Snuff box

a snuff box and snuff technology, applied in the field of snuff boxes, can solve the problems of large number of components, disadvantageous consumption of the whole snuff box volume, and inability to shift the metal plate,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

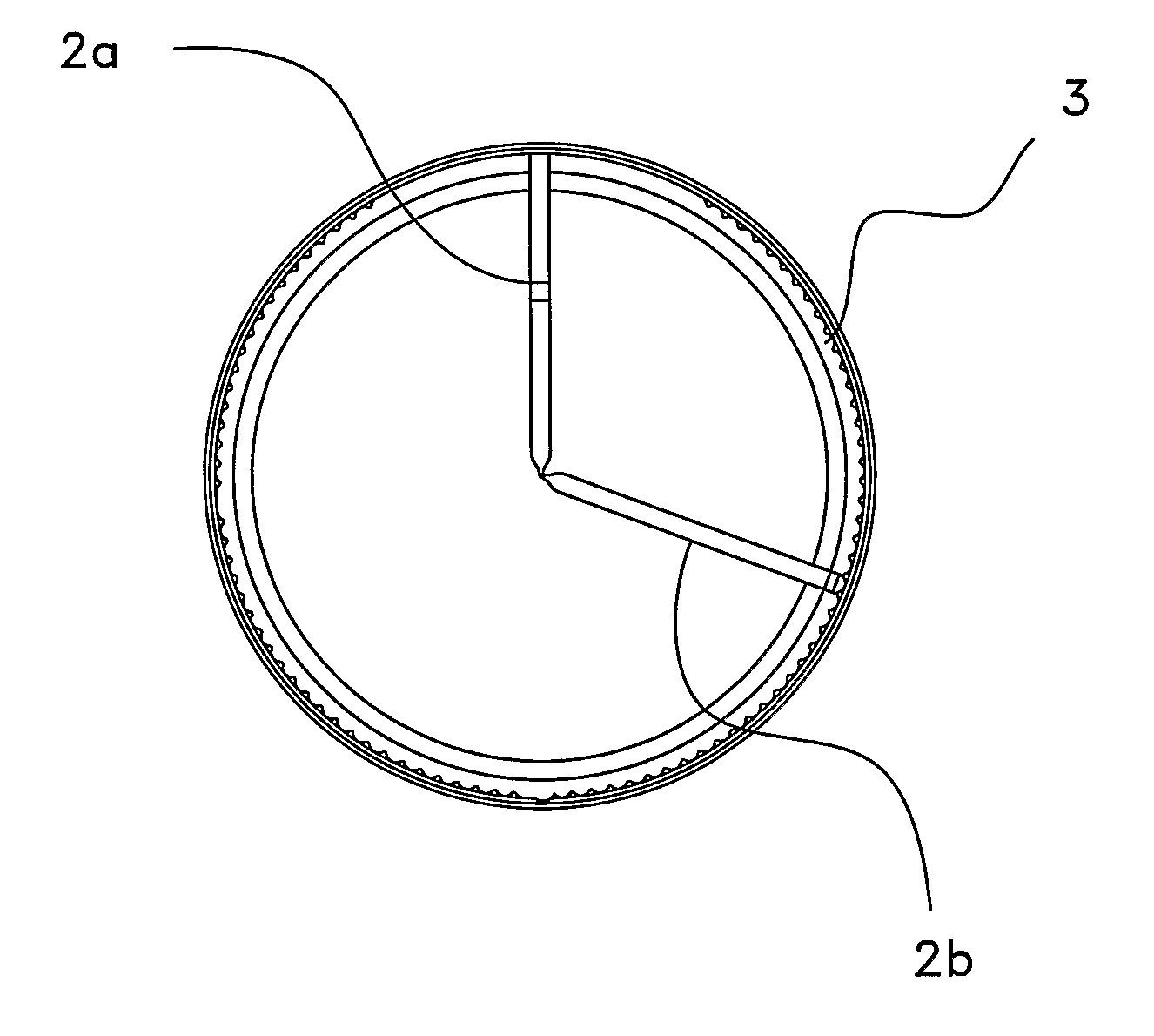

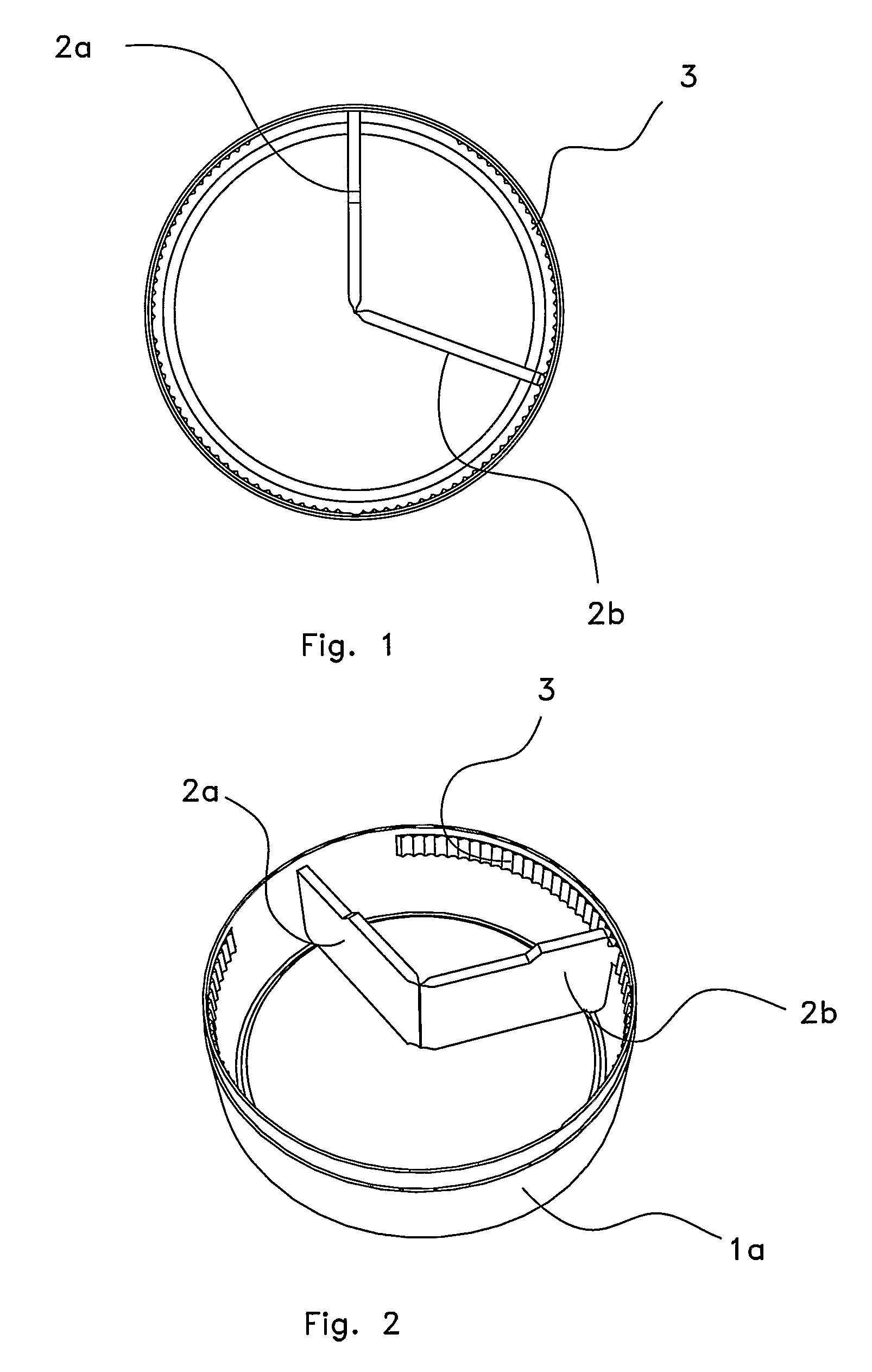

[0020]FIGS. 1 and 2 show a first embodiment of the snuff box bottom part 1a seen from above and at an oblique angle from above, respectively. The bottom part 1a is essentially cylindrical with a covered bottom and is adapted for receiving a lid. In the bottom part 1a is a dividing wall 2a, 2b with two halves arranged, a fixed dividing wall part 2a and a moveable dividing wall part 2b. The fixed dividing wall part 2a is a plane piece of material that extends from the cylinder wall towards the box centre and is fixedly arranged in this position. From the centre axis of the box a moveable dividing wall part 2b extends towards the cylinder wall. The moveable dividing wall part 2b is attached to the moveable, but in such a way that it can be pivoted relative to that.

[0021]On the cylinder wall interior a number of recesses 3 are arranged and a protruding portion of the moveable dividing wall part 2b is normally placed in one of these recesses. If the moveable dividing wall part is made to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com