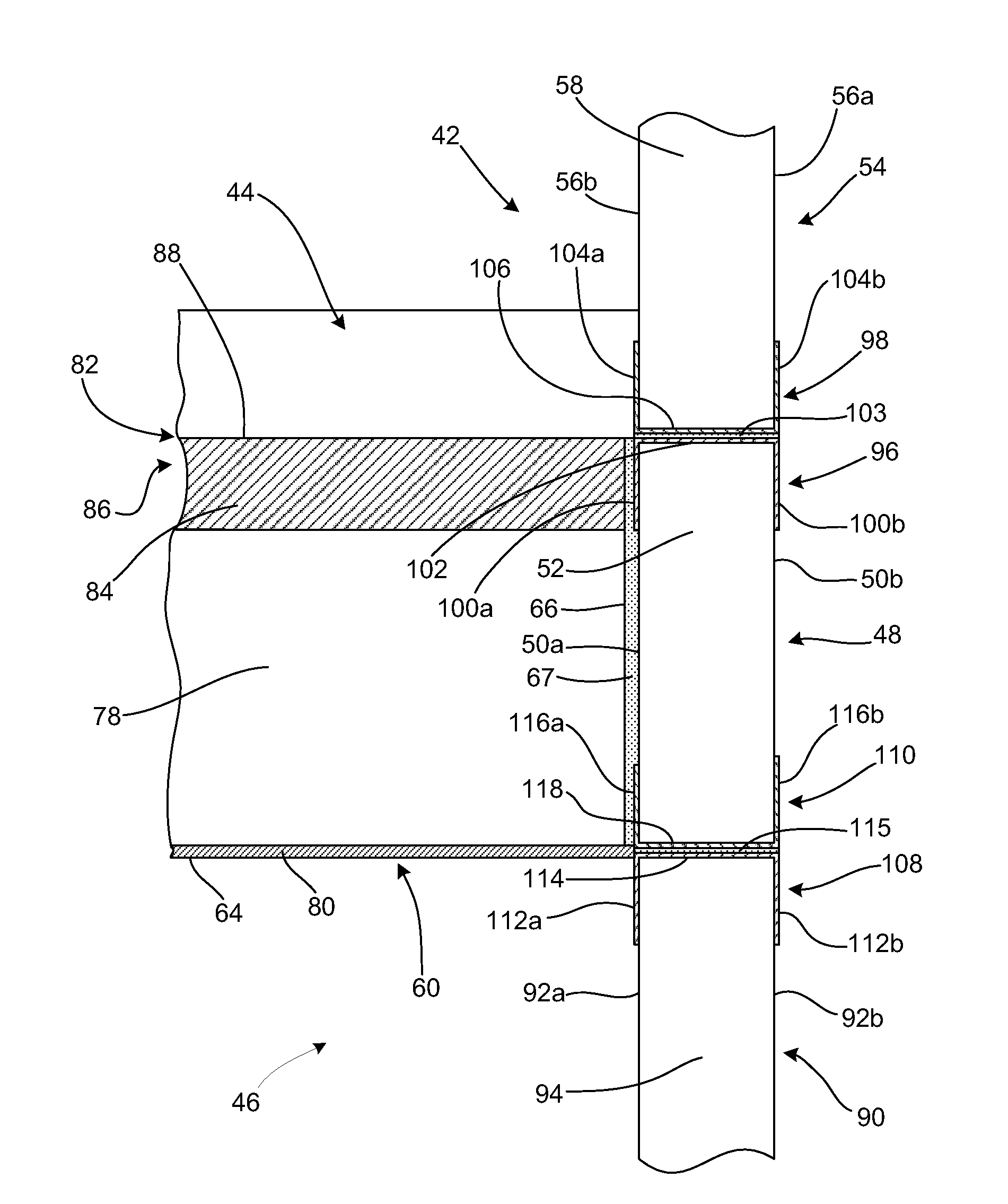

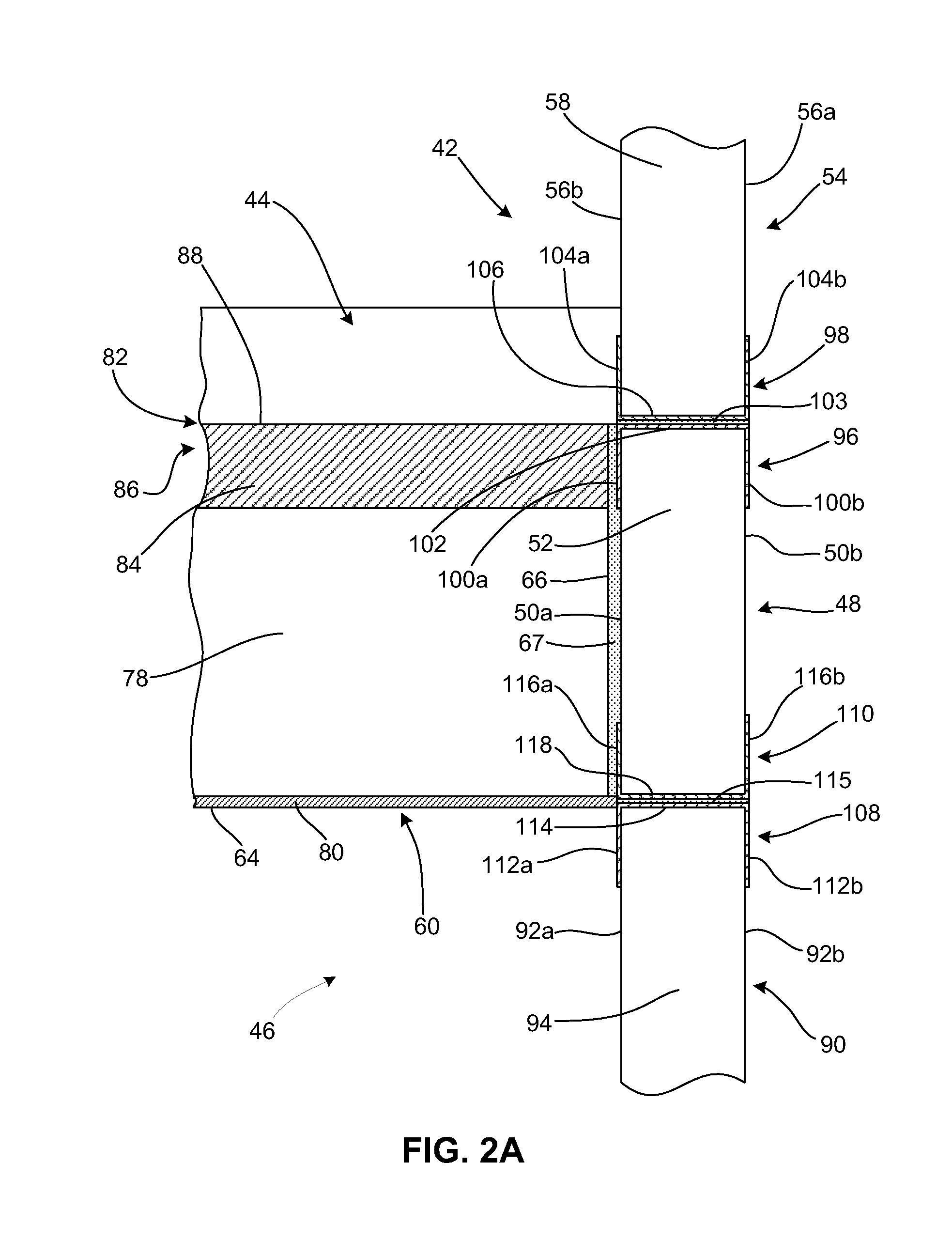

Connection for sandwich panel and foundation

InactiveUS20090313926A1Great strength-to-weight ratioLight weightBuilding roofsWallsMechanical engineeringSandwich panel

A joint connecting a sandwich panel to a foundation comprising, a sandwich panel having a core and two outer layers separated from one another by the core, an anchor in the foundation, a U-shape member having two side walls and a bottom wall extending between the sidewalls, the bottom wall defining a opening that is aligned with the anchor in the foundation and a securing member insertable through the opening in the bottom wall of the U-shape member and engaged to the anchor to secure the U-shape member to the anchor, wherein the U-shape member is connected to the outer layers of the sandwich panel by bonding material between the outer layers of the sandwich panel and the side walls of the U-shape member.

