Tank type high-pressure vacuum circuit breaker

A vacuum circuit breaker and high-voltage technology, which is applied to high-voltage air circuit breakers, high-voltage/high-current switches, circuits, etc., can solve the problems of high pressure bearing, complicated manufacturing process, and increased manufacturing difficulty of vacuum interrupters. , to achieve the effect of reducing the difficulty of manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

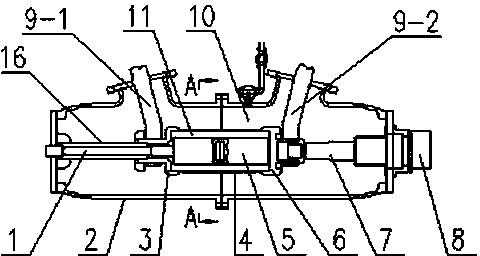

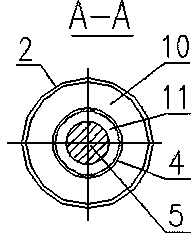

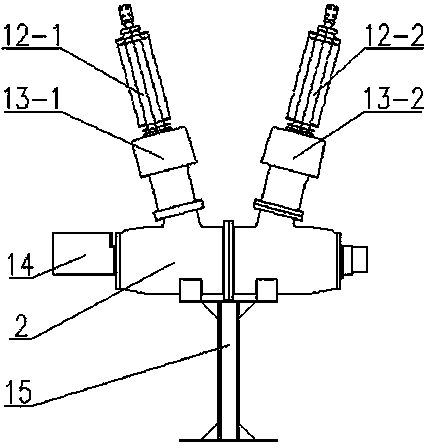

[0024] Provide the specific embodiment of the utility model below in conjunction with accompanying drawing.

[0025] Such as figure 1 with figure 2 As shown, the present invention includes a vacuum interrupter 5, and a large insulating cylinder 4 made of epoxy resin is installed outside the vacuum interrupter 5, and the left and right shielding electrodes 3 and 3 are respectively installed at the left and right ends of the large insulating cylinder 4. 6. A small insulating cylinder 16 is installed on the left end of the left shielding electrode 3, and the cavity between the vacuum interrupter 5 and the large insulating cylinder 4 and the cavity between the small insulating cylinder 16 and the operating insulating rod 1 are connected to form a sealed low-voltage Gas compartment 11, the tank body 2 is installed outside the large insulating cylinder 4 and the small insulating cylinder 16, the cavity between the large insulating cylinder 4 and the small insulating cylinder 16 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com