External stabilizing structure for work boots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

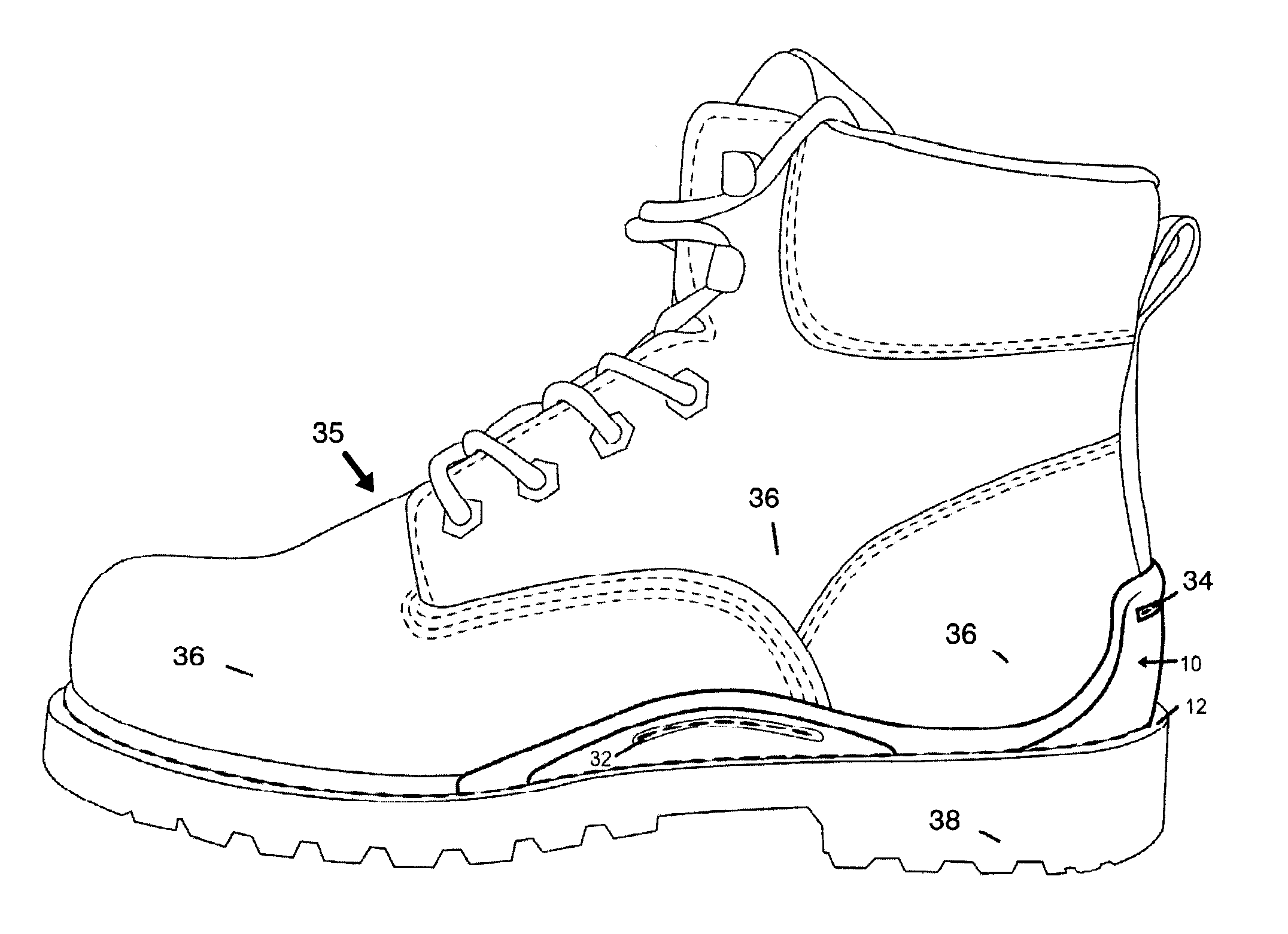

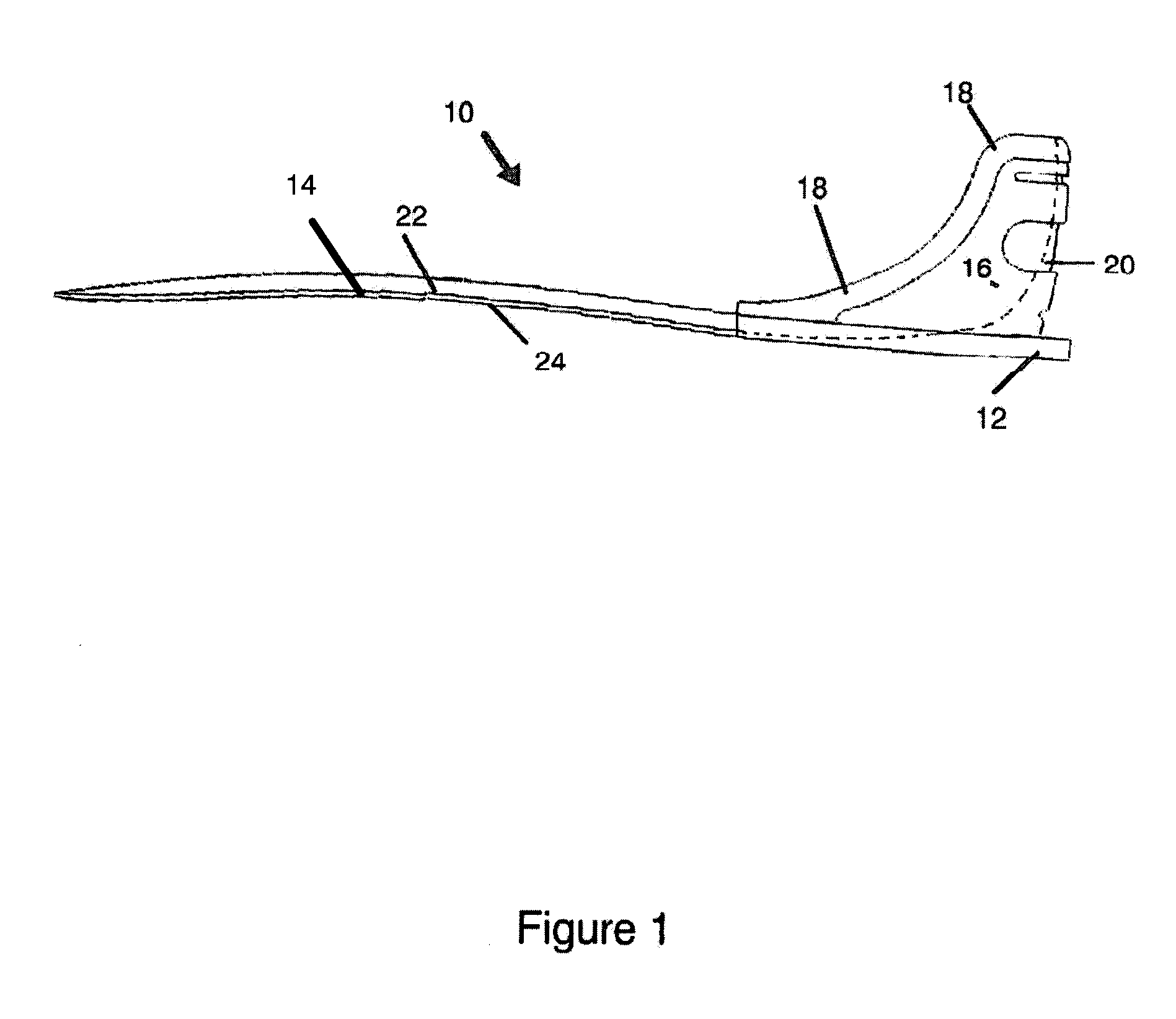

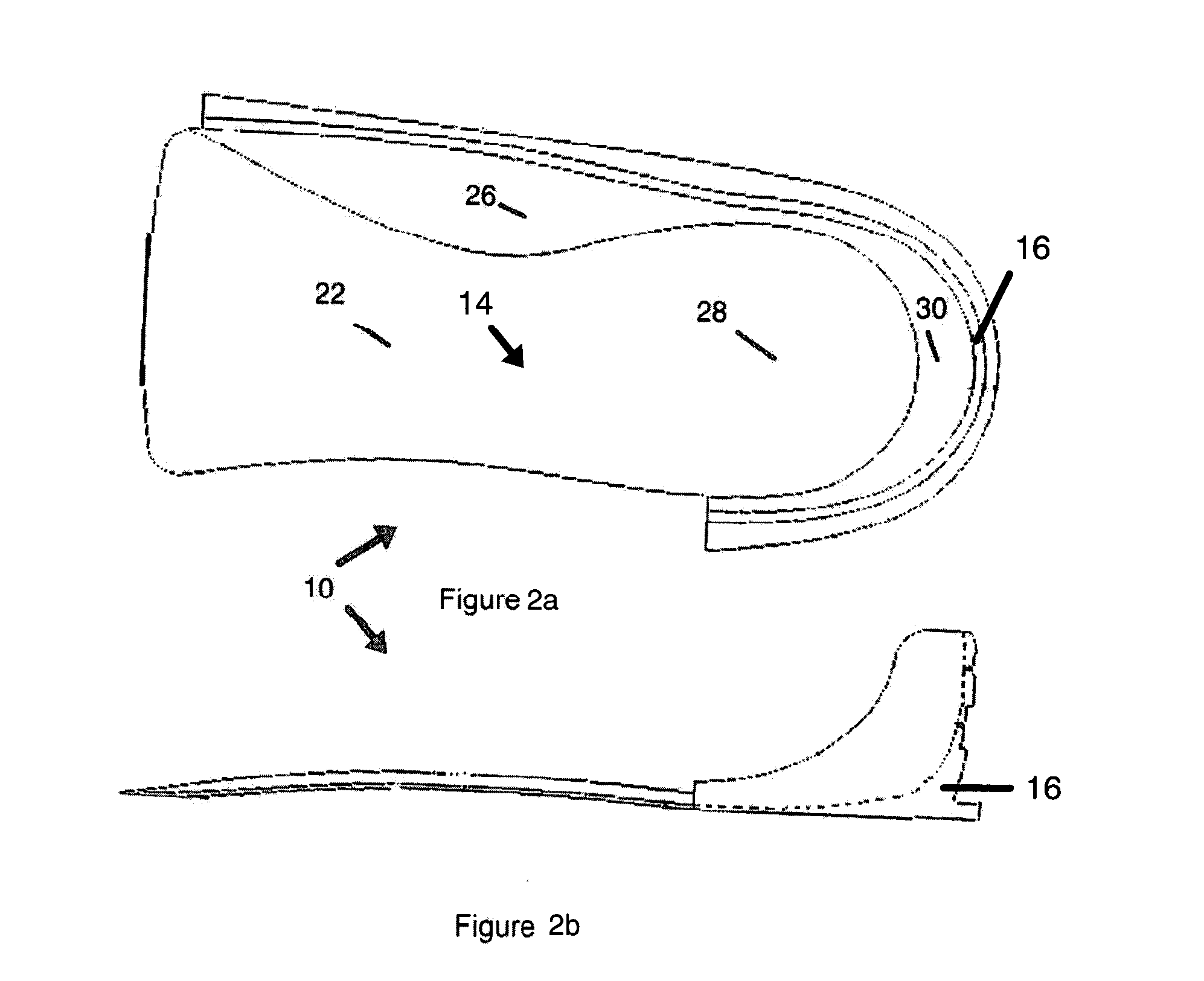

[0027]Referring now to FIG. 1, the external boot stabilizing structure (10) is a structural element for use in work boots and similar types of footwear. More specifically, the external stabilizing structure (10) comprises a molded footbed (14) and a heel support structure (16). The external stabilizing structure (10) is designed to integrate into conventional work boot designs with little or no modification of the design. The external stabilizing structure (10) extends from the heel towards the toes of the wearer to provide external support to the upper under approximately 75% of the wearer's foot. It also enhances the stability of the heel by augmenting the internal counter of the boot upper. The external stabilizing structure (10) comprises a single piece of stiff and resilient hard-molded material, such as plastic, that is permanently secured to the bottom of the boot upper and above the boot outsole or midsole (if present).

[0028]The molded footbed (14) of the external stabilizin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com