Vibration-Free Machining of Pilgrim Mandrels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

LIST OF REFERENCE NUMERALS

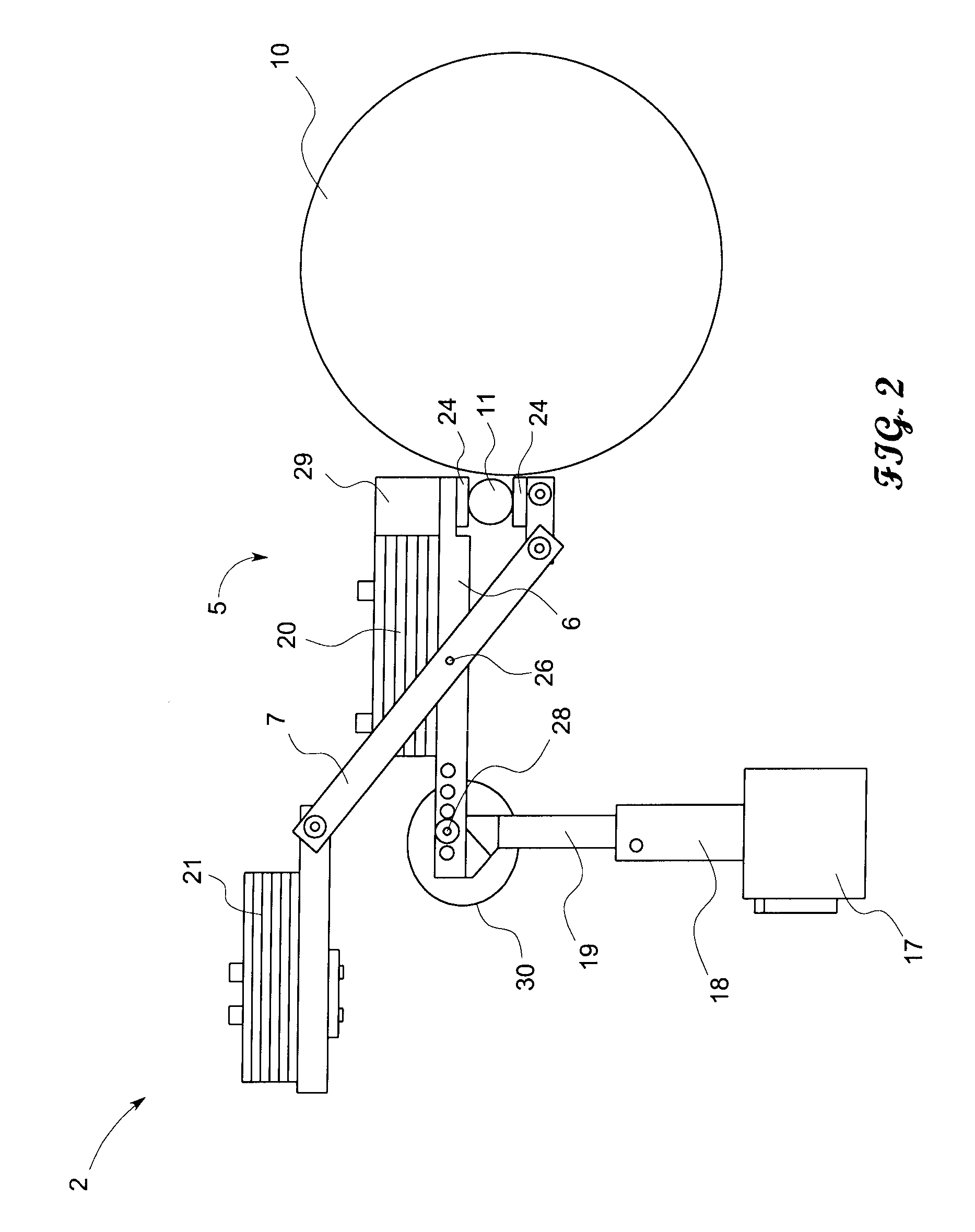

[0041]1 Device[0042]2 Support collar plate[0043]3 Vibration-measuring finger[0044]5 Clamp[0045]6 Gripper arm[0046]7 Gripper arm[0047]10 Grinding wheel[0048]11 Pilgrim mandrel, workpiece[0049]12 Drive mechanism[0050]13 Tip[0051]17 Base[0052]18 Tube[0053]19 Shaft[0054]20 Weight[0055]21 Weight[0056]24 Insert[0057]25 Insert[0058]26 Shaft[0059]27 Vibration sensor[0060]28 Pivot shaft[0061]29 Active vibrations damper[0062]30 Hinge

