Low weight container closure

a container closure and low weight technology, applied in the field of low weight container closures, can solve the problems of high manufacturing and production costs, high cost of manufacturing and manufacturing closures, and often directly related to the size of the closur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]While this invention is susceptible of an embodiment in many different forms, there are shown in the drawings and will be described herein in detail specific embodiments thereof with the understanding that the present disclosure is to be considered as an exemplification of the principles of the invention. It is not intended to limit the invention to the specific illustrated embodiments.

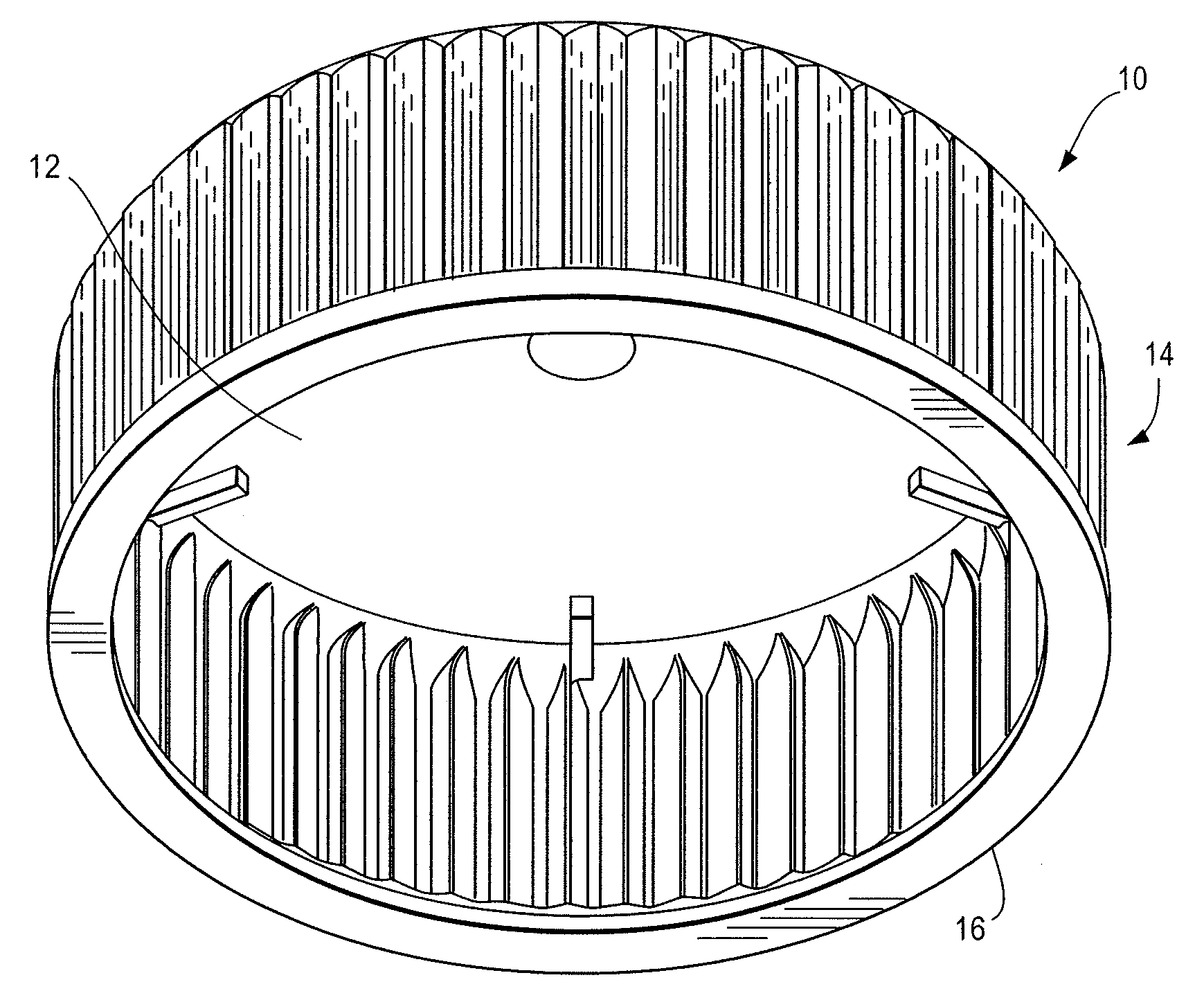

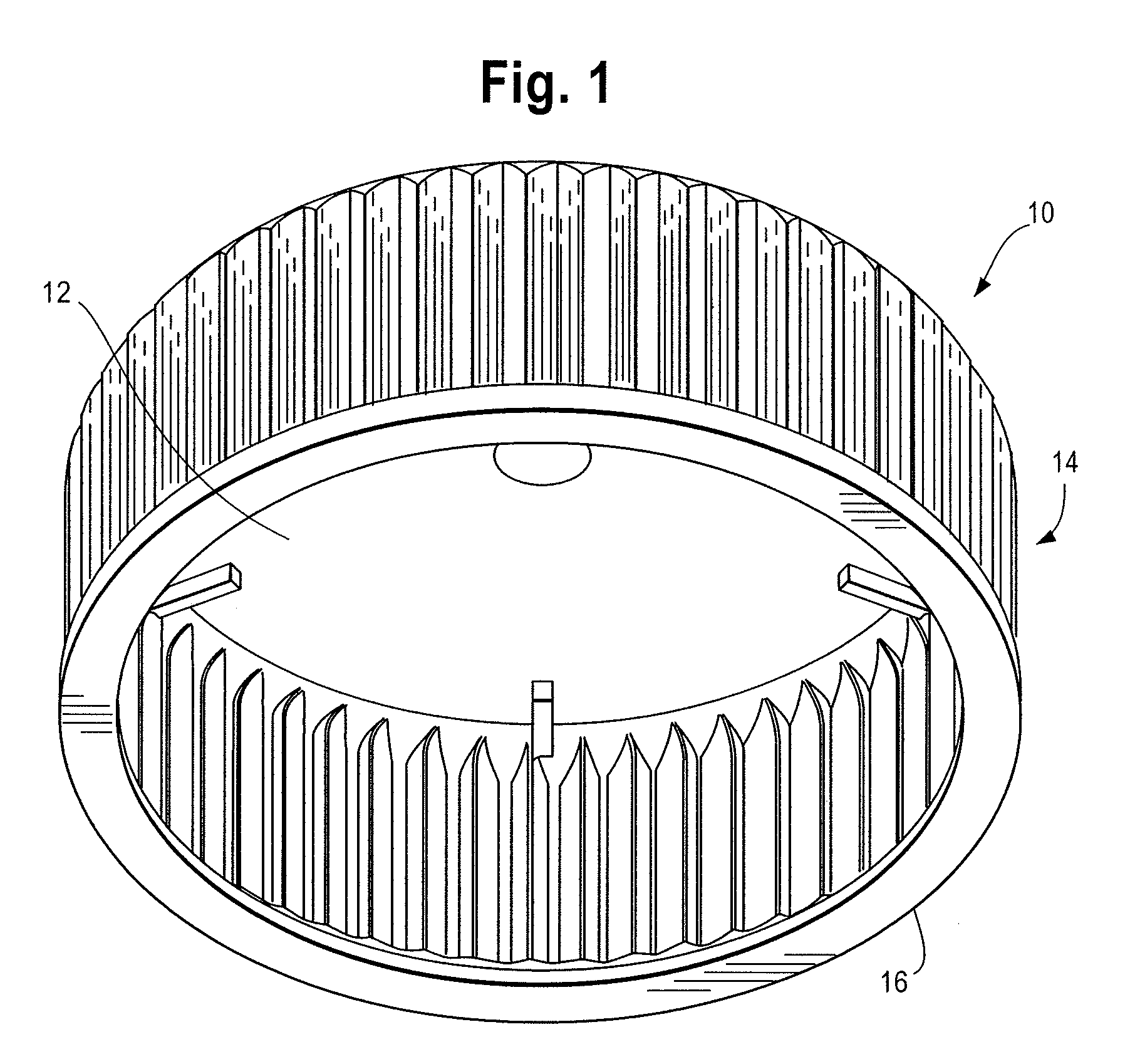

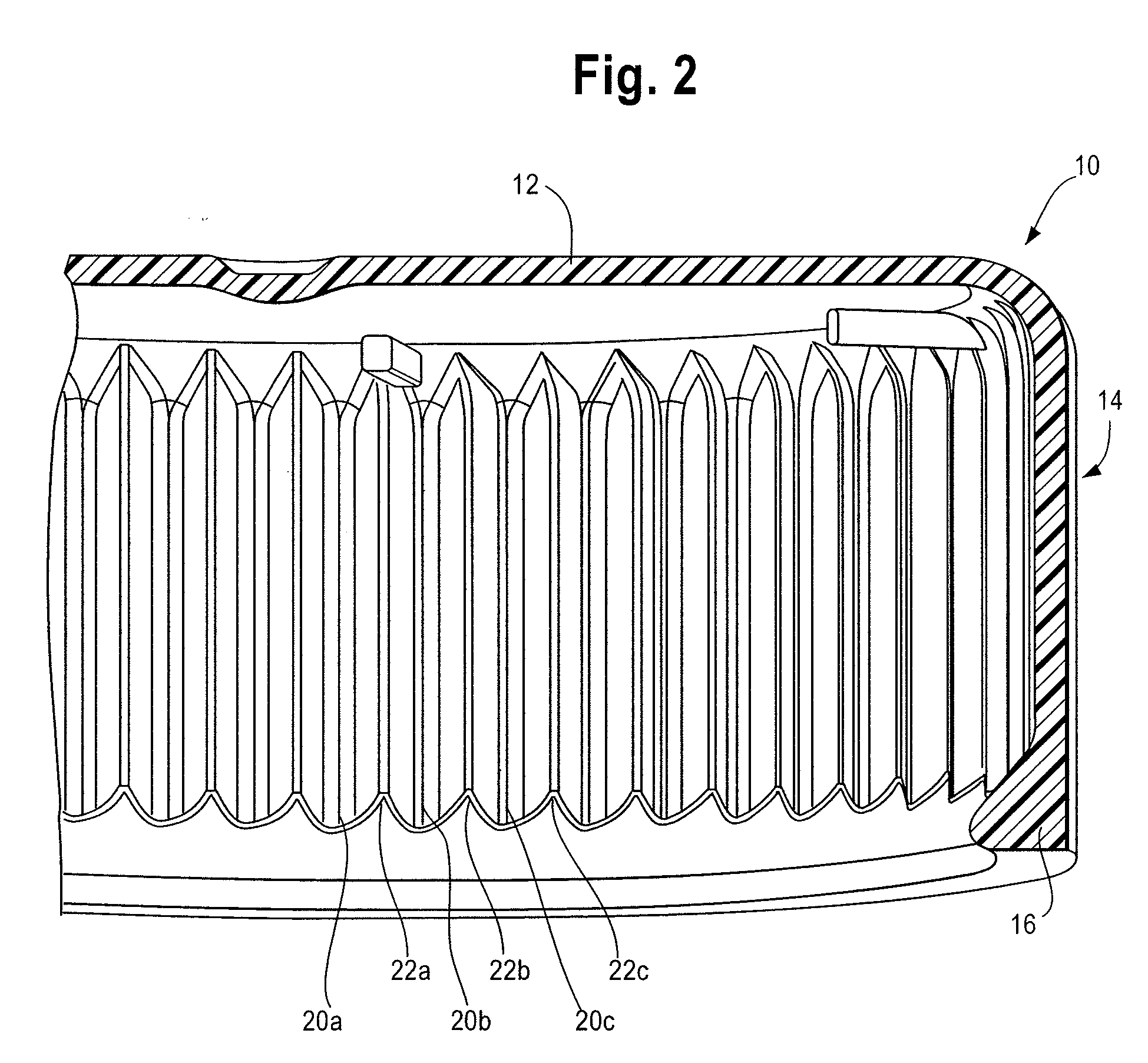

[0032]Embodiments of the present invention include a low weight container closure. The closure can be short weighted so as to minimize the weight and amount of material used to produce such a closure. Furthermore, the closure can retain its strength required for repeated handling, application, and removal of the closure. In embodiments of the present invention, the closure can include corrugation, grooves, protrusions, ridges, and / or zig-zags that make up both the interior and exterior of the closure's skirt.

[0033]In embodiments of the claimed invention, the closure, including a top wall portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com