Heat-dissipating device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

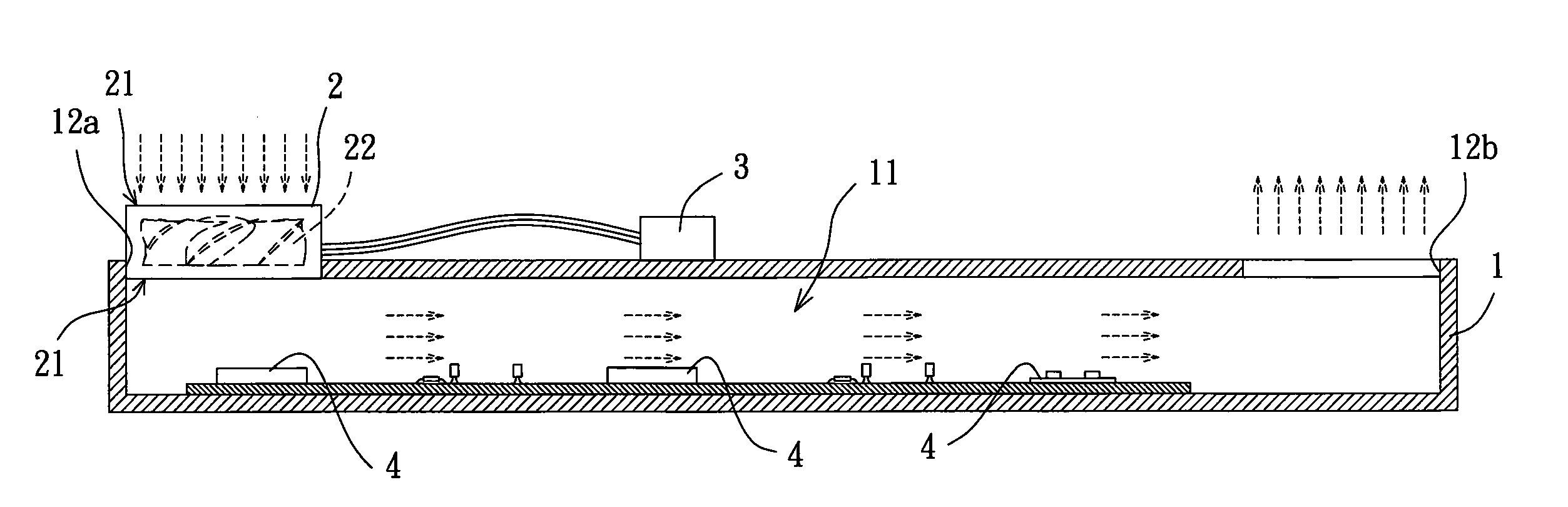

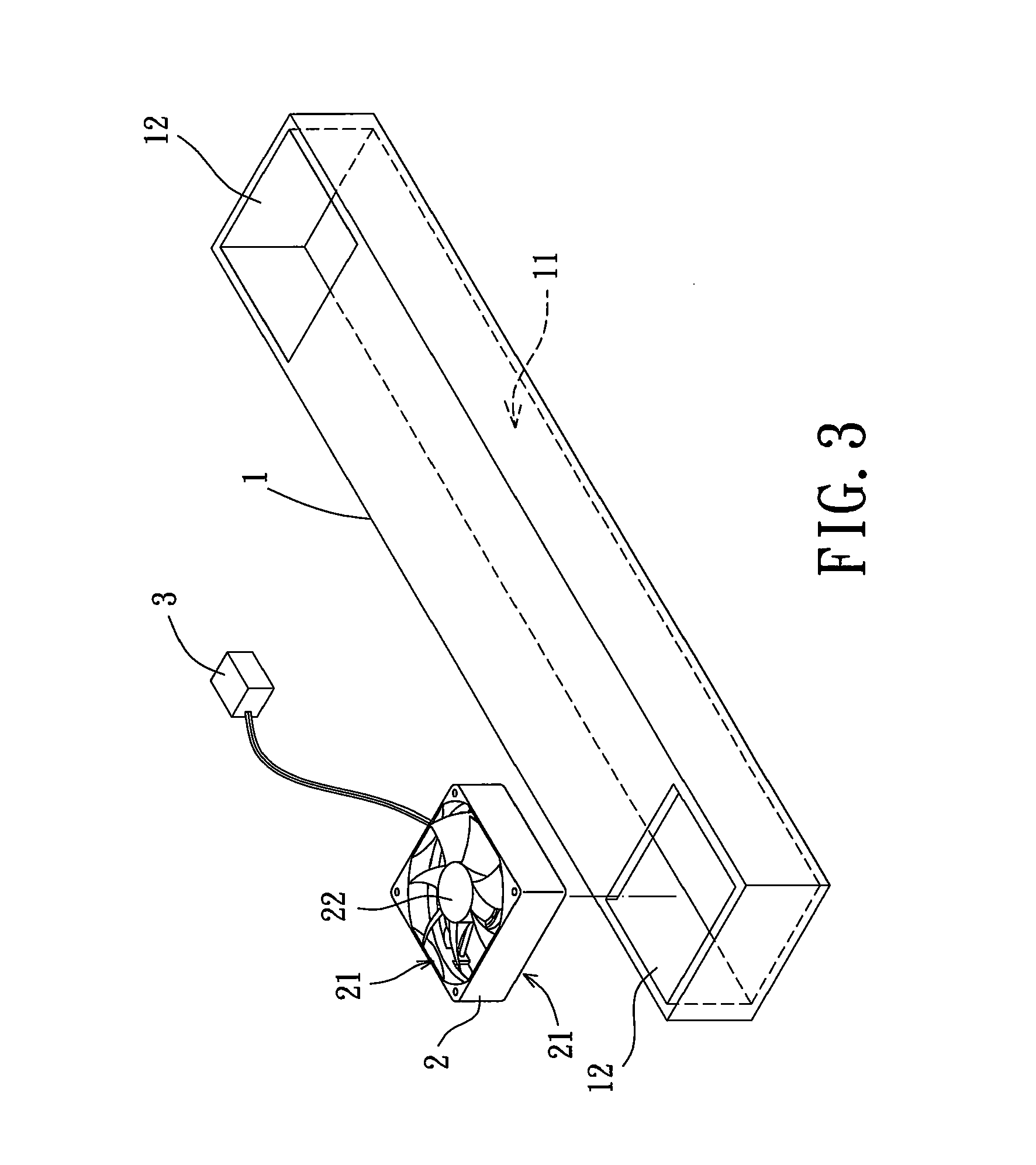

[0024]A heat-dissipating device according to the preferred teachings of the present invention is shown in FIG. 3. The heat-dissipating device includes a heat-dissipating member 1, at least one heat-dissipating fan 2, and a rotation control unit 3 adopted for control over rotating direction of the said at least one heat-dissipating fan 2.

[0025]The heat-dissipating member 1 can be integrated with an electronic product having at least one electronic element. The heat-dissipating member 1 is a hollow casting and preferably made of heat-conducting material, especially of material with high thermal conductivity. The heat-dissipating member 1 has an airflow chamber 11 inside and includes a plurality of air-guiding holes 12 in communication with the airflow chamber 11.

[0026]The at least one heat-dissipating fan 2 can be of blower type or axial flow type. In the preferred form shown in FIG. 3, the heat-dissipating device includes one heat-dissipating fan 2 of axial type. Furthermore, the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com