Sliding compression reaction chamber mechanism

A technology of reaction chamber and sliding connection, which is applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical instrument, etc., can solve problems such as sticking, topping, poor reliability, etc., and achieve Reliable positioning, guaranteed fluency, and appropriate torque effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

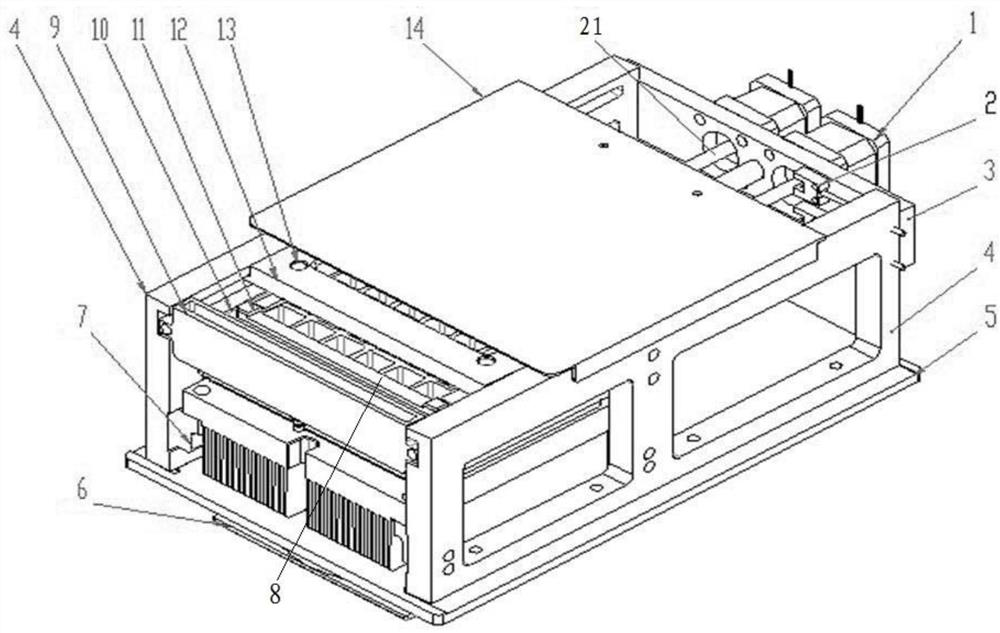

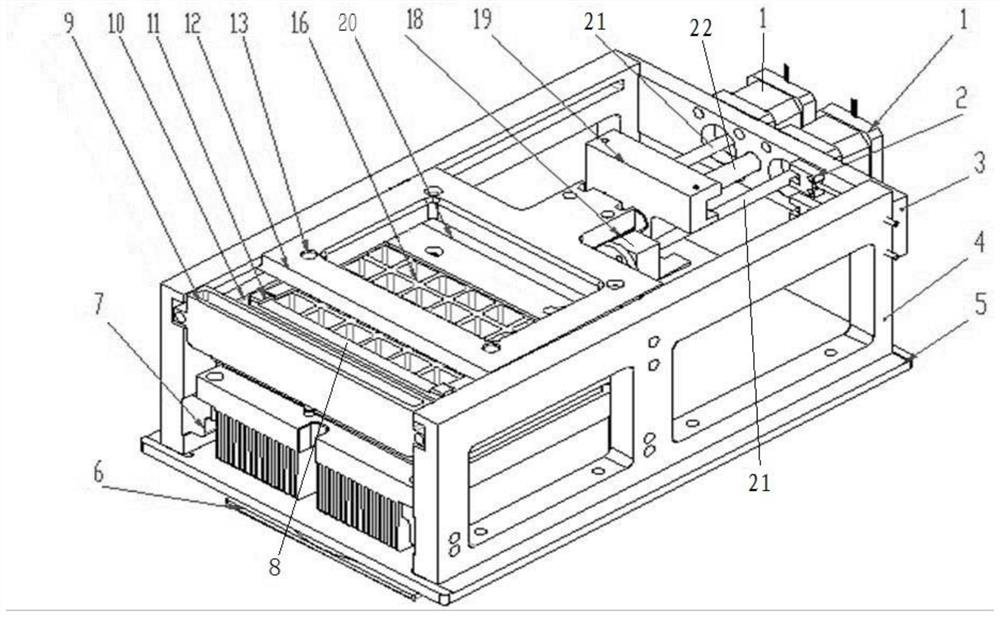

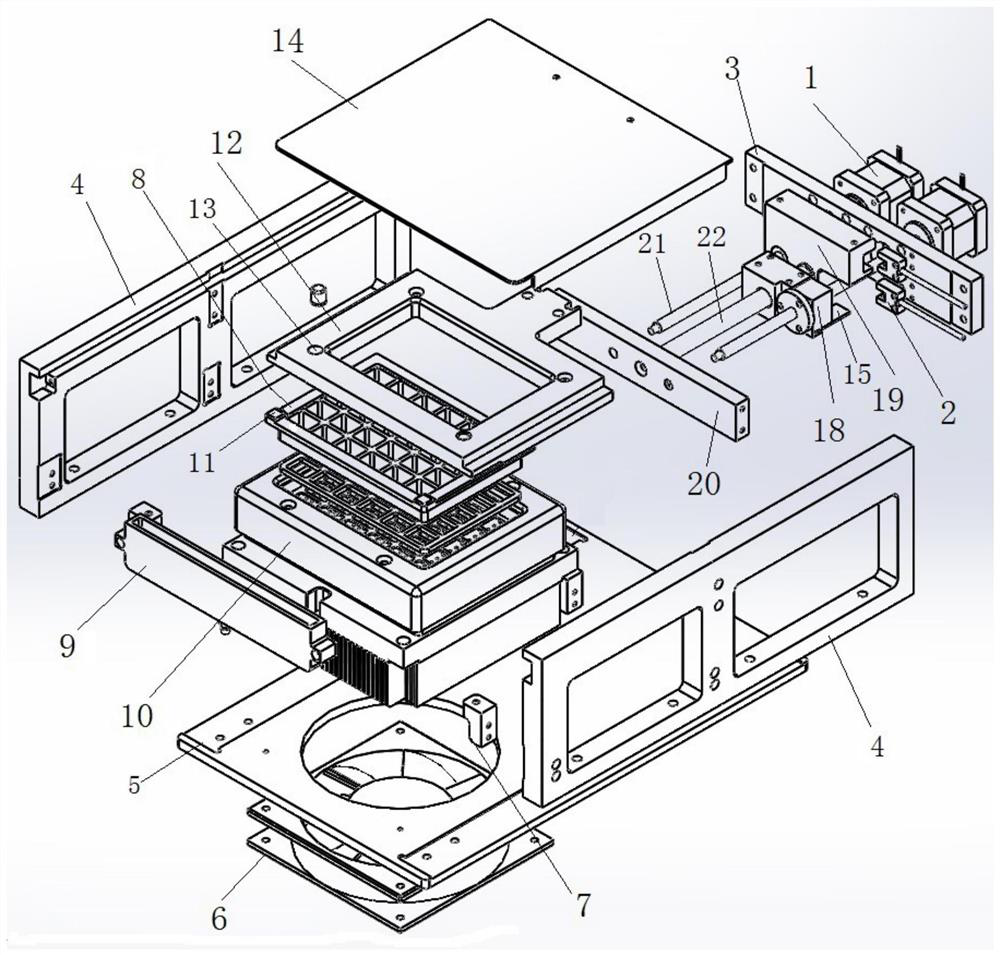

[0023] Such as Figure 1 to Figure 3 As shown, the present invention provides a sliding compression reaction chamber mechanism, including a frame, and the frame includes a bottom plate 5, support plates 4 located on opposite sides of the bottom plate 5, and a driving device 1 is provided on the frame, and the driving device 1 is fixedly connected with the support plate 4 through the fixed plate 3. The bottom plate 5 is provided with a limit block 7, the limit block 7 is used to limit the reaction chamber 10 arranged on the bottom plate 5, so as to realize the stable connection between the reaction chamber 10 and the bottom plate 5, the reaction chamber 10 is provided with a silicone ring 16, The silicone ring 16 has the function of cushioning and sealing.

[0024] Such as figure 1 , figure 2 As shown, the frame is slidably connected to the sliding upper cover 12, and the support plate 4 is provided with a chute that is slidably connected to the sliding upper cover 12.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com