Owner:MILLPORT ASSOC

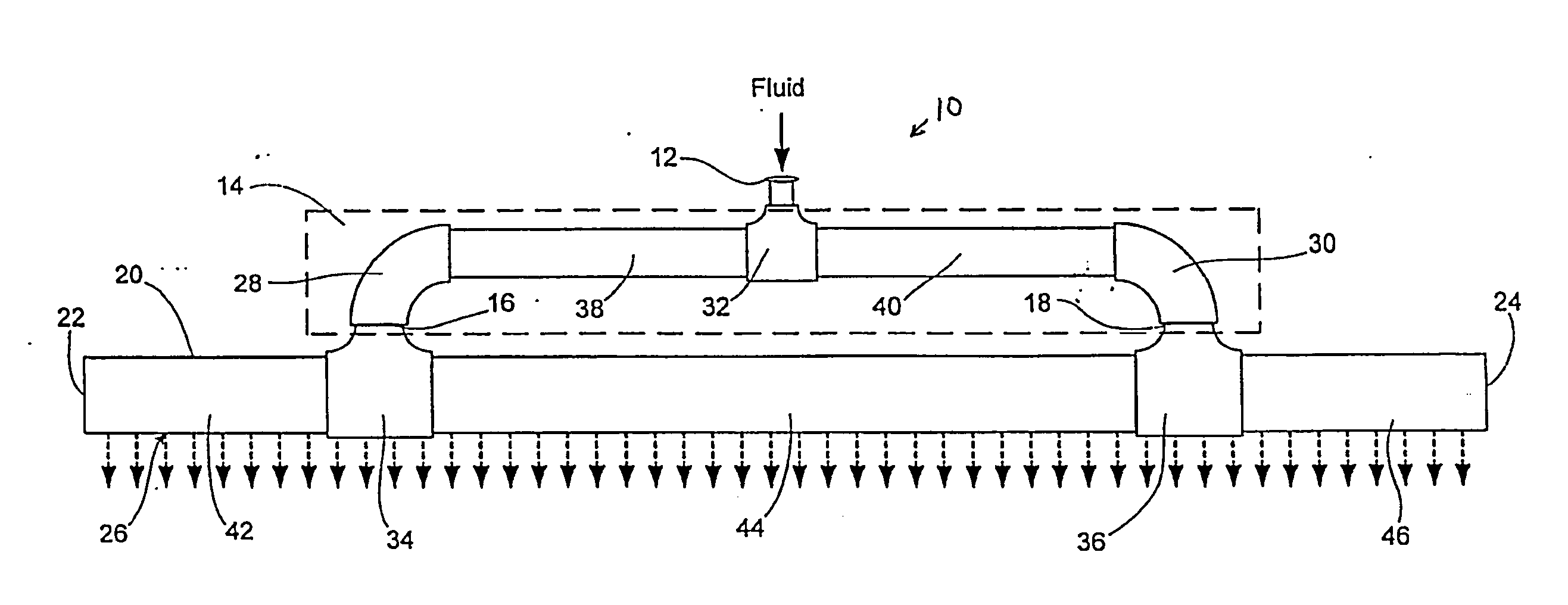

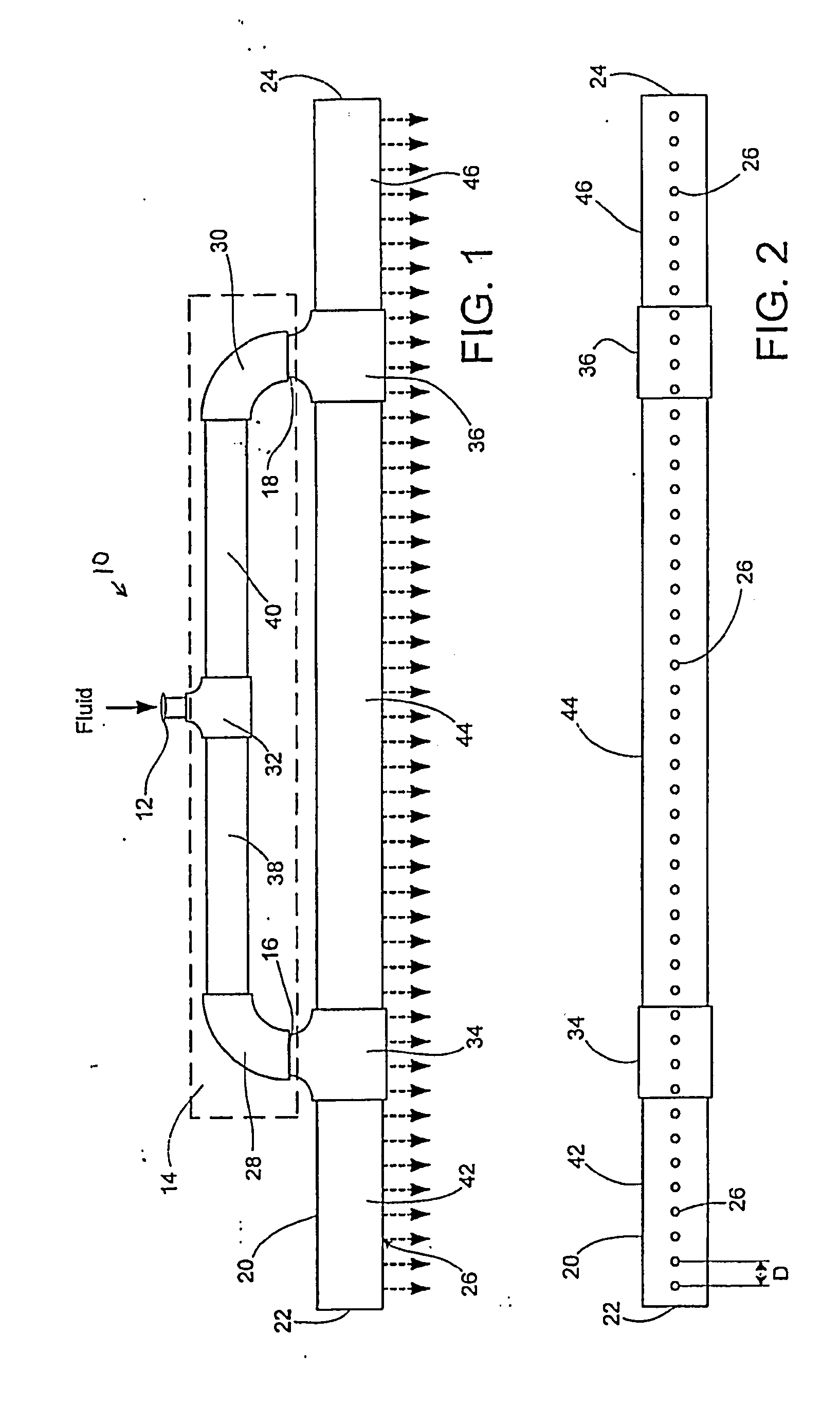

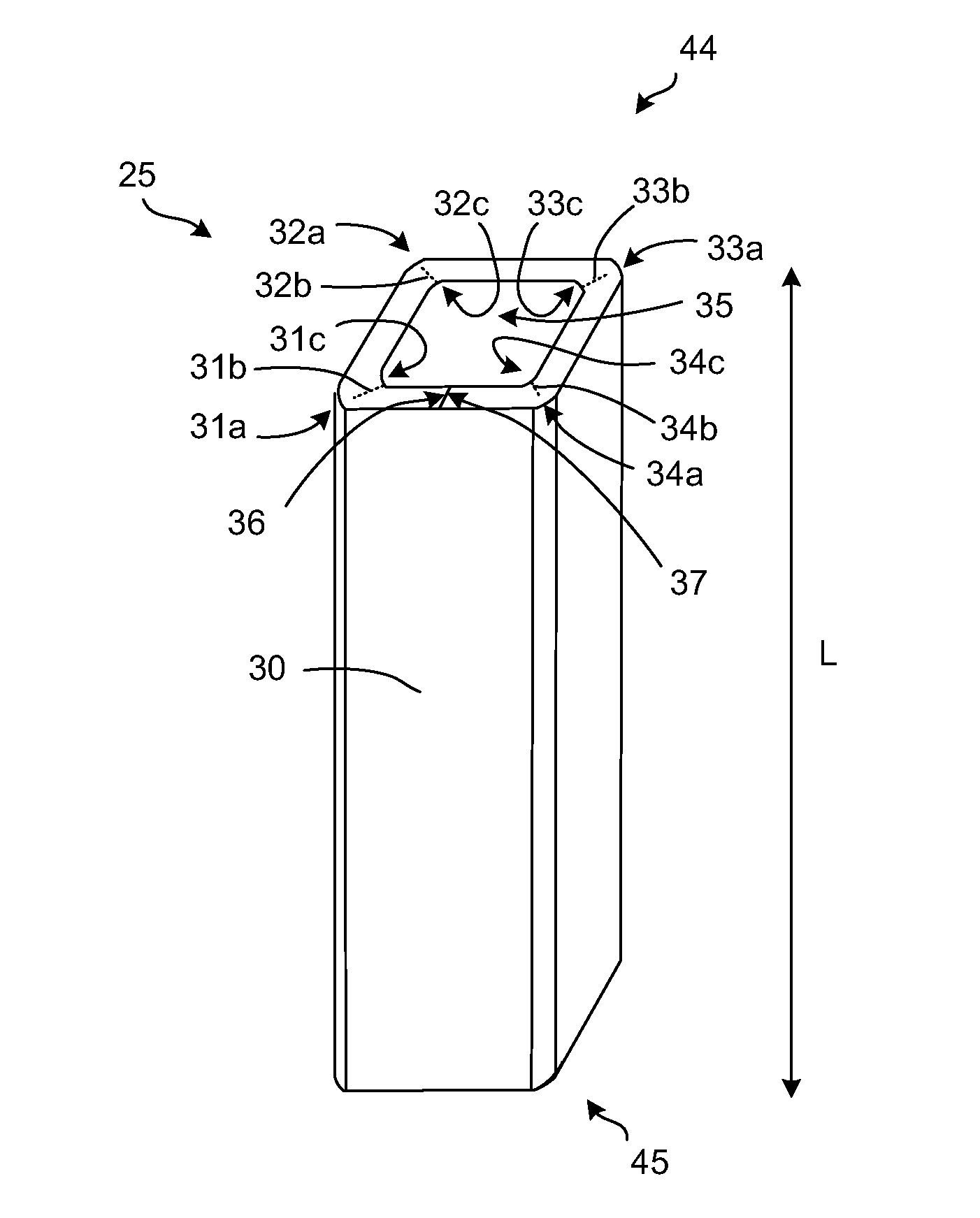

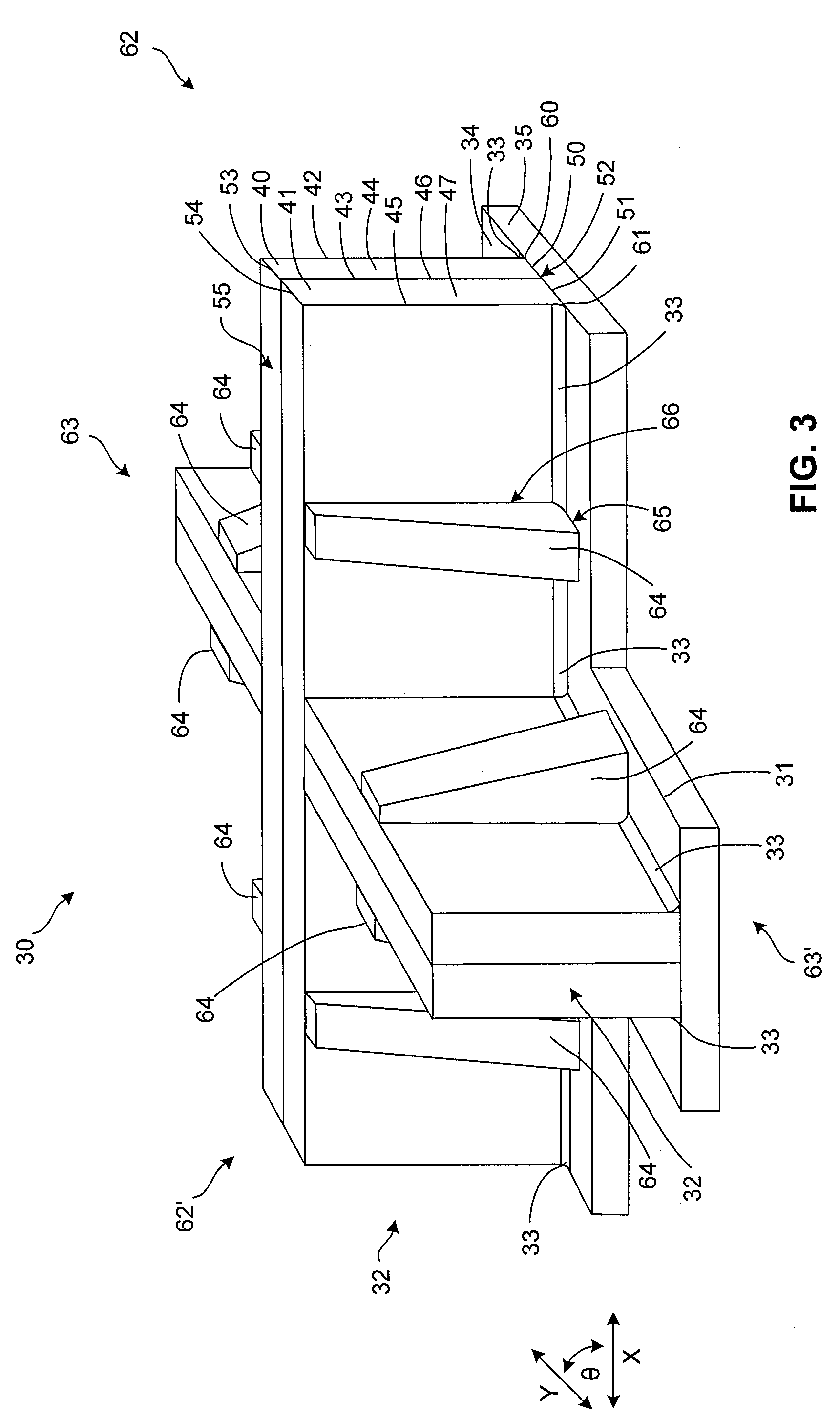

Nozzle system and method for manufacturing composite sandwich panels

InactiveUS20140263759A1Great strength-to-weight ratioLight weightSpray nozzlesBuilding componentsEngineeringSandwich panel

A nozzle and system for manufacturing composite sandwich panels, including an input port configured to receive a fluidic production material for forming a composite sandwich panel; a branching element coupled to the input port, wherein the production material that enters the branching element is output from a first end and a second end of the branching element; and an elongate tubular member coupled to the first end and the second end of the branching element for receiving the production material, wherein the elongate tubular member has a first end; a second end and a plurality of openings formed in the elongate tubular member such that the received production material is output through the plurality of openings. In another embodiment, the nozzle includes a second plurality of openings formed in the elongate tubular member.

