Laundry treating machine

a technology of washing machine and nozzle, which is applied in the field of washing machine, can solve the problems of generating abnormal noise, reducing water pressure, and creating a vortex in the conventional top loading type of washing machine, and achieves the effects of preventing abnormal noise during drainage, preventing the generation of a vortex, and quiet operation of the washing machin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Hereinafter, a top loading type washing machine (hereinafter, referred to as ‘washing machine’) according to an exemplary embodiment of the present invention will be described in detail with reference to the accompanying drawings.

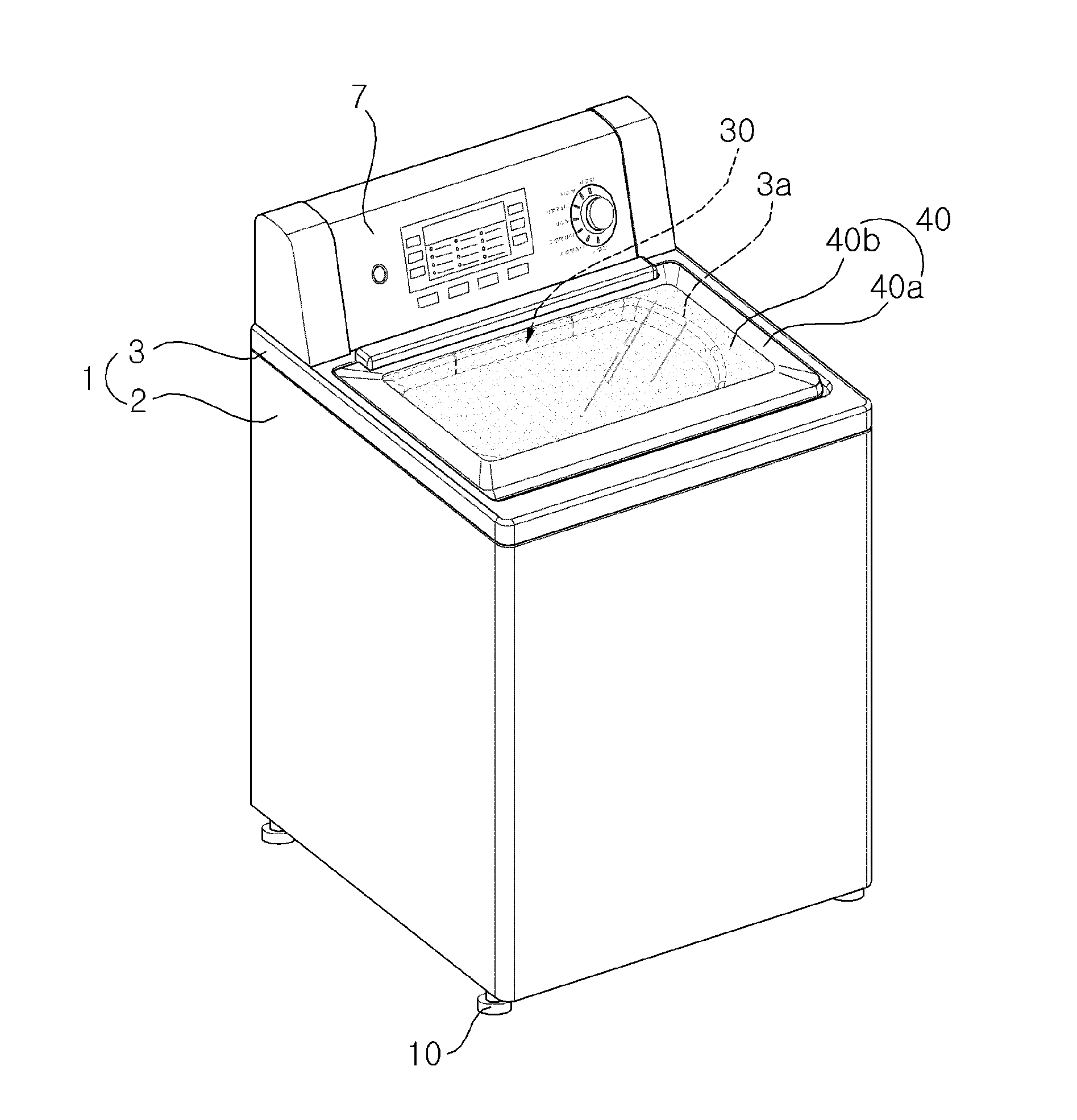

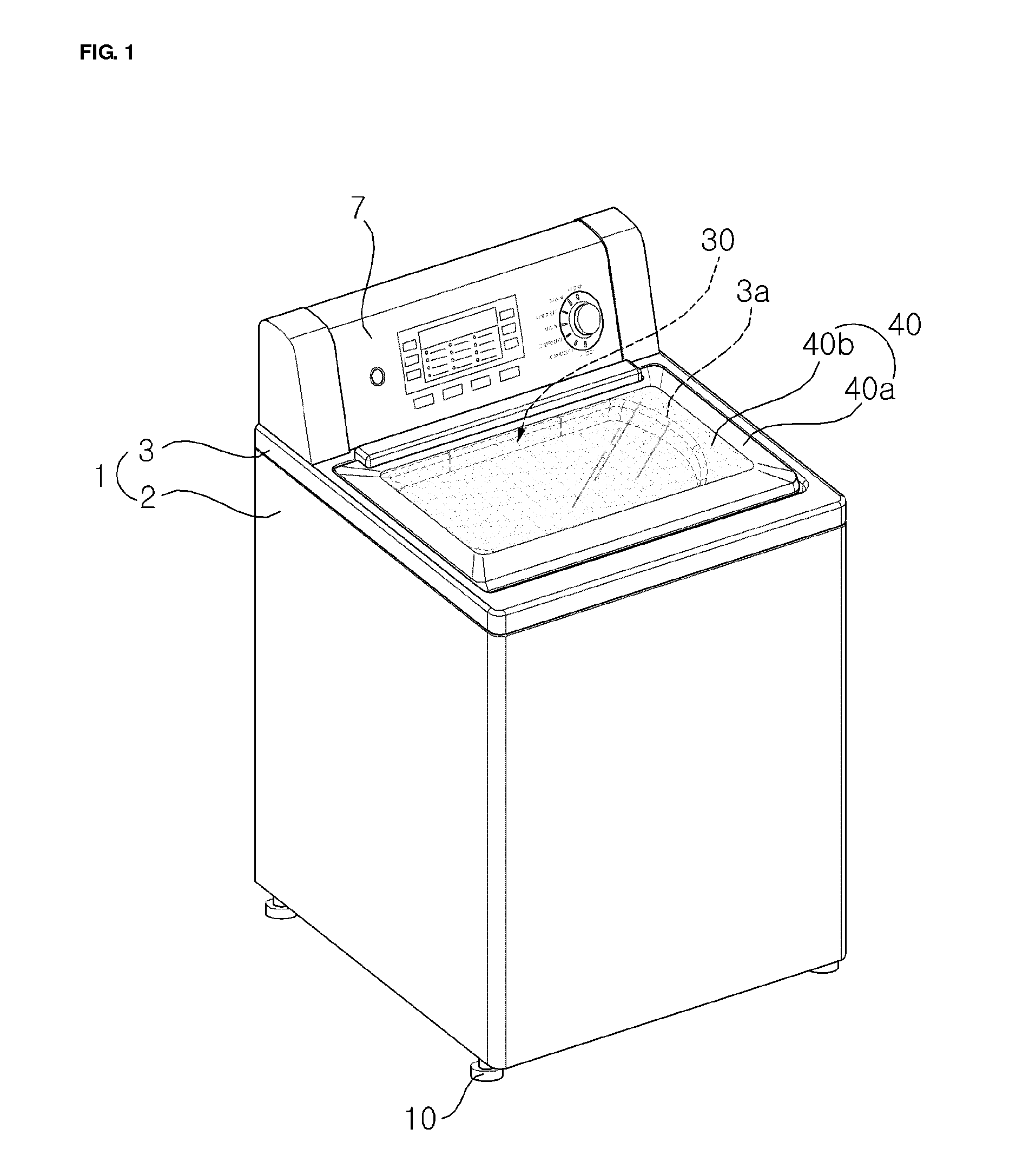

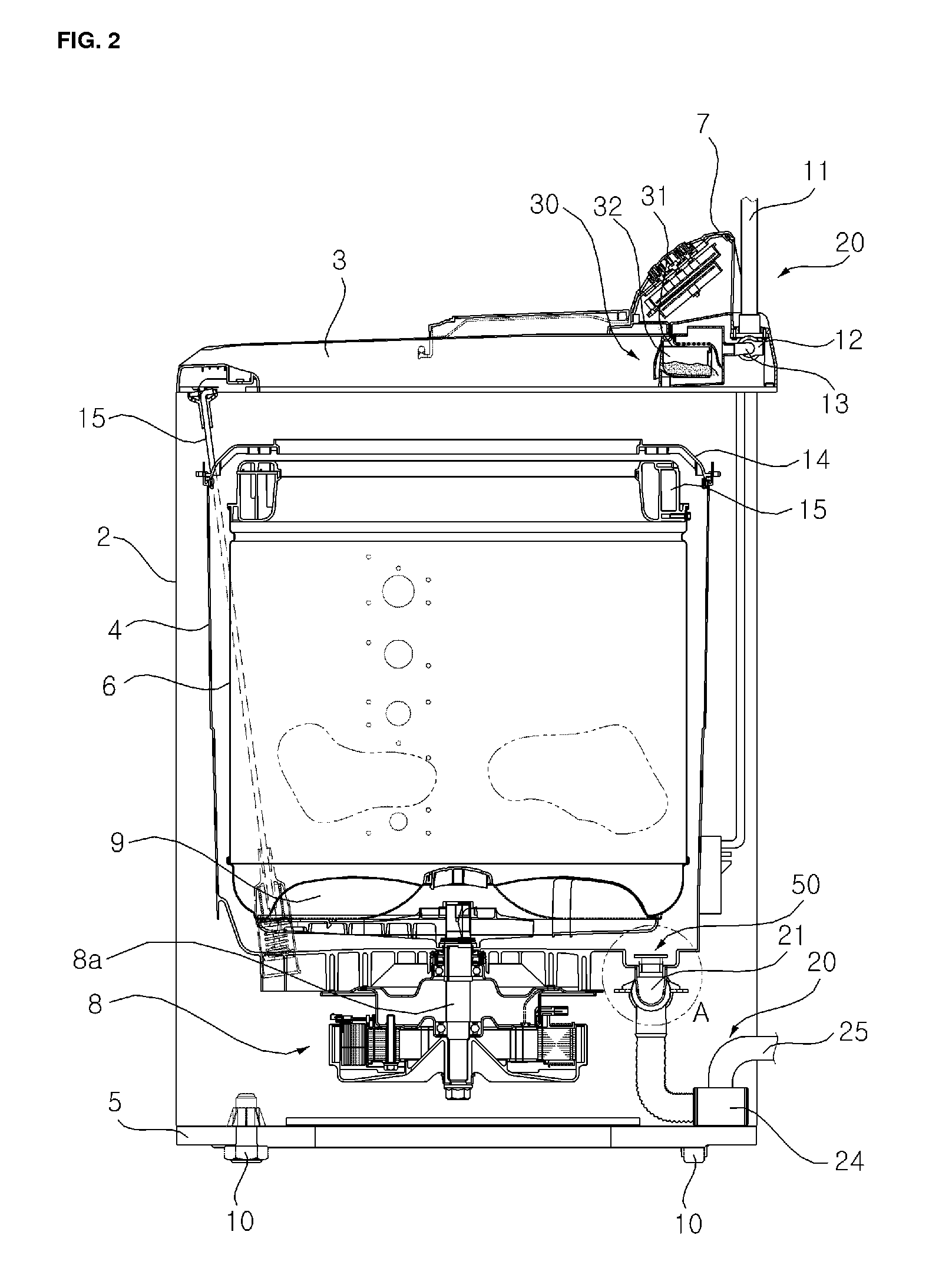

FIG. 1 is a perspective view of a top loading type washing machine according to a first exemplary embodiment of the present invention, and FIG. 2 is a longitudinal cross-sectional view of the washing machine shown in FIG. 1.

Referring to FIGS. 1 and 2, the washing machine according to the first exemplary embodiment of the present invention comprises a case 1 forming an outer appearance of the washing machine and a leg assembly 10 connected to the bottom of the case 1.

The case 1 comprises a cabinet 2 configured to be open at the top and bottom surfaces and constituting the sides of the washing machine, a top cover installed so as to cover the open top surface of the cabinet 2, and a base 5 installed on the open bottom surface of the cabinet 2.

Within the cabin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com