Seamless ball structure

a technology of seamless ball and ball body, which is applied in the field of seamless ball structure, can solve the problems of threads being broken, ball not suitable for use, and not being able to meet the needs of use, and achieve the effects of reducing manufacturing costs, increasing structural strength, and easy and efficient manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]A preferred embodiment of the present invention is now described with more details with reference to the accompany drawing.

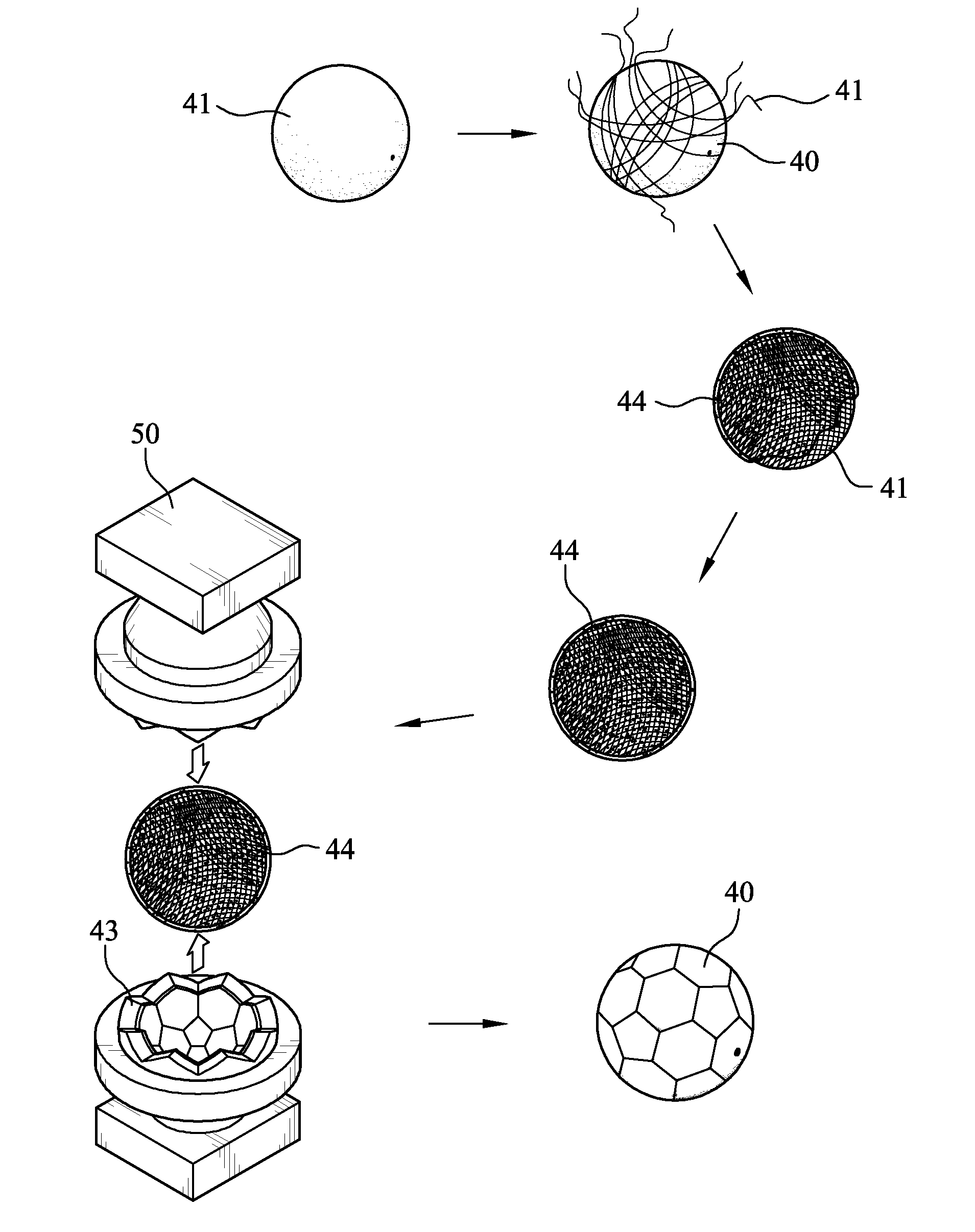

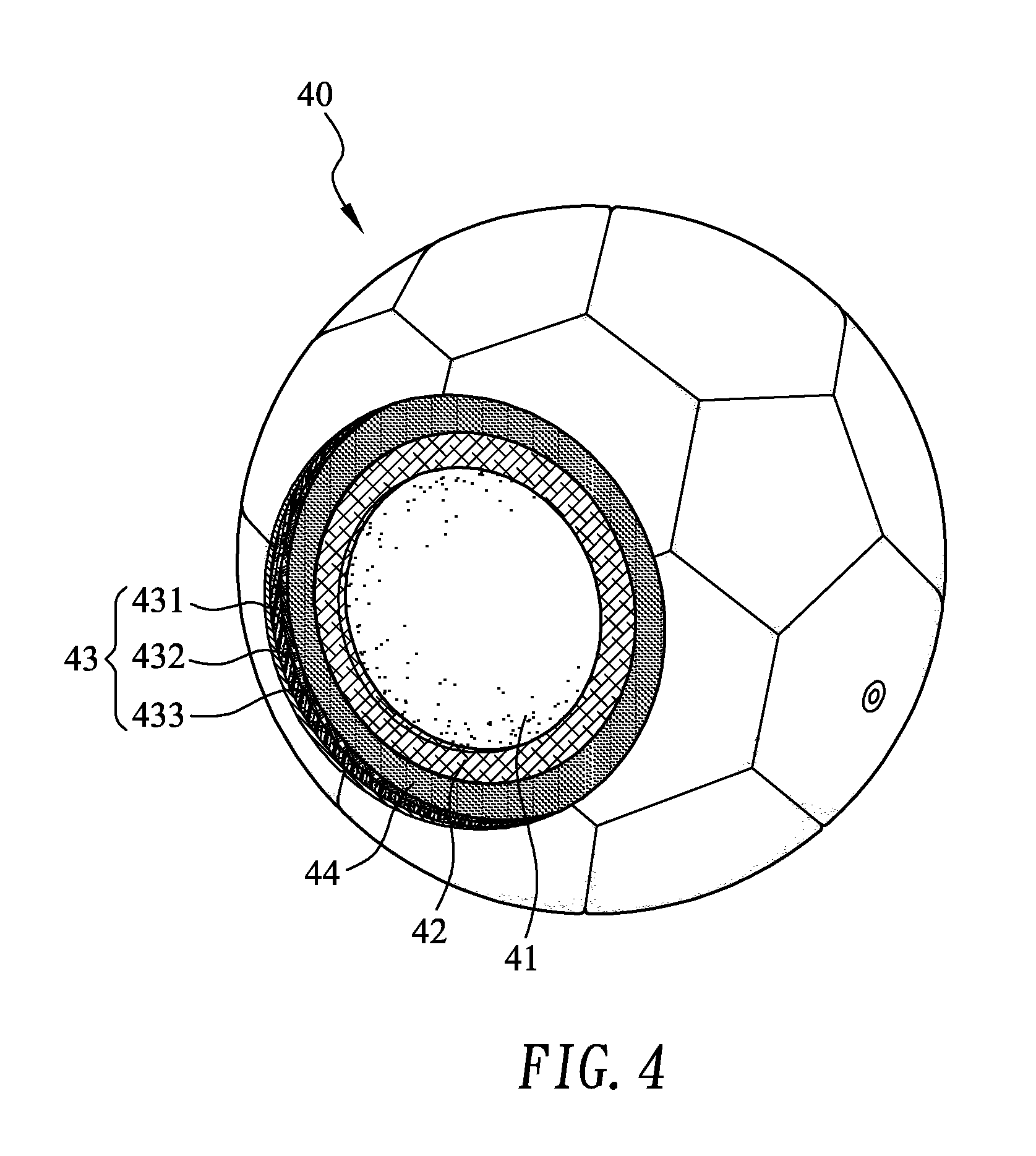

[0024]Please refer to FIGS. 4 and 5. A ball 40 with the seamless ball structure according to a preferred embodiment of the present invention includes an inflatable inner bladder 41, which is internally located at a center of the ball 40 and usually made of an elastic rubber material.

[0025]On an outer surface of the inner bladder 41, an inner yarn layer 42 having a predetermined thickness and fully attached to the inner bladder 41 is formed by winding a plurality of yarns around the inner bladder 41. With the inner yarn layer 42 being formed of yarns, it is possible for the inner bladder 41 wound around by the inner yarn layer 42 to responsively expand and contract when the inner bladder 41 is inflated and deflated, respectively, without becoming wrinkled or deformed to produce an unsmooth surface of the inner bladder 41.

[0026]An emulsion prepared with a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com