Owner:MILLPORT ASSOC

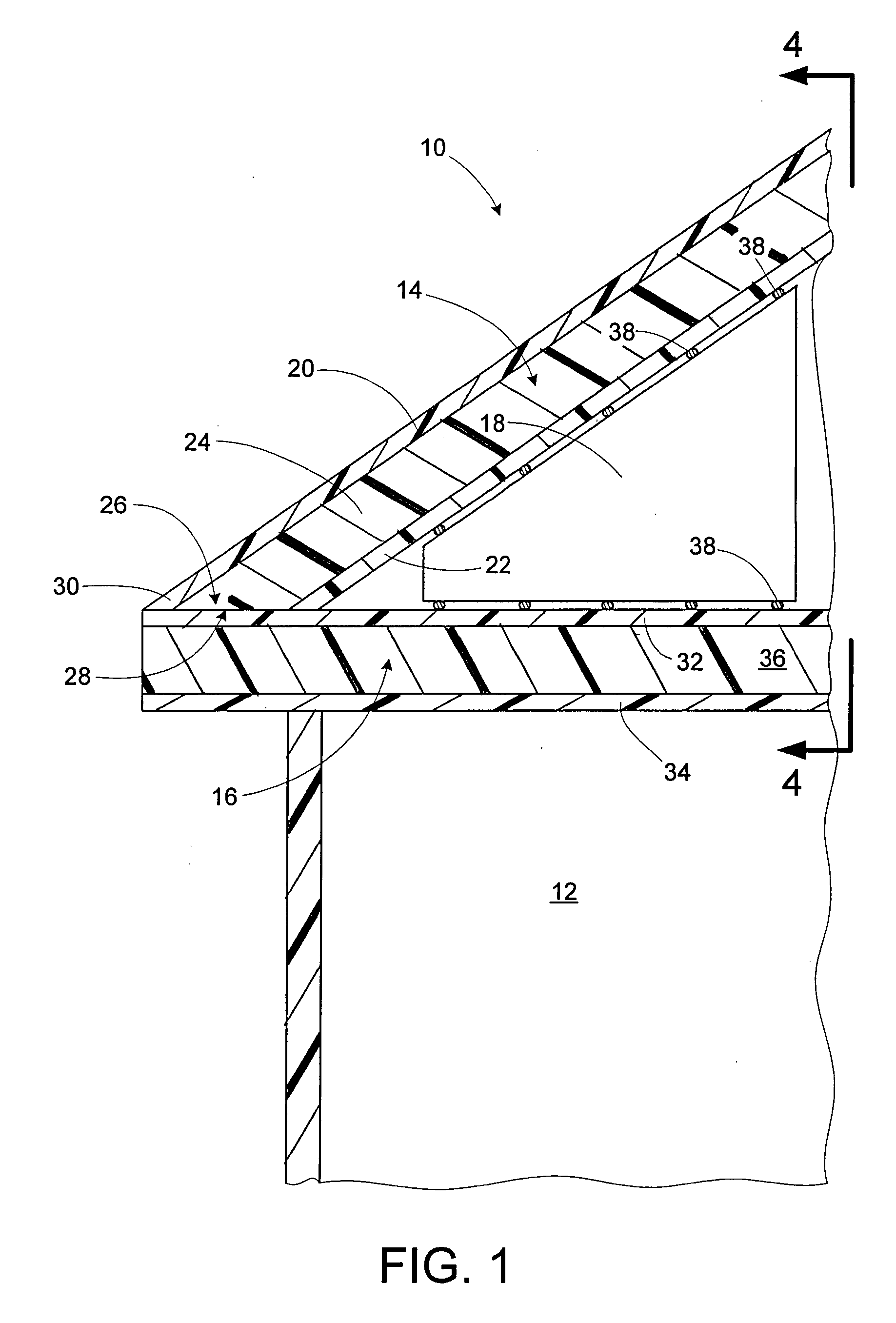

Roof construction joints made of sandwich panels

InactiveUS20090307995A1Great strength to weight ratioLight weightBuilding roofsRoof coveringEngineeringStructure based

A roofing joint includes a union member that joins two sandwich panels. An edge portion of the sandwich panels is cut and removed, e.g., by a miter cut. The edge portion is generally cut based on the pitch of the roof for the structure. The roof joint is formed by aligning the union member between the edges of the panels. Thus, the panel cores are in contact with opposing surfaces of the union member, such that the cores of panels are in physical contact with the union member. In one embodiment, the union member extends above the surface of the roofing joint (e.g., extends above the first outer surface of the panels). In another embodiment, the union member extends below the surface of the second outer surface of the panels. A bonding material is injected or otherwise adhered to areas of intersection for the first and second panels and the union member to protect the joint from environmental elements (e.g., water penetration, snow, hail, etc.). In another embodiment, a channel guide is secured relative portion to the roof to direct liquid (e.g., water, rain, sleet, snow, etc.) that accumulates on the roof to a desired location.

Owner:MILLPORT ASSOC

Columnar structural component and method of forming

InactiveUS20140260085A1Great strength-to-weight ratioLight weightStrutsMetal-working apparatusStructural elementEngineering

A columnar structural component and method of forming a columnar structural element from a sandwich panel includes forming a number of sets of recesses in the sandwich panel and bending the sandwich panel at each set of recesses to form a columnar structural element. The columnar structural component includes a number of support members at least partially disposed within an area bounded formed with the sandwich panel is bent in the areas of the sets of recesses.

Owner:MILLPORT ASSOC

Ceiling support construction and methods

