Heat dissipation device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

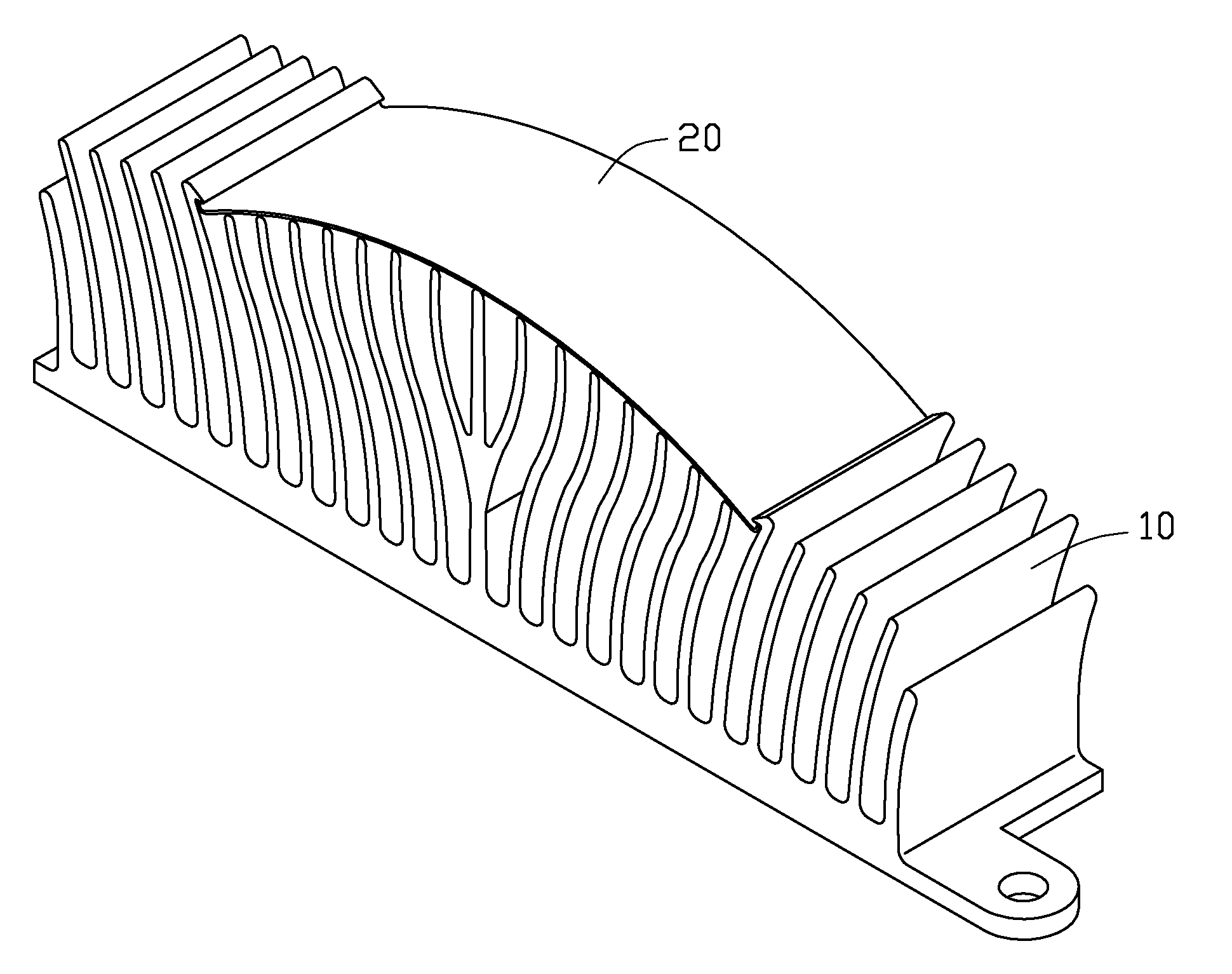

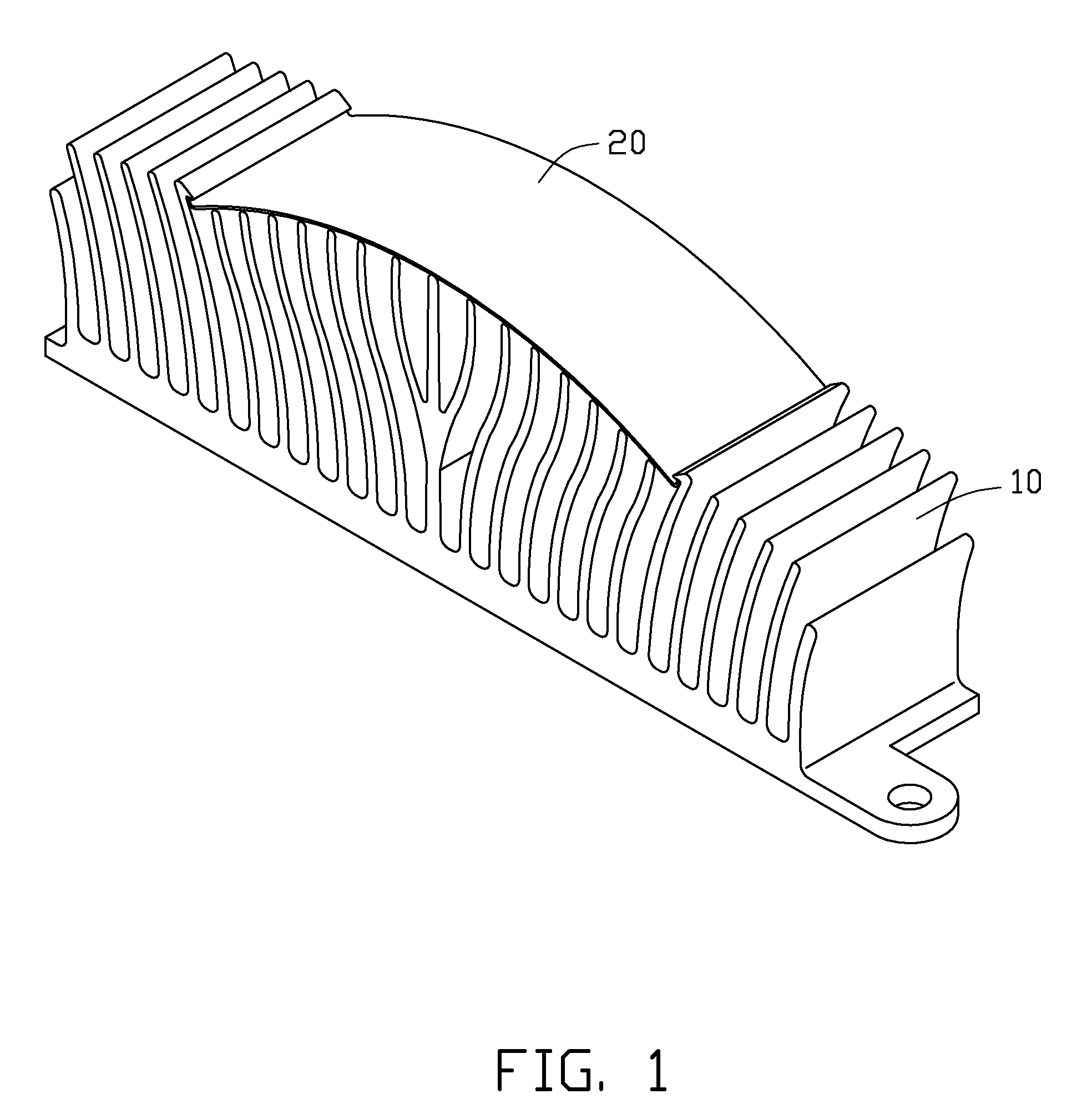

[0010]Referring to FIG. 1, a heat dissipation device in accordance with the disclosure is provided to dissipate heat generated by an electronic component (not shown) mounted on a printed circuit board (not shown). The heat dissipation device comprises a heat sink 10 thermally contacting the electronic component and a label member 20 securely disposed on the heat sink 10.

