Method and apparatus for hip femoral resurfacing tooling

a technology for femoral resurfacing and tooling, which is applied in the field of system, kit and method for joint prosthesis installation tools, can solve the problems of adversely affecting the goal of satisfactorily restoring, affecting the fixation of components, and affecting the performance of these implants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0048]FIGS. 5 and 6 depict a prosthesis holding tool 50 according to an aspect of the invention for seating the sleeve component 10 of a two-part prosthesis onto the prepared femoral head 7′ of the femur 1. The tool 50 is cannulated with a central bore 51 to allow guiding on the guide pin 30 initially used to prepare the femoral head. The sleeve 10 has a central hole 12 in the proximal portion to allow the guide pin 30 to pass through it. The central bore 51 of the tool 50 is capable of receiving the guide pin 30 and slidingly journaling on the guide pin to insure that the tool is aligned with the prepared femoral head axis B-B while seating the sleeve. The tool distal portion has a sleeve interface 52 for receiving the sleeve 10. The sleeve interface 52 has holding features 54 that conform to a portion of the sleeve outer surface and retain the sleeve with suitable features such as detents 55 or tines. Because of the preferred tapered sleeve exterior configuration wedging with the ...

third embodiment

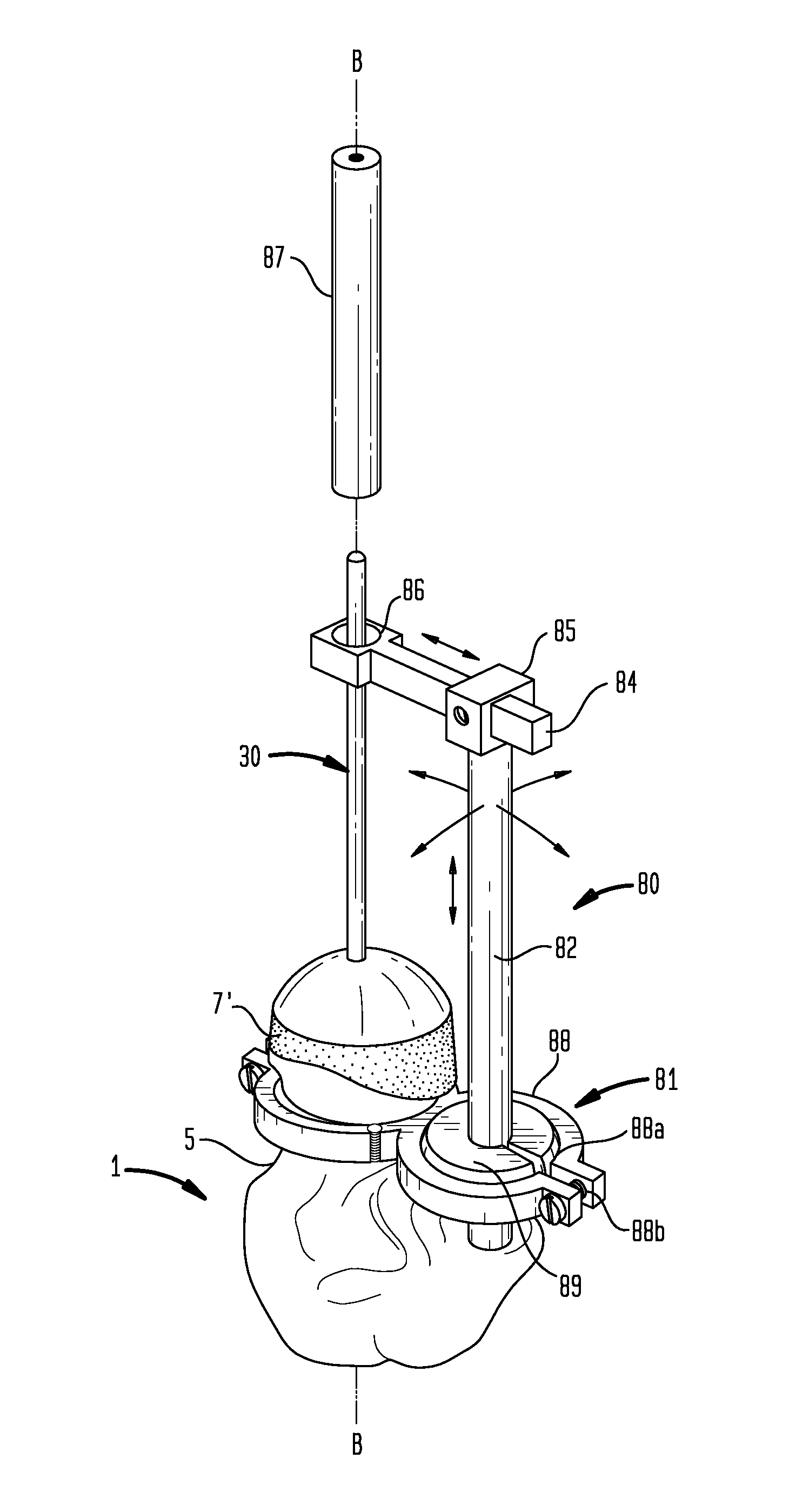

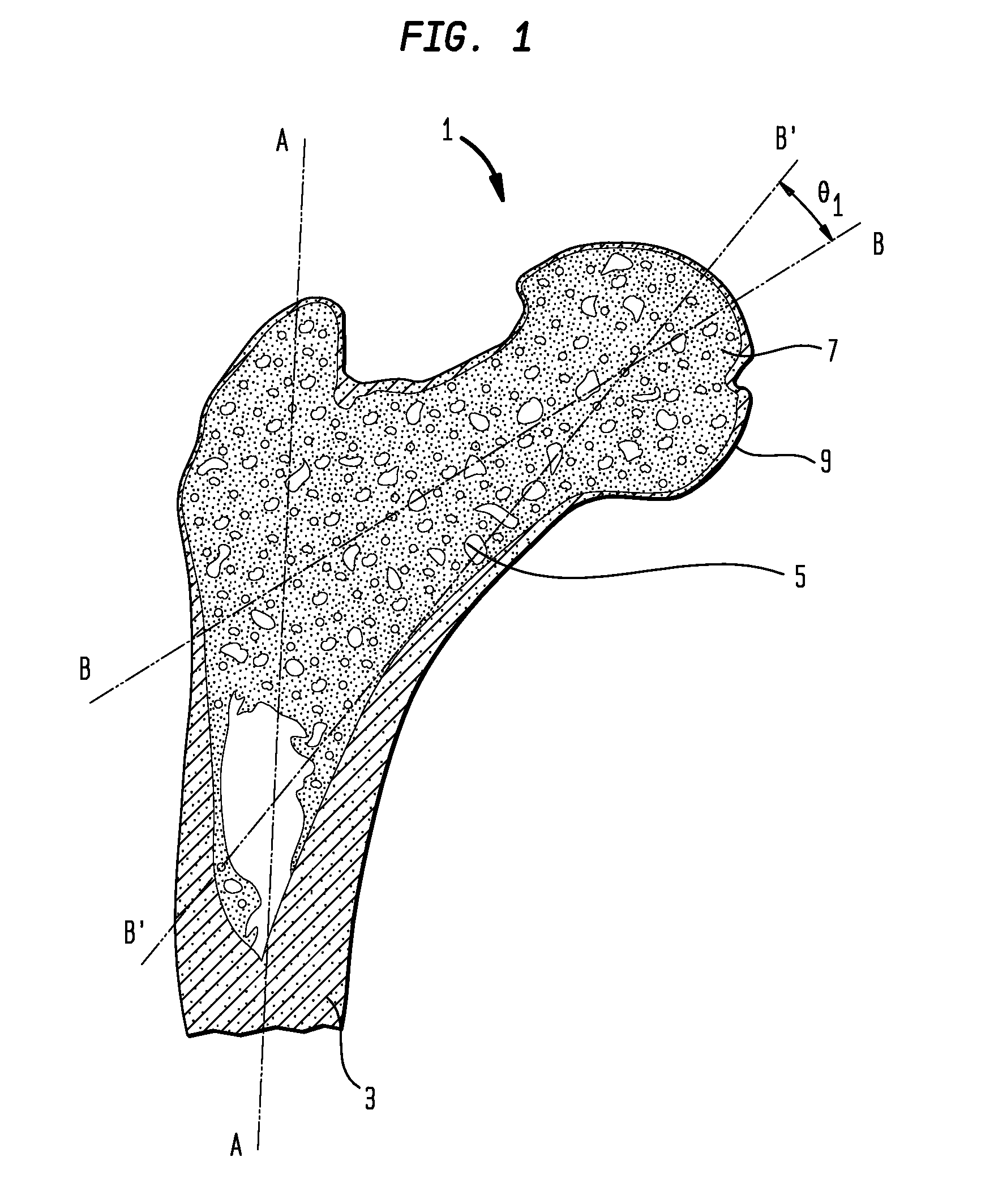

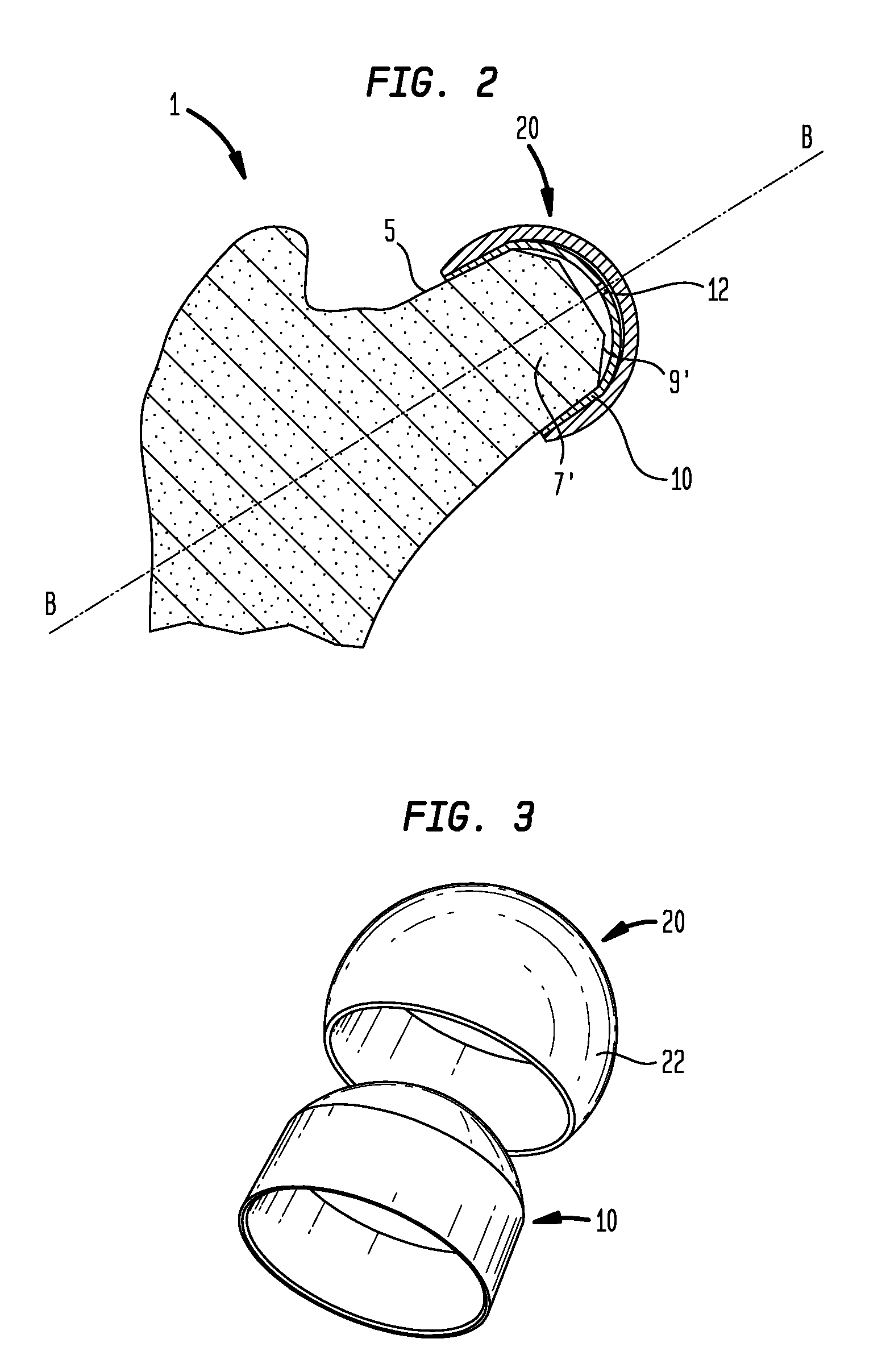

[0053]FIGS. 13-19 show tools and methods according to an aspect of the invention wherein an alignment jig 80 is attached to a femoral neck 5 to install a ball prosthesis 20′ on a prepared femoral head 7′ along a prepared femoral head axis B-B determined from the guide pin 30. In this embodiment, the invention is used to seat the ball component 20′ rather than the sleeve 10. The ball component 20′ depicted is a one-piece type prosthesis with a cavity fitting directly on the prepared femoral head 7′ although the aspects of the invention applicable to a one-piece ball component 20′ are also applicable to any modular ball component such as ball component 20. Fitting a ball component 20′ presents problems because the axis B-B cannot be directly located by the datums of the previous embodiments, either by guiding on the guide pin 30 or the bore 31, during the installation of the ball because the pin must be removed prior to installing the component and the bore is inaccesible as the head ...

second embodiment

[0054]Turning to FIG. 13, the alignment jig 80 is attached to a proximal portion of the femur 1, preferably at the femoral neck 5. The femoral head 7 has been prepared, as previously discussed with respect to FIG. 4 and the guide pin 30 is temporarily left in place. The alignment jig 80 is comprised of a femoral mount 81, an axial extension 82 and a radial extension 84 with a pin location guide 86 at the proximal end of the extension. The pin location guide 86 is an aperture having a central axis that can be aligned to be co-axial with the femoral head axis datum provided by the guide pin 30 or the bore 31 and consequently with axis B-B. The jig 80 has various clamps, slides and rotational adjustments that provide sufficient degrees of freedom to allow the pin location guide 86 to be co-axially positioned with axis B-B. The pin locator 87 has a bore with a central axis. The bore is sized to slidingly engage on the guide pin 30 projecting from the femoral head and the locator 87 has ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameters | aaaaa | aaaaa |

| sizes | aaaaa | aaaaa |

| degrees of freedom | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com