DESCRIPTION

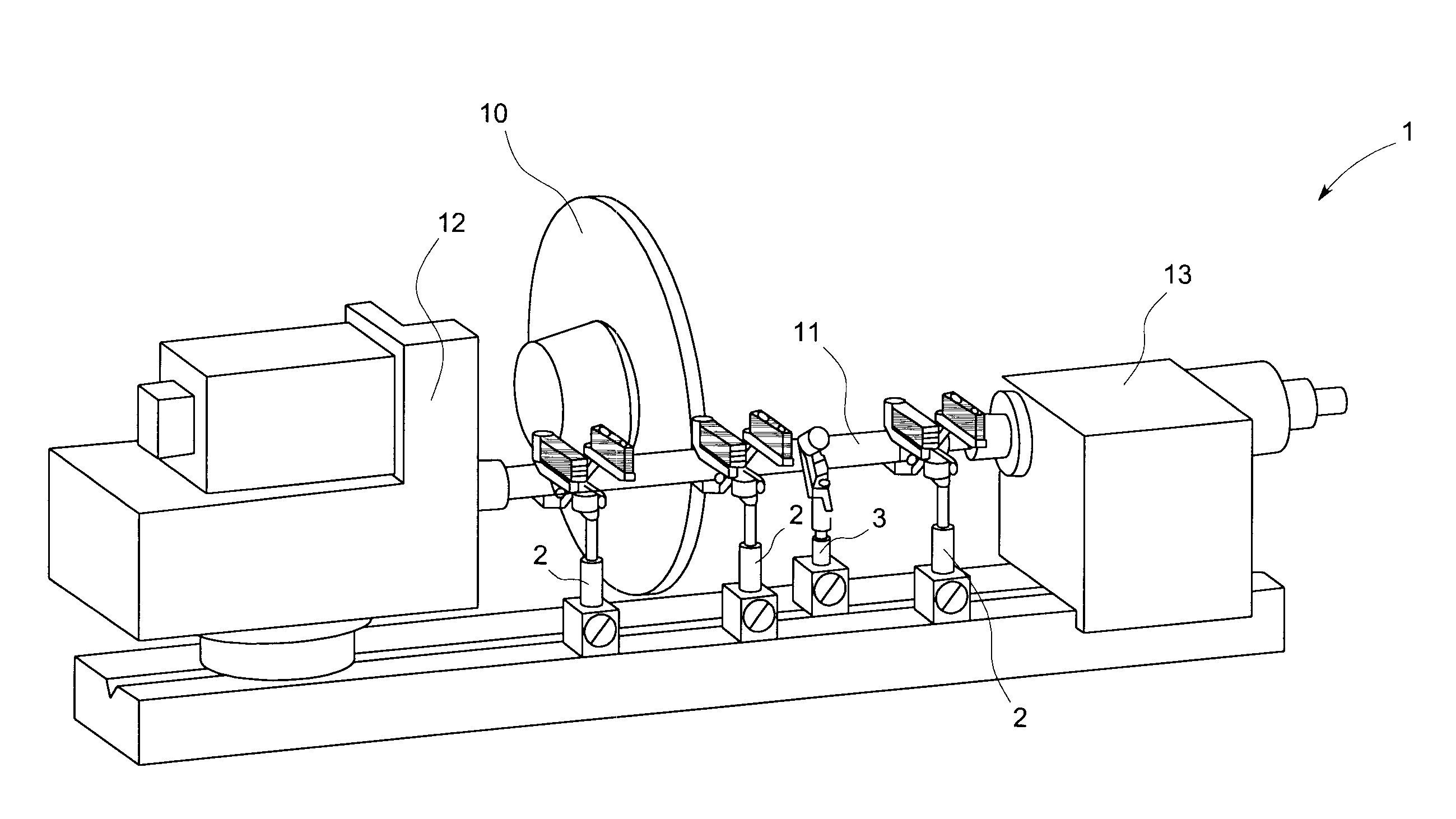

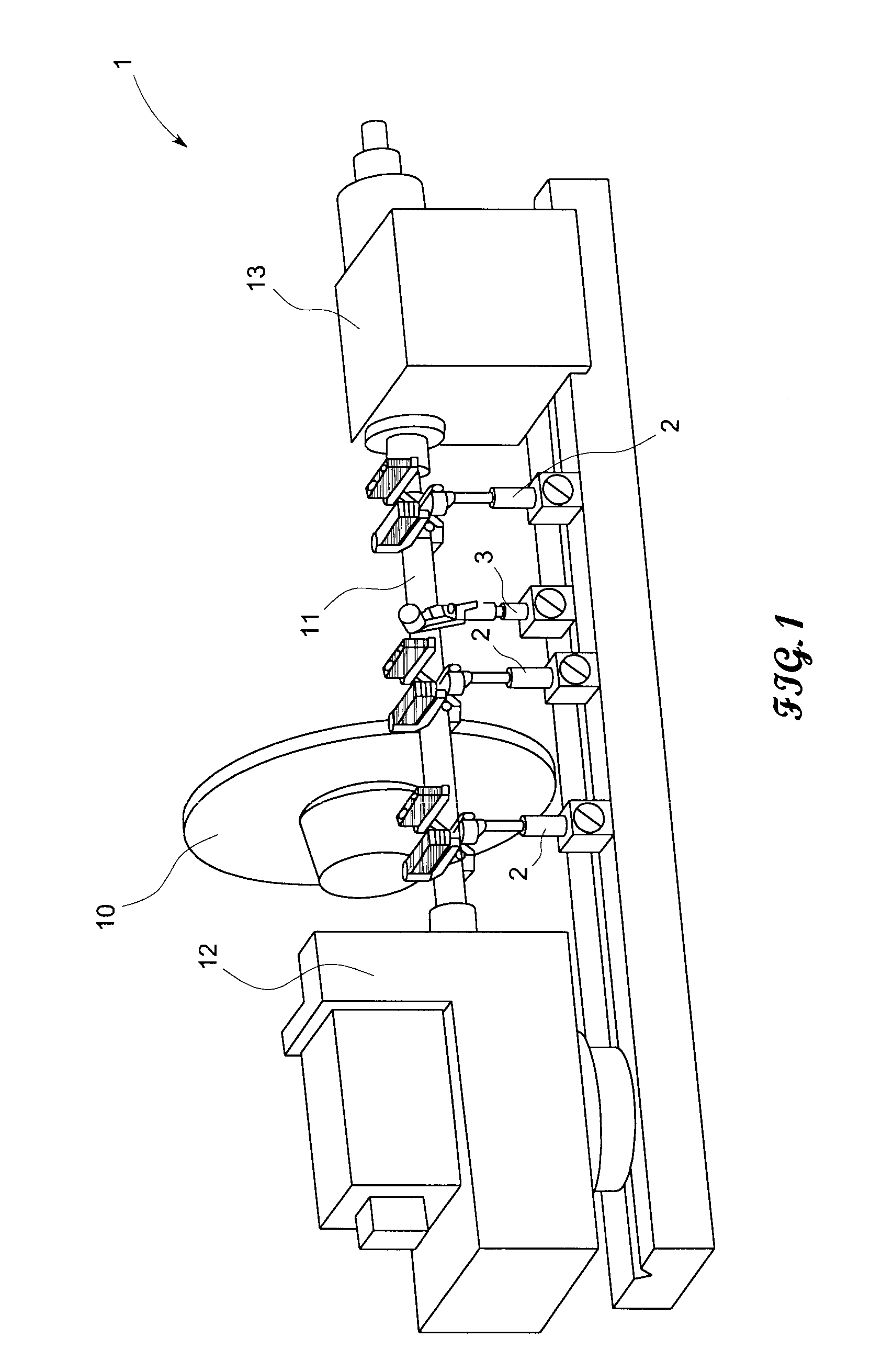

[0063]In a device 1, represented in FIG. 1, for processing a pilgrim mandrel 11, which is clamped at both ends, by means of a grinding wheel 10, three support collar plates 2 are provided, which hold the pilgrim mandrel 11 between its ends, free of vibration. The pilgrim mandrel 11 is clamped between two tips 12, 13 of the device 1, one of which is driven. A vibration-measuring finger 3 is used for measuring vibrations, or deflections, being generated by the contact between the pilgrim mandrel 11 and the grinding wheel 10. Prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com