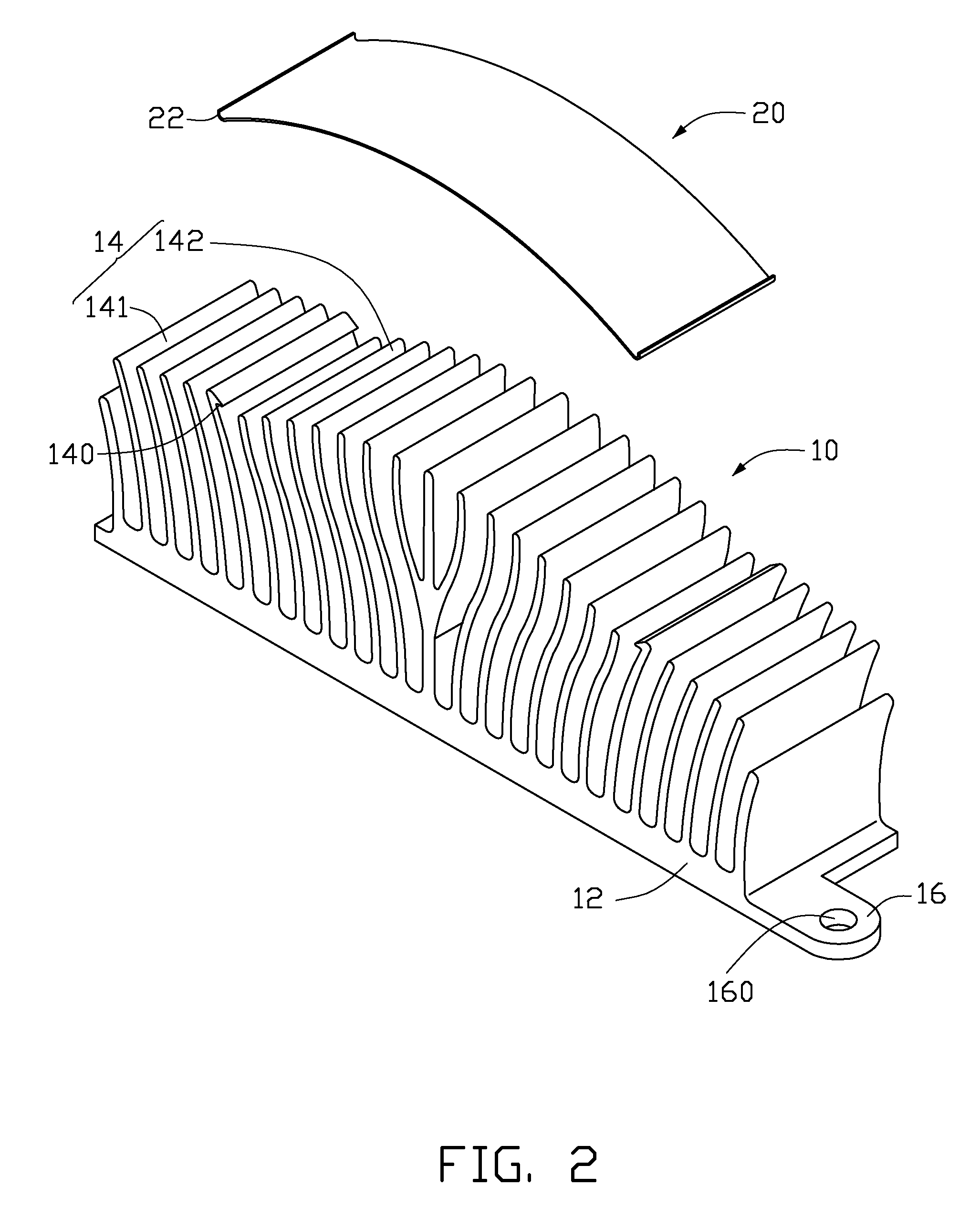

[0011]Also referring to FIG. 2, the heat sink 10 is integrally formed of metal with good heat conductivity, such as aluminum, copper, or alloys thereof. The heat sink 10 comprises a rectangular base 12 and a plurality of fins 14 extending upwardly from a top surface thereof. The fins 14 are spaced from each other and extend along a width of the base 12. Between each two adjacent fins 14 a passage (not labeled) therebetween allows airflow therethrough. The fins 14 comprise a plurality of first fins 141 divided into two parts located at opposite lateral sides of the base 12, respectively, and a plurality of second fins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com