Sight for a firearm

a technology for sighting and firearms, applied in the field of sight, can solve the problems of separating the plastic sight from the anchoring position and affecting the safety of the firearm, and achieve the effect of further increasing the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

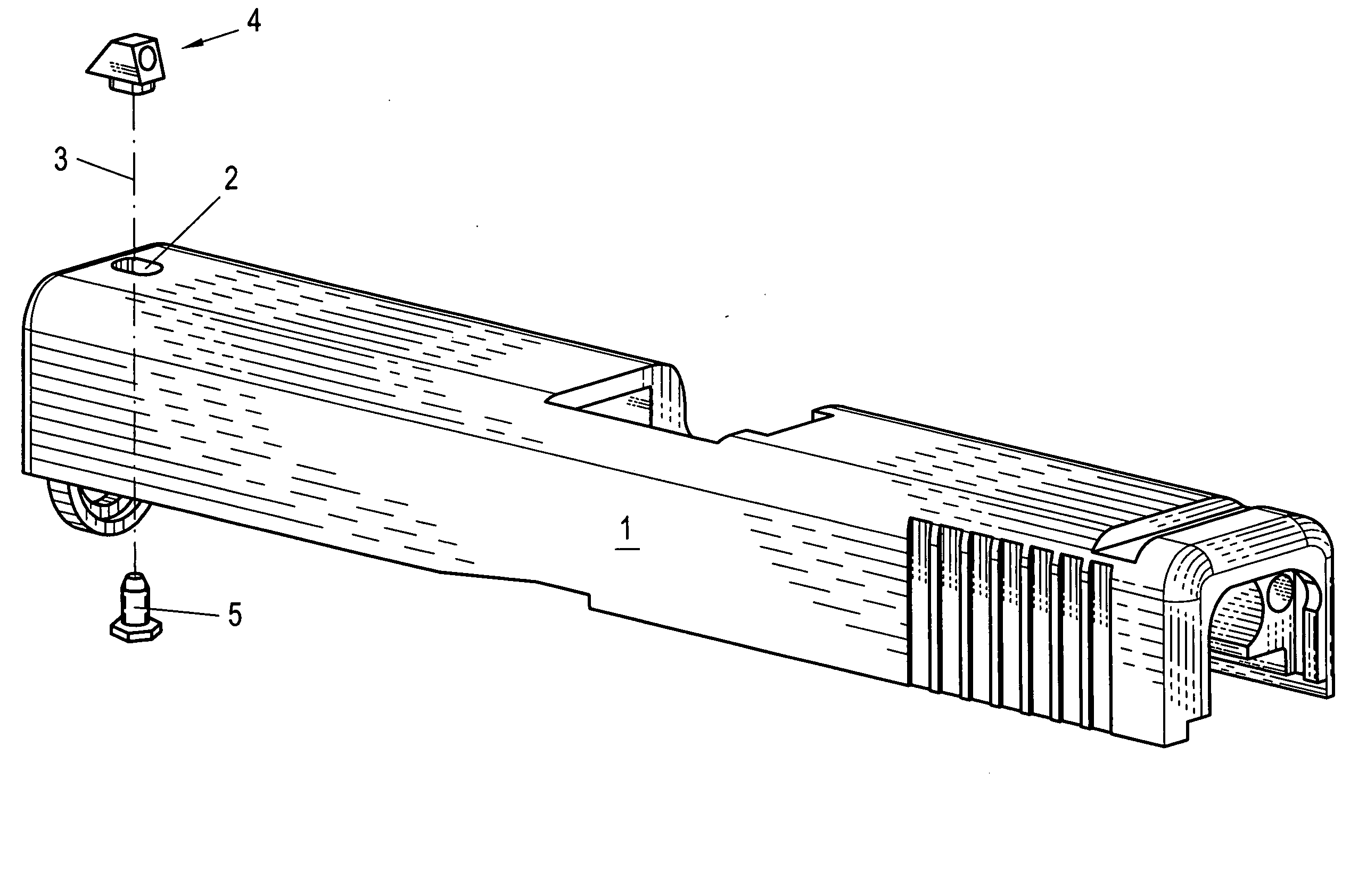

[0019]FIG. 1 shows a carriage 1 of a firearm in whose front region is located a through-opening 2 which is oblong in the cross-section thereof. Along the axis 3 of this opening, displaced upwardly or downwardly in the manner of an explosion, is an inventive sight 4 and a corresponding fastening screw 5.

