Muzzle attachment system

a technology of muzzle attachment and muzzle, which is applied in the field of muzzle attachment system, can solve the problems of preventing easy manual removal of muzzle attachment, and achieve the effects of preventing fouling, quick and easy attachment and detachment, and preventing fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

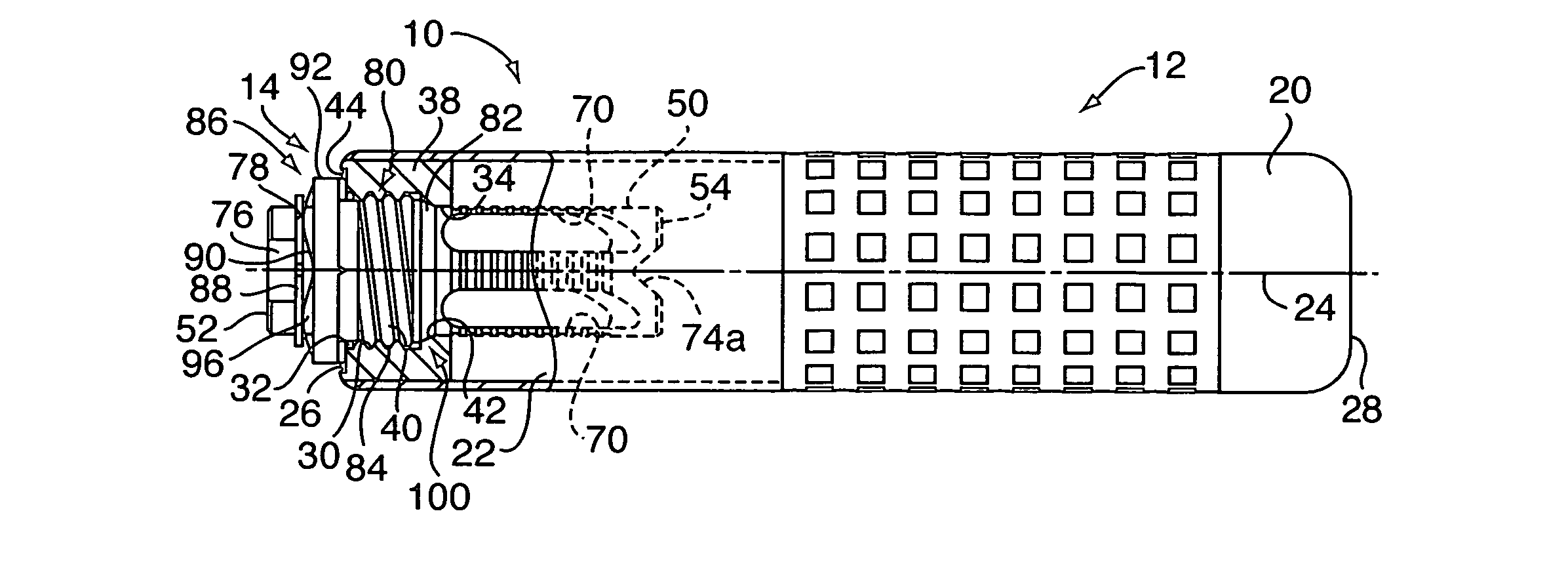

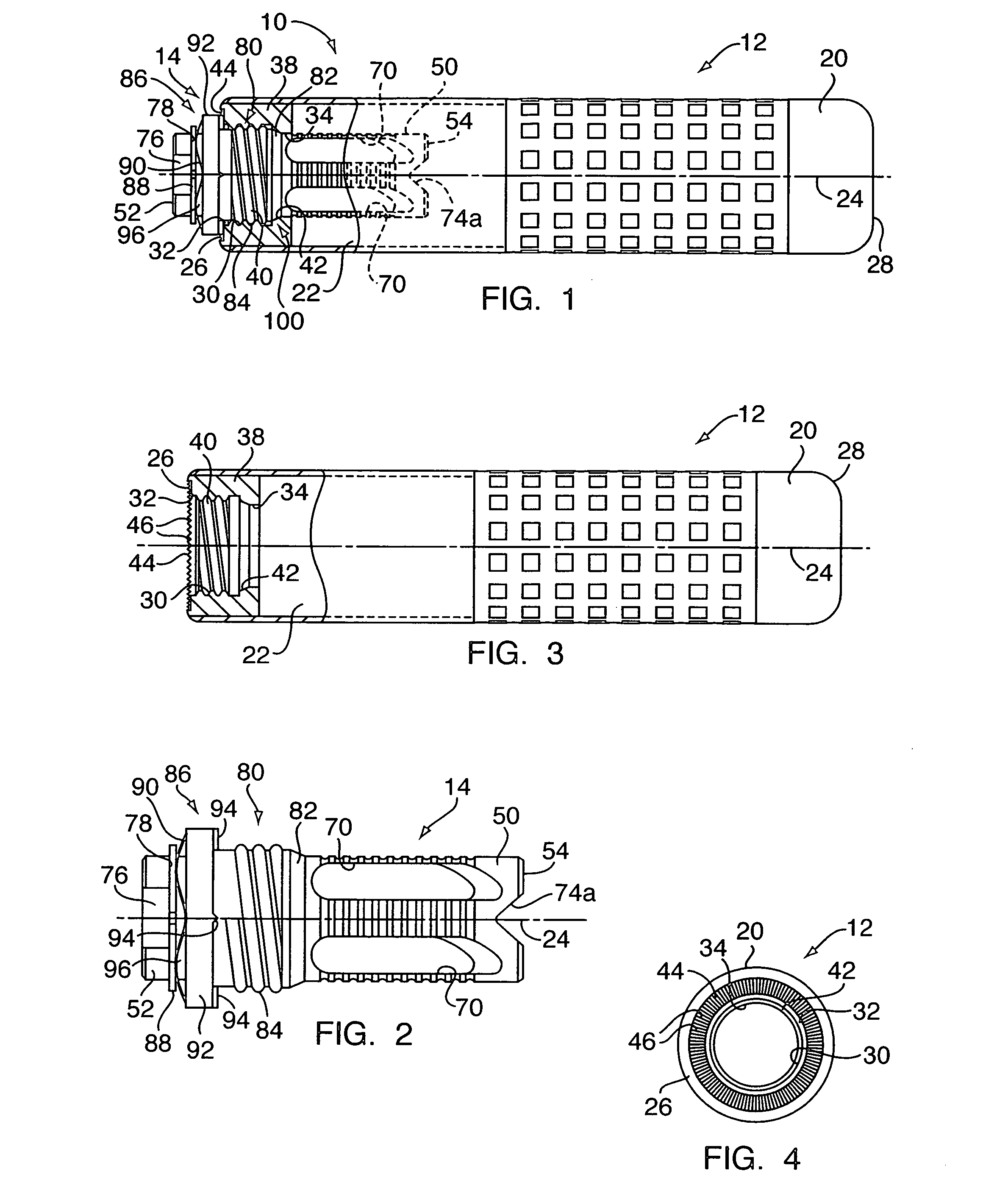

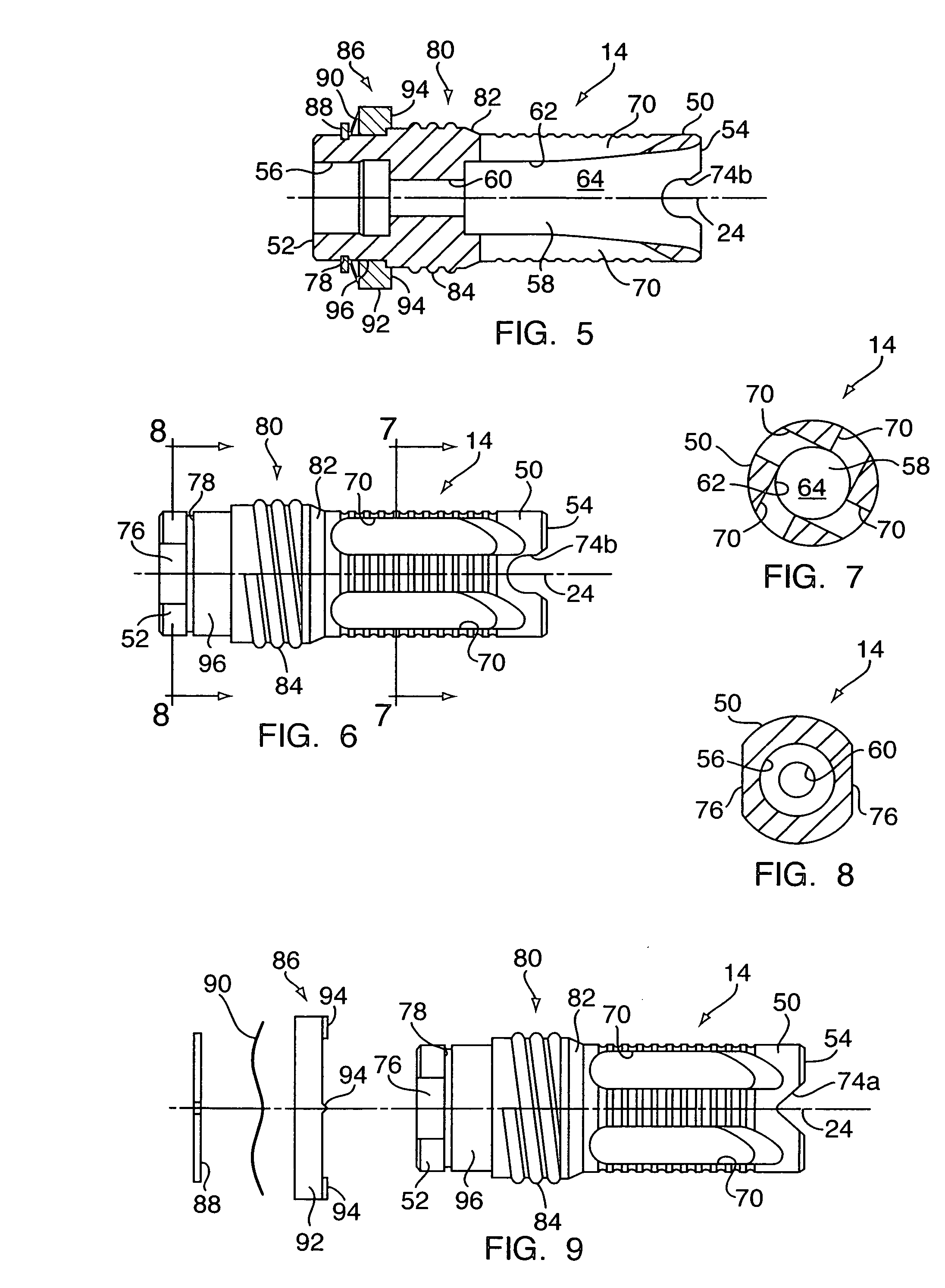

[0028]Referring to FIG. 1, a muzzle attachment system 10 according to an embodiment of the present invention, includes a silencer 12, also known as a sound suppressor, and a flash suppressor 14. Referring to FIGS. 3 and 4, the silencer 12 has a cylindrical body 20, partially defining an interior volume 22, which interior volume 22 concentrically surrounds a firing axis 24 of a firearm (not shown). The cylindrical body 20 extends between a first end 26 and a second end 28, the first and second ends 26, 28 each disposed substantially perpendicularly to the firing axis 24.

[0029]In the vicinity of the first end 26, proximate to a muzzle (not shown) of the firearm when the silencer 12 is connected to the firearm, an internal passage 30 is defined within the cylindrical body 20. The internal passage 30 extends between a first passage opening 32 in the first end 26 and a second passage opening 34, the second passage opening 34 communicating with the internal volume 22. The internal passage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com