Air flare apparatus and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

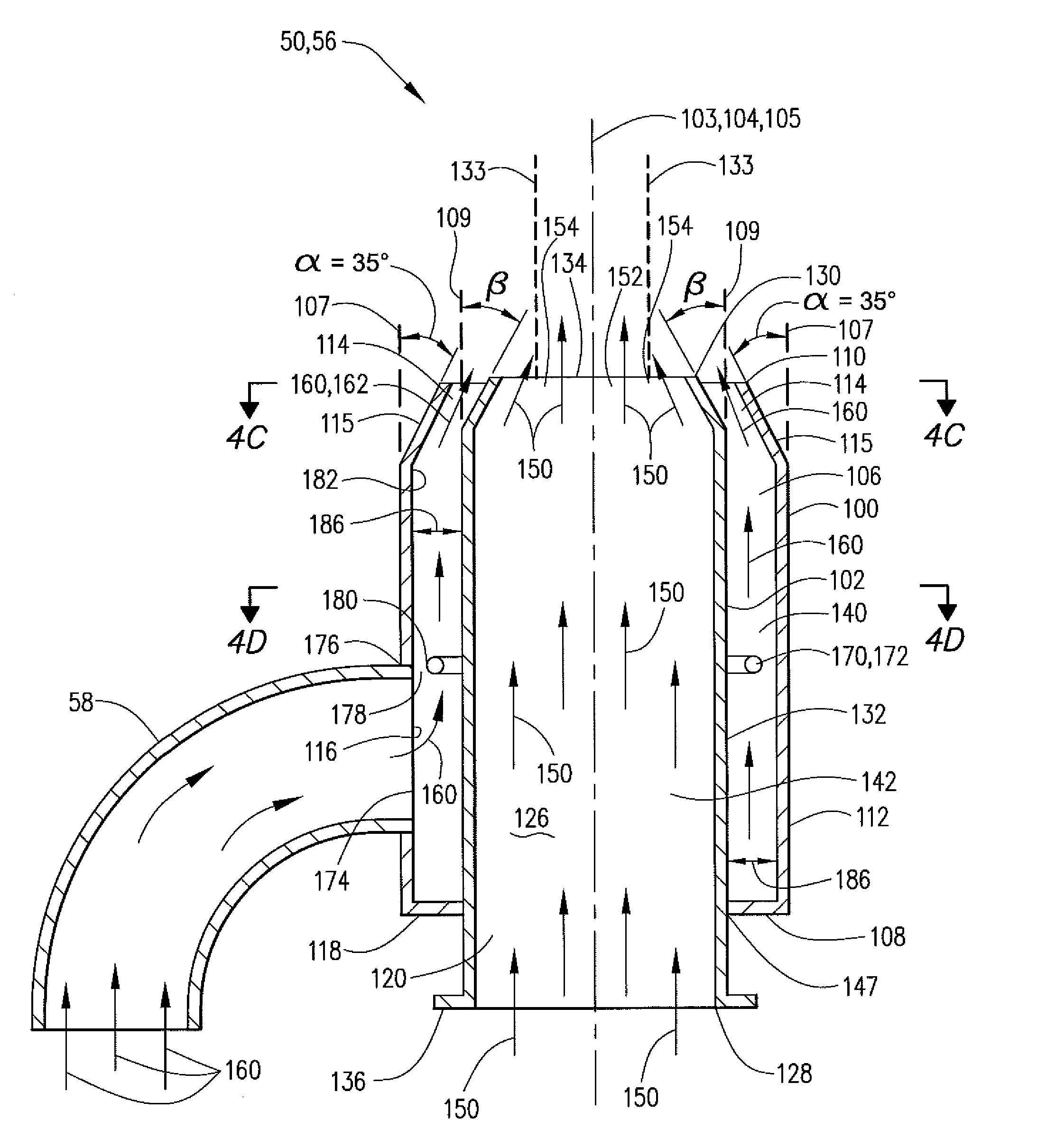

[0098]The inventive flare apparatus 50 was operated to smokelessly fire about 84,000 lb / hr of propane with about 34,000 standard cubic feet per minute of air representing about 13% of the theoretically required stoichiometric air requirement for complete combustion of propane. The flame outline shown by FIG. 14A was produced. Conventional air flare technology would have required about 30% of the theoretical stoichiometric rate or more than twice as much air. That is, the inventive technology required about half of the customary airflow to achieve smokeless operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com