Vacuum storage container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

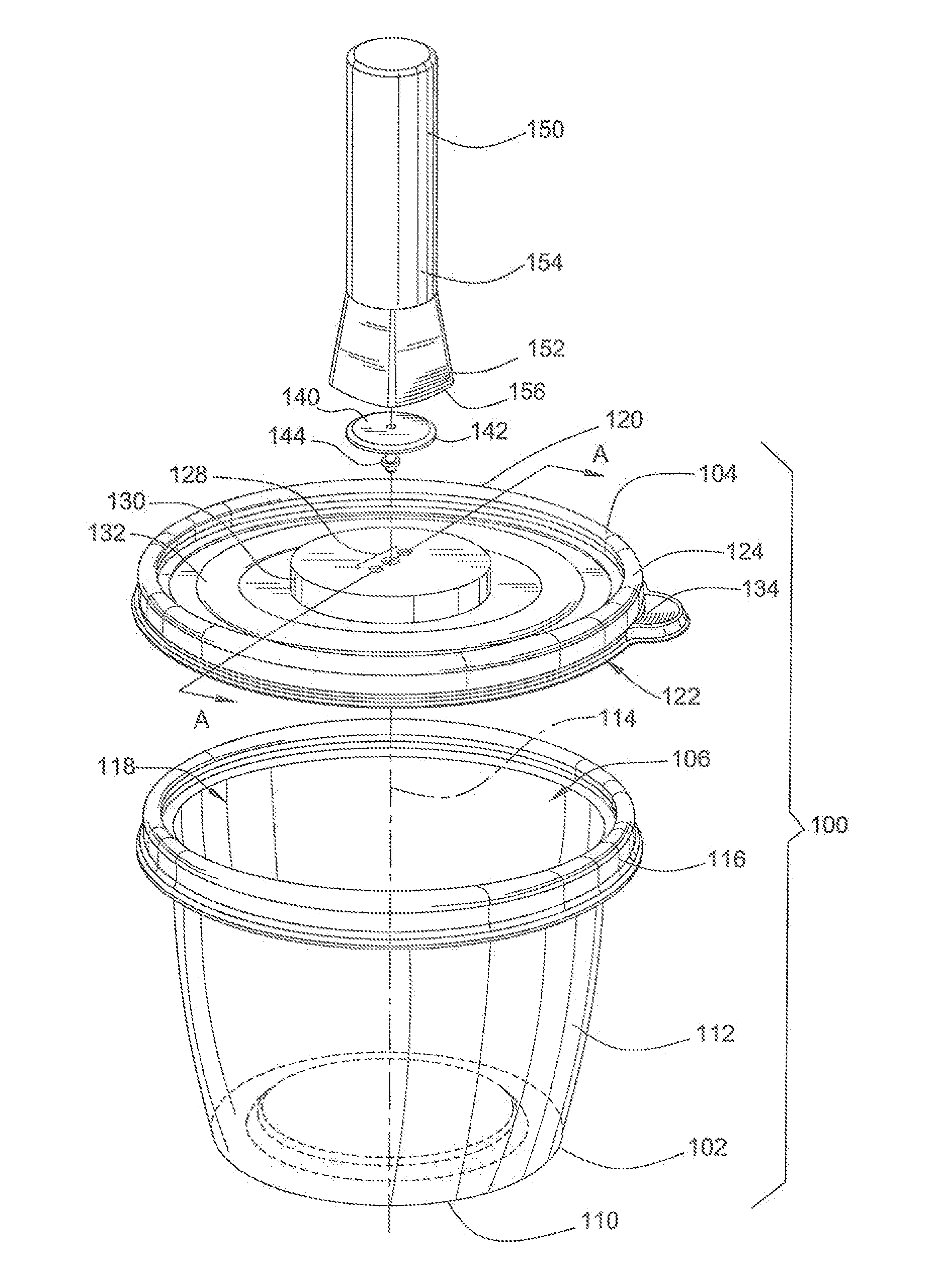

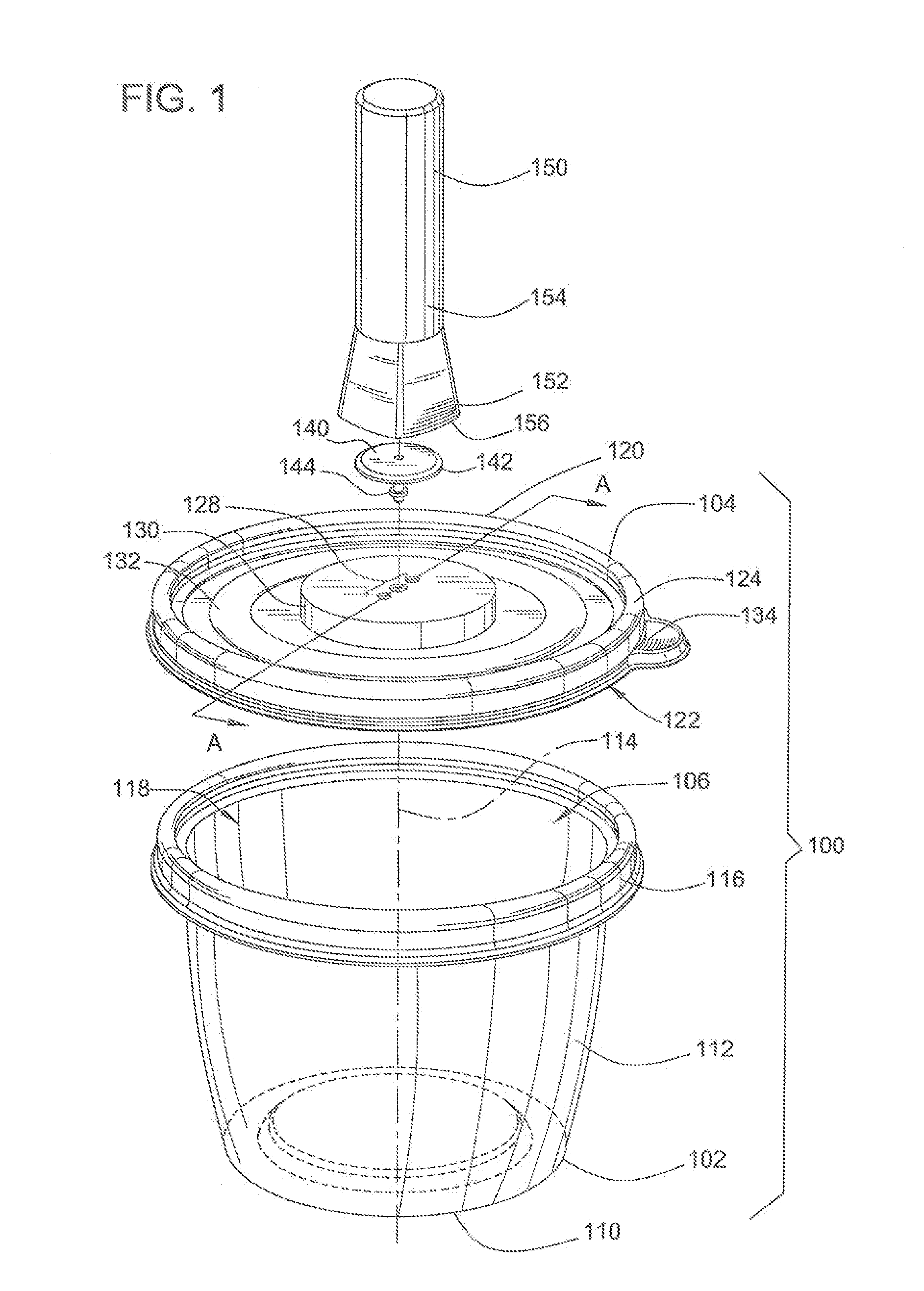

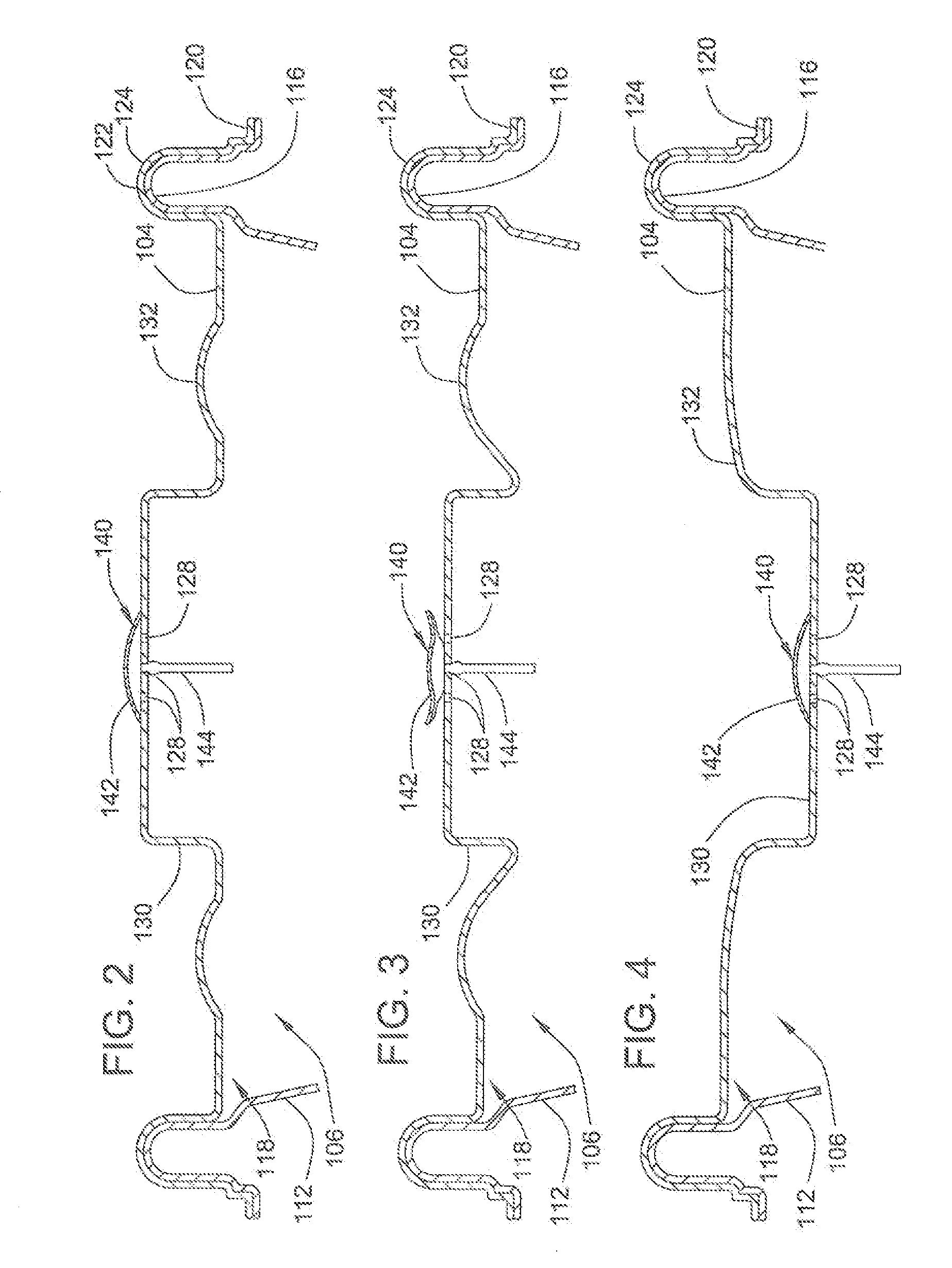

[0030]FIG. 1 illustrates a vacuum storage container 100 that includes a base 102 and a detachable lid 104. To receive items for storage, the base 102 is shaped to delineate a storage cavity 106. In the illustrated embodiment, the base 102 may have a bowl-like shape and may include a generally flat, circular bottom wall 110 and a cylindrical, upward extending sidewall 112 joined to the bottom wall. The bottom wall 110 and the sidewall 112 can generally define a central axis line 114. In some embodiments, to facilitate nested stacking of multiple bases together, the sidewall can inversely taper or angle radially outwards from the axis line 114. The upper edge of the sidewall 112 provides a rim 116 that outlines an opening 118 through which the storage cavity 106 can be accessed. In other embodiments, the storage container can have different shapes including a different number and orientation of the bottom and sidewalls. For example, the storage container can be rectangular and the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com