Non-circular pins for closure group assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]The following embodiments of the present invention have many advantages, including improving the performance of turbine wheels by providing a fully bladed closure design.

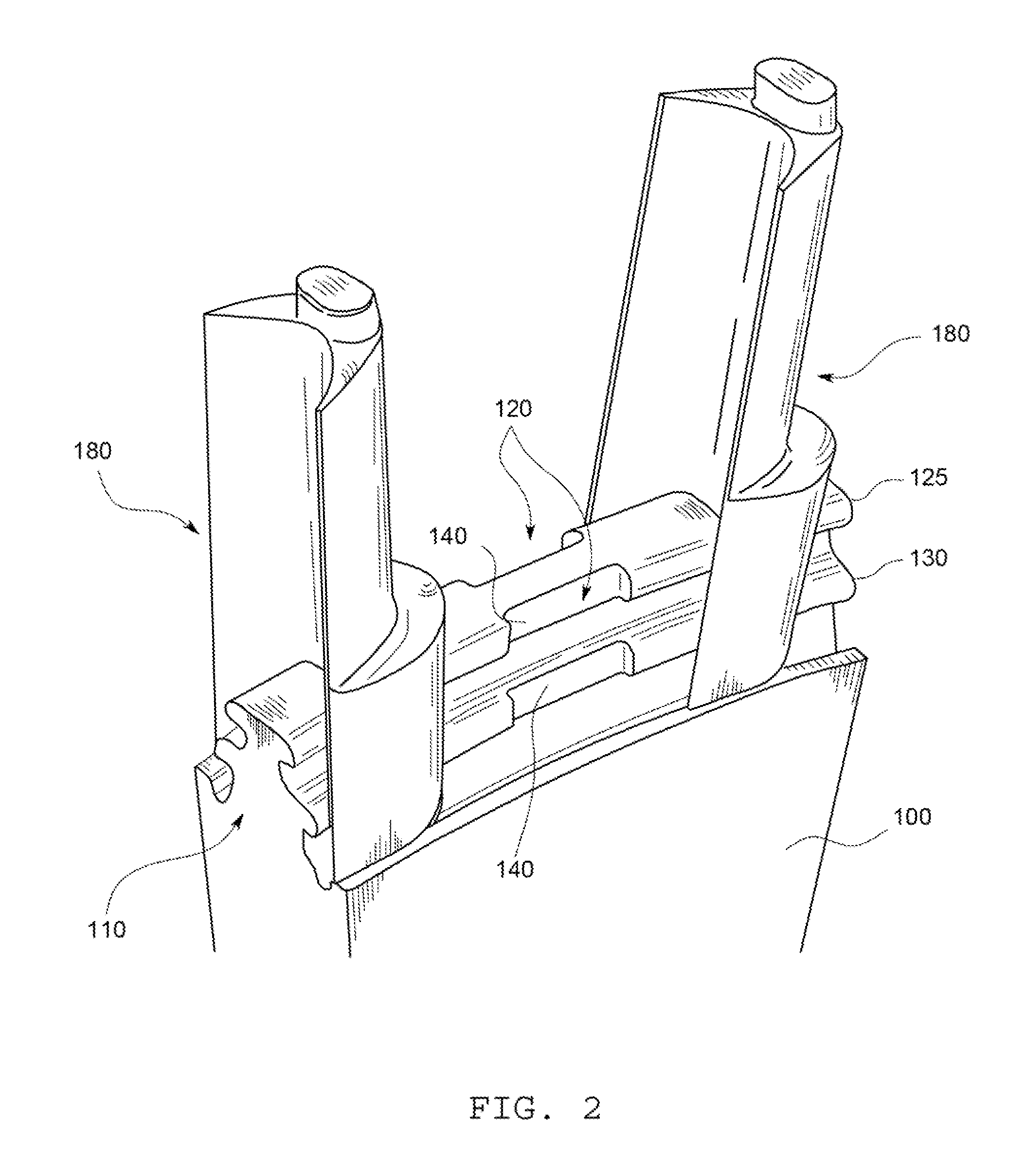

[0026]The fully bladed closure design for a tangential entry dovetail utilizes three bladed buckets, including a bladed closure bucket and an adjacent bladed bucket on each side of the bladed closure bucket. The adjacent bladed buckets provide a flat skirt dovetail on their circumferential face adjacent to the bladed closure bucket. The flat skirt at the interface of the bladed closure bucket and the adjacent bladed bucket allows the full width of the flat skirt on each face to support a retaining key there-between.