A ceiling construction and method for supporting an upper level of structure using sandwich panels having insulative cores. The ceiling construction has a lower level wall sandwich panel and an upper level wall sandwich panel, each of which with two outer layers and a core separating the outer layers and an upper level wall sandwich panel. Adhered to the lower level wall sandwich panel is a beam configured to support the upper level of the structure.

Owner:MILLPORT ASSOC

Sandwich panel ground anchor and ground preparation for sandwich panel structures

InactiveUS8733033B2Raise the ratioLight weightBuilding repairsBuilding material handlingArchitectural engineeringSandwich panel

A ground anchor and method for anchoring a building to the ground. The ground anchor has a base member having a core and an outer layer connected to the core. The ground anchor also has a support member having two outer layers separated from one another by a core, the support member having a top surface and a bottom surface. A bonding material connects the bottom surface of the support member to the outer surface of the base member. Bonding material also connects the top surface of the support member to a building element. The ground anchor is buried in the ground at the construction site and connected to the building to anchor the building to the ground.

Owner:MILLPORT ASSOC

Sandwich panel ground anchor and ground preparation for sandwich panel structures

InactiveUS20090320387A1Great strength-to-weight ratioLight weightBuilding repairsBuilding material handlingSandwich panelEarth anchor

A ground anchor and method for anchoring a building to the ground. The ground anchor has a base member having a core and an outer layer connected to the core. The ground anchor also has a support member having two outer layers separated from one another by a core, the support member having a top surface and a bottom surface. A bonding material connects the bottom surface of the support member to the outer surface of the base member. Bonding material also connects the top surface of the support member to a building element. The ground anchor is buried in the ground at the construction site and connected to the building to anchor the building to the ground.