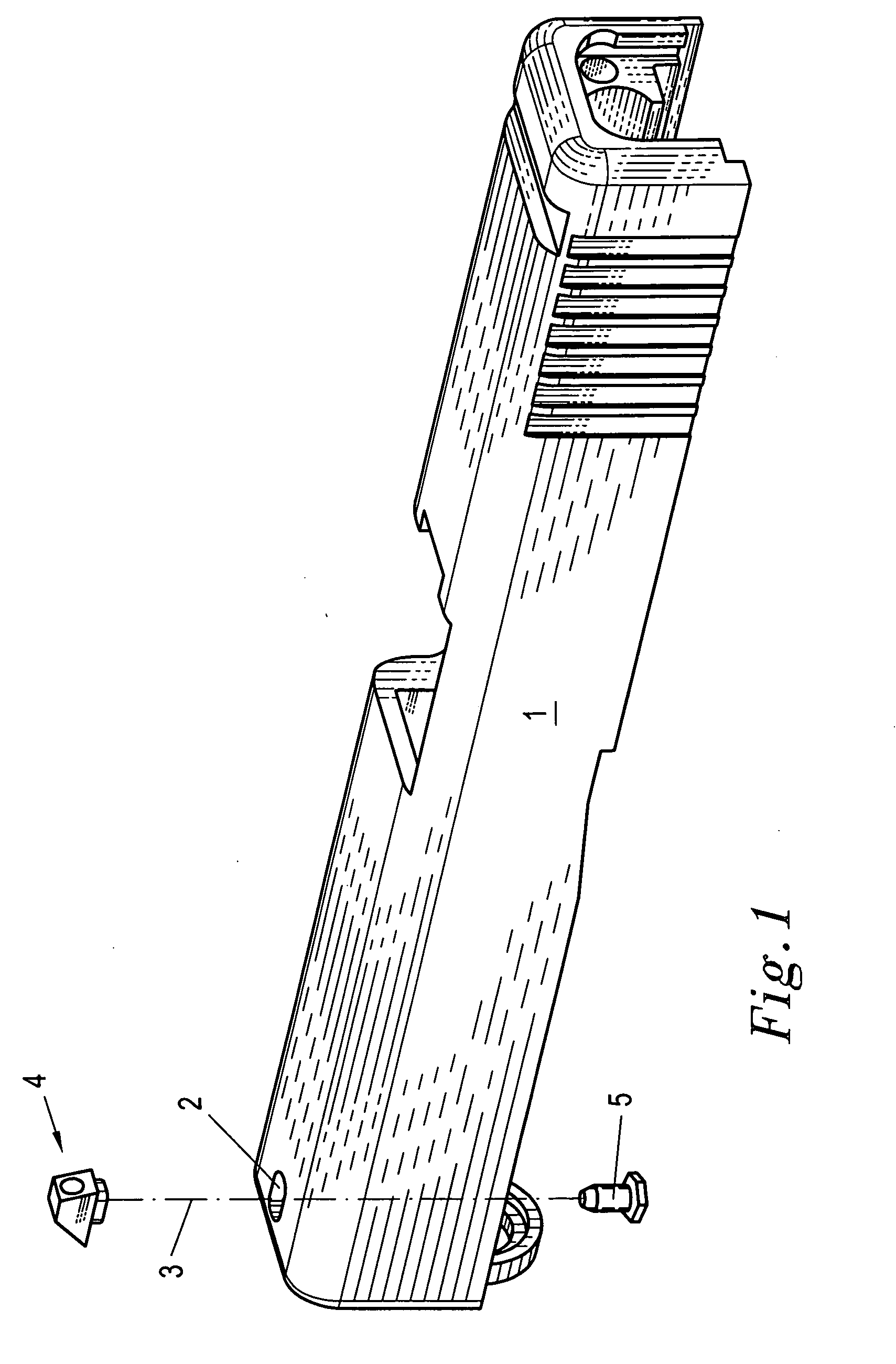

[0020]FIG. 2 shows the assembled state, wherein, for a better illustration, a part of the carriage 1 is broken away.

