Riveting device for metal sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

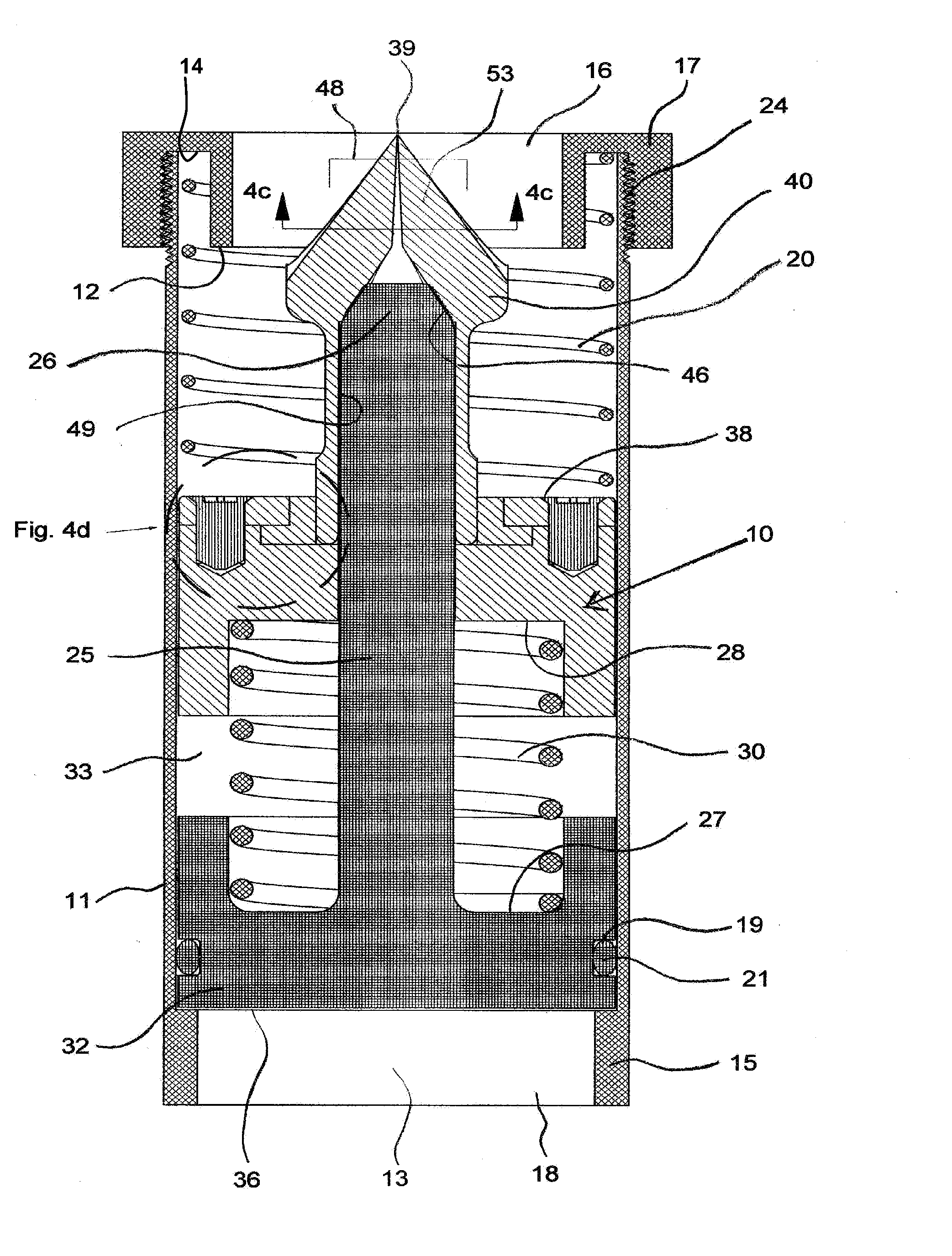

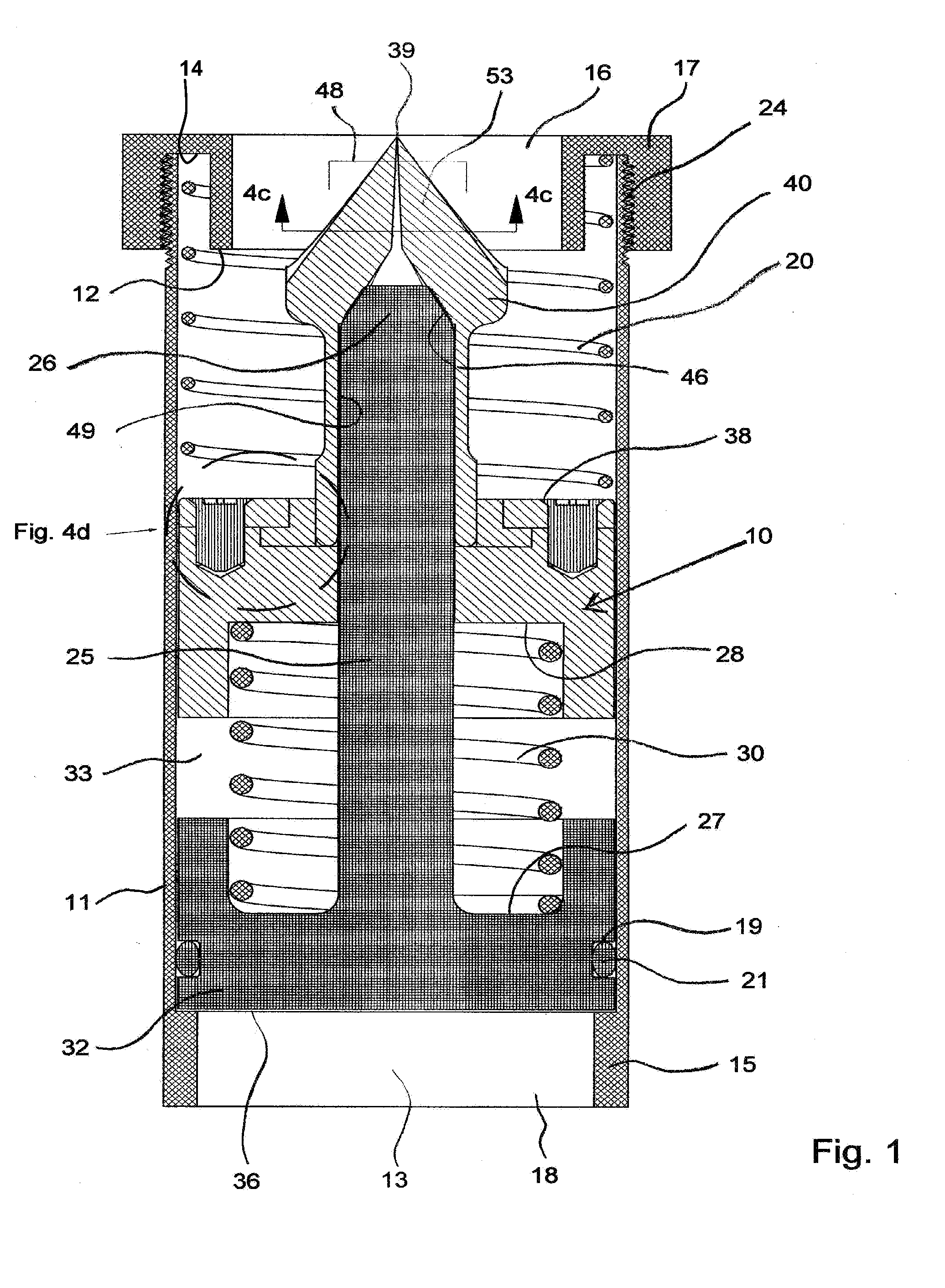

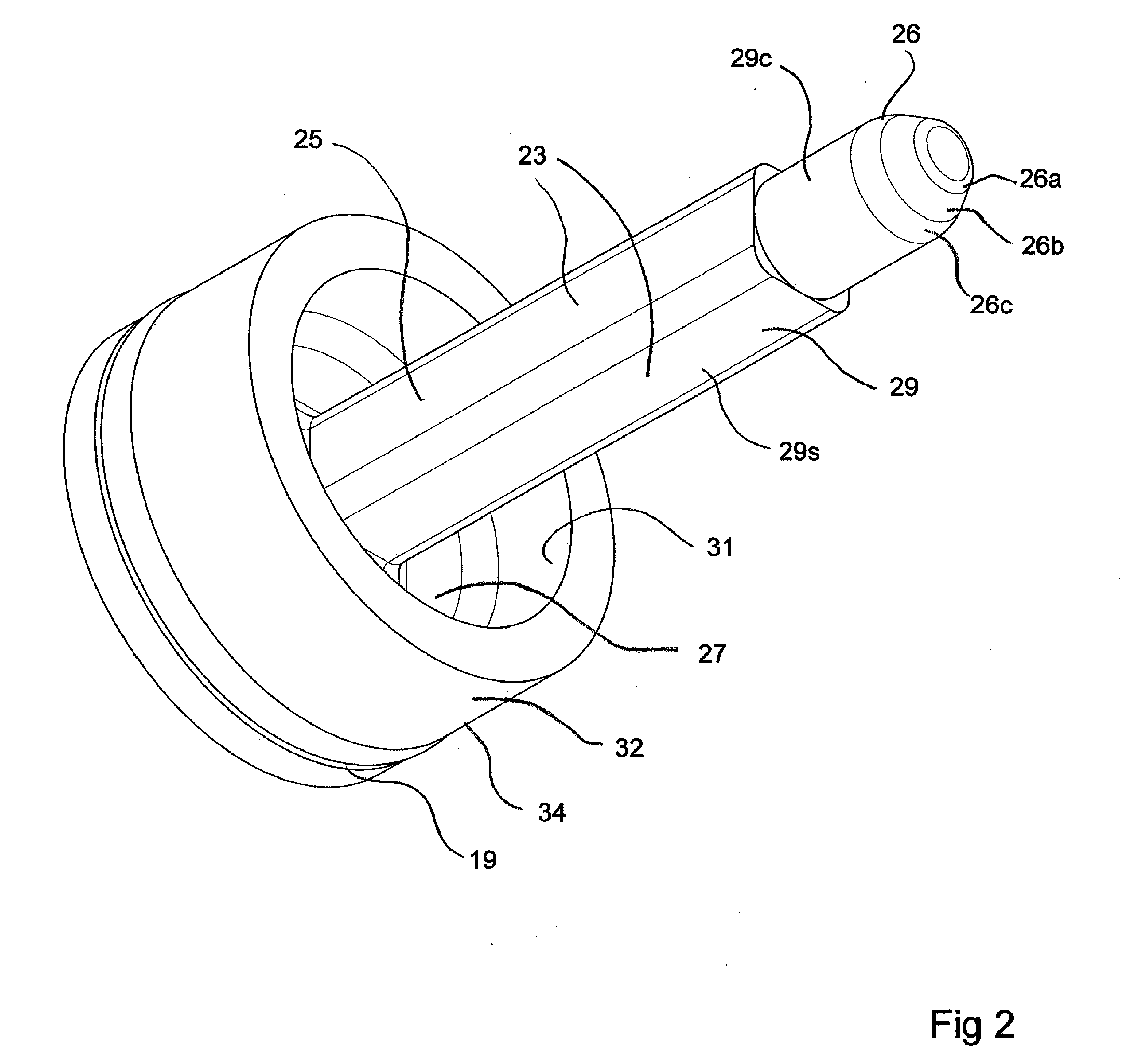

The present invention provides a labor-saving metal plate riveting device that rivets a plurality of plates in one single step. It combines a puncturing device with a means for folding back extrusions produced when the plates are first punctured.

The present invention discloses a method and a device such that given an unsupported side of a stack comprising a plurality of substrates coplanarly arranged, the user can, by applying the invented tool to the other side of the configuration, perforate the entire configuration transversely and rivet the substrates together in a single step.

The present invention is a substrate-piercing device comprising a piercing mechanism and a riveting mechanism. Initially, upon positioning of the device upon a plurality of substrates to be fastened together, a charge deploys a piston outwardly toward the substrate. Suitable charges are those originating from coiled spring, voltage potential, compressed air, fluid or a chemical charge such as propane or gu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com