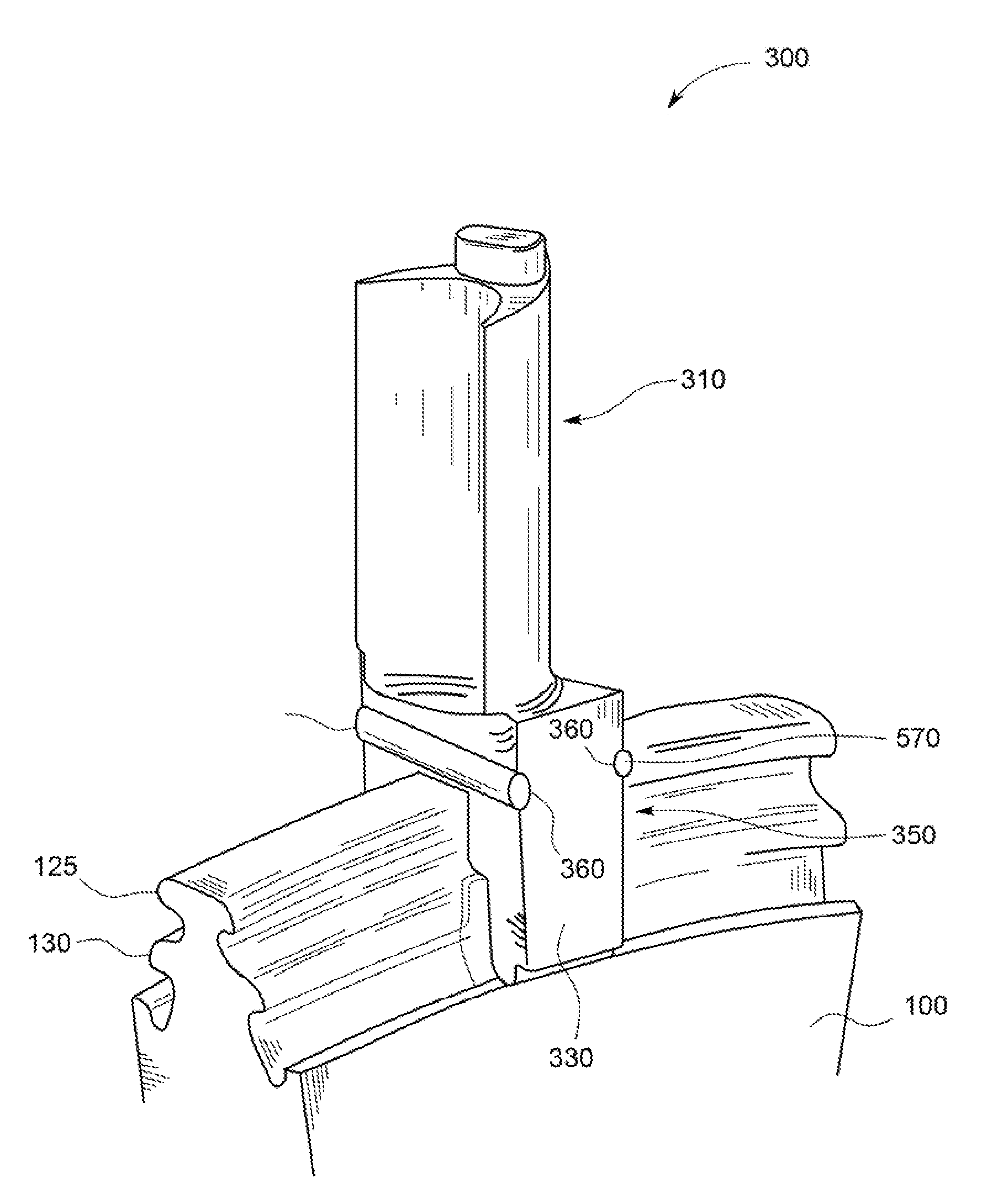

[0027]FIG. 2 illustrates an exemplary inventive turbine wheel including a male dovetail portion on substantially an entire periphery of the wheel. The turbine wheel 100 includes a male dovetail 110 portion on substantially an entire periphery of the wheel. The male dovetail 110 may include one or mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com