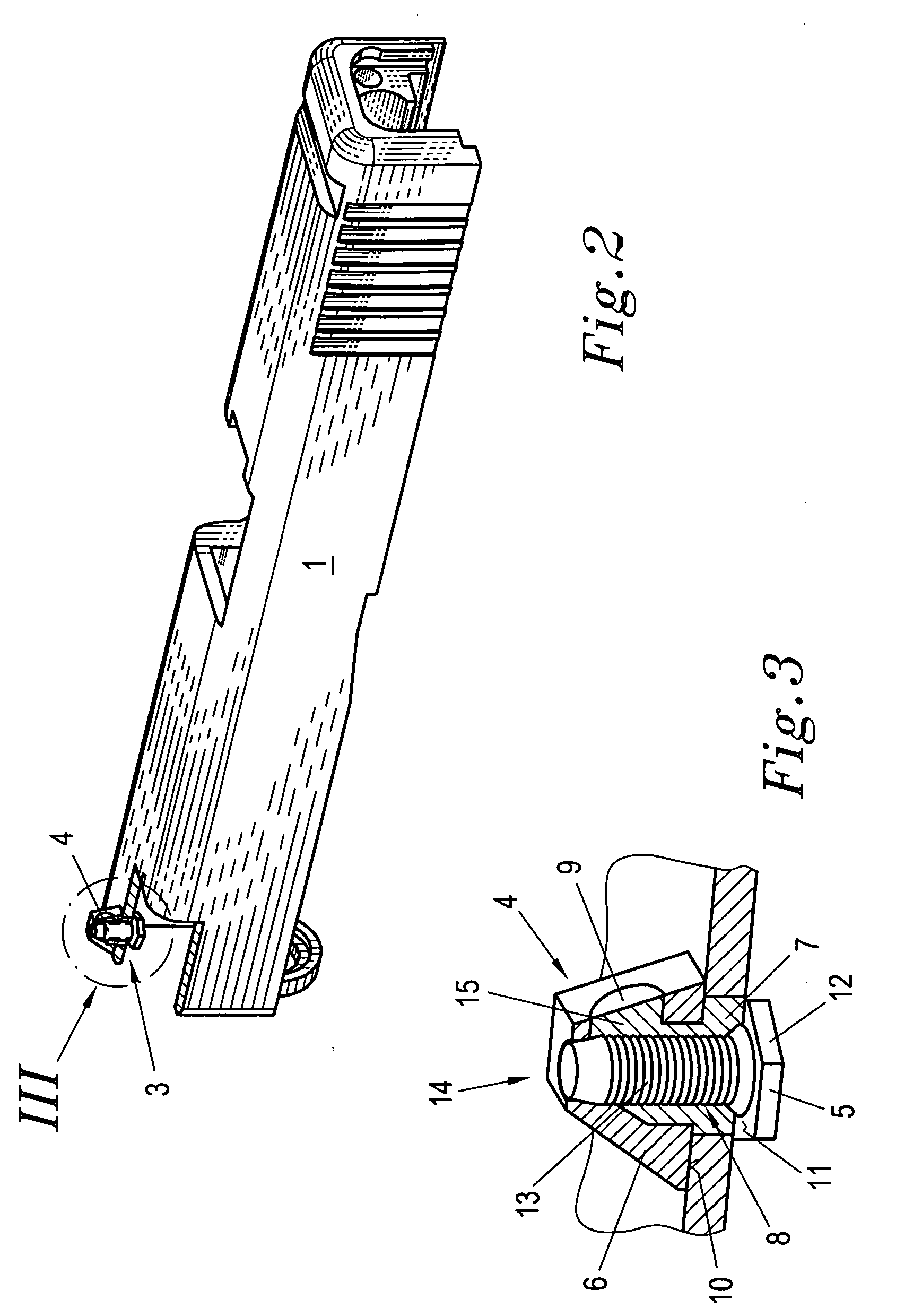

[0021]FIG. 3 shows detail III on a larger scale. It can be seen that the sight 4 is composed of an inner body 15 and an outer sleeve 6, wherein the inner body forms a leg 7 which can be inserted rapidly and tightly into the through-opening 2. Parallel to the axis 3, preferably in alignment with the axis 3 of the through-opening (FIG. 1), the inner body 15 has at its leg 7 and past the leg 7 an internal thread 8. In the illustrated embodiment, the inner body 15 of the sight 4 also forms a sight point 9 which facilitates aiming with the firearm.

[0022]The screw 5 has an ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com