Wellbore annular pressure control system and method using accumulator to maintain back pressure in annulus

a control system and annulus technology, applied in the direction of earth drilling, fluid removal, borehole/well accessories, etc., can solve the problems of increasing the duty cycle and increasing the size of the primary pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

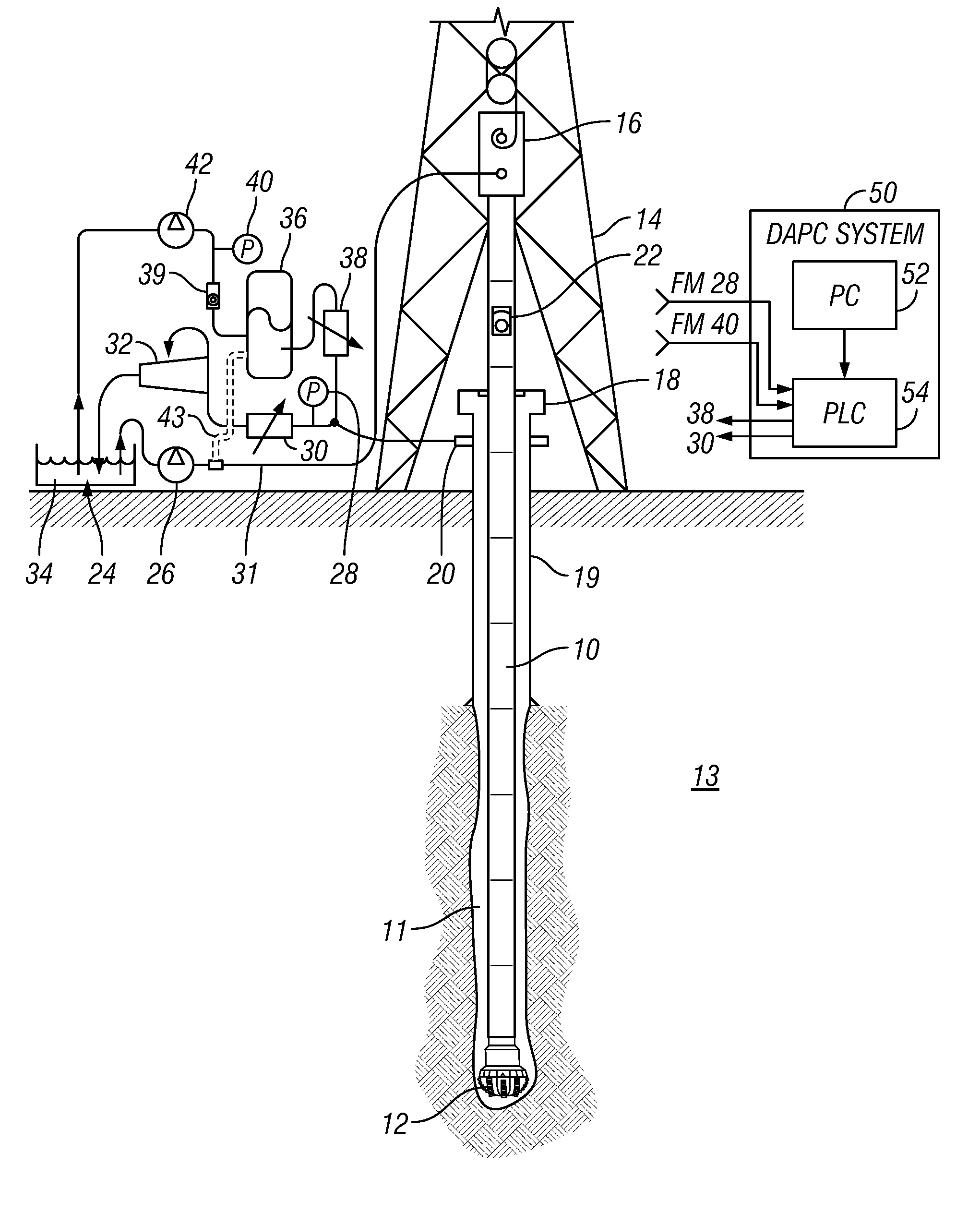

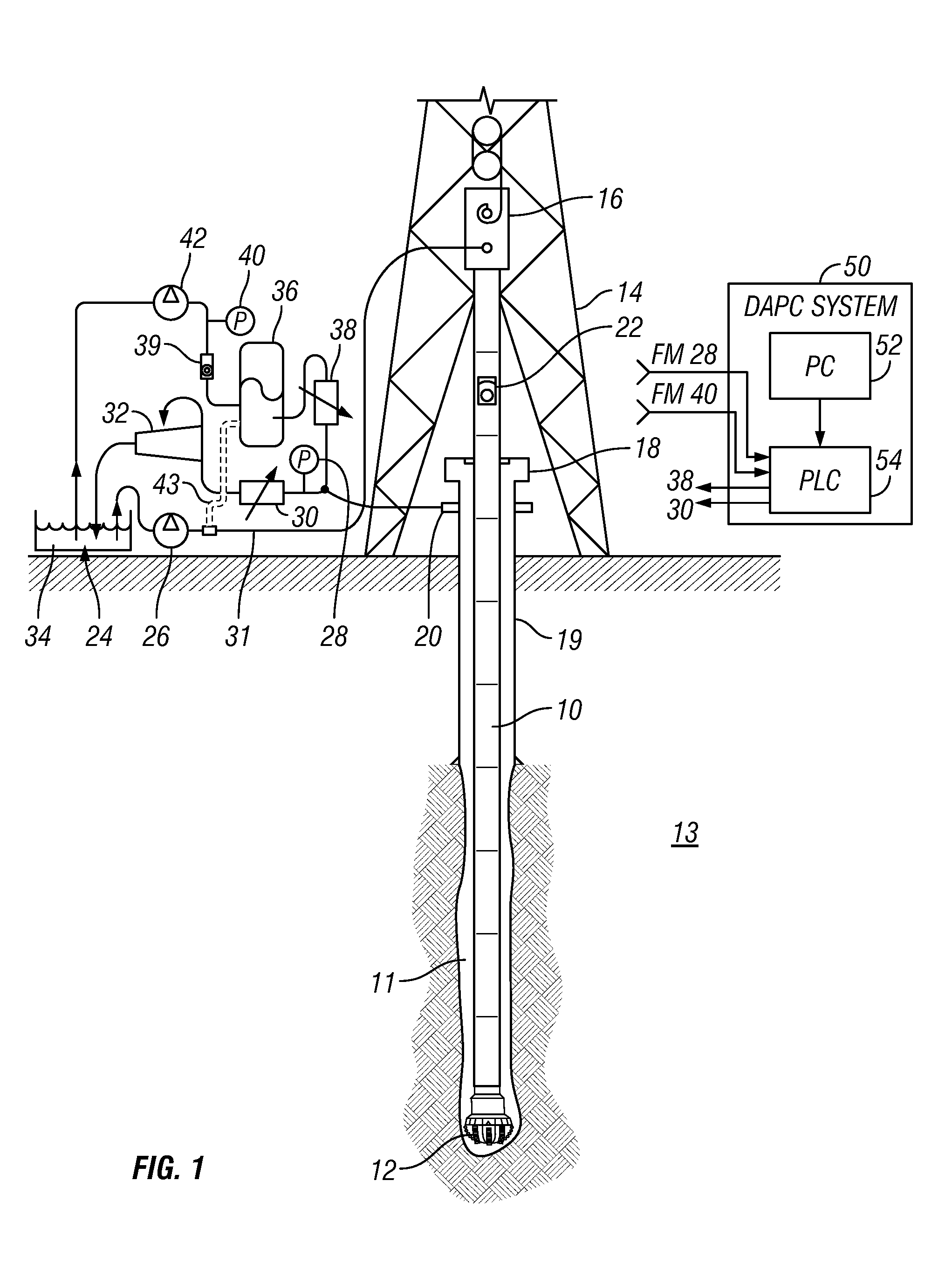

[0013]An example drilling system including an example back pressure system according to the invention is shown schematically in FIG. 1. A drilling rig 14 or similar hoisting device suspends a drill string 10 in a wellbore 11 being drilled through subsurface rock formations 13. A drill bit 12 is coupled to the lower end of the drill string 10, and is rotated by the drill string 10. Drill string rotation is enabled either by an hydraulic motor (not shown) coupled in the drill string 10 or by equipment such as a top drive 16 suspended in the drilling rig 14. Application of some of the weight of the drill string 10 to the bit 12 and the rotation imparted to the bit 12 cause the bit 12 to drill through the formations 13, thereby extending the length of the wellbore 11.

[0014]At the Earth's surface, a primary pump (“mud pumps”) 26 lifts drilling fluid (“mud”) 34 from a tank or pit 24 and discharges the mud 34 under pressure through a standpipe and flexible hose 31 to the top drive 16. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com