Elastic clip

a technology of elastic clips and clips, applied in the field of elastic clips, can solve the problems of high cost, difficult mass production, and a lot of effort and time for structure assembly, and achieve the effect of reducing labor costs and facilitating fabrication and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

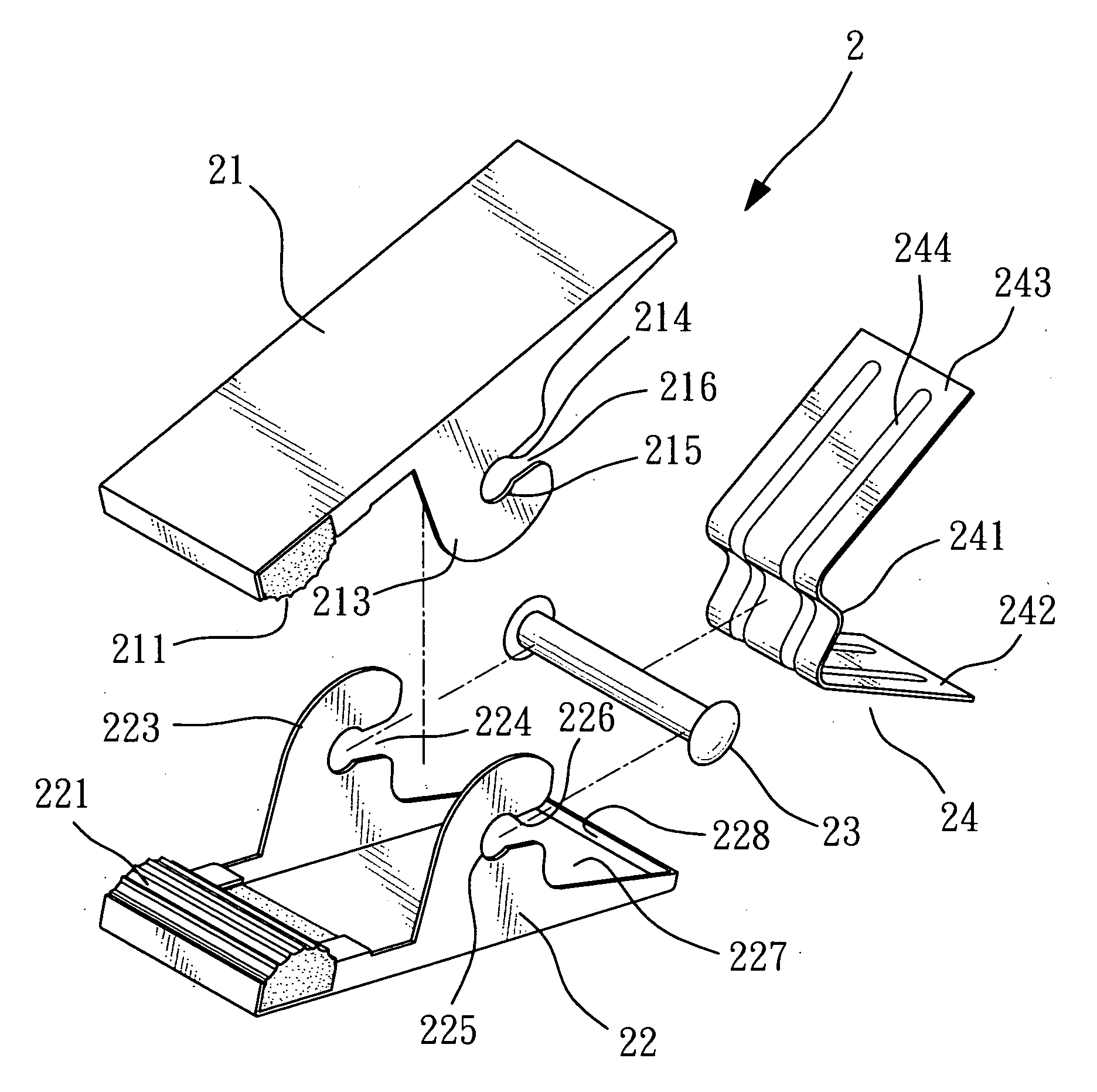

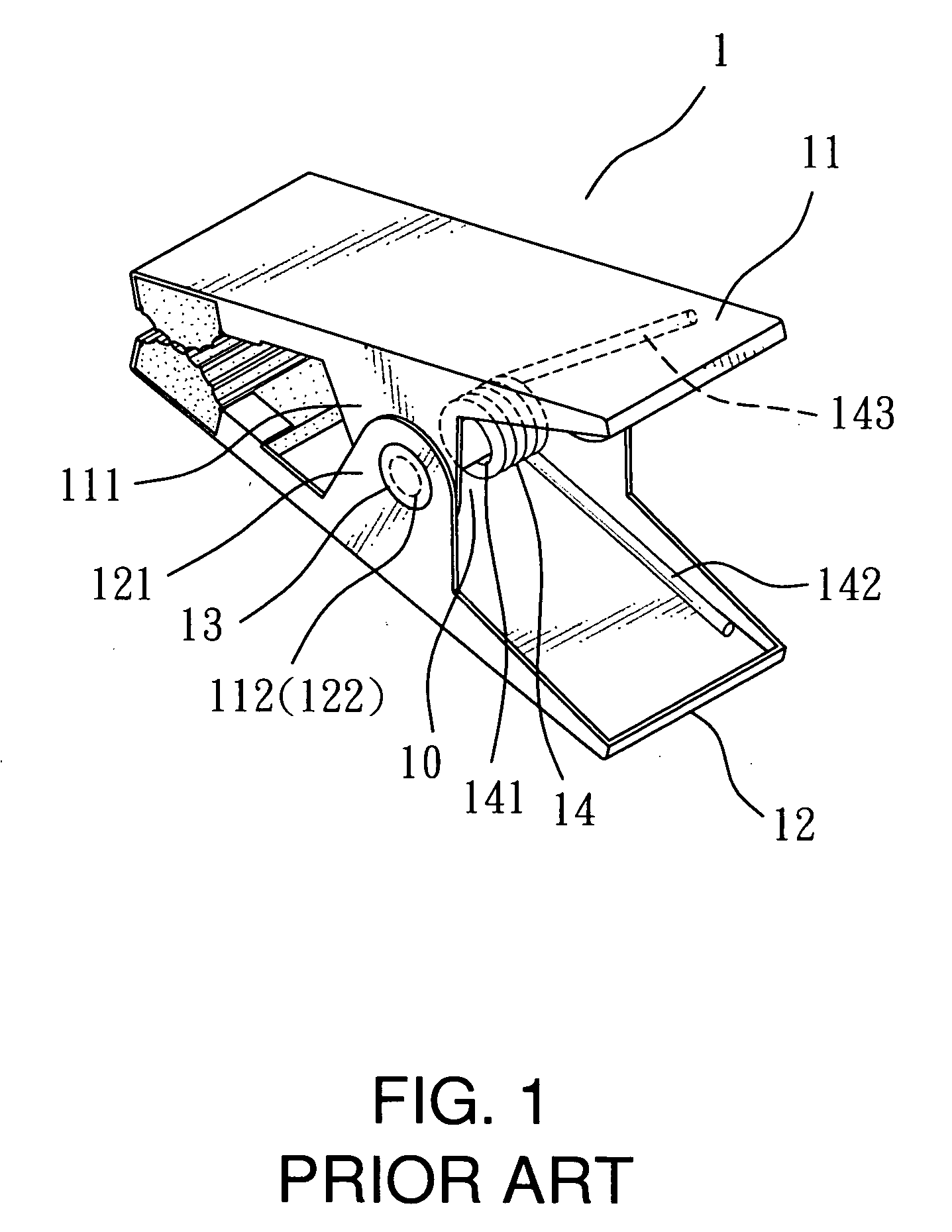

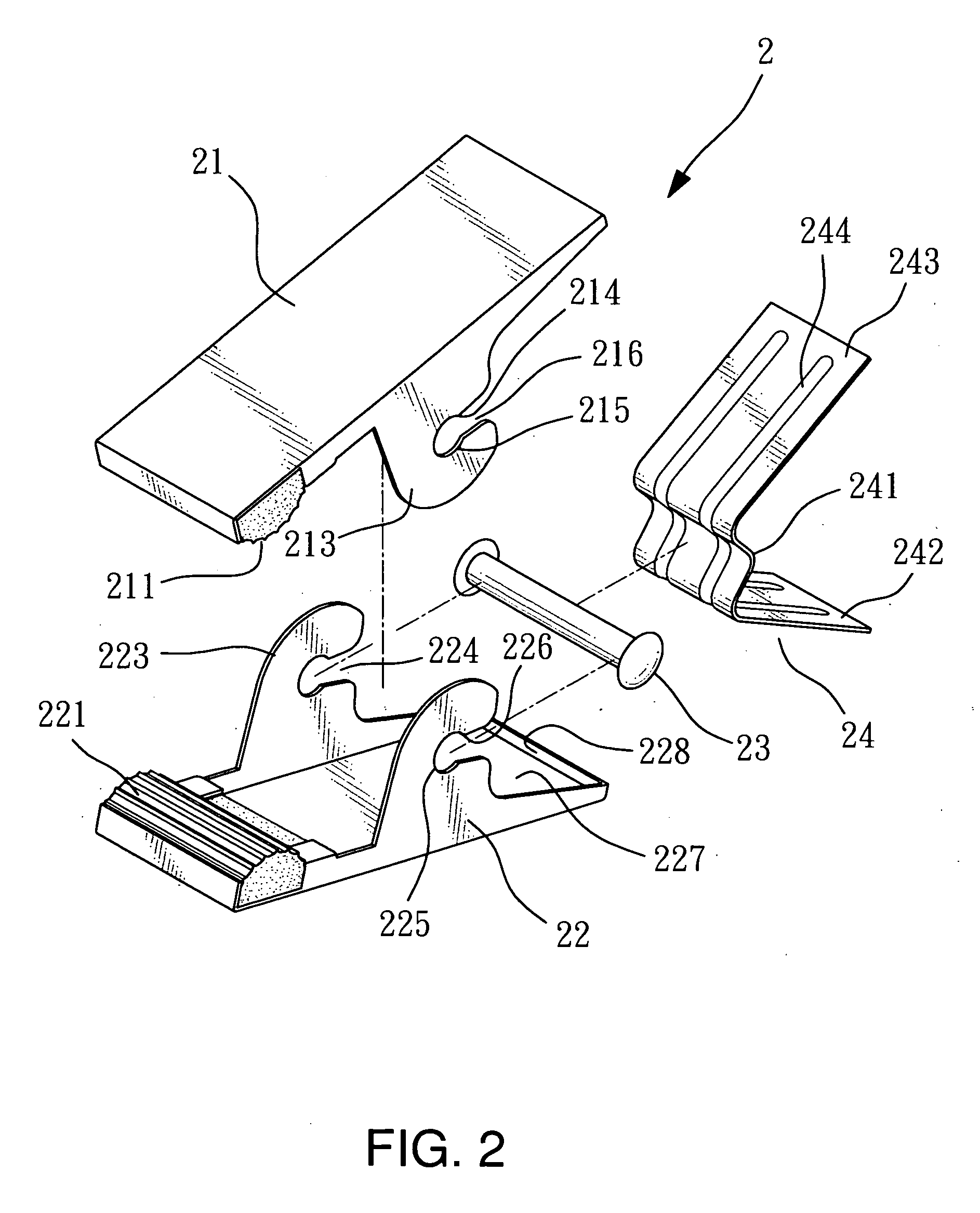

[0013]Referring to FIGS. 2 and 3, the invention provides an elastic clip 2 which includes a first clipping blade 21, a second clipping blade 22, a pin 23 and an elastic reed 24. The first clipping blade 21 and the second clipping blade 22 face each other.

[0014]The first clipping blade 21 has a first clipping portion 211 at a front end, a first depressing portion 212 at a rear end and a first inner recess 217 on an inner side that has a rear end formed a first detent wall 218. It also has a pair of first lugs 213 in a middle portion corresponding to each other. Each first lug 213 has a first transverse notch 214 and a first pin hole 215 at a tail end of the first transverse notch 214. The first pin hole 215 and the first transverse notch 214 are joined at a slightly protrusive juncture to form a first retaining spot 216.

[0015]The second clipping blade 22 has a second clipping portion 221 at a front end, a second depressing portion 222 at a rear end and a second inner recess 227 on an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com