Subprojectile having an energy content

a sub-projectile and energy content technology, applied in the direction of ammunition projectiles, weapons, explosives, etc., can solve the problems of increasing the blast effect, extending the three-dimensional incendiary effect, and flying at high speed and burning autonomously

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

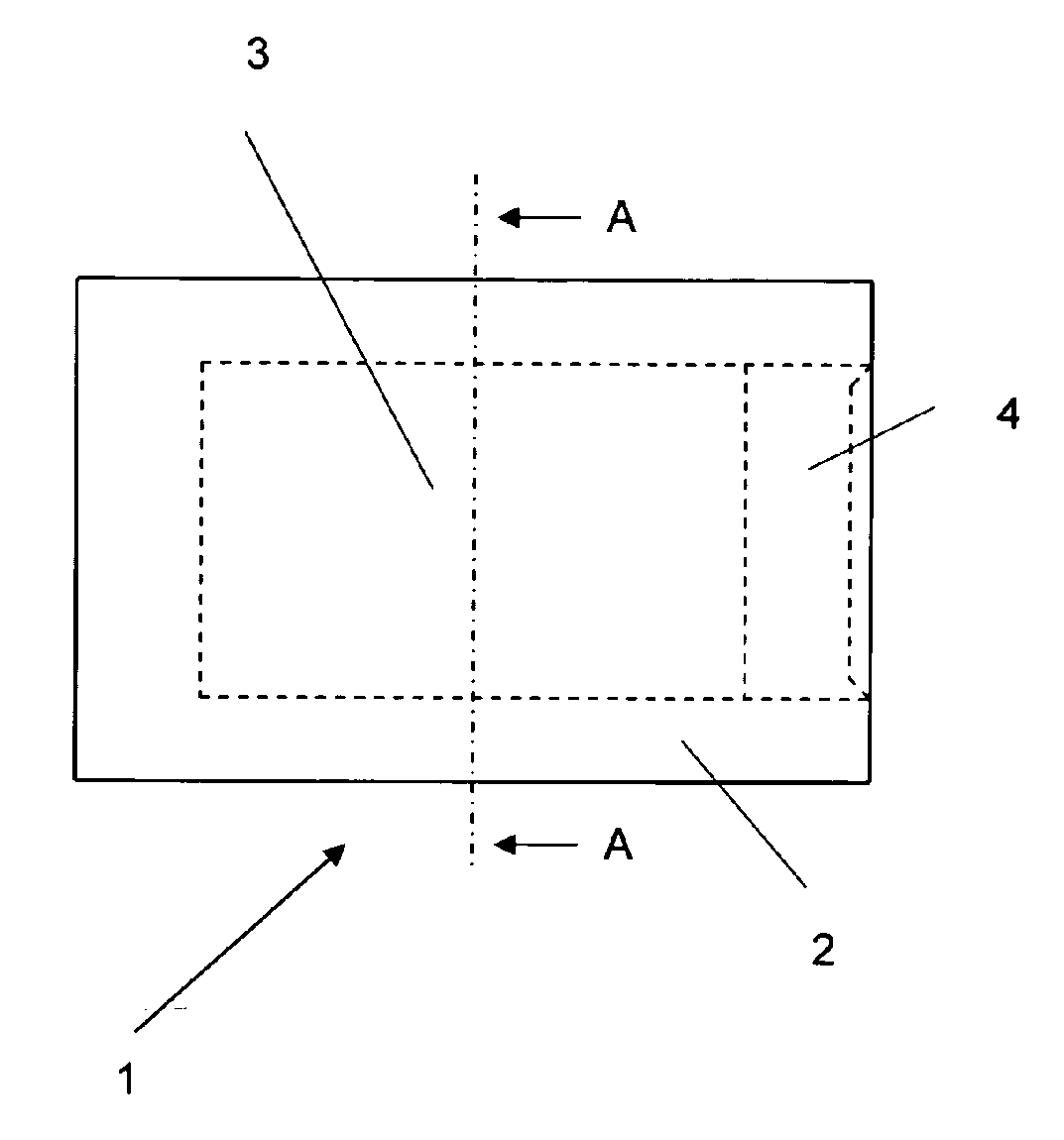

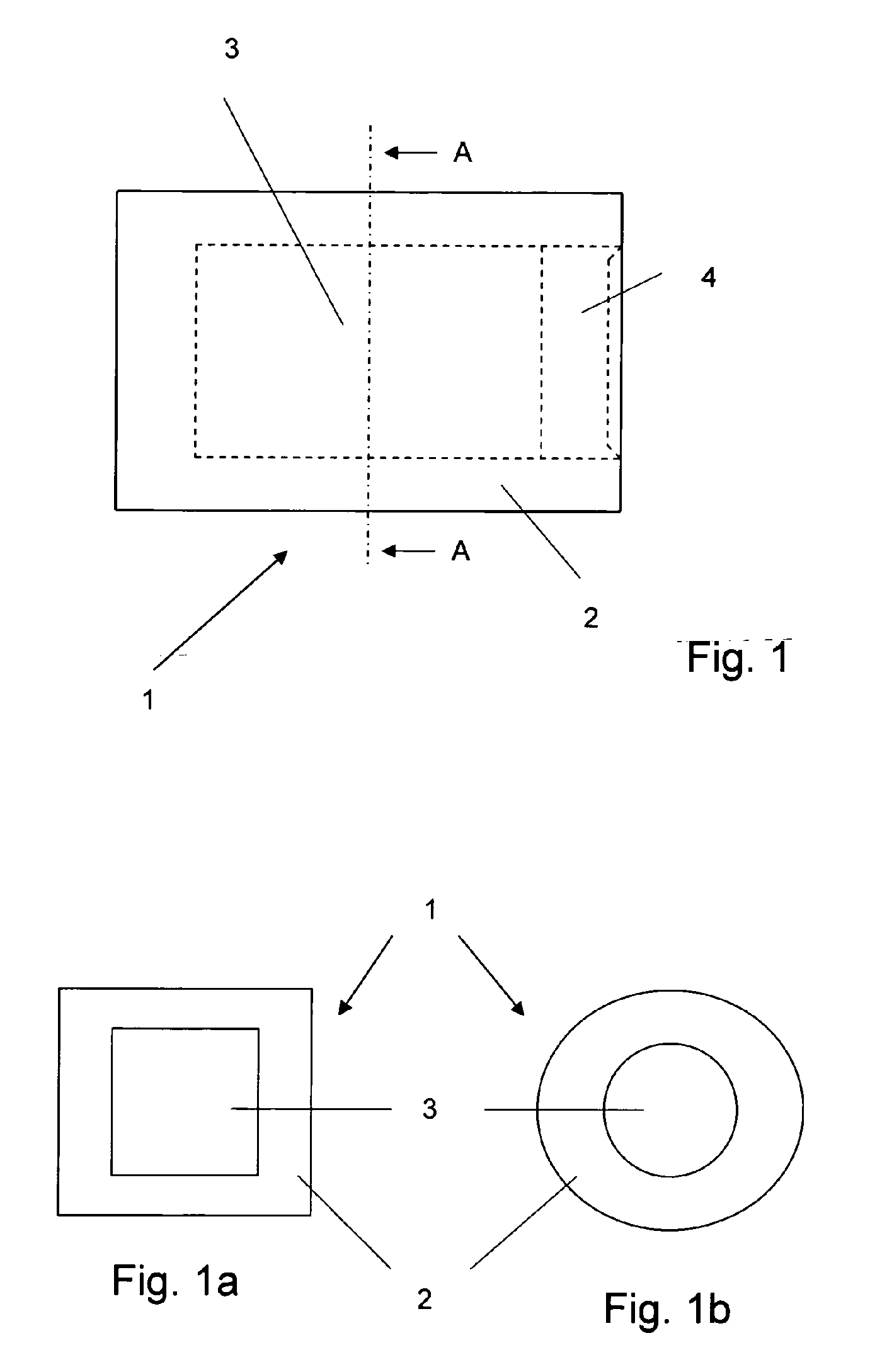

With reference to a projectile as described in DE 10 2005 039 901 A1, this projectile may be adapted for use as a projectile in accordance with the present invention, wherein the adapted projectile has submunitions 1 which have a hard-metal body and / or heavy-metal body 2, with a bore or recess 5, for holding an energetic component 3. An igniter 4 preferably ends flat with the housing body 2.

The energetic component 3 may be a powder, a rod material, or the like.

In a first non-limiting embodiment of the invention, the zirconium powder is precompressed in the projectile bore 5, and the igniter 4 is metered and is compressed to about 400 MPa. The ratio used for this purpose may, in this case, be 10 / 1.

In a further non-limiting embodiment of the invention, pyrofuze is cut into parts with a length of 8 mm, and is inserted into the projectile bore 5. In this case as well, the igniter 4 is metered and compressed. A ratio of 10 / 1 is also sufficient in this case, and it is been found to be adv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com