Owner:MILLPORT ASSOC

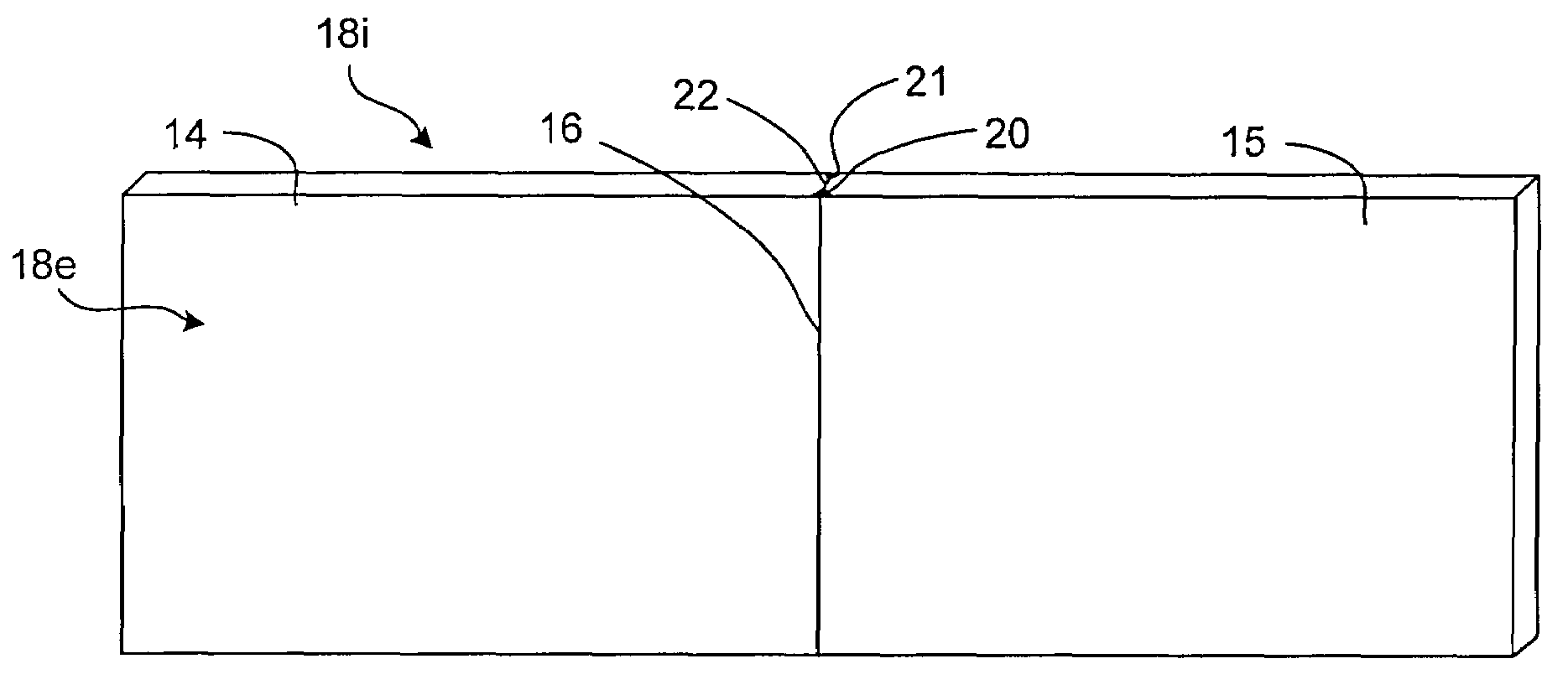

Composite sandwich panels and method of forming round corners in composite sandwich panels

InactiveUS20140272311A1Raise the ratioLight weightSynthetic resin layered productsLaminationEngineeringSandwich panel

A method for forming a curved surface in a planar composite sandwich panel, the method including: providing a sandwich panel having a first outer layer and a second outer layer spaced from the first outer layer by a panel core. The first outer layer, the second outer layer and the panel core are substantially planar. The sandwich panel includes a first end, a second end and at least one edge. One or more recesses are formed in the second outer layer and the panel core of the sandwich panel, wherein each of the one or more recesses form a continuous channel between the first end and the second end along a first axis. A bonding material is applied to at least one edge of the sandwich panel. A force is applied to at least a portion of the sandwich panel to impart a curved outer surface in the sandwich panel, wherein the curved outer surface is formed by the first outer layer. The sandwich panel is then secured for a predetermined period of time to maintain the curved outer surface.

Owner:MILLPORT ASSOC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com