Electromechanical transducer and method of manufacturing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0016

[0017]The first embodiment deals with a capacitive micromachined ultrasound transducer (CMUT) as an electromechanical transducer to which the present invention can be applied. However, the present invention is applicable not only to CMUTs but also to any electromechanical transducers that have a similar structure (a structure in which a substrate is divided by grooves to form first electrodes of the respective elements). For example, the present invention is applicable to ultrasonic transducers that use distortion, a magnetic field, or light (piezoelectric micromachined ultrasound transducers (PMUTs), magnetic micromachined ultrasound transducers (MMUTs), and the like). In other words, electromechanical transducers to which the present invention can be applied are not limited to those whose lower electrodes 103 (first electrodes) to be described later are structured as below.

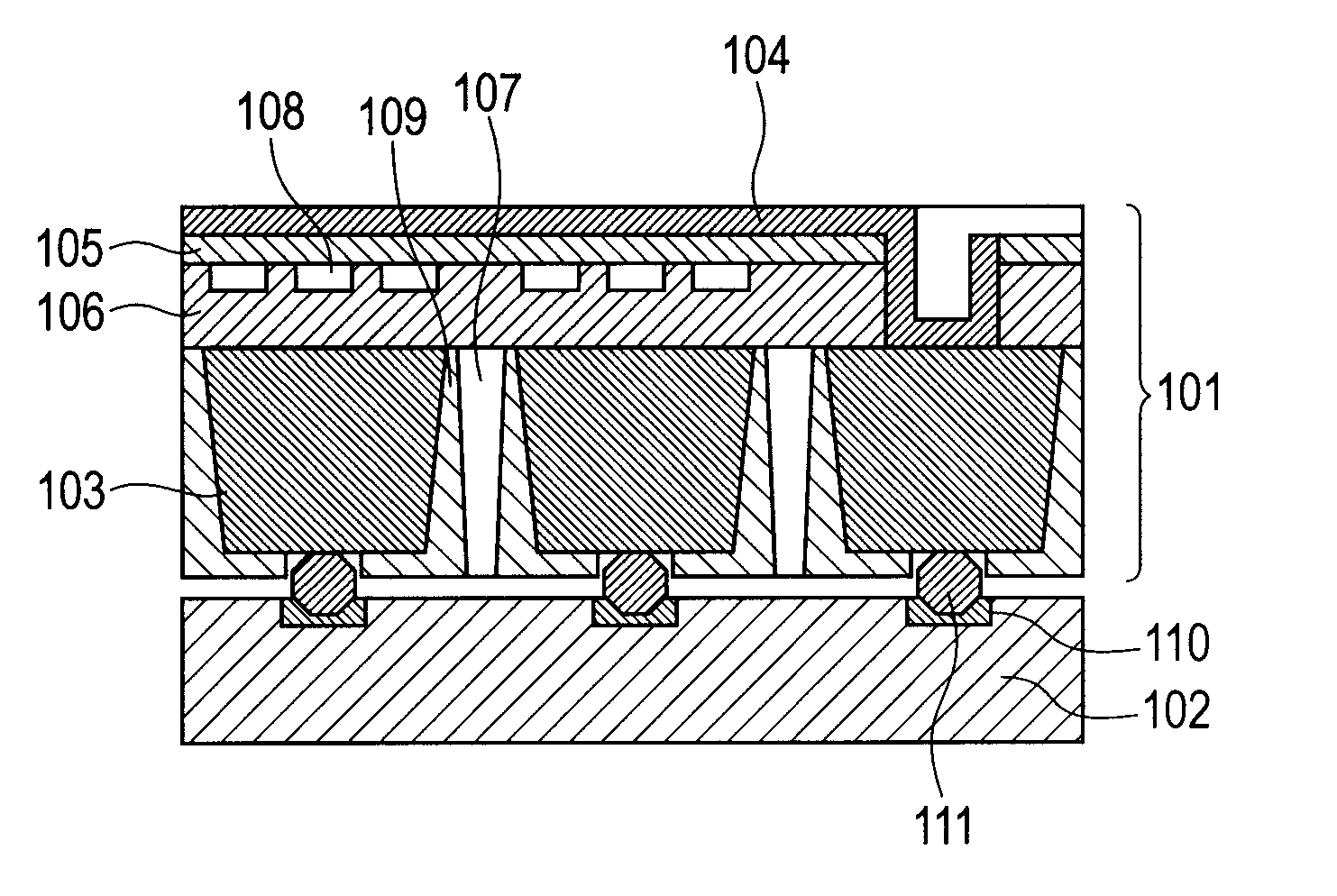

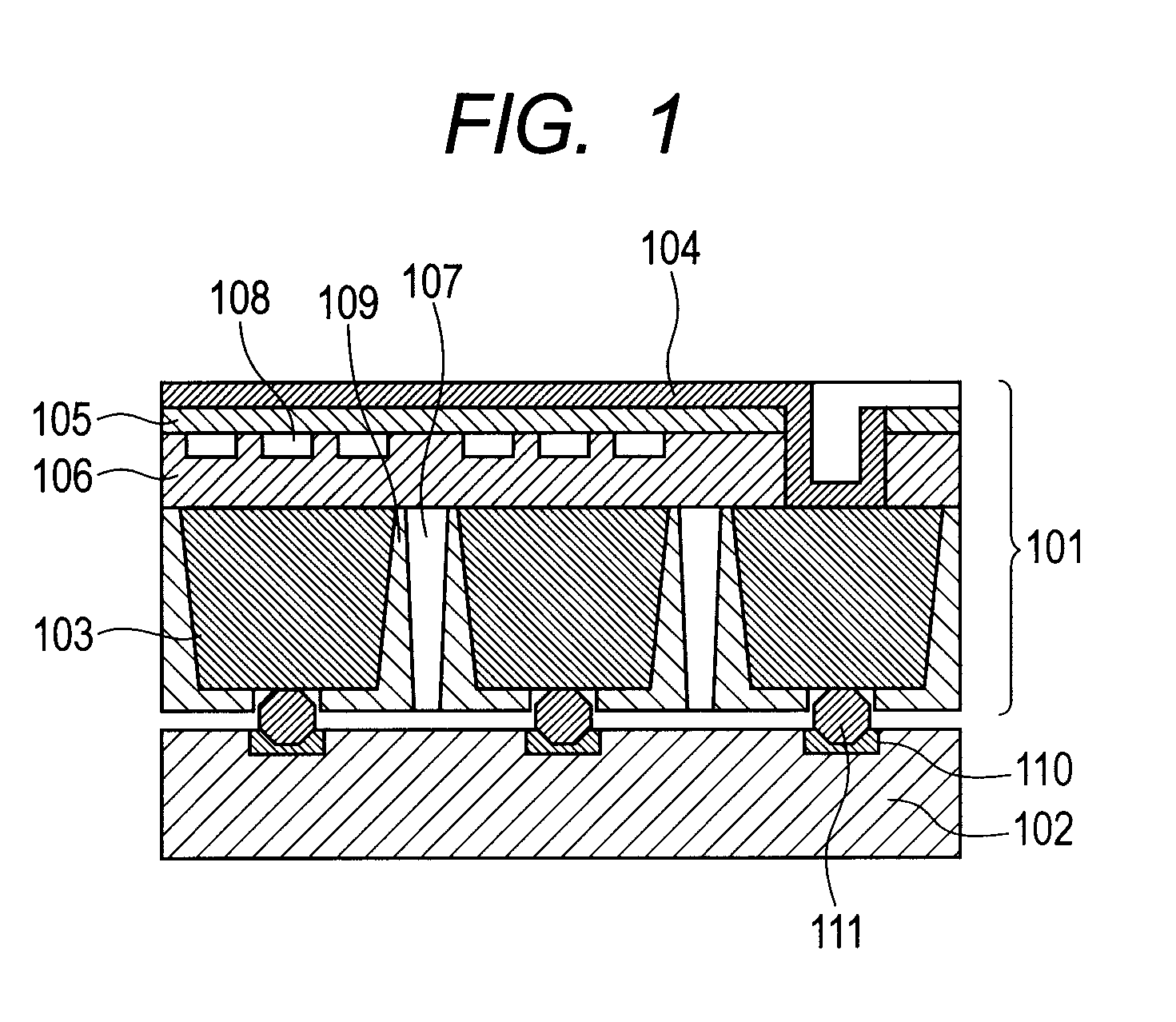

[0018]As illustrated in FIG. 1, which is a schematic diagram illustrating the sectional structure of the...

