Seed Treatment Apparatus

a technology for treating apparatus and seeds, which is applied in the direction of liquid surface applicators, seed coating/dressing, seed immunisation, etc. it can solve the problems of high cost of seed application, and large amount of chemical waste, so as to reduce the waste of treatment products and minimize the waste of excess treatment products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

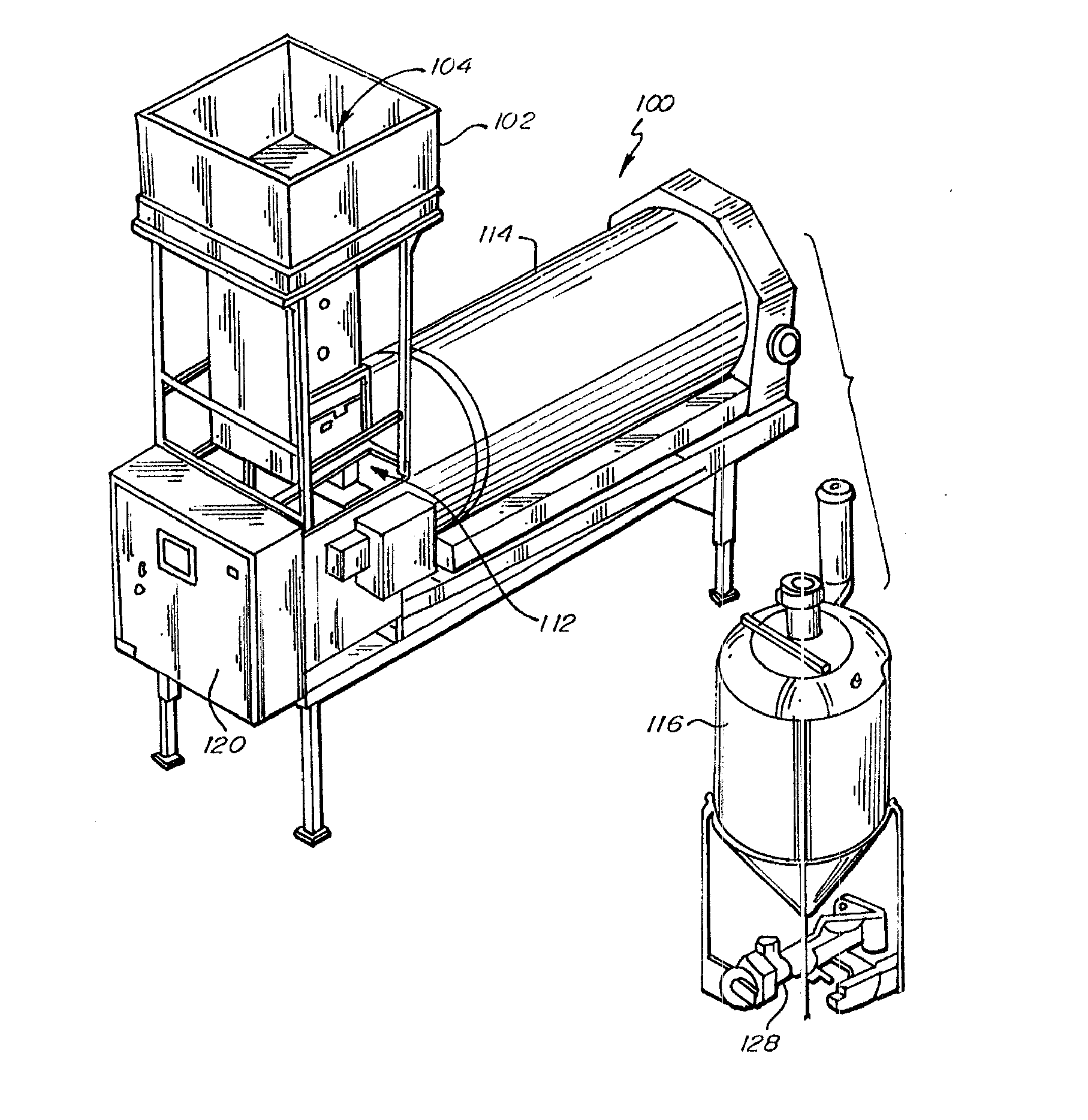

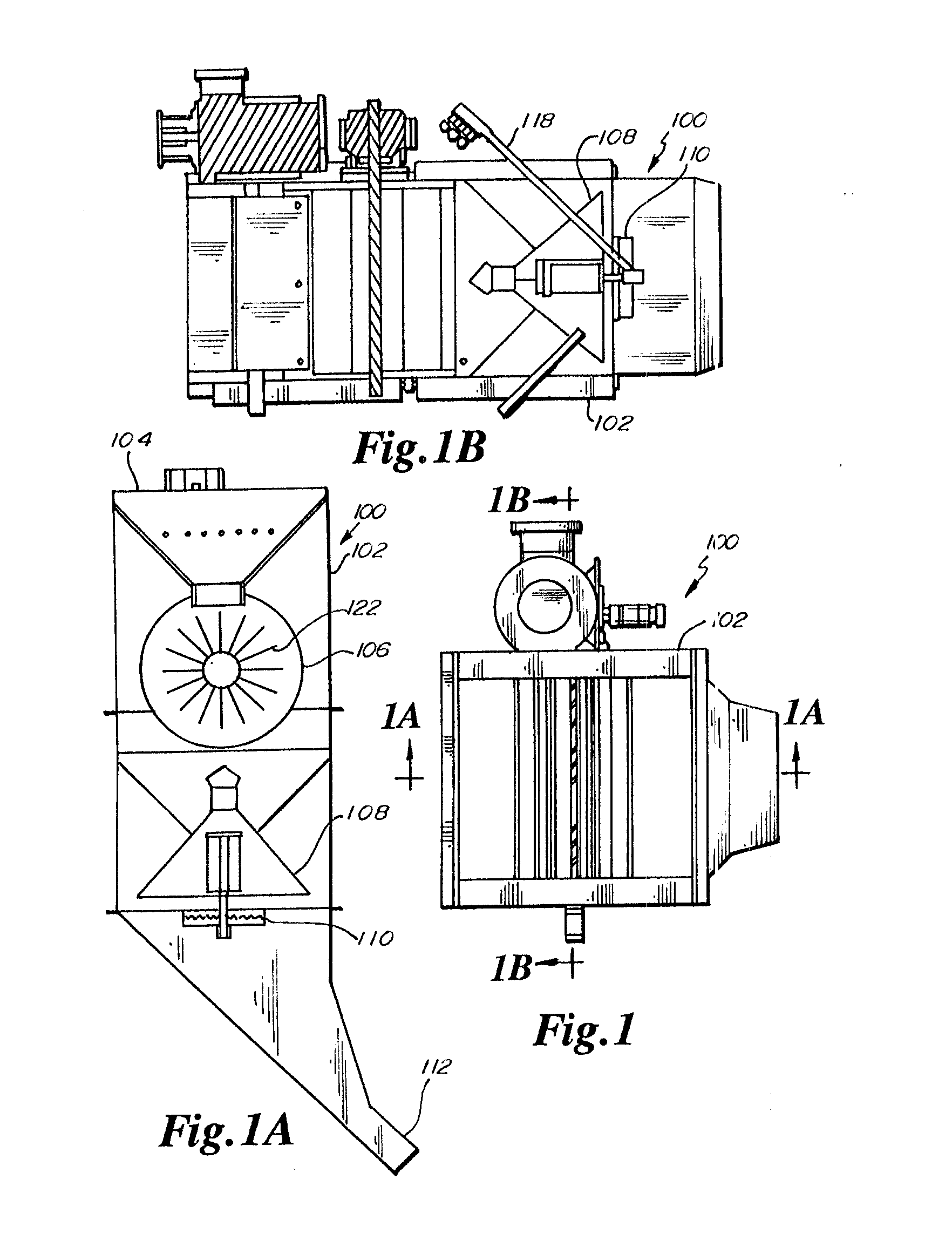

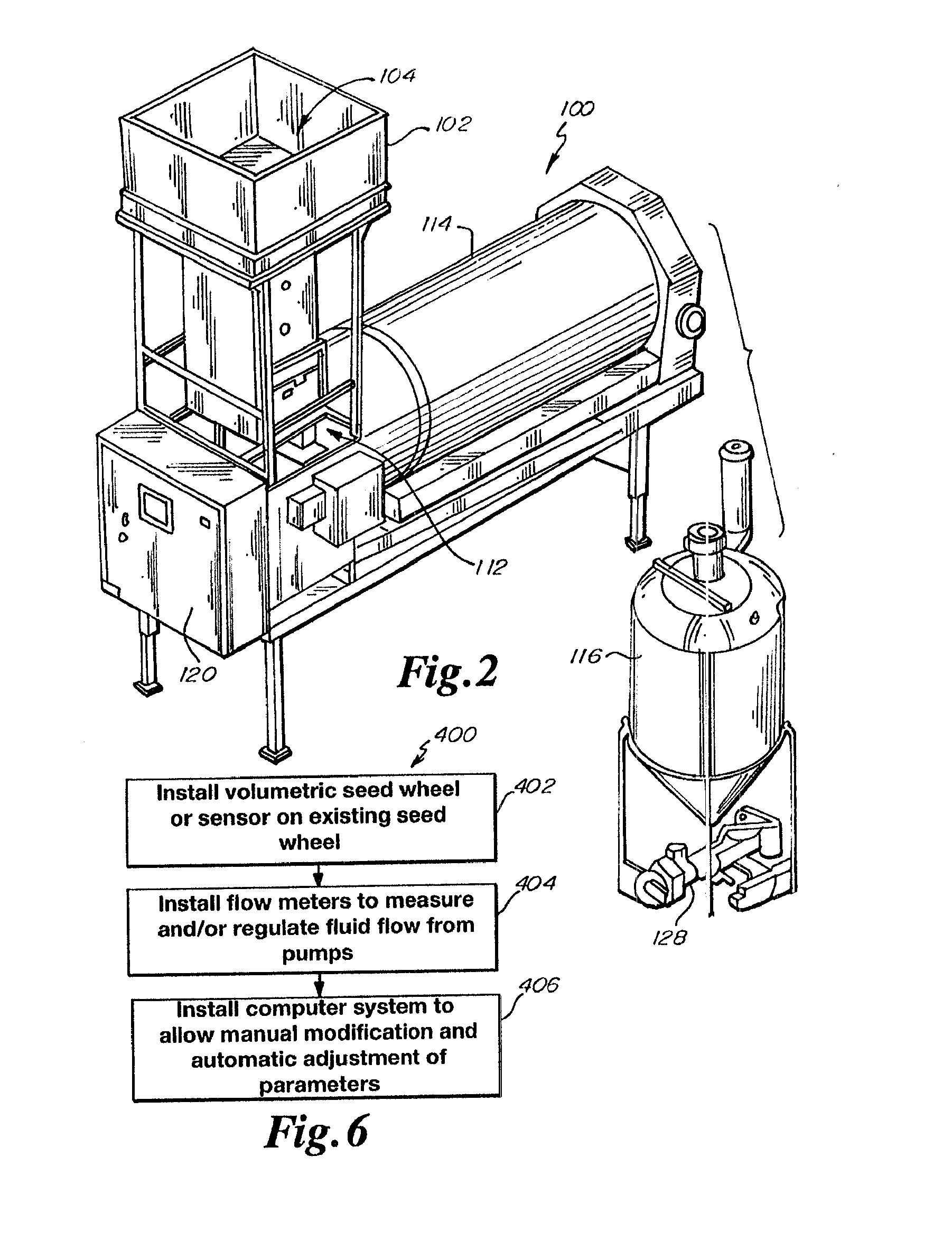

[0023]Referring to FIGS. 1, 1A, 1B and 2, there can be seen elements of a seed treatment apparatus 100 according to an embodiment of the present invention. Seed treatment apparatus 100 can include a housing 102 including an inlet 104, a seed wheel 106, a dispersion cone 108, an atomizer wheel 110, and an outlet 112. Housing outlet 112 can connect to a polishing drum 114 or mixing chamber. The atomizer wheel 110 can be fluidly connected to one or more treatment tanks 116 containing products for treating the seeds via an inlet tube 118. The system can be connected to a computer system with a processor having a control panel 120 for monitoring and / or adjusting the system.

[0024]FIG. 3 depicts a flowchart showing a process 200 by which seeds can be treated according to an embodiment of the present invention. Seed can first be fed into the apparatus at the housing inlet at step 202 such that it travels through the apparatus under the influence of gravity. In a preferred configuration, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com