second embodiment

[0025

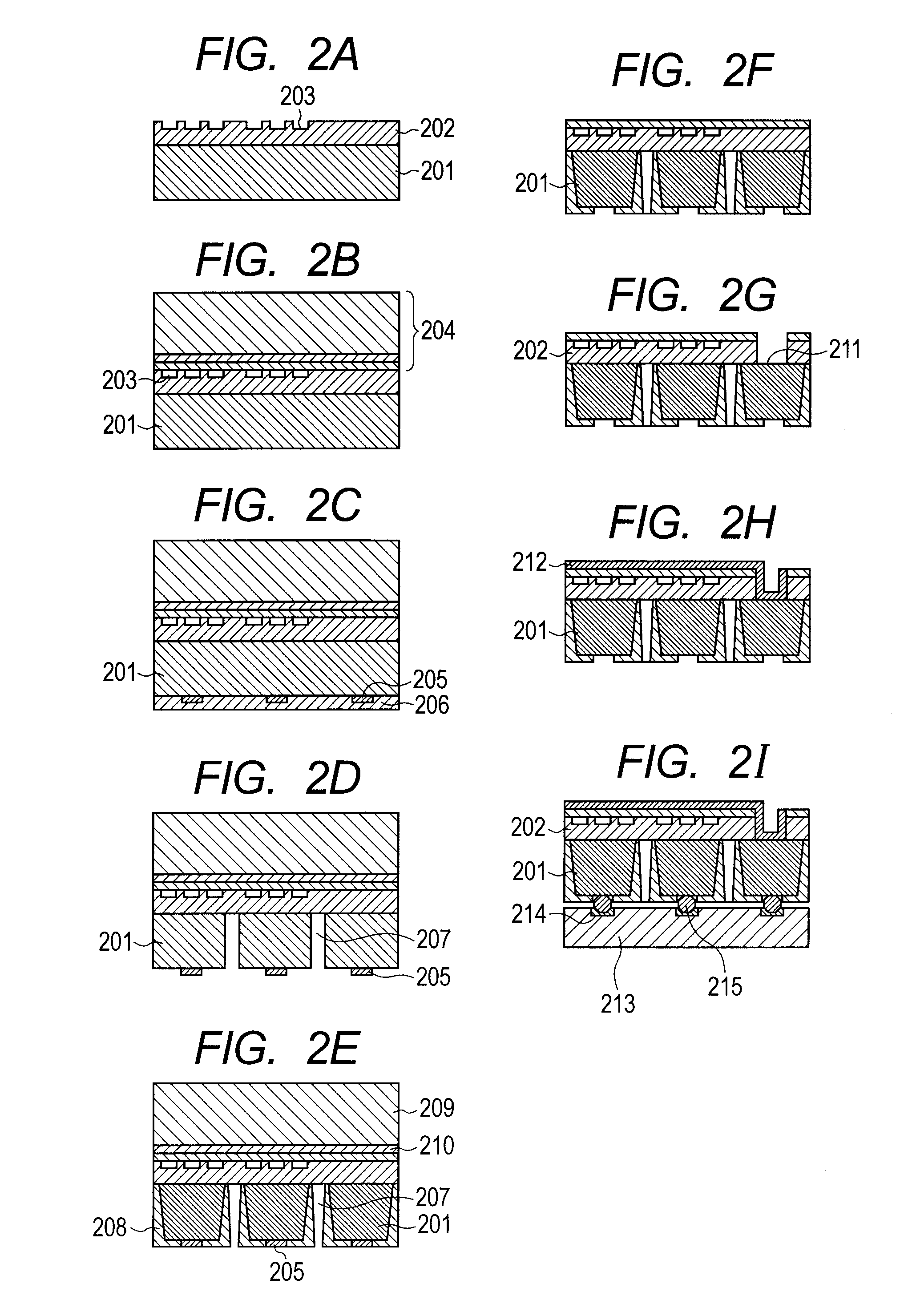

[0026]The second embodiment deals with a method of manufacturing a CMUT as an electromechanical transducer to which the present invention can be applied. According to the manufacturing method of this embodiment, a CMUT is manufactured as follows. A Si substrate is prepared in which grooves separate lower electrodes of respective elements from one another, and insulating films are formed on lower electrode surfaces that face the grooves. An SOI substrate is bonded onto the Si substrate to form a membrane, and the lower electrodes are wired to a circuit board. The insulating films on the outer side walls of the lower electrodes separated from one another by the grooves are formed by thermal oxidation.

[0027]By thermally oxidizing the lower electrodes, oxide films are formed on the outer side walls of the lower electrodes to be thicker toward the groove opening side, and a device form in which the groove width is narrower toward the groove opening side is obtained